Overcurrent protective device interrupting rating (IR) and equipment short-circuit current rating (SCCR) are key considerations for the safety of commercial and industrial electrical systems. If inadequate overcurrent protective device IR or equipment SCCR is present, a serious potential safety hazard exists. As a result, the NEC and Occupational Safety and Health Administration (OSHA) have added requirements that draw attention to this issue that are resulting in changes to equipment design and specification.

Overcurrent protective device interrupting rating (IR) and equipment short-circuit current rating (SCCR) are key considerations for the safety of commercial and industrial electrical systems. If inadequate overcurrent protective device IR or equipment SCCR is present, a serious potential safety hazard exists. As a result, the NEC and Occupational Safety and Health Administration (OSHA) have added requirements that draw attention to this issue that are resulting in changes to equipment design and specification.

This article focuses on equipment SCCR marking requirements with an emphasis on proper equipment installation requirements according to the NEC.

Unlike the product standards, theNECidentifies the overcurrent protective device IR and equipment SCCR marking requirements. More importantly, it also addresses the installation requirements for proper application of overcurrent protective device IR and equipment SCCR.

Interrupting Rating

It’s important to understand the difference between the IR of overcurrent protective devices (such as fuses and circuit breakers) versus equipment SCCR (such as devices, appliances, apparatus and machinery).

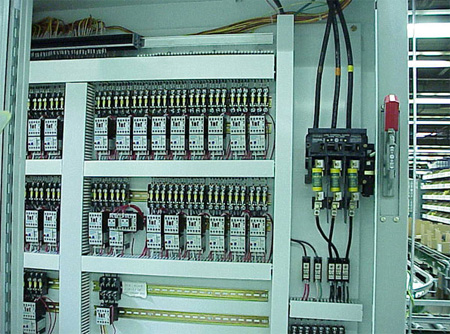

Figure 1. The NEC requires marking of the interrupting rating on a current-limiting fuse per NEC 240.60(C)

IR is defined in the 2011 NEC Article 100 as “the highest current at rated voltage that a device is identified to interrupt under standard test conditions.” Therefore, IR simply is the highest current that an overcurrent protective device is rated to safely clear. According to NEC 110.9, the IR of the overcurrent protective device must be no less than the current available at the equipment’s line terminals.

The NEC requires the marking of the interrupting rating of fuses per NEC 240.60(C) and circuit breakers per 240.83(C) [see figure 1].

Short-Circuit Current Rating

The 2011 NEC Article 100 defines SCCR as “the prospective symmetrical fault current at a nominal voltage to which an apparatus or system is able to be connected without sustaining damage exceeding defined acceptance criteria.” Therefore, SCCR simply is the highest current that equipment is rated to safely withstand.

NEC 110.10 requires that the equipment SCCR “be selected and coordinated to permit the circuit protective devices to clear a fault, and to do so without extensive damage to the electrical equipment of the circuit.” Notice thatNEC110.10 indicates that a specific circuit protective device (fuse or circuit breaker) might be required to provide proper protection.

NEC 110.10 also says the protective device must protect the equipment fromextensivedamage. Therefore, damage can occur to equipment after a fault, but it can’t result in a shock or fire hazard outside of the enclosure.

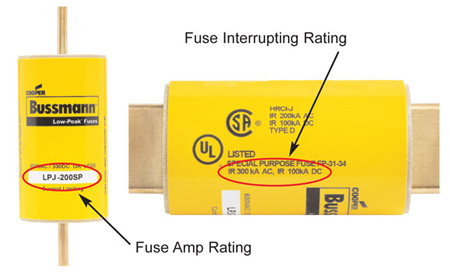

Figure 2. This is an example of marked SCCR on an industrial control panel nameplate

The acceptable damage criteria for SCCR testing and evaluation in product standards is another topic for an in-depth discussion not covered in this article. Typically, acceptable damage might render the assembly or a component in the assembly as useless. The main objective of the product standard SCCR acceptable damage level, however, is to prevent a shock hazard or a fire outside the enclosure.

If a violation of NEC 110.9 or 110.10 occurs, and the fault current exceeds the IR of the overcurrent protective device or the SCCR of equipment, a catastrophic and violent failure of the overcurrent protective device or equipment can occur.

OSHA 1910.303(b)(4) and 1910.303(b)(5) contain similar language to NEC 110.9 and NEC 110.10, so both newandexisting overcurrent protective devices and equipment must have adequate IR and SCCR.

SCCR Marking Requirements

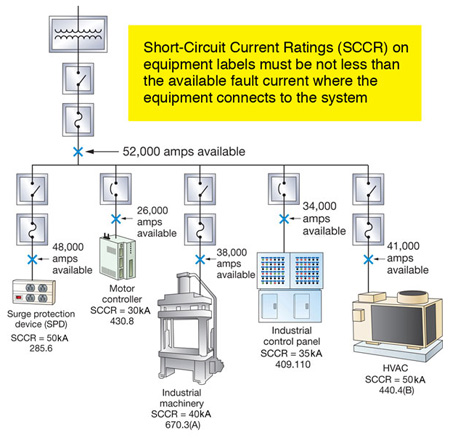

In the past, equipment such as HVAC, industrial control panels and industrial machinery was considered “utilization equipment” and was overlooked regarding proper SCCR and the ability to withstand fault currents. To correct this issue, the 2005NECadded new requirements for marking equipment SCCR to correlate with the product standards.

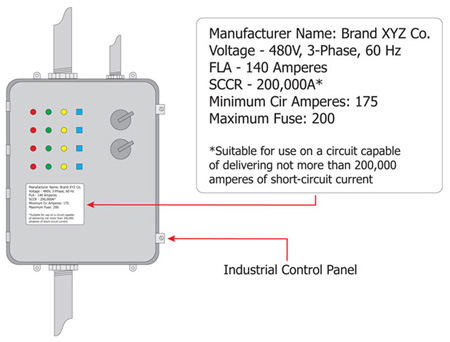

The 2005 NEC added SCCR marking requirements for motor controllers in NEC 430.8; HVAC equipment in 440.4(B); industrial control panels in 409.110; and industrial machinery in 670.3(A).

In addition, 409.110(3) and 670.3(A) also contained fine print notes (changed to information notes in the 2011 NEC) that UL 508A, Supplement SB was an approved method for determining equipment SCCR for industrial control panels and industrial machinery (see figure 2).

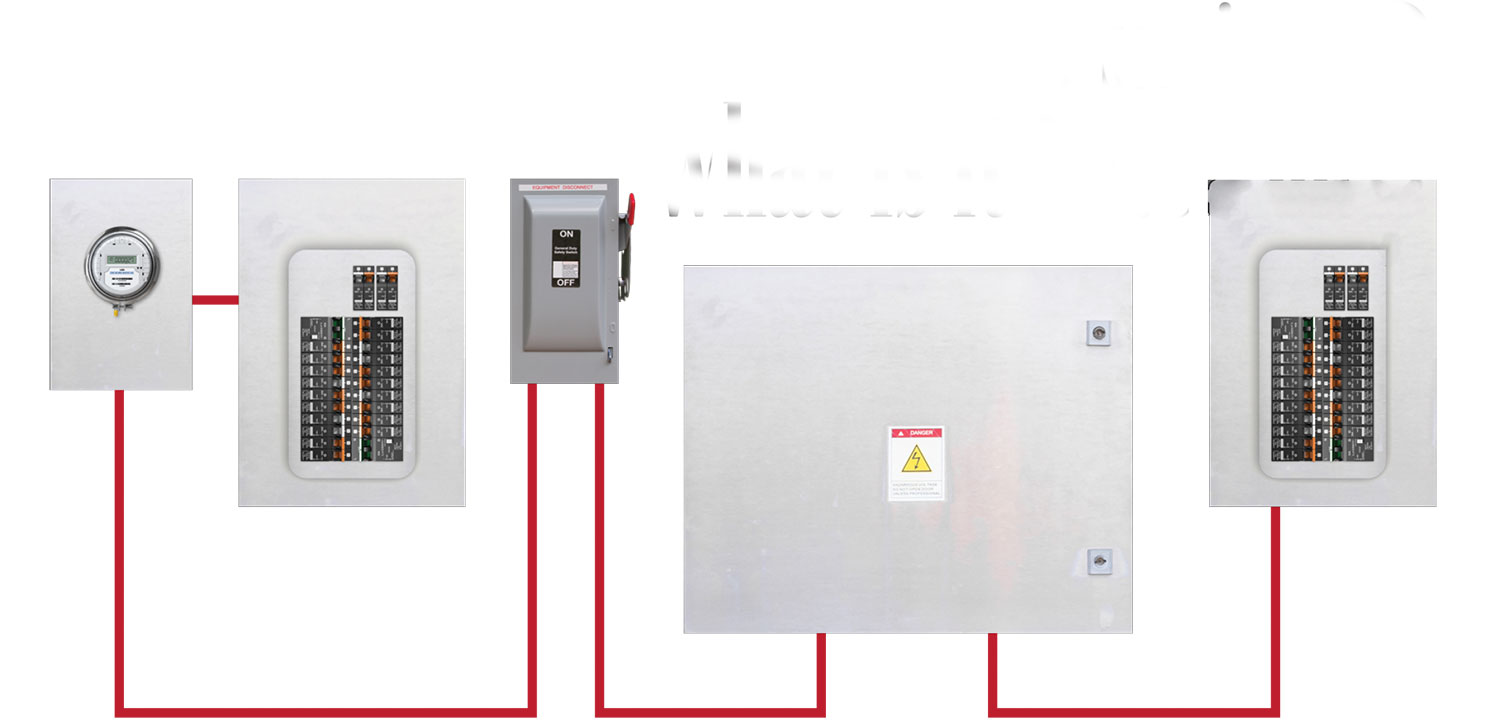

Figure 3. This demonstrates the available fault current and proper application of equipment SCCR.

In the 2008 NEC, Section 409.110 was changed to add an exception that SCCR wasn’t required to be marked on industrial control panels that contain only control components to correlate with the requirements of UL 508A. Therefore, if the industrial control panel contains only control circuit components (components that don’t supply loads such as motors, lighting, heating, appliance or receptacles), then an SCCR marking is not required.

SCCR Installation Requirements

Changes to theNECSCCR equipment-marking requirements were designed to help draw attention to the withstand capabilities of equipment and, combined with the existing requirements of NEC 110.10, prevent installation of underrated equipment.

In the 2011 NEC, additional requirements were added for industrial control panels and industrial machinery that complement and reinforce the requirements ofNEC110.10. Specifically, a new section, 409.22, was added to require that an industrial control panel not be installed where the available fault current exceeds its SCCR as marked in accordance with 409.110. Similar wording was added for industrial machinery per a new section in NEC 670.5.

The added text in 409.22 and 670.5 draws attention to the fact that industrial control panels and industrial machinery must be designed and manufactured with an SCCR that is adequate for the installation.

Therefore, if equipment such as an industrial control panel is being installed in an industrial facility, the system designer must communicate the maximum fault current to the equipment supplier so the supplier can design the equipment with SCCR no less than the fault current where installed in accordance with NEC 409.22 and 110.10.

The process would be similar for HVAC equipment in commercial and industrial building facilities, although not specifically stated other than the requirements of NEC 440.4(B) and 110.10.

Another requirement highlighting proper equipment ratings was added in the 2011 NEC. A new section, 110.24, requires commercial and industrial service equipment to be marked with the maximum available fault current, and to be remarked if modifications of the electrical installation resulted in an increase of the maximum available fault current. The intent of this change was to assure compliance withNEC110.9 and 110.10 for service equipment (see figure 3).

The 2011 NEC changes discussed in this article have helped increase awareness of available fault current and proper equipment SCCR by system designers, installers and AHJs. In many jurisdictions, AHJs have responded to these changes by requiring the available fault current to be documented at equipment and by red-tagging equipment if found with an inadequate SCCR. Because of this, system designers and installers are identifying the fault current at equipment and communicating these requirements to equipment manufacturers.

System designers and installers also are realizing that once the equipment is installed with inadequate SCCR, there are no easy fixes. The only options are equipment modification and recertification or reduction of fault current (through use of additional conductors, isolation transformers or reactors).

Additionally, equipment might be relocated within a facility or to another facility that has increased fault currents, causing additional concerns for flexibility of application for equipment. This can result in costly delays and increased equipment cost.

As a result, equipment suppliers now are being requested to provide equipment with high SCCR. This, in turn, brings equipment design changes to meet the requirements for high fault-current installations.

For more information on industrial control panels and SCCR, see Section 4 of the Cooper Bussmann “Selecting Protective Devices” handbook. Download it free by clicking on the “register for free download links” and submitting the required information at http://bit.ly/SPDhandbook.

Find Us on Socials