Back in 1835, the first constant electric light was demonstrated; the lighting industry was born and has been changing ever since. Our electrical industry has seen many technology changes over the past 40 years with introductions and growth of ground-fault circuit interrupters (GFCI), arc-fault circuit interrupters (AFCI), photovoltaics (PV), electric vehicles (EV), wind generation and more. Solid-state lighting is another new technology that is blossoming as we speak. Walk with me, if you will, for a quick review of LED lighting.

Why Solid-State Lighting

It’s all about reducing energy usage. Many changes in the construction industry revolve around reducing our energy footprint. Not only has how we build a structure changed, the products that go in them have as well. The United States Energy Information Administration (EIA), in 2012 reported a downward trend in average per-household energy consumption over the last 30 years. (http://www. eia. ggov/todayinenergy/detail. cfm?id=6570). They estimate that the average household consumed 90 million BTUs in 2009. Over the last 5 years, the BTU consumption in the residential sector declined by 7%; while over this same period, the housing stock in the U.S. grew by more than 3.5 million homes. This reported decline in BTU consumption is being attributed to improvements in efficiencies realized in many aspects of a home and comes in spite of the fact that we continue to build larger homes and more of them. Homes built today sport double-pane windows, high-energy efficiency furnaces, and higher rated insulation as a start. The building envelope has never been better.

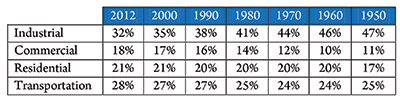

In the U.S., we consumed 121,550 trillion BTUs in 2012. The EIA reports energy usage by industrial sector, commercial sector, residential sector and transportation sector. Each of these are self-explanatory except for the transportation sector which I learned is made up of airlines, railroads and trucking companies. Our consumption breakdown is shown in Table 1.

Table 1. Energy Consumption Breakout per year, per sector

Lighting is a big part of each of these sectors. In fact, lighting represents nearly 22% of electricity consumed in the United States. Of that 22 percent, 51% is comprised of commercial lighting, 27% residential lighting, and 14% industrial. The last 8% is found in outdoor stationary lighting. Based on what I have learned, in my opinion, the large leaps in lighting technology that we have seen in this industry can be traced to recognizable events in our history. The 1930s and 1940s demonstrated a need for energy-efficient lighting in American plants building our war machines; the oil crisis of the 1970s was a key stimulator for the development of the fluorescent bulb. With respect to the LED, experimentations occurred as early as the 1960s. Early LEDs were inefficient but met the needs of specific applications. It was not until researchers put their eyes on general lighting that the inefficiencies of LEDs were addressed. The larger focus and emphasis on sustainability by the “green” movement, as some call it, drove recent developments around LED technology for energy reduction needs, as well as for environmental concerns. Lighting is the low-hanging fruit from an electrical energy reduction point of view. An incandescent light is mainly an infrared source, and 92% of the energy is transferred into heat and only 8% is truly light. For solid-state devices, more than 45% of the energy they produce is light, and the remainder is conducted heat. This means that the contribution of inefficient lighting on the air-conditioning load is greatly reduced, as well as, a secondary effect. In addition to the great opportunity for energy savings, solid-state lighting appeases the environmental concerns that surround fluorescent lighting as these devices contain mercury.

Because lighting is such a low-hanging fruit for energy savings, as recent as 14 years ago the U. S. Department of Energy partnered with private industry to lead the creation of high efficiency devices that focused on packaging LEDs together in one package for the purpose of general lighting. As the sustainable market and energy independence continues to put pressure on our society, LED technology will continue to grow by finding more applications that will continue to drive the cost of this technology down. The benefits of LED lighting go beyond energy savings and into maintenance as these devices perform much longer than their predecessors perform. Some have forecasted that LED lighting will represent 46% of general illumination lumen-hour sales by 2030.

The LED

LEDs are solid-state devices that do not require heating of a filament to create the light that they provide. The light is generated when current passes through a chemical compound, a man-made diode. The makeup of the diode determines its performance and quality of light. This is a semiconductor device much like those in many electronic products we use. Once the diode is manufactured, wires are placed well into the semiconductor material to ensure it is strong and that it provides good connection while used. Then the wires are wrapped in a transparent plastic casing. Their design must take into consideration some critical parameters including heat, color, brightness, and efficiencies.

Photo 2. LEDs in our homes

An LED does not usually fail like an incandescent light bulb or other similar devices, as it doesn’t normally just quit working; it usually experiences a gradual decay in the light that it emits; its efficiency will suffer. The typical LED device carries a thermal resistance rating, an indicator of how well it transmits heat. Those with a thermal resistance rating in the single digits remove heat the quickest. Another rating you will find associated with LEDs is maximum allowable junction temperature. This value is important as it tells how much sustained heat the junction of the device can tolerate. A good LED, with respect to heat, will have high maximum allowable junction temperature ratings and low thermal resistance ratings. This information about temperature ratings is important, as considerations for removal of heat from the LED is important to lighting manufacturers with respect to product design and ambient conditions.

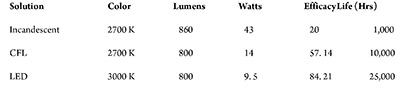

LEDs change how we consumers look at lighting solutions. For example, we can’t measure LEDs by wattage. Lumens, color, and efficacy are key parameters that need to be considered. Webster defines a lumen as “a unit of luminous flux equal to the light emitted in a unit solid angle by a uniform point source of one candle intensity.” Lumens measure how much light you are getting from a bulb. More lumens means it is a brighter light; fewer lumens means it is a dimmer light. When shopping for the right bulb for the application and you are looking at LEDs, think lumens and not watts. Table 2 shows some comparisons to help convey the differences:

Webster defines efficacy as “the power to produce a desired result or effect.” Luminous efficacy is a measure of how well a light source produces visible light. It will be expressed as lumens per watt. Color needs to be comparable. It is easy to get a more “blue” LED that is higher lumens and efficacy but be disappointed in the color qualities.

Lifetime of LED systems is measured differently from traditional systems. Incandescent and fluorescent lamps measure average lumens and life. When it comes to the light bulbs that are not LEDs, we speak of a term average life. The average life of a lamp is determined when 50% of the lamps initially installed are still operating. LEDs do not share the same characteristics. First of all, as discussed earlier, LEDs do not have the same failure mode. LEDs lose light over time generally when designed correctly. This light loss, common for all lamp sources, is called lumen maintenance. Also, LED lighting systems have more than one light source device, unlike incandescent lamps. So, in cases where an LED device fails, the other LEDs normally continue to operate. The bottom line is that we cannot compare traditional lighting systems’ lifetime to LEDs very well due to these characteristics. Rather than a measurement of percentage of devices that fail after so many hours of operation, LEDs measure the percentage loss of light after hours of operation. For example, an L70 lamp has a 70% lumen maintenance at 25,000 hours at a given ambient (25°C), and an incandescent 60-W A-lamp lifetime is 5 out of 10 lamps fail at 1000 hours. This is very different.

Table 2. Comparisons that convey the differences in LEDs

The Driver

Much like fluorescent lighting, which requires a ballast between the voltage supply and the lamp, an LED solution requires a driver. The driver is the power supply for the LEDs. Although not the only way LEDs are powered, it is recommended to power LEDs from a low-voltage, constant-current DC power source to produce light. Too little current and voltage will result in little or no light, and too much current and voltage may damage the light-emitting junction of an LED—this is referred to as “current dependency.” The voltage must be regulated very carefully as small changes in voltage will result in large changes in the flow of current. Temperature of the LED will impact the performance curve of the device in that as the heat rises, it takes less voltage to cause a higher current to flow; and as current increases, more heat is generated by the LED. If not controlled, the LED will fail due to what is called thermal runaway. As you can see by this discussion, the driver is a very important part of this picture as it manages the LED to ensure a long bright life.

Drivers are self-contained but can be a part of the circuit of the LED light engine. The driver is intended to do two things: 1) Make sure the LED operates to the intended design level, and 2) Provide adequate quality of power on the electrical system. You don’t want a lot of total harmonic distortion (THD). Power factor correction is also provided to achieve the lowest apparent power on the electrical grid. When LEDs are driven by a regulated constant-current power supply, the light output variation and lifetime issues resulting from voltage variation and voltage changes are managed. The driver is also that part of the picture that performs the dimming functionality. In technical terms, constant current and constant current reduction are the most efficient and reliable ways to operate and control an LED device.

In most cases, drivers and LEDs are paired by a manufacturer. This is important as the most cost effective, longest quality life solution is provided when the driver and LED are paired together. Keep in mind that this solid-state lighting industry is not as standardized as many other aspects of the electrical industry. It is a rapidly changing technology that has a long runway of more performance gains much like the computer processor had in the 1980s through today.

The Application

All that is left is the installation and application of these solid-state lighting devices in a way that doesn’t violate the National Electrical Code and that meets all manufacturers’ instructions. Your best bet for success, if you are the LED novice as I am, is to purchase the driver and LED light engines together from the same manufacturer or based upon the recommendations of the manufacturer. This is a new and changing industry with little availability of industry standards. LED recessed retrofit modules are a great example where this occurs. LED manufacturers are more often combining the driver with the LEDs because it provides the most light, best cost, and most reliability at the ideal efficiencies. There could be safety implications in the form of shock if the applications are not correctly installed as well as the possibility of reducing the life of the LED solution.

Photo 3. The LED packaged for home lighting

LED solutions are packaged in various ways. You can purchase a bulb, much like the compact fluorescents that are on the market, or you can buy the LED and driver separately, which must be installed in luminaire. Be aware that these devices work best when an efficient means to remove heat is in place. Most luminaires designed for LED lamps or specifically designed LED kits address the heat removal. Solutions such as LED bulbs placed into existing Edison-based luminaires may or may not provide the life you expect as proper ventilation and heat syncing may not be ideal. If you put an LED bulb, for example, in a recessed can or enclosed luminaire, the life will degrade faster. You can purchase dedicated LED luminaires that make heat transfer a part of the design. These are designed specifically for LED lighting. Those LEDs in dedicated luminaires commonly last over 10 and possibly over 20 years — significantly longer than an LED bulb in higher temperature conditions.

Installing a luminaire designed for LEDs is similar to installing any luminaire. The luminaire itself may be designed differently but the installation into the space/structure is business as usual for the installer. Stick with off-the-shelf product and follow the installation requirements for lighting as laid out in theNEC.

Closing Remarks

Today LED lighting systems with control features are at price parity to traditional fluorescent systems. Controls are an important component to maximize energy savings and are now part of the ASHRAE, IECC, and Title 24 codes. Solid-state lighting makes it possible for fewer lumens to deliver the same light level because a properly designed LED system can be optically controlled more efficiently. These new lighting solutions are enabling designers to do what they never have been able to do before. Because of the fact that lumen depreciation is much better, application designs can use higher light loss factors over longer periods of time, saving more energy. In addition to reduced energy, you can have fewer luminaries to light the same square footage as improved optical control and higher light loss factors are now made available by these new devices. The fact that over 99% of current installed based luminaires in and around buildings are eligible for replacement with LEDs, we will definitely be seeing more of these devices in the future. LEDs are truly a transformational technology that saves energy but also contributes to improving the environment.

As always, keep safety at the top of your list and ensure that you and those around you live to see another day.

Find Us on Socials