In the course of my travels for many years now, it has become apparent that most electricians don’t understand Ohm’s law, watts and torque. It’s very simple. Electrical wires and connections need to operate at a temperate of no more than 60° or 75° Celsius.

Ohm’s Law

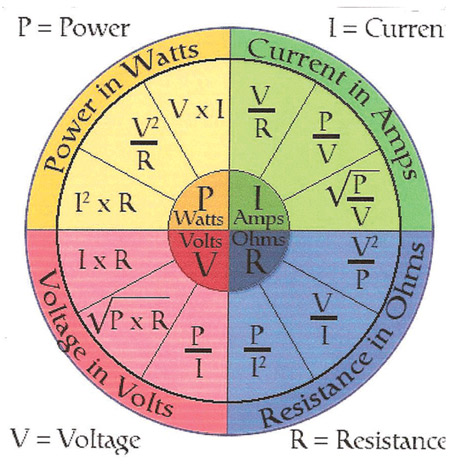

The only way to measure the temperature is to measure it with a thermometer. You cannot calculate it. On the other hand, you can easily measure volts and amperes and calculate ohms and watts. That’s watts of power going in. How fast heat leaks out, depends absolutely on the ambient air temperature or quantity of dirt or fiberglass.

Algebra

Now for the hard part: algebra. I know most guys make a retrograde advance to the rear when they hear the word “algebra,” but it’s really not that hard. Ohm’s law is usually stated as E = IR. That doesn’t tell you much. We will divide both sides by I to get E/I = R, because you cannot read R at zero to one ohm accurately. If a multimeter says a nominal 75-watt bulb has 12.5 ohms at 10° Celsius (50° Fahrenheit), it’s telling the truth. But for a piece of wire or its connections, we should expect ohms to be a decimal point followed by a bunch of zeros before we get to a significant digit.

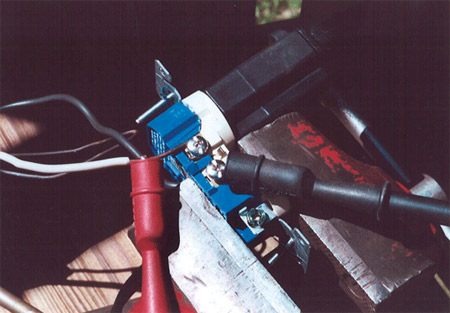

There is a catch. You need a volt meter with a milli-volt AC scale. A cheap meter with a bottom scale of zero to two whole volts simply won’t work. My old ohmmeter is supremely accurate with a minimum reading of 0.1 mV AC. Any other good meter with a minimum reading of one or ten mV AC should suffice. No accuracy is needed for amps. My throwaway box heater burns 11.5 amps. They may vary from 11 to 12. Where you need accuracy is on the mV AV reading.

Now all you have to do is take your mV reading and divide by 1000 to get whole volts, and then divide by 11.5 amps to get ohms. This number should be a decimal point followed by a lot of zeros. Table 8 says 12 AWG solid has 1.93 ohms per thousand feet. That’s a long circuit. Let’s consider a short circuit, says a GFCI receptacle at the service entrance with six inches of black conductor and six inches of white conductor, total one foot. The resistance of the wire is 1.93 ohms divided by 1000. This is OK for a load of 20 amps.

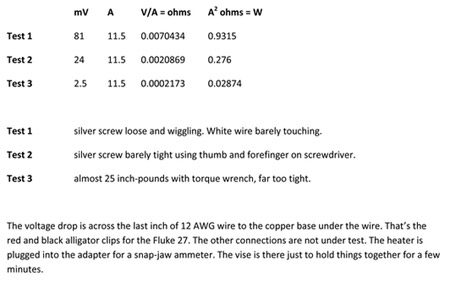

Figure 1. Tabulation of experiment

What are not acceptable are bad connections. You’ve got four connections: black conductor to a circuit breaker, white conductor to the grounded busbar, and the same to brass and silver screws on the device. Those four connections are each about a half-inch long. Those connections need to have about the same resistance as an unbroken half-inch of 12 AWG, or 1.93 divided by 1000 divided by 24.

The way you get a good connection is with a properly calibrated torque screwdriver.

The Experiment

This is the fun part, but first you need one more small dose of the dreaded algebra. Power in watts, joules of work per second, is I2R in concepts, or A2 ohms or VA in units. You should have at least one memorized. Remember that we calculated resistance by measuring millivolts and dividing by amps. Now we can calculate watts by taking the square of 11.5 amps times ohms. Not too bad. But what if I plug in two heaters? That would be 23 amps. A 20-amp circuit breaker is required to handle that overload for quite a few minutes. Now do the math. Double the current, squared, times the same resistance is quadruple the heat in watts. Can 12 AWG survive? Can the connection survive? No, they’ll cook. Clean, tight connections will get too hot. Loose connections with unstripped plastic under the screws will start a fire.

Photo 1. Alligator clips on terminal to measure voltage drop.

One more fly in the ointment. If you run one, two or ten heaters at 11.5 amps on a 200-amp service, it should work just fine. We’re assuming that resistance is fixed. In the real world, as temperature rises, resistance rises. As resistance rises, watts rise. It’s a vicious circle, like sliding off a barn roof. You start at 20°C (68°F). After a while it’s 60°C (140°F). For really bad work it’s 204°C (400°F). That’s a good temperature for baking cookies. But red screw-on wire connectors turn beige and vinyl tape turns to charcoal. You’re lucky the house didn’t burn down.

In my first test, the silver screw was loose and wiggling. The 12 AWG was looped around and free to slide out, which it did, while I got the other end poked into a GFCI. In my second test, I turned the screwdriver with my thumb and forefinger to more than zero inch-pounds, maybe two, with the wire still free to rotate. In the third test, I got to about 23 inch-pounds. That was way too right. Twenty-five would have ripped the 8-32 screw right out.

Notice that in the tabulated results the ohms and watts collapse to one-tenth, all with the same throwaway heater that cooked itself a few years ago.

Electrical connections need to be just as clean. Don’t guess; use a torque wrench. Don’t use an 18-inch breaker bar.

Find Us on Socials