There are two important areas regarding protection of property and persons. Appropriately, these requirements are located in Chapter two of the NEC, labeled, Wiring and Protection. This article will focus on ground-fault circuit-interrupter (GFCI) protection for persons and ground-fault protection of electrical equipment (GFP). One must understand that there are two main differences between these two forms of protection.

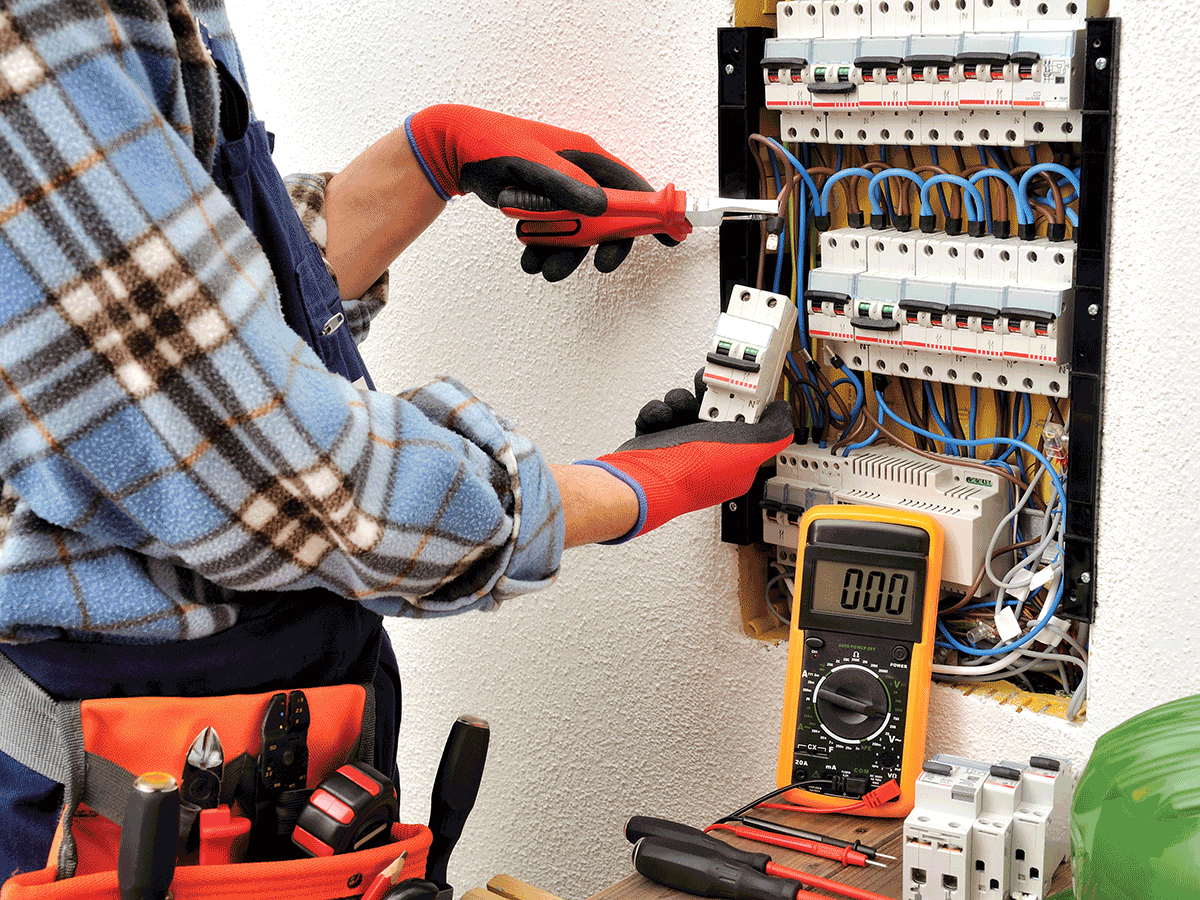

Photo 1

Ground-fault protection of equipment and ground-fault circuit interrupters for personnel are essential to safety. Often people in the electrical industry learn about the requirements for ground-fault protection in electrical service equipment by the “school of hard knocks” when a ground-fault in a service not equipped with a ground-fault protection device endures the forces of a destructive ground-fault leading to a total burndown of their electrical service, or equipment, to their facilities. These situations lead to questions: How are we protected? How is the electrical equipment protected?” Why is this protection required? Too late, it seems, some in the industry learn that injuries, death, property loss, and downtime for facilities are all situations that can result when the required ground-fault protection for equipment or ground-fault circuit interrupters are not installed as required by the National Electrical Code.

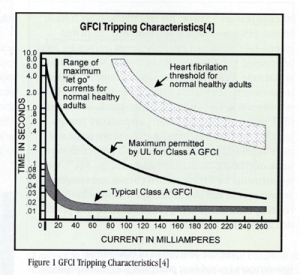

Figure 1

“The purpose of thisCodeis the practical safeguarding of persons and property from hazards arising from the use of electricity. ThisCodecontains provisions necessary for safety. Compliance therewith and proper maintenance will result in an installation that is essentially free from hazards.” These principal purposes are so critical to the users of theCodethat they are set forth in the initial section of theCode.NFPA Standard 70 is a minimum electrical requirements safety standard, which simply means that one must, at the very least, comply with those minimum requirements. See Section 90-1(a) and (b) of theNEC.

Photo 2

For the protection of personnel

Article 100 of theNECdefines ground-fault circuit interrupter as, “A device intended for the protection of personnel that functions to de-energize a circuit or portion thereof within an established period of time when a current to ground exceeds some predetermined value that is less than that required to operate the overcurrent protective device of the supply circuit.”

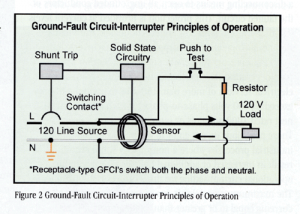

Figure 2

GFCI protection is required to provide protection against the hazards of electric shock and electrocution. The Underwriters Laboratories (UL) requirements for Class A ground-fault circuit interrupters is that the device will open (trip) when the continuous 60 cycle differential current exceeds 6 mA, but shall not trip at less than 4 mA. One can see by these values of current at which GFCIs operate that these types of protective devices are sensitive to low-level current leakage (see figure 1).

The GFCI is a current sensing device that, in basic terms, monitors the current balance in the ungrounded (hot) conductor and the neutral (grounded) conductor (see figure 2). If the current in either conductor changes by more than 6 mA, the GFCI will open. In other words, the GFCI monitors the current coming and going through the sensors. In a ground-fault condition, the current is seeking all paths back to the source. The device trips. So when one is troubled by the alleged nuisance tripping of a GFCI, chances are the device is just doing its job. One should troubleshoot the circuit, not defeat the GFCI to eliminate the alleged nuisance tripping.

Photo 3

The requirement for ground-fault circuit interrupters first appeared in Section 210-22(d) of the 1971National Electrical Code,which read, “For residential occupancies all 120-volt, single-phase, 15- and 20-ampere receptacles installed outdoors shall have approved ground-fault circuit-interrupter protection for personnel. The effective date of this requirement shall be January 1, 1973.” The 1971 edition of theNECalso required GFCI protection for all construction site receptacles rated at 15- and 20-amperes, effective January 1, 1974. The requirements set forth in Section 555-3 for marinas and boatyards stated that ground-fault protection for shore power receptacles “may be provided with GFCI protection,” which was permissive at that time. Those rules have since become mandatory requirements. See Section 555-3 of the 1999NEC.

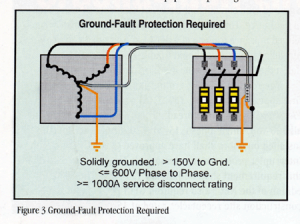

Figure 3

The requirements in Section 680-6 for receptacle location and GFCI protection was, and still is, a mandatory requirement. As theCodedeveloped over the years, more and more additional requirements for GFCI protection were made mandatory. In the 1999 edition of theNEC,the requirements for GFCI protected circuits and receptacles are widespread and numerous. These devices have certainly contributed to the personnel safety and protection as required by theNEC.

Photo 4

For the protection of equipment

Now compare ground-fault protection (GFP) for equipment. Once again one must look to the definitions in Article 100, where ground-fault protection of equipment is defined as, “A system intended to provide protection of equipment from damaging line-to-ground fault currents by operating to cause a disconnecting means to open all ungrounded conductors of the faulted circuit. This protection is provided at current levels less than those required to protect conductors from damage through the operation of a supply circuit overcurrent device.”

First, consider the service equipment. Section 230-95 requires ground-fault protection for all solidly-grounded wye electrical services of more than 150 volts to ground, but not exceeding 600 volts phase-to-phase for each service disconnect rated 1000 amperes or more (see figure 3). These provisions do not apply to fire pumps or continuous industrial processes where a non-orderly shutdown would result in increased or additional hazards. The maximum operational current setting for these devices is 1200 amperes. The maximum time delay is one second for ground-fault currents equal to or greater than 3,000 amperes. These equipment protection requirements are a result of a history of destructive burndowns of electrical equipment operating at these voltage levels.

Photo 5

An electric arc generating a tremendous amount of heat is readily sustained at these higher voltage levels. Conductive ionized gases produced by these arcs contribute to the electrical explosion and can go from a phase-to-ground fault to a phase-to-phase short circuit and result in destructive magnetic and thermal forces that cause the equipment to literally melt down (see photos 1 and 2). TheNECdoes not require ground-fault protection for services at voltage levels less than 150 volts phase-to-ground; however, it is permitted to be installed on those services.

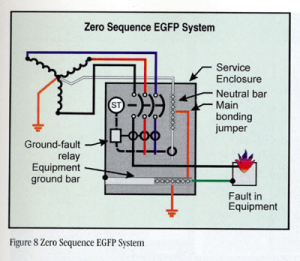

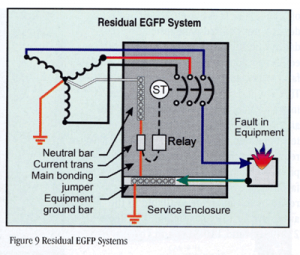

There are basically two types of ground-fault protection (GFP). The zero sequence type, which may have more than one form, and the residual type, sometimes referred to as a neutral ground strap type. Both are designed to protect downstream equipment from destructive arcing burndowns (see figures 7, 8, and 9). It should be pointed out here that ground-fault protection equipment will not protect equipment from line-to-ground faults on the line side of this ground-fault protective device.

Figure 8

Ground-fault protection of equipment first became a requirement in theNational Electrical Codein the 1971 edition of Section 230-95. The requirement for ground-fault protection in health care facility electrical feeders downstream of a GFP service disconnecting means was introduced into the 1975 edition of theNEC.The main reason for this second level of protection downstream is to localize a destructive ground-fault condition to the device in trouble and keep the continuity of service to the facility and prevent a total blackout condition at the facility. This feeder protection is required to be 100 percent selective so that where a ground-fault occurs downstream from the feeder overcurrent device, only the feeder overcurrent device will open and the service and feeder main will remain closed. The coordination is achieved by theCoderequiring a six cycle, or greater, separation between the tripping times of both levels. These ground-fault protective devices are required to be tested, in accordance with the instructions provided with the equipment for the particular type of ground-fault protection used, when first installed. This is a performance test that includes injecting a current and measuring current and time, and is not just the pressing of a test button on the equipment. Testing is also required for service and feeder ground-fault protection devices in other than health care facilities. A written record of these test results shall be made available to the authority having jurisdiction. See Sections 230-95(c) and 110-3(a) and (b).

Observance of minimum standard required

Figure 9

TheNational Electrical Codeis a minimum standard, so we need to do at least that much. With that in mind, one can conclude that GFP is required for all service disconnecting means at the voltage rating of over 150 volts phase-to-ground but not exceeding 600 volts phase-to-phase. Looking a bit further, if we had an electrical service rated at 1600 amperes and 480/277 volts and the “six disconnect” rule were being applied as allowed by Section 230-71, meaning six disconnects rated at 400 amperes each, there would be no requirements for GFP to be installed for the service; installation would be optional. Obviously the system could benefit if a ground-fault protective device were installed as a main disconnect for the service, but this would not be required by theNEC.Ground-fault protection for equipment is required by Section 215-10 for feeder disconnects, 230-95 for service disconnects and in health care facilities, 517-17 for second level protection and coordination where a service disconnect is a ground-fault protective device.

Making the comparison between ground-fault circuit interrupters and ground-fault protection of equipment by carefully using the definitions and rules set forth in theNational Electrical Code,one can easily see the differences between the two types of protection. Ground-fault protection of equipment protects equipment, and ground-fault circuit interrupters protect people. Both types are equally important in maintaining the spirit and content of theCode.We hope this helps clear up some of the confusion between the requirements and reasons for both types of ground-fault protection. These two topics are covered more extensively in theIAEI Soares Book on Grounding,7thEdition.

Find Us on Socials