As members of IAEI, we are among some of the best when it comes to inspectors, something of which we must take advantage when it comes to doing what you do on a daily basis, inspect. We work hard across the country to understand the National Electrical Code and all of its grey areas as well as the application of products in our industry, but sometimes it is that one overlooked detail, like how do you conduct an inspection, that can make all of this knowledge for naught. If your methods of executing the inspection are sloppy and erratic, there is a good chance that a code violation goes overlooked or completely missed because a room was skipped. New inspectors especially have a daunting task in front of them. Not only must they become masters of the NEC, they must deal confidently with those who will question their objections and with the stress of time management; and they must also learn the fundamentals of how to conduct the inspection itself. The question of how to conduct an inspection may seem trivial to a person who has been inspecting for more than twenty years but be not mistaken—remember back when you first began—this is not as easy as it seems.

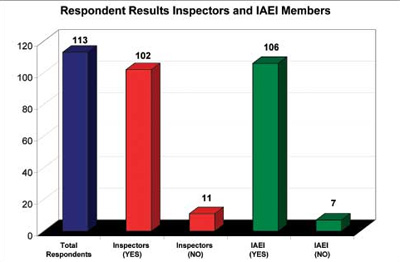

Figure 1. With 113 respondents, and more coming even after the survey was shut down, this survey was well received and very popular. All of the 102 inspector respondents to this survey were IAEI members. The message I received loud and clear was how eagar IAEI members are to help others succeed.

Simply Moxie

I never cease to be amazed by some electrical inspectors when they spout article, section and titles of the NEC as if they have the entire book memorized, including the year that particular section was adopted in the code. How in the world can a person absorb that much information and just how long does it take to achieve that level of expertise? are thoughts that echo in my head. I am amazed when walking a site with a seasoned electrical inspector, watching as his/her eyes scan an installation, and a violation is seen. Without blinking an eye, he gives an article and a section number and shows me exactly what was not installed correctly. Not only do I have the article and section but if I probe, I can get the why and when this portion of the code was put in place, a complete history lesson in the matter of a few minutes.

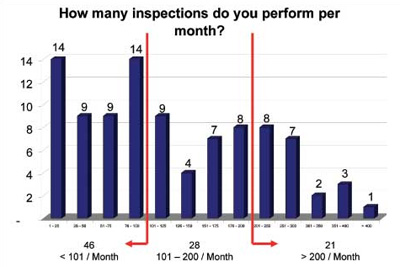

Figure 2. With an average of 142 inspections per month, it is quite clear that working efficiently is very important for an inspector. Some respondents reported more than 300 inspections per month.

Individuals that have these abilities did not get there overnight. They didn’t wake up one morning, implant the NEC chip in their head, and become this wealth of information. They worked for it. This is from years of walking various structures, researching and living their trade. At some point in time, they were new to this business and the code book seemed impossible. I have spoken to many electrical inspectors in hopes of creating an article that would be enlightening to some on the inspection itself. Just like the person who can spew code articles and sections, these individuals devour a structure in a way that leaves no stone unturned. It is second nature and, again, it didn’t happen overnight. Today’s “Safety in Our States” will share the results of my survey and hopefully plant seeds, lay the foundation so to speak, for future dialog on this topic. After all, this is yet one more benefit of your IAEI membership. If you are a new inspector, you are among the best. Take advantage of those who have been in the business for years and are darn good at it.

Insight from the survey

As you review the tables in this article for some of the results of this survey, it should be clear that this is just the tip of the iceberg. There is a huge opportunity in the area of providing organized materials around guidance and tools related to conducting an inspection. In researching for this article, I found that the resources for new inspectors are minimal at best. That being said, there was one common message that I heard. Inspectors were clear that the primary source of education for conducting inspections is in their IAEI membership, the contacts they have made. This is the unmeasured value of your IAEI membership and attendance of local, state, and section meetings. Never underestimate the value of your membership. Usually we tend to measure value in how much we saved on books and on training or other tools. It’s usually where we can affix a dollar amount to what we receive. What we sometimes fail to realize is the hidden value that you cannot measure. When it comes to educational material, I could argue that more learning occurs around a coffee pot and a water fountain than you could possibly imagine. It’s that quick conversation, that aha moment, which is your IAEI membership delivering the value to which it is impossible to affix a price tag.

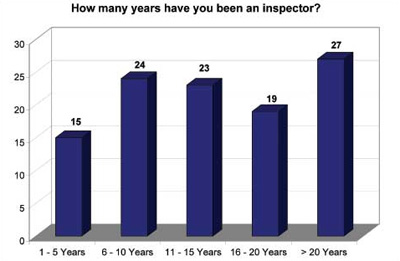

Figure 3. Survey respondents were nicely distributed representing a wide range of experience (108 of the respondents to this survey answered this question).

After sifting through the results of this survey, I can conclude that there is more work to be done. There was one specific question that was asked to which this article does not share the results. The question was pertaining to what specific technique inspectors use while inspecting a structure and what educational classes have been taken. The responses varied considerably. The message received loud and clear was that an inspector should have a process and be consistent. Keep your eyes on this column for more on this topic as I will be probing deeper on this topic.

Sharing words of wisdom

I will leave you, the reader, with the following words of wisdom left by the electrical inspectors responding to this survey. I hope that these quotes spur more discussion and debate on this topic. There is a huge opportunity to provide those tools necessary for young and new inspectors coming in to this trade. IAEI is the resource for this knowledge.

“Keep an open mind. The code book offers many routes to a code-compliant installation. Just because you haven’t seen it before doesn’t mean that it defies the Code.”

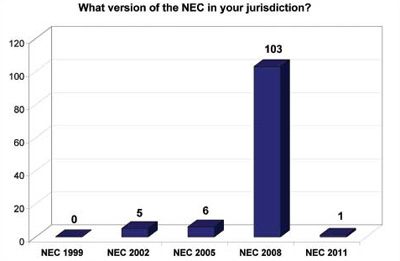

Figure 4. NEC-2008 was most popular in this survey. We will begin the 2011 NEC adoption cycle across the U. S. and there are still some areas on the 2002 version of the NEC. One respondent reported that his jurisdiction will be on NEC-2011 beginning January 1, 2011. Some jurisdictions inspect to more than one version of the NEC, for example a respondent from Texas indicated he inspects to the 2002, 2005, and 2008 versions of the NEC.

“. . . develop a process for specific types of inspections and use the same process every time. That should minimize the chance of missing components of the inspection that are important.”

“. . . Dress the part . . . Wear a shirt and a tie and look the part!”

“Learn the Code and verify your code violations. Don’t go by memory or by what you think is in the Code. I think a checklist would be very valuable to those starting out.”

“Listen before you talk and ask questions before deeming something is non-compliant, you may not be seeing the full picture. Realize that you do not know everything in the Code; even experts disagree on the correct interpretation of the Code. Do not discount the knowledge of your customers (contractors). . . . Remember to communicate. When you listen to a different opinion you will learn. The object is education, either you educate the contractor or the contractor can educate you; both are win/win. You earn the respect of your customer as someone willing to listen and work with and not to be feared.”

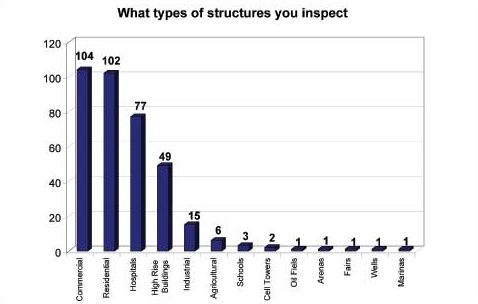

Figure 5. Commercial and residential inspections topped the charts, but hospitals and high-rise buildings were not too far away. Inspections on each of these types of facilities are going to vary. Know the structure you are going to inspect, as what you may be looking for will probably be different. A few respondents noted that they will do some research before going to the inspection.

“Join the IAEI and talk to experienced inspectors.”

“Do not be in a hurry. If something looks questionable, then cite it; a retraction, if you are in error, can always be withdrawn.”

“Be consistent, be comprehensive, be accurate, and be respectful.”

“Know the electrical code. Have experience with the installations. Be at or above the level of knowledge of those you are inspecting.”

“Enforce the code to individuals with the same respect and foresight that you would in justifying yourself to a judge and a twelve-person jury.”

“Take all the time you need; don’t get in a hurry.”

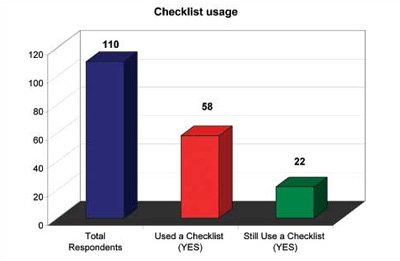

Figure 6. Checklists are quite controversial for various reasons. One hundred ten respondents to this survey answered this question. Fifty-eight of them have used a checklist in the past but only 22 still include a checklist as part of their work.

“Be firm and fair and consistent.”

“If you don’t know something, don’t bluff your way through it. Tell them you will research it and get back to them.”

“Know the electrical code and how to apply it. Know how electrical systems are installed and work.”

“Slow down…. Do not allow yourself to be distracted by individuals while making your inspection.”

“Leave it better than you found it.”

“Conduct yourself in a professional matter.”

“Be calm, be patient and, most of all, remember it’s not personal.”

“Ask questions! If you get asked a question in the field and you are not sure of the answer, tell them you will get back to them after looking it up; you are not required to have the code memorized. A right answer is better than a guess. If you have never performed a job (hazardous, high voltage, etc.), when you have a contractor you can trust, pick their minds. You both learn from it. At field evaluations, talk to the person doing the field evaluations; find out what different standards allow. Be willing to learn, even from the electricians. Remember, no one is perfect. Do not be afraid to admit you made a wrong call.”

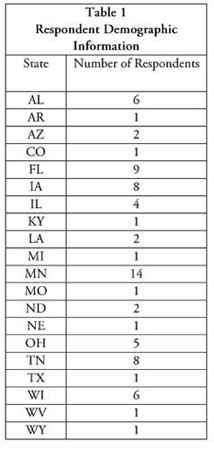

Table 1. Only 75 respondents indicated the state in which they reside. Thank you to everyone who participated.

“Study and attend meetings pertaining to the NEC.”

“Do not forget when you were on the other side of the fence.”

“Be accurate and know the code!”

“Go through the code book and make a list of what you are looking for on each job.”

“Take your time and don’t get in a hurry. Always check grounding and bonding.”

“Do not try to memorize the code, just learn to use it.”

“When issuing a correction notice, always cite the code violation with code sections. Never say that this is the way YOU want it. Be courteous and confident. Show respect and you will get respect.”

“Serve an apprenticeship with an experienced inspector.”

“Be sure the violations you write up are valid. Cite the code section and issue. Do not slip above the minimum standards of the NEC.”

“Know the code and understand each inspection. There is a lot of interpretation.”

“Take notes — document everything.”

“Always study the NEC article that pertains to what you are looking at. You will discover that it takes 4–5 years’ experience before you really feel comfortable in your inspection process. Always keep an open mind and use some common sense; never forget you are a public servant in this endeavor, not the electric sheriff.”

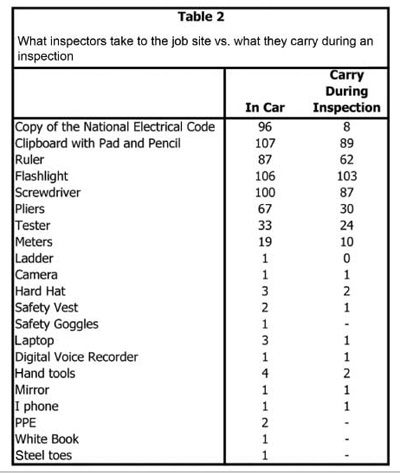

Table 2. It is clear from these results that this question should be a survey unto itself. The question was not formulated in such a manner as to stimulate the reviewer. A future article just may be in order to dig deeper in this area.

“You can’t know everything, especially at first, but use as many timesaving tools as possible; and attend IAEI meetings and training as often as possible. Through all my years in an apprenticeship, as a journeyman and as an electrical contractor, I did not learn as much as I have by attending IAEI meetings.”

“Purchase a NEC Handbook and read the commentary. There is always more than one interpretation of what is written, but stay consistent and treat everyone equally. Strict but fair. Be an educator and moderator.”

“Don’t be afraid to ask questions of the electricians or your supervisor, as nobody can keep all this stuff straight when it may have been years since you last saw a certain situation.”

“Look at each jobsite individually. Do not attempt to judge a job by the installer.”

“Slow down, stay calm. Take the job in small parts and not as a big project, it can become overwhelming.”

“You don’t have to worry about learning the code it will come with experience, work more on how you treat the people you’re working with (like you would want to be treated).”

“Look at code issues in relation to safety first and installation second. Also be on time and organized and willing to listen and educate your inspection clients.”

“The job is not about inspector vs. contractor. They are our customers and the first thing you should learn is customer service. Without contractors, we would not have a job. Our primary focus should be on electrical safety, but we must be able to point out violations in a way that is palatable to our customers. We can all learn from each other; and the first guy you meet that thinks he knows everything, you should run from him. He will be the one that gets someone hurt.”

“Do a ride along with other inspectors to see how they do it or more. Just to see how each looks at a job and how problems are worked out.”

“It’s simple, ‘Most anyone can read a book and regurgitate the requirements, but a true professional inspector knows his customer and gets his message across without overpowering or belittling the customer.’”

“Challenge yourself with thought-provoking questions regarding code requirements and hunt for the answers in the code book—you’ll learn so much!”

“Recognize that you have limitations with your knowledge and don’t be afraid to seek assistance. Membership in IAEI gives you unlimited access to industry experts to answer those unique, one-of-a-kind scenarios. Be firm, fair, and factual in your approach to inspections—most of all, be diplomatic.”

“Don’t just look at an electrical installation, trying to find code language that makes it in violation of the code; but rather look for proper interpretation and all exceptions that would make the installation code-compliant.”

“Keep a safe distance from arc flash potential. Study the codebooks and workbooks. Discuss things with electricians and other inspectors.”

“Know the code and be able to explain, in a nice way and with patience, what the code requirement is and why it is important.”

“Be as thorough as you can be, and document all corrections and send a copy—not just a phone call—to installers. I keep a copy of all inspection reports, and it has helped me when an issue arose a year later.”

“Ask yourself, before writing up a violation, two questions: What is the hazard? and Am I exercising common sense?

“Make sure that there isn’t any power on what you are inspecting.”

Find Us on Socials