History of Aluminum Wire

Photo 1. Aluminum wiring incorrectly installed on copper-only receptacle

Electricity is transmitted from the utility generating station to individual meters using almost exclusively aluminum wiring. In the U.S., utilities have used aluminum wire for over 100 years. It takes only one pound of aluminum to equal the current-carrying capacity of two pounds of copper. The lightweight conductors enable the utility to run transmission lines with half the number of supporting structures. The utility system is designed for aluminum conductors, and utility installers are familiar with installation techniques for the types of aluminum conductors used in utility applications.

Feeder and branch-circuit wiring systems were designed primarily for copper conductors. Aluminum wiring was evaluated and listed by Underwriter’s Laboratories for interior wiring applications in 1946; however, it was not used heavily until 1965. At that time, copper shortages and high prices made the installation of aluminum branch-circuit conductors a very attractive alternative. At the same time, steel screws became more common than brass screws on receptacles.1 The aluminum wire and the receptacle devices were both listed in accordance with the available product standards. As aluminum wire was installed more frequently, the industry discovered that changes were needed to improve the means of connecting and terminating smaller aluminum wire. Installation methods for utility grade aluminum conductors were also different, and workmanship was an important factor in making reliable connections.

The use of steel screws with utility grade aluminum wire resulted in a connection point that was more sensitive than copper or aluminum wire terminated with the previously used brass screws. Almost all reported problems involved 10 AWG and 12 AWG branch-circuit connections, so let’s focus on this type of connection and explain why it was more difficult to achieve a stable connection. The pre-1972 aluminum wire is often referred to as either EC grade aluminum, AA-1350 or utility grade aluminum. I will use these three terms interchangeably.

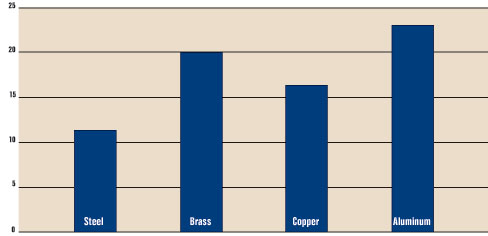

Several factors led to the reported failures of aluminum conductors with steel screws. One of the most often cited reports on aluminum wiring, The Report of the Commission of Inquiry on Aluminum Building Wire, evaluated information published between 1941 and 1978 and identified 19 different factors that might have affected the contact resistance of aluminum wiring.2 The most likely and often identified culprits were: workmanship, thermal expansion differences and creep. Table 1 shows the coefficients of linear expansion for aluminum, copper, steel and brass.

Poor workmanship is generally recognized as the primary source of failed connections. Incorrect installation methods included incorrectly tightened connections, wires wrapped the wrong way around binding screws, and aluminum conductors used in push-in connections or with devices meant only for copper (see photo 1).

Because the connections were often made incorrectly, a chain of events was initiated that sometimes led to failure at the connection. The connection was loose to begin with due to improper tightening torque, and the physical properties of the aluminum/steel interface tended to loosen the connection more over time. Aluminum and steel have significantly different rates of expansion. Because the two materials would expand and contract at different rates under varying load and temperature conditions, they would gradually develop a smaller contact area. Since the contact area was reduced, the resistance increased. As the resistance increased, the temperature also increased at the termination point. A similar problem occurred when the aluminum conductors were incorrectly terminated in the push-in connections intended only for copper conductors.

Another property of aluminum that is often referenced is known as the creep of a conductor. Creep is a property of all metals, and each metal has a unique rate of creep. Creep is the measurement of the rate of change of a material’s dimensions over a period of time when exposed to a force at a particular temperature. EC grade aluminum building wire has a higher creep rate than copper building wire. In comparison, AA-8000 aluminum alloys have creep rates very similar to copper building wire. This means that AA-8000 conductors perform very much like copper conductors at terminations.

Cold flow is a related term that also refers to the permanent deformation of a material when subjected to a force; however, cold flow is the result of a momentary force and does not vary over time. Cold flow is a necessary property of metals that allows a good connection to be made between separate components during the connection process.

Corrosion is often cited as a contributing cause of failure at aluminum connections. In 1980, the National Bureau of Standards performed a study to determine what caused the high resistance at aluminum/steel connections in receptacles.3 The study revealed that the formation of intermetallic compounds (alloys of aluminum and steel) caused the high resistance terminations, not corrosion or aluminum oxide. The thin, protective layer of oxide on aluminum conductors contributes to the excellent corrosion resistance of aluminum. When terminations are made correctly, the oxide layer is broken during the termination process allowing the necessary contact to be made between conducting surfaces.

Aluminum Wire in the NEC

The National Electrical Code has permitted the use of aluminum wire since 1901, a mere four years after the first recognized national electrical code was published in 1897.4 This is remarkable considering that aluminum had only been commercially feasible in large quantities since 1889 with the combined improvements in refining alumina from bauxite (the Bayer process in 1889) and producing molten aluminum from alumina (Hall-Heroult process in 1886).5 By comparison, many sources indicate that copper has been used for thousands of years, and the modern electric system only began in the 1880s.

The NEC has required aluminum alloy conductors for branch-circuit wiring (12–8 AWG) since 1981. The Code never explicitly prohibited aluminum building wire; however, there was a period in the early 1970s when UL withdrew the listing for aluminum building wire and revised the listing to require aluminum alloy conductors.

During this process, there was no listed aluminum building wire available except remaining stock. Today’s “new technology” aluminum building wire is made of AA-8000 series aluminum alloy. These alloys were developed in the late 1960s and were listed and manufactured beginning in 1972. At about the same time, CO/ALR devices were required for aluminum wire branch circuits and listed by UL. These devices were developed to be used reliably with 10 and 12 AWG conductors and must have brass screws.

AA-8000 series aluminum conductors were first specifically required by the NEC in 1987. The language has remained virtually unchanged since then, and can be found in the 2005 NEC Section 310.14. AA-8000 series aluminum alloy conductors have physical properties that are significantly different from the previously used AA-1350 aluminum conductors. To identify these conductors in the field, look for the designation “AA-8XXX” in the legend on the conductor or cable assembly; these are the only type of aluminum building wire conductors that are UL listed.

AA-8000 series aluminum alloy building wires are manufactured according to ASTM B-800. In the U.S., they are generally compact stranded according to ASTM B-801. Compact stranding reduces the diameter of the conductor by 9–10%. Compact stranding allows conductors to be installed in smaller conduit than their compressed stranded equivalents. Equal ampacity AA-8000 aluminum and copper conductors can usually be installed in the same size conduit. Annex C in the 2005 NEC has a separate set of tables for determining conduit fill when using compact stranded conductors. These tables apply equally to compact stranded aluminum or copper conductors. Each table for compact stranded conductors is designated by an “(A)” following the table number [i.e., Table C.1(A)]. Table 5A is a separate table of conductor properties for compact aluminum conductors and is located in chapter 9 of the NEC.

Although many changes were made in the aluminum conductors used for building wire, industry changes in connectors are equally significant. In 1978, UL issued a standard for connectors for aluminum building wire. This standard, UL 486B, contained much more rigorous testing methods than had previously been required. Today, UL 486B has been combined with UL 486A and the combined standard contains requirements for both copper and aluminum wire connectors.

Industry Standard Installations

Beginning in 2005, the NEC has started referencing through fine print notes the National Electrical Installation Standards (NEIS), a new series of standards published by the National Electrical Contractors Association (NECA). One of these standards is NECA/AA 104-2000, titled “Recommended Practice for Installing Aluminum Building Wire and Cable.” According to the foreword of NECA/AA 104-2000, the standards “define a minimum baseline of quality and workmanship for installing electrical products and systems.”6 This standard was jointly developed with the Aluminum Association. NECA is currently in the process of developing an equivalent standard for installing copper building wire.

Installing aluminum building wire requires the same process as installing copper building wire. The insulation should be stripped from individual conductors using tools manufactured for the conductor type and insulation type, or by standard methods such as penciling or whittling the insulation from the conductor. Never “ring cut” the insulation since you risk nicking the conductors inside. One common perception regarding aluminum building wire is that it is more susceptible to breaking when nicked than copper building wire. This opinion is based on experiences from “old technology” aluminum wire that was made of AA-1350 or EC grade aluminum prior to 1972. The EC grade wire then available was 99.5% pure aluminum, hard-temper and was more notch sensitive than copper building wire. This is no longer true since AA-8000 aluminum alloy building wire is a fully annealed aluminum alloy conductor that is very strong and flexible.

Photo 2. Legend on commercially available AA-8000 conductor

Where terminating with a compression connector, the bare conductor should then be inserted into the connector barrel and crimped with the tool recommended by the connector manufacturer. Compression connectors are generally marked with the required die size. After the crimping process is complete, any excess oxide inhibitor should be removed from the conductor.

If terminating a conductor with a set-screw connector, the bare conductor should be wire brushed and an oxide inhibitor applied to the bare conductor. The screw should then be tightened using a torque wrench or torque screwdriver. Using these tools will insure that the connection is tightened to the torque value recommended by the connector manufacturer. Over tightening the screw can be as detrimental to the long-term performance of the connection as a loose connection. Many electricians believe that “the tighter the better.” Unfortunately, over tightening can lead to damaged conductors and connection points.

Proper tightening (torqueing) is essential to achieve a reliable connection. Once the proper torque is achieved, there is no need to go back and re-tighten the lug after a period of time with AA-8000 series aluminum alloy conductors. However, all electrical connections should be periodically inspected in accordance with NFPA 70B.7

Oxide Inhibitor

Oxide inhibitor use is considered good workmanship for all 600-volt terminations, whether wired with copper or aluminum conductors. The oxide inhibitor provides a barrier at the connection point that excludes moisture and other potentially damaging environmental substances. Oxide inhibitor must be compatible with the conductor type. Different manufacturers make compounds that can be used with copper only, aluminum only, or both copper and aluminum. Be sure to choose the compound listed for the application. Compression connectors often come pre-filled with the appropriate oxide inhibitor. When connectors are tested for compliance with UL 486B, the conductor is prohibited to be wire brushed or abraded, and oxide inhibitor may only be used if the connector is pre-filled with the antioxidant. Therefore, mechanical set-screw terminations are tested without wire brushing and oxide inhibitor.

According to the UL GuideInfo (UL White Book) for wire connectors (ZMVV), oxide inhibitor for aluminum or copper wire may be used if the connector manufacturer recommends its use on the connector documentation. Oxide inhibitor is of the most value when making connections between uncoated copper and aluminum. This type of connection is subject to galvanic corrosion when in the presence of an electrolyte. Since most lugs today are made of tin-plated aluminum, galvanic corrosion is limited except in the case of severe electrolytic environment or significant damage to the connector plating.

Wire Brushing

For 600 V wire, you should wire brush the exposed conductor before applying the oxide inhibitor and terminating the conductor. This step will remove any excessive oxide from copper or aluminum wire and remove any pieces of insulation or other contaminants that might interfere with your connection. The thin layer of oxide that is naturally on copper or aluminum conductors will be broken by the physical act of tightening the setscrew connection or crimping the compression connection. According to the UL listing for wire connectors (ZMVV), wire brushing aluminum or copper conductors may be performed if the connector manufacturer recommends its use on the connector documentation.

Mechanical vs. Compression

Mechanical set-screw lugs are reliable when used with AA-8000 or copper conductors. Most commercially available lugs provided with equipment are made of an AA-6000 series aluminum alloy body plated with tin. UL 486B allows aluminum connectors to be manufactured without this plating, but only for connectors rated for aluminum conductors only. Since the standard lug is dual-rated, it is plated with tin to prevent galvanic corrosion between the copper conductor and the aluminum connector.

Compression connectors are available for aluminum only, copper only, or dual-rated for copper and aluminum. Examples of typical connector markings are included in photo 4. Some compression connectors are pre-filled with anti-oxidant and some are not. When deciding whether to specify or install compression or set-screw connectors, the application is the most important factor. Based on both field installations and laboratory testing, set-screw connections are equally reliable on both copper and aluminum conductors.8

Belleville Washers

NECA/AA 104-2000 (p. 10) recommends the use of a Belleville washer when connecting aluminum conductors to existing copper bus bar or studs. NFPA 70B indicates in 24.4.2.1 that if a Belleville spring washer has been flattened it should be loosened and re-tightened to manufacturer’s specifications. A flattened Belleville washer indicates over tightening, or possible overheating and loss of temper. If discoloration is present, the washer has most likely been overheated and should be replaced.

Pin Connectors

The use of pin connectors (adapters) is widely considered to be an acceptable requirement when specifying or installing aluminum conductors. The use of pin connectors allows aluminum conductors to be used when the provided conductor is not rated for use with aluminum. For instance, a pin connector with aluminum conductors could be used if existing equipment terminations are only rated for use with copper conductors, or the existing terminations are not sized properly for the required aluminum conductor size (i.e., a lug with a maximum size 500-kcmil provided for use with a 750-kcmil conductor). In these situations, a pin connector can be used to transition from the aluminum conductor to the incompatible termination.

Photo 3. Compact stranded aluminum conductor

Caution must be used when installing pin connectors (also known as wire adapters). The UL Guide Information for Wire Connector Adapters (ZMOW) states that “Adapters to be assembled to wire using a special tool are intended to be assembled using the tool specified by the manufacturer in the instructions which are provided in the unit container in which the adapters are packaged. Such tools are identified by appropriate marking.” When inspecting the installation of pin connectors, it should be verified that the proper tool and method of installation were used. The connector is generally marked with a die requirement, and use of the proper tool can be verified by inspecting the crimp(s). If the connector was installed with a dieless crimper, the inspector should ask for documentation from the connector manufacturer showing that the crimper used was recommended by the connector manufacturer.

Installations with incorrectly installed pin connectors may lead to overheating connections and a hazardous condition. Possible results of using the wrong tool can include connections that are under- or over-crimped. Either condition can lead to overheating and failed connections.

Pin connectors are not required for connecting AA-8000 aluminum alloy conductors to properly sized dual-rated mechanical set-screw connectors listed under UL 486B. The industry standard for lugs in equipment is to use a dual-rated aluminum body lug. These lugs are generally manufactured using AA-6000 series aluminum alloy and are tin plated. Laboratory and field installations have proven that AA-8000 conductors are as reliable as copper building wire when properly installed on set-screw lugs.9 As a corollary to this statement, improper installations of both copper and aluminum wire are susceptible to failure.

The most common point of failure in electrical circuits is at the termination. Using unnecessary pin connectors increases the number of connections and can significantly increase the risk of failure in the circuit. Additionally, since pin connectors generally require special and/or proprietary tools and a particular method and number of crimps, the opportunity for incorrect connections is much greater than with normal set-screw lugs. The specification and installation of pin connectors should be avoided unless absolutely necessary.

Flexibility

Table 1. Coefficients of expansion

Because of the alloying and annealing processes, AA-8000 conductors are more flexible than equivalent ampacity copper conductors.10 The NEC has begun to recognize this difference in physical properties with the revision of Table 312.6(B), which requires the same bending space at terminals for equal ampacity copper and AA-8000 conductors. For instance, 500-kcmil copper would require the same bending space as 750-kcmil AA-8000 aluminum.

Pulling Tension

AA-8000 series aluminum alloy building wires have a higher strength to weight ratio than copper building wires. Since copper must be approximately twice as heavy to achieve the same conductivity, AA-8000 has inherent advantage in vertical applications and when pulled through conduit. When installing AA-8000 conductors in vertical conduit runs, Table 300.19(A) in the NEC lists the distances allowed before strain relief is required for the conductors. When pulling conductors through conduit, pull tension calculations should always be made before the pull. There are many software programs and examples available explaining how to calculate pull tension. One factor that changes for different conductors in the calculations is the maximum allowable pulling stress; for AA-8000 series conductors, it is 0.006 lbs/cmil. For copper, the value is 0.008 lbs/cmil. When pulling, use a listed wire pulling compound that is rated for the insulation on the conductor.

Conclusion

As with most products used in the electrical industry, there is a variety of information available on the installation and use of aluminum building wire. Much of the information is unsupported and simply incorrect. Unreferenced articles, anecdotal examples and dire warnings should be carefully evaluated to determine if there is evidence to support the claims made.

Aluminum building wire today is at least as safe and reliable as copper building wire. Listed connectors are evaluated and manufactured specifically for aluminum connections. AA-8000 conductors now have over 30 years of field installation examples proving their reliability and have been recognized in the NEC for nearly 20 years.

AA-8000 series aluminum alloy conductors provide a safe and reliable method of designing and installing electrical systems. They are available as single conductors, in cable assemblies such as MC cable and SE cable, and a variety of other configurations to meet the needs of different installations.

For Additional Information

If you have questions about the information in this article, please feel free to contact the author at (702) 341-5856 or by email at Christel.Hunter@Alcan.com.

References

1 “Glowing Electrical Connections.” Electrical Construction and Maintenance (February 1978): 57-60.

2 Wilson, J. Tuzo. “The Report of the Commission of Inquiry on Aluminum Building Wiring, Part 2.” Queen’s Printer for Ontario (1979): 106-107.

3 Newbury, D. and Greenwald S. “Observations on the Mechanisms of High Resistance Junction Formation in Aluminum Wire Connections.” Journal of Research of the National Bureau of Standards (1980): 429-440.

4 Daniels, G. “The Controversy Over Aluminum Wiring.” Popular Science (May 1976): 58.

5 International Aluminium Institute website. (2000) Retrieved October 3, 2005 fromhttp://www.world-aluminum.org/history/index.html.

6 NECA/AA 104. “Installing Aluminum Building Wire and Cable.” National Electrical Contractors Association (2000): 1-26.

7 NFPA 70B. “Recommended Practice for Electrical Equipment Maintenance.” (2002).

8 Ganatra, R. and McKoon, T. “Reliability of connections: a comparison of aluminum alloy stranded conductors and electrically equivalent copper conductors.” Wire Journal International (1998).

9 Ibid.

10 Beckman, M. and Ganatra, R. “Flexibility and Springback Characteristics of 600 Bolt Insulated Conductors.” IAEI News (July/August 1997).

Find Us on Socials