This article reviews two very essential safety requirements of the Canadian Electrical Code for motor control circuits, grounding and why it’s so significant that control circuits be prohibited for use as motor disconnecting means.

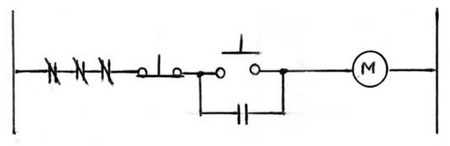

Figure 1. Motor control circuit diagram

As a basic requirement, Rule 28-500 Control required specifies that every motor must be provided with a motor starter or controller for starting and stopping the motor. Sub-rule 1 also provides a list of exceptions to the rule, namely:

• A single-phase, 125-volt, cord-connected motor up to 1/3 horsepower;

• A motor controlled by a general use disconnect switch;

• A single-phase portable 125-volt motor, up to 1/3 horsepower controlled by a horsepower rated switch; or

• Several motors controlled by a single motor controller.

First addressing the motor control circuit grounding issue, Rule 28-506 Grounded control circuit requires that when a motor control circuit is supplied from a grounded electrical source, the grounded side of the motor control circuit must be arranged so that an accidental ground in the control wiring will not start the motor or prevent stopping of the motor.

Seems like a common sense requirement, but how is this to be accomplished? This simply means that the grounded side of the motor control circuit must be on the side of the motor starter coil opposite from the motor control contacts. Consider the motor control circuit diagram in figure 1. Which is the grounded side of the circuit? What do you think might occur if the other side of the control circuit happened to be the grounded side?

In this diagram, the rule requires that the right-hand side of the control circuit must be the grounded side. Should the grounding of the circuit accidentally be reversed, a short-circuit in the control wiring between the motor starter coil and the motor control contactor would energize the starter coil, causing the motor to start up on its own.

Alternatively, a short-circuit between the stop pushbutton and the motor control contactor would not cause the motor to start, but once started, the motor could not be stopped by means of the motor control circuit, since the STOP pushbutton would then be out of the control circuit and thereby prevented from stopping the motor.

Addressing our second point, Rule 28-602(4)specifies that a motor disconnecting means must not be electrically operated, either automatically or by remote control. This simply means that before working on a motor or the motor-driven machinery, we must always disconnect and lock-off the electrical power supply to the motor. Disabling the motor control circuit by using a lock-off switch is not a permissible or safe means of disconnecting the motor. A lock-off stop device in the control circuit will prevent the motor from starting. However, a short circuit in the control wiring could cause the motor to start unexpectedly and create an unsafe condition. For this reason, de-energizing the motor control circuit is not permitted as the motor disconnection means.

As with past articles, you should always consult the electrical inspection authority for a more precise interpretation of any of the above.

Find Us on Socials