Code Making Panel 2 recognized the need for arc-fault circuit-interrupter (AFCI) protection when it accepted proposals and accompanying substantiation for the 1999 National Electric Code. Now, as the January 1, 2002, implementation of AFCI requirements in Section 210-12 of the 1999 NEC rapidly approaches, the technology and level of protection provided by various types of AFCIs are progressing rapidly as well.

In fact, the code panel anticipated that progress, correctly believing that a delayed effective date would spur AFCI development and completion of an AFCI product standard (UL 1699). What the panel may not have anticipated was that technology would advance so quickly as to provide new protection opportunities, unforeseen in both the 1999 NEC and UL 1699.

Instead of broadly considering the problem of arc-initiated fires, the Code’s AFCI content appears to focus on single-product technology. As a result, current AFCI Code requirements, while appropriate for the technology available at the time of adoption, could result in a solution that may not provide the most comprehensive protection. In this article, the authors discuss the limitations of the technology and solutions in the current code language as well as the risks those limitations pose, especially in series arcing on the branch wiring, cords, and extension wiring. We will also describe what we believe to be the solution (the Outlet Branch Circuit AFCI) and encourage its recognition and support.

Photo 1. Lamp cord arc manifests into fire

Regardless of regulatory and technology issues, there’s no disagreement on the need for AFCI protection. It’s been clearly demonstrated in Consumer Product Safety Commission (CPSC) data, which have been widely cited in numerous Code proposals. Residential electric equipment is involved in approximately 41,000 fires each year, resulting in more than $650 million in annual property loss. That alone would justify extensive investment in AFCI technology. Add 360 fire deaths and thousands of injuries annually, and the case for AFCI protection is undeniably closed.

In searching for a comprehensive solution to the arcing problem, it’s important to understand what arcing is, the different types of arcs that occur, and how common they are in residential wiring systems.

Arcing is a luminous discharge of electricity across an insulating medium. An arc can cause a fire once the electrical energy from the arc is converted to thermal energy. The heat generated is then transferred to a combustible material that ignites.

Arcing occurs in wiring in two basic forms: parallel arcing and series arcing. Parallel arcing is an arc fault between two conductors—hot and neutral or hot and ground. An example is a metal object penetrating the insulation of a cable or cord, “”shorting”” the hot wire to the neutral or equipment grounding conductor.

Series arcing occurs on a single conductor when there is a break in the conductor and an arc is established between the conductor’s broken ends. Examples include loose terminations in a twist-on wire connector, loose device connections, and partially severed lamp cords.

There is no data indicating which type of arcing is more prevalent—nor where each is most likely to occur in a branch circuit. But what’s important is that we recognize that both arcing types contribute to the problem. Therefore, a solution should address both series and parallel arcs that occur on branch wiring, power supply cords, and extension wiring.

The current UL 1699 standard recognizes five different types of AFCI devices. By UL definition, none of these five AFCI types provides protection of the entire branch circuit, power supply cords, and extension cords connected to them. Branch Feeder AFCIs protect branch circuits—but offer only “”limited”” protection of cords. Outlet AFCIs protect only cords. Combination AFCIs come closest to providing complete protection of the branch circuit and connected cords.

However, the most advanced AFCI type didn’t exist when UL 1699 was published. It’s the Outlet Branch Circuit AFCI—an AFCI receptacle that provides series protection for the entire branch circuit including cords and extension wiring. It also provides parallel protection downstream from the point of installation, protecting the branch circuit, cords, and extension wiring, extending to, but not including powered devices. This technology is so new it has not yet been recognized by the standard.

Here are the five currently recognized AFCI types with their UL definitions:

•Branch Feeder AFCI– A device installed at the origin of a branch circuit or feeder, such as at a panelboard, to provide protection of the branch circuit wiring, feeder wiring, or both against the unwanted effects of arcing. This device also provides limited protection to branch-circuit extension wiring. It may be a circuit breaker type device or a device in its own enclosure, mounted at or near the panelboard.

•Outlet Circuit AFCI– A device installed at a branch-circuit outlet, such as an outlet box, to provide protection of cord sets and power-supply cords connected to it (when provided with receptacle outlets) against the unwanted effects of arcing. This device may provide feed-through protection of the cord sets and power-supply cords connected to downstream receptacles.

•Combination AFCI– An AFCI which complies with the requirements for both Branch Feeder and Outlet Circuit AFCIs. It is intended to protect downstream branch-circuit wiring, cord sets and power-supply cords.

•Portable AFCI– A plug-in device intended to be connected to a receptacle outlet and provided with one or more outlets. It is intended to provide protection to connected cord sets and power-supply cords against the unwanted effects of arcing.

•Cord AFCI– A plug-in device connected to a receptacle outlet to provide protection to the power-supply cord connected to it against the unwanted effects of arcing. The cord may be part of the device. The device has no additional outlets.

These definitions tell only part of the story, for they don’t reveal that Branch Feeder AFCIs essentially protect against parallel arcs only … that Combination AFCIs protect against both parallel and series arcs … and that the Outlet AFCI protects against series arcs only. However, you will find this important information in UL 1699’s test criteria.

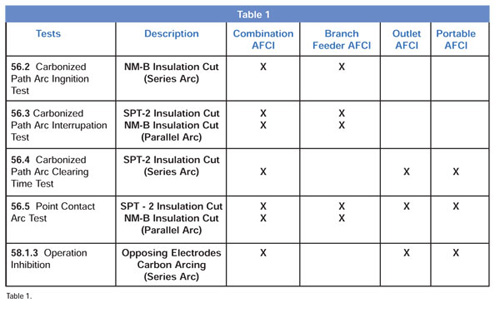

The UL 1699 tests are summarized (Table 1) with additional test details in the following paragraphs. It’s also important to fully understand the type of arc and the level of energy present at each of the different arcing events.

Table 1.

The various UL test sections simulate specific types of real-world arcing. We’ve included examples to clarify the protection the various recognized products actually provide. Keep in mind that the variety and conditions for arcing vary greatly, as do the technologies available for detecting and mitigating arcs before ignition. A device may not be required to stop a specific type of arc—but that doesn’t mean that type of arc can’t cause a fire.

56.2 – Carbonized-Path Arc Ignition Test

This test simulates such real-world conditions as a screw or nail driven through the wall that initiates a series arcing condition by severing the hot conductor. This test is performed using a piece of NM-B cable with ground. As prescribed in the UL standard for sample preparation, NM-B is cut and pyrolized, simulating a severed line conductor that develops a carbon path over time. The test also calls for a piece of cotton fire indicator placed adjacent to the cut.

When power is applied to the circuit, the AFCI is supposed to clear the arcing that occurs on the sample before the cotton fire indicator ignites.

The Combination AFCI clears this event as an actual series arc. Current UL-listed Branch Feeder AFCI devices don’t—because they rely on 30mA Ground-Fault Protection for Equipment (GFPE) technology for detection and circuit deenergization. That means they require the presence of ground, with the arc being detected as leakage rather than a series arc.

Should ground wire terminations be loose or absent (as in older dwellings with two-wire branch circuits), a series arc will go undetected by a Branch Feeder AFCI until the arc propagates to a parallel arcing condition. Once this parallel arc reaches 75A, the Branch Feeder AFCI will clear it. Before that happens, there’s a significant potential for ignition of combustible materials in proximity of the fault. This condition is highly repeatable in the laboratory using the test criteria.

56.3 Carbonized Path Arc Interruption Test

This test simulates such conditions as a cord running through a doorway, with the cord having been severed or damaged by being repeatedly pinched. 56.3 is a parallel arc clearing test required of Branch Feeder and Combination AFCIs, performed on both 16AWG SPT-2 flexible cord and NM-B sheathed cable. Samples have a transverse cut made across the conductors and the insulation. Each sample is then wrapped in PVC and fiberglass tape and pyrolized using alternating cycles of high voltage. Once power is applied to the circuit, the AFCI must detect and clear the arc within eight arcing half cycles.

56.4 Carbonized Path Arc Clearing Time Test

How would Combination, Outlet, and Portable AFCIs respond to severed lamp or appliance cords; loose terminations at cord ends, devices or twist-on wire connectors; or even loose circuit breaker terminations? This test is intended to find out. A sample of pyrolized SPT-2 cord is wired into the branch circuit in series. When power is applied, a series arc crosses the sample’s carbonized path. Per the UL requirement, the sample is wired so that there are no adjacent conductors—so the arc is a true series arc, with no possibility of a subsequent parallel fault developing. The AFCI must deenergize the circuit within one second. This test is required for Combination and Outlet AFCIs but not required for Branch Feeder AFCIs.

56.5 Point Contact Test

All AFCI devices must face the point contact or “guillotine” parallel arc fault test. It simulates the severing or “shorting” of hot to neutral or hot to ground resulting from a metal object (for example, a chair leg) breaking through insulation. This test covers Branch Feeder and Combination AFCIs and includes both SPT-2 and NM-B cable. A steel blade contacts first one conductor and then the second at a “point contact,” creating a parallel arc fault. Test criteria include limiting the short circuit current to a minimum of 75 amperes rms using a prescribed length of 14 AWG NM-B. The AFCI must clear the arc fault within eight arcing half cycles.

58.1.3 Operation Inhibition Test

(Arc Generator or Opposing-Electrode Test)

The opposing-electrode test simulates loose terminations or a severed conductor as a series arcing condition. This series arc fault test is required for Outlet, Combination, Portable, and Cord AFCI products but not for Branch Feeder AFCIs. The test uses an arc generator consisting of opposing copper and carbon electrodes. The arc generator connects in series with the LINE, with various loads applied. With the electrodes touching, the circuit is closed. The electrodes are then slowly separated until arcing occurs. The AFCI must clear the arcing condition in less than a second. This test accurately reflects types of series arcing that occur in the real world, as arcing can cause fire at currents at or below 5 amperes.

UL 1699 also calls for a thorough battery of additional tests the products must pass, which simulate conditions that may cause the device to nuisance trip. Common arcs such as a light bulb failing, switches being actuated, or the plugging in of loads should not be detected by the AFCI. Nuisance tripping testing in UL 1699 is very thorough, and all manufacturers are taking additional steps to eliminate any nuisance tripping.

While the NEC mandates AFCI protection of branch circuits, it doesn’t currently address protecting the power supply or extension cords plugged into a branch circuit. Outlet Branch Circuit AFCIs provide unequivocal protection of cords plugged into the branch circuit, not simply “”limited”” protection as in the case of Branch Feeder AFCIs. This level of protection coupled with protection of the branch circuit fully addresses the problem of arcing-related fires, providing protection that consumers have a right to expect. Outlet Branch Circuit AFCIs will provide familiarity and convenience for the installers and homeowners as well. Outlet Branch Circuit AFCIs are currently undergoing extensive testing and will soon be commercially available.

Find Us on Socials