Significant number of electricians are being seriously burned and often killed from an accidental electrical flash while working equipment “hot.” Most of these serious accidents can be eliminated or significantly reduced if the electricians wear the proper type of protective clothing.

In a previous IAEI article, I discussed the need for better integration of the NFPA family of electrical codes and standards. The essential element of such integration is a more useful and complete set of electrical codes and standards that can more closely meet the needs of the end-user. A case in point and one that hopefully can become a model for this type of integration occurred in the 2002 National Electrical Code. Code-making Panel 1 accepted a proposal and comment that resulted in the addition of a new 110.16 entitled Flash Protection. The purpose of this article will be to review the development of the new section and see if it offers the potential to serve as a model or example of the types of integration that can best serve the needs of the end-user.

Photo 1. Fires in electrical equipment are proceeded by varying degrees of arc-flash and arc-blast conditions resulting from short circuits or ground faults or both.

The Proposal Stage

During the 2002 Code cycle, Ray A. Jones, of Electrical Safety Consulting Services, Inc. submitted Proposal 1-235 that would have added a new 110.15 to read as follows:

110-15. Flash Protection.For other than residential occupancies, switchboards, panelboards, loadcenters, and motor control centers shall be marked in the field to indicate the incident energy in calories per square centimeter for a worker at a distance of 18 in.

Mr. Jones had a long and distinguished career with Dupont and presently owns his own electrical safety consulting a business. He is highly regarded as a leader in electrical safety and was recently appointed as the chairman of NFPA 70E, Electrical Safety Requirements for Employee Workplaces. Mr. Jones offered the following substantiation for his proposal:

Significant number of electricians are being seriously burned and often killed from an accidental electrical flash while working equipment “hot.” Most of these serious accidents can be eliminated or significantly reduced if the electricians wear the proper type of protective clothing. If switchboards, panelboards, loadcenters, and motor control centers were individually marked with the incident energy, the personnel would easily know what type of protective clothing to wear, because its rating is based upon the available incident energy in calories per square centimeter. These calculations can easily be made by an engineer or a knowledgeable contractor by using a formula which was presented in an IEEE paper by R.L. Doughty, T.E. Neal, and H.L. Floyd II, “Predicting Incident Energy to Better Manage the Electric Arc Hazard on 600 V Power Distribution Systems”, Record of Conference Papers IEEE IAS 45th Annual Petroleum and Chemical Industry Conference, September 28–30, 1998. This formula also appears in the 2000 edition of NFPA 70E, Electrical Safety Requirements for Employee Workplaces. The formula is E MB = 1038.7D B 1.4738 t A [0.0093F 2 — 0.3453F + 5.9675] Where E MB = incident energy from a box in cal/cm 2 D E = Distance from arc in inches. Assume 18 inches for this calculation.

t A = Arc duration in seconds

F = Bolted fault short circuit current

These requirements do not include residential occupancies because the available short circuit current is generally low enough so as not to be of a major concern.

The proposal contained two significantly unique aspects to it. First, the proposal addressed the need to protect workers from a perspective beyond that of a standard installation requirement. Typically, the NEC addresses those types of requirements that provide protection from the hazards of electricity when considered from the perspective of the installation. This approach leads to the inclusion of provisions directly related to the installation of electrical systems and equipment. Other codes and standards provide detailed provisions and recommendations such as specific work practices that should be followed to provide protection for workers and other personnel that might be exposed to the hazards. Specifically, the proposal required a field marking to warn workers of the potential nature of the hazard by providing them with a rating, in cal/cm2, of the incident energy level that they could expect to encounter while working on or near such equipment. The purpose of the cal/cm2 rating was to permit the worker to evaluate the relative risk and ascertain the level of personal protective equipment, including flame-resistant clothing, that would be needed to adequately protect him from the hazard.

The second unique aspect of this proposal was that it sought to integrate a requirement of NFPA 70E with that of NFPA 70, the NEC. NFPA 70E, Part II, requires that an arc flash hazard analysis be performed when working on or near energized conductors that are not placed into an electrically safe work condition.

Code-making Panel 1 accepted the proposal in principle by adding a FPN to reference NFPA 70E and making some minor editorial revisions. During the balloting period, the written ballot resulted in an affirmative vote of eleven to one. The one negative vote, however, was by the panel chair and raised valid concerns about the enforceability and usefulness of the new text.

The requirement is not enforceable and will not improve electrical safety. The three published methods of calculating incident energy result in considerably different values. This would create a dilemma for the authority having jurisdiction in trying to enforce some specific value. In addition, the FPN refers to NFPA 70E-2000 for calculation methods. NFPA 70E-2000 only contains one reference on how to perform the calculation of incident energy and this is a non-enforceable (informative) annex. The NFPA 70E committee specifically placed this material in an informative annex because of the variation in calculation methods. Furthermore, the incident energy value has little meaning to the electrical worker. Process industries, such as pharmaceuticals, typically must work on “”hot”” equipment. This is recognized as a serious problem, but the proposed solution does not provide a suitable answer. The NFPA 70E committee is addressing this problem and it would be better to wait for the experts in this area to devise a solution that can be added to NFPA 70E, rather than the more general NEC.

The Comment Stage

Figure 1. Figure 1 contains an example of a label that complies with the basic provision of 110.16.

The concerns raised in the negative vote became the focus of many comments to CMP-1 to reverse their action and reject the proposal during the comment stage. The majority of the comments addressed the enforceability of the requirement and whether it would result in an increased level of safety or protection for the worker. There were also a considerable number of comments that suggested this proposal was beyond the scope of the NEC. Others also suggested that there needed to be a stronger statement that the preferred practice is to always deenergize equipment and conductors and place them into an electrically-safe work condition before work is begun. Still others questioned whether the NFPA 70E means to accomplish the required calculation was suitable and empirically based. All of these were valid concerns and CMP-1 accepted in principle a comment that sought to provide a middle ground, a starting point of sorts, for this type of requirement. The text accepted by the panel reads as follows:

110.16 Flash Protection

Switchboards, panelboards, industrial control panels, and motor control centers that are in other than dwelling occupancies and are likely to require examination, adjustment, servicing, or maintenance while energized shall be field marked to warn qualified persons of potential electric arc-flash hazards. The marking shall be located so as to be clearly visible to qualified persons before examination, adjustment, servicing, or maintenance of the equipment.

FPN No. 1: NFPA 70E-2000, Electrical Safety Requirements for Employee Workplaces, provides assistance in determining severity of potential exposure, planning safe work practices, and selecting personal protective equipment.

FPN No. 2: ANSI Z535.4-1998, Product Safety Signs and Labels, provides guidelines for the design of safety signs and labels for application to products.

The panel statement generated by CMP-1 is indicative of the overwhelming opinion of the panel that this provision would enhance worker safety if only by raising their awareness of a potential hazard.

The panel concludes that requirements for warning of potential electrical hazards are within the purpose of the NEC, and agrees with the need to warn qualified persons of the potential of arc flash hazards in non-dwelling locations. However, the panel wants to emphasize the importance of de-energization and implementation of safe work practices outlined in NFPA 70E, in addition to recommending the use of appropriate personal protective equipment.

Application of the Rule

The true measure of any new or revised Code requirement can only be evaluated with experience and with a certain expectation that the revision or addition to the Code provides a suitable starting point or framework upon which our understanding is developed. Let’s look at one example that reveals how an end-user was able to quickly comply with the new requirement and enhance the safety of workers in their global facilities.

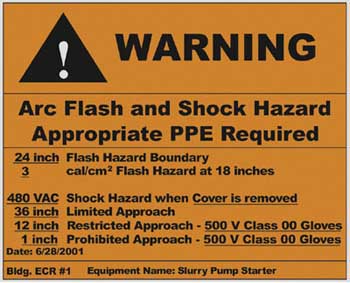

Figure 2. This figure contains an example of a site-specific enhanced labeling format that provides a significant amount of information to any worker who may be required to approach electrical equipment while in an energized condition.

The accepted text of 110.16 requires two steps for compliance. First, a determination needs to be made if a facility contains switchboards, panelboards, industrial control panels, and motor control centers that are likely to require examination, adjustment, servicing, or maintenance while energized. Note that the requirement specifically excludes such equipment where located in dwelling occupancies. The substantiation for the original proposal pointed out that the short-circuit current and related incident energy levels in these types of occupancies are generally low enough that they do not constitute a significant concern. Keep in mind that there may be particular locations and electrical systems for dwelling occupancies that the risk could still be significant. In any event, once the determination is made that such equipment will be approached while in an energized condition, a field marking shall be made. The marking must be visible to the worker and it must warn qualified persons of potential electric arc flash hazards. Note that, like the original proposal, the text does not mandate who shall perform the field marking. Some see this as a fault in the requirement. Essentially, it was an attempt to recognize that the manufacturer, the installing contractor, and the owner all have a responsibility in ensuring that the field marking occurs. Granted this does place a burden on the authority having jurisdiction (AHJ), but he or she ultimately is less concerned with who does the marking and mostly concerned with ensuring that the marking is done.

Figure 1 contains an example of a label that complies with the basic provision of 110.16.

As can be seen, the label is simple in its design and merely intended to serve as a hazard awareness flag at the point of the hazard. Unfortunately, as described in several of the comments submitted, far too many workers approach these types of equipment with no or inadequate personal protective equipment. This applies to supervisory personnel as well as the actual electricians that may be performing the work. Studies and data indicated that it is not unusual for arc blasts and flashes to extend to distances well beyond 10 ft.

Taking the Next Step

Beyond mere compliance with the Code, many seek to provide a level of safety beyond the minimum prescribed level. The provisions in 110.16 provide the additional benefit of becoming a framework for an enhanced level of safety related to the hazard of arc blasts and flashes.

Figure 2 contains an example of a site-specific enhanced labeling format that provides a significant amount of information to any worker who may be required to approach electrical equipment while in an energized condition.

As can be seen in figure 2, the label is divided into two parts. The upper half meets the requirements of 110.16. The lower half provides specific information related to an identified piece of equipment, in this case, a slurry pump starter. Notice that label identifies the flash hazard boundary, as required by NFPA 70E, Standard for Electrical Safety Requirements for Employee Workplaces – 2000, Section 2-1.3.3.2, at 24 inches. The flash hazard boundary is the distance at which the incident energy exposure, measured in cal/cm2, warrants the use of FR clothing and other personal protective equipment. The label also provides the flash hazard rating of 3 cal/cm2 at 18 inches. This is essentially what would have been required had the original proposal been accepted by CMP-1. The label also contains important shock hazard information that is not required by the NEC but is necessary for compliance with NFPA 70E. Finally, the label specifies the need for specific PPE, in this case, Class 00 gloves, when working within the restricted or prohibited approach boundaries.

The design was developed by DuPont and may be freely used by anyone. Their label combines a NEC installation requirement with an NFPA 70E work practice provision and in doing so provides compliance with both. Copies may be purchased from DuPont Printing Services by contacting Maria Harrington at 302-773-2628.

Conclusion

Too often, we get locked into thinking that a standard or code has a highly specialized purpose and any deviation from that purpose is misaligned. Perhaps, instead, we should consider the full usefulness of the particular code or standard and see how its use can improve and move us closer towards its intended purpose. In the case of the NEC, we have the most widely adopted and utilized code in the world. Doesn’t it make sense to “”piggy-back”” off that standard? In this case, the inclusion of 110.16 resulted in three significant accomplishments. First and foremost, it enhanced worker safety by requiring a warning for workers of the potential arc blast or arc flash hazard. Remember, the recognition of arc blast and flashes associated with electrical incidents is a relatively new concept and much needs to be learned and taught about the effects of such arcs and blasts. A simple and concise warning requirement like that of 110.16 may be all a worker needs to stop them from preceding with a hazardous task. Second, the inclusion of 110.16 is a starting point for better integration of the NEC with other important and related codes and standards. How is this possible? Since the NEC is so widely adopted and referenced it can become a springboard for cross-referencing or integrating these other standards. For example, Article 450 of the NEC contains requirements for transformers. Wouldn’t it be beneficial to the end-user of the Code if he could turn to Article 450 for installation requirements and while there see specific references to NFPA 70B—Recommended Practice for Electrical Equipment Maintenance for Maintenance Recommendations, and to NFPA 70E for specific work practices and requirements when inspecting the transformer while in an energized condition?

One problem, of course, is the difficulty and unforeseen consequences that may result when one code or standard contains a mandatory reference to another. This is generally not permitted in the NEC because it poses great difficulty for jurisdictions that adopt the NEC but do not adopt the other code or standard. But there are ways around this that I believe enhance both the usability of the NEC and increase the accessibility of these lesser known codes and standards. Section 110.16 is a case in point. The requirement contains no such mandatory reference but it, in essence, supports a requirement of a related standard. In this way, 110.16 may provide a third benefit in that it may serve as a model for further enhancements of the NEC that integrate requirements from other related codes and standards into the NEC.

The inclusion of 110.16 was a bold and important step in the 2002 NEC. Already, progressive companies have found ways to comply with provisions and enhance worker safety. Further proposals should study the development of 110.16 and use it as a model for further enhancements of worker safety through better integration of electrical codes and standards.

Find Us on Socials