What’s tall, holds some dusty stuff, and at times can go boom? You guessed it, grain elevators. This just may be a topic you don’t hear discussed very often, yet there are statistics associated with these structures that may surprise you. Headlines such as “Three More Victims Found after Explosion at Kansas Grain Facility . . .” or “2 Hurt in Grain Elevator Explosion in Tracy, Minn. . .” are very concerning and found all too often. A simple Google search for “grain elevator explosion” brings to light the urgency of safety in these types of facilities. Grain elevators have been around for quite some time and will be around for years to come as they are critical not only to many farmers across this country but also to this country’s economy. The statistics and news reports tell us we need to be concerned about grain elevator safety, which deserves your attention and your efforts when it comes to preventing what is happening across the United States — explosions that claim millions of dollars in property and many lives.

Photo 1. Grain elevators enable the handling of loose grain in large volumes.

Background

Grain elevators have been around for a very long time; they were invented in Buffalo in the 1842 /1843 time frame to eliminate the need to bag and handle grain. They enabled the handling of loose grain in large volumes. A grain elevator includes a complex of facilities focused on handling grain. That would include offices, weigh-bridges, storage facilities and more. The United States Department of Labor’s Occupational Safety & Health Administration (OSHA) describes grain handling facilities as those “that may receive, handle, store, process and ship bulk raw agricultural commodities such as (but not limited to) corn, wheat, oats, barley, sunflower seeds, and soybeans. Grain handling facilities include grain elevators, feed mills, flour mills, rice mills, dust pelletizing plants, dry corn mills, facilities with soybean flaking operations, and facilities with dry grinding operations of soycake” (http://www.osha.gov/SLTC/grainhandling/index.html). When it comes to safety concerns, any business that has a grain elevator on-site that is utilized for the storage, transport and/or processing of a raw agricultural commodity is a prime target. As an example, these may also include breweries where malt and other ingredients are stored.

These facilities usually employ a bucket elevator or a pneumatic conveyor to take grain from a lower level to a higher level ultimately deposited in a silo or other similar storage facility. They come in all shapes and sizes from smaller grain elevators found on a farm to large grain elevators run by companies that focus only on this aspect of the grain trade. These larger grain elevator complexes are the beginning of a journey for the grain they hold, which finds its way to grain wholesalers, exporters and local users, being emptied out of the silos or bins by gravity into railroad cars, barges or other movers like trucks. This is a very efficient way to handle massive amounts of grain and beats the backbreaking job of handling bags or sacks of the stuff. It’s a process that is critical to our U.S. economy.

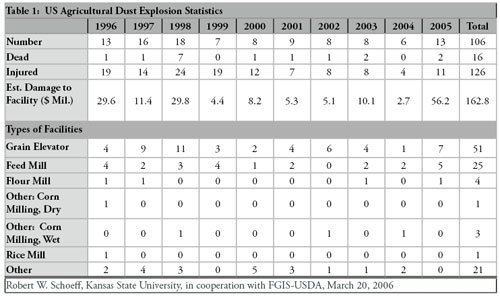

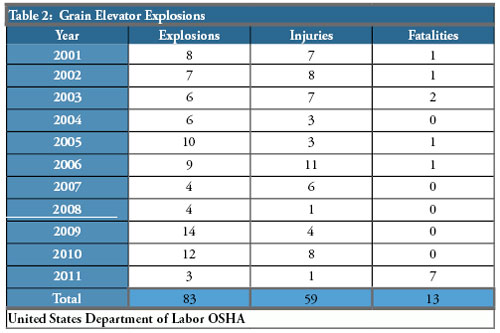

The statistics around grain elevators and dust explosions, in general, command our attention. Over the ten-year period reported in table 1 coming out of a Kansas State University study, there were 16 deaths, 126 injuries and $162.8 million in damage due to “dust” explosions. Grain elevator explosions are specifically called out in this report showing 51 explosions over this ten-year period from 1996 through 2005. More recent statistics are available from OSHA and show that over a more recent ten-year period, 2001 through 2011, there have been 83 explosions 59 injuries and 13 deaths.

Table 1. U. S. Agricultural Dust Explosion Statistics

The above statistics cover explosions, but the hazards in these grain handling facilities are many. Having grown up in a steel mill town [Aliquippa] in the Pittsburgh, Pennsylvania, area, I can remember sitting around the table listening to my father talk about the dangers that he witnessed in the steel mill and the lives that were lost. Mills, grain elevators and similar types of facilities have certain things in common; there are high areas, gratings, many rotating machines and ultimately many locations where life and limb are at risk. Workers can be exposed to a wide variety of life-threatening hazards in these facilities. Some examples include, but are not limited to, fires and explosions from grain dust accumulation, suffocation from engulfment and entrapment in grain bins, falls from heights, crushing injuries and amputations from grain-handling equipment. Suffocation is the leading cause of death in grain bins. This typically occurs when a worker enters a filled bin and walks/works on the grain without fall protection. A person can be engulfed and trapped when caught in flowing grain. Bridged grain and vertical piles of stored grain can also engulf a worker who enters a bin. Contrary to what you may think, only a few seconds pass before you realize you are entrapped and engulfed by flowing grain, leaving you helpless to free yourself. Suffocation shortly follows as a result of being buried alive in the grain.

Table 2. Grain Elevator Explosions

The bottom line is that the handling and transporting of grain creates many hazards in addition to the hazard of the dust created by the process. Unlike the other hazards, the dust problem is one that can become a ticking bomb. Dust is typically very fine and gets just about everywhere. This dust can become an important piece of the recipe for an explosion. The elements of a dust explosion include fuel, oxygen, containment/enclosure and an ignition source. The dust generated at these grain elevator environments is the fuel.

Dust as a Fuel

Any Boy Scout or Girl Scout can tell you how to start a fire — it doesn’t include grabbing the largest available log and holding a match to it. No, quite the opposite; you gather smaller materials (kindling) and ignite those first. In general, the hazard increases as particle sizes decrease. The surface area to mass ratio of the dust particle is a key criterion with combustible dust. The ability of a particular dust to explode is determined by its concentration in air and is influenced by factors such as chemical composition and particle size. In the January/February 2010 issue of IAEI magazine, the inaugural printing of the “Safety in Our States” column included a discussion specifically on how an electrical fire starts. The basic principles discussed there apply here as well. It was shared in that article that “When it comes to ignition, for a solid to burn, it must be volatilized. For ignition to occur, the material first must be capable of propagating self-sustained combustion. The warming, the heat, causes chemical bonds to break and the material to be decomposed into volatile substances which either ignites in the presence of a pilot or it auto ignites.” In that article, I focused on the burning of building materials; here we are talking about materials of much smaller size which increases the overall ignitible surface area. Dust particles, from a size perspective, are smaller than 0.42 mm (420 microns). For comparison sake, granules are in the 0.42 mm to 2 mm size and pellets are larger than 2 mm in diameter. The size of dust is important as there are code requirements that reference dust particle sizes. Article 500 of the NEC, Hazardous (Classified) Locations, Classes I, II, and III, Divisions 1 and 2, during the 2011 code cycle, introduced a definition for combustible dust as “Any finely divided solid material that is 420 microns (.017 in.) or smaller in diameter (material passing a U.S. No. 40 Standard Sieve) and presents a fire or explosion hazard when dispersed and ignited in air.” Proposal 14-9 of the 2011 cycle Report on Proposals (ROP), which is available at www.nfpa.org/70, was accepted to add this definition. This proposal was submitted by the American Chemistry Council (ACC) to retain the reference to dust size which was recently removed from other documents. This same definition made it into Article 506, as well.

Photo 2. The dust generated at these grain elevator environments is the fuel.

Dust clouds present a very nice recipe for ignition as there is plenty of oxygen and surface area for ignition; but in addition to dust clouds, the presence of layered dust is also a significant safety concern. Dust can settle on horizontal and vertical surfaces, and to some extent, it can also settle on ceilings. This settled dust, depending upon the surface on which it has settled, has an opportunity to dry out, resulting in the lowering of its ignition temperature. This layered dust has been identified to be the source of damaging secondary explosions. Secondary explosions, in many cases, have been much more devastating than the initial explosion which may have resulted from ignition of airborne dust. It very well may have been a small explosion whose resulting pressure waves caused the structural vibrations that were enough to dislodge layered dust which, in turn, became fuel for yet another explosion. This secondary explosion will typically be much larger and result in a chain effect of more explosions, dislodging even more dust carrying the explosions well beyond an isolated location to quite possibly the entire facility.

Ignition Sources

I guess it would be accurate to say you can’t have an explosion without an ignition source. Ignition sources can come in different forms including thermal, mechanical or electrical energy. Welding, cutting operations, matches, lighters, cigarettes and even space heaters are all examples of ignition sources that have been identified in fire investigations as the cause of dust explosions. The source, though, doesn’t necessarily have to be some external activity to the process. The equipment itself can lead to ignition through friction, misaligned belts or pulleys, metallic buckets striking leg casings and slippage of belts and more; these are all sources of ignition. The point here is that you don’t need a flame to create a dust explosion. Over one-half of the dust explosions in Germany in 2005 were from non-flame sources. Common sources of ignition include:

- electrostatic discharge

- friction

- arcing from machinery or other equipment

- hot surfaces, including, e.g., overheated bearings

- fire

It is, however, often difficult to determine the exact source of ignition post-explosion. Static charges can occur by friction at the surfaces of particles as they move against one another and build up to levels leading to a sudden discharge to earth. The use of electric power has also been identified. Sparks from the normal operation of switches, contacts, rotating machinery, and fuses can generate sufficient energy to ignite dust clouds. I have read of various incidents that involved electricity, including one where a light bulb with a faulty extension cord was being used to illuminate a bucket elevator boot pit and caused an explosion. The heat generated by arcing and sparking or even glowing contacts can generate the energy needed to ignite dust.

Photo 3. Sparks from the normal operation of switches, contacts, rotating machinery, and fuses can generate sufficient energy to ignite dust clouds.

The recipe for disaster also includes the presence of oxygen and the containment/enclosure. The influence that oxygen has on fire is quite obvious and it is hard to reduce its presence. The amount of oxygen in air is more than adequate to support grain dust explosions. Falling or airborne dust acts to “mix” the dust particles with air. It is very desirable to minimize this mixing activity for obvious reasons. Combining an oxygen rich mixture of dust particles and a contained area with an ignition source provides the explosion with the right recipe for devastating energy.

The Safety Plan and Operating Procedures

I have two words when it comes to your safety plan — “Coin Up!” For those military personnel out there, you probably know what I’m talking about. Your safety plan is a critical part of your business and when challenged with the words “Coin Up” you should be able to produce it.

For those who may not be familiar, a challenge coin is something the military uses to enhance morale and remind Brothers in Arms of their commitment to each other. The origin of the challenge coin dates back to the Second World War where it was first used by the Office of Strategic Services personnel who were deployed in enemy held France. The coins back then were a local coin used to prove your identity. They were your bona fides that you had to produce during a meeting to help verify who you said you were. These coins may have been standard coins for the area, but they were unique in specific aspects such as the type, date, and a few other unique features of the coin. These details would be examined by each party, and they prevented infiltration into the meeting by spies. Today these coins represent each military individual’s commitment to his or her unit. Other organizations have produced these coins to raise awareness and to build bonds for many different reasons. The tradition of a challenge is the most common way to ensure that members are carrying the unit’s coin. The challenge begins when a challenger draws the coin and slaps it on the table or bar. Those being challenged must immediately produce their coins. Anyone failing to do so must buy a round of drinks for the challenger and for everyone else who has his or her challenge coin. However, if those being challenged produce their own coins, the challenger has to buy the round of drinks for the group. There are many different rules around the challenge but suffice it to say, for the purposes of this discussion, “Coin Up” is a challenge to produce your safety plan.

Photo 4. Combining an oxygen rich mixture of dust particles and a contained area with an ignition source provides the explosion with the right recipe for devastating energy.

The following is by no means everything you need to include in your safety plan and procedures but are some highlights. Most of these were taken from NFPA 654, “Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids.” The referential documents offered as part of this article should be reviewed and understood and should ultimately influence the content of your safety plan and operating procedures.

Emergency Action Plan (EAP): Include your procedures for reporting of emergencies and evacuations. Include critical operations as well. Your employees need to understand how to assist in orderly evacuations. The EAP should be reviewed with all new hires, when their responsibilities change, and when the EAP changes. Include the EAP in your training. Make sure that you identify and follow applicable federal, state and local laws and regulations.

Grain Handling Requirements: You need at least two emergency escape routes from certain locations. Reference OSHA 1910.272(O)(1) and (2) for the requirements of these escape routes.

Safety Training: Make sure your training is job specific and some may say annually; but more frequent sessions are advisable. It’s important to ensure your employees can identify the hazard and understand how to prevent problems. Dust accumulation is a problem in these facilities. Ignition sources should be understood and identifiable. Those who have to access or enter bins must understand engulfment and mechanical hazards. Make sure they know their entry and rescue procedures.

Housekeeping: As discussed above, layered dust presents opportunities for subsequent explosions after the initial event. Your plans must include proper house cleaning which should call for the immediate cleaning when dust layers are noted to be 1/32-inch of thickness or more over a surface area of at least 5% of the floor area of the facility or the room. This thickness may change based on the type of dust as well. Make sure that there are no surfaces that are hard to get to and clean. Dust will continue to collect in these areas without your knowledge. Only use vacuum cleaners that are approved for dust collection.

Electrical Equipment: The use of appropriate electrical equipment for the environment and the proper wiring methods are very important to safety in these locations. Equipment bonding is very important. Some electrical equipment can become warm or hot. Motors, transformers, lights and other types of equipment not only offer surfaces for dust to rest but also act to dry that dust, again providing the perfect recipe for disaster.

Dust Control: In addition to housekeeping, there are ways to minimize the escape of dust from the process equipment. Ventilation systems should be considered as well as dust filters and collection systems. Minimize or eliminate activities that generate dust clouds, especially if ignition sources are present. As noted above, the ability to identify these dust cloud generating processes and ignition sources is critical.

Inspection: Inspect areas routinely. Make sure you have access to all areas and that there are no hidden surfaces that can accumulate dust.

Ignition Source Control: The ability to identify ignition sources should lead you to be able to limit these sources in your facility. Proper machine maintenance can help here as degrading machines may offer opportunities for friction and sparks to be generated. Heated surfaces and other sources of heat or sparks should be addressed.

Vehicles and Tools: The vehicles and tools on the job site should receive critical review. Maintenance of the vehicles, tools and equipment used in these dust areas is important to eliminate ignition sources and dust cloud generation.

Closing Remarks

Grain elevators are target rich environments when it comes to safety concerns. There are many tools available today to help ensure these facilities operate in a safe manner. We need to read, understand and “Coin Up” when it comes to our safety plans. Grain elevator explosions don’t have to occur. I hope this article stimulates the discussions that need to occur in various publications and educational forums to drive a downward trend in the statistics around grain elevator explosions.

Remember, keep safety at the top of your list and ensure you and those around you live to see another day.

Related Codes and Standards

Find Us on Socials