In the last article, we discussed cable wiring methods. Continuing in Chapter 3, we find ourselves considering the various raceway systems used in electrical installations. We will be covering the various raceway Articles from 342 to 362, and we are still using the 2011 National Electrical Code. Again, we will be discussing just those articles that are commonly used in combination electrical inspections. First, let’s review the layout of these articles. Generally speaking, they have similar formats: 3xx.10 deals with “uses permitted” and 3xx.12 contains “uses not permitted”. At times, there will be no “uses not permitted” section if there are no specific issues, such as in Article 342 and 344. In some of these articles, there will be a 3xx.14 that addresses dissimilar metals. This topic needs to be addressed with some of the materials used in order to prevent galvanic corrosion, which can result in a failure to the raceway system. Where the raceway is acting as the grounding path, corrosion could have a really drastic result.

Next, you will find 3xx.20 Size, which will describe any size limitations, including the minimum and maximum sizes permitted for each type of raceway. The number of conductors allowed in the systems can be found in 3xx.22, which will refer you to the appropriate location elsewhere in the code and to the tables you need to use. Also in this section, mention may be made regarding cables and when and how they may be installed in the raceway. Sections 3xx.24 and 3xx.26 contain information regarding Bends, including how to properly make them and the limits on how many are allowed.

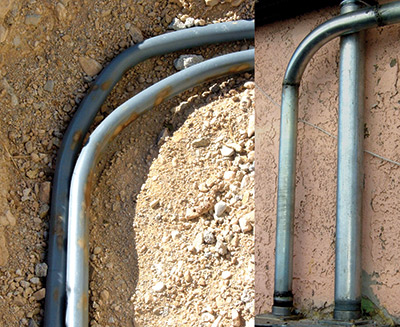

Photo1. In these photos, we have EMT and RMC installed in a facility; both of these installations show good workmanship.

Note that bending of non-flexible conduit requires specific tools, so make sure the proper tools are being used. The use of the correct tools insures the system is not damaged and maintains the proper dimensions and integrity of the material. Driving a truck over a conduit that has been placed on a raised curb in order to bend it is not an approved method; yes, I’ve seen this attempted! Similarly, a torch is not the approved method for heating and bending PVC, as we have specific equipment to heat PVC without damaging it in order to create bends.

The number of bends is consistent in the code, which states that the maximum will be the equivalent of four quarter bends (360 degrees total) between pull points. The code does not address whether the bends have a small or large radius; a bend is a bend. Often I have had contractors say that they made a long radius bend, so I should allow a little code relief. While large radius bends may make pulling easier, the code doesn’t offer relief for the number of bends based on the radius. The other issue is that short radius bends make it harder to pull stiffer conductors through. There are good reasons for the limits on the number of bends; if there are too many bends, the pulling friction on the conductors is likely to cause damage to the conductor insulation. Remember, the 360-degree rule is the maximum; when installing conductors, fewer bends are better for labor and provide insurance against damaged conductors.

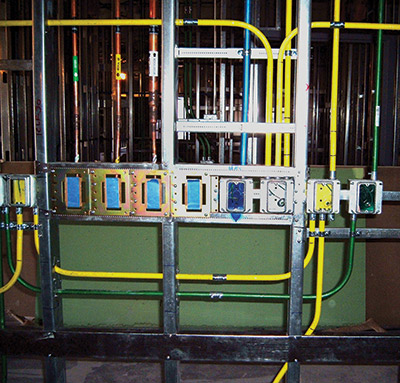

Photo 2. In the upper photo, it appears to be EMT installed as artwork; however, it still contains conductors and therefore is still subject to the code. If my math skills haven’t failed me, it appears that each run is well over 360 degrees of bends. In the lower photo, my first question was “Did the contractor own a bender?” The occupants of the facility confirmed my thoughts and informed me that the installers weren’t electricians.

The next item in some of the articles is 3xx.28, which deals with the Reaming and Threading issues related to the specific type of raceway. All cut edges shall be reamed or otherwise finished to remove rough edges. There are several tools available that will do this in a professional and time efficient manner. This seems like a very basic requirement, but it is often overlooked by some of our installers. Failure to ream the edges can lead to damaged conductors, shorts and other related failures. As both a master electrician and inspector, when I would come onto a job to check it, I would randomly stick my finger down inside the connectors to verify that the raceways had been properly reamed. This is a very basic code requirement, but don’t get complacent about it.

Field cut threads on raceways that are threaded also have a couple of items to verify. First, they are to be cut with a taper thread, which is a standard cutting die with a taper of 1 in 16 (3/4 inch taper per foot), this is an essential requirement. Also, look for threading which may be done for an extended length, as this will cause an issue with the mating female threaded devices bottoming out and not creating a good tight threaded joint. There is a short raceway, or nipple, which is called running thread. It is cut on a straight thread die and has a special use. This cannot be duplicated on normal raceways using the tapered die, so just be aware. Also, field-cut threads on raceways which have a specific coating to resist corrosion must have a field-applied protectant applied to the fresh cut threads to prevent these from damage over time and environmental exposure. Commit the taper to memory if you are going to take a test for either inspector certification or electrical trade certification, as this is one of the standard test questions.

Photo 3. As an inspector, you have to keep your eyes peeled; here we have PVC on the left that was bent using a torch, which has resulted in damage to the conduit. On the right, I’m not even sure it is an approved conduit, it might just be automotive muffler piping which is welded to create a raceway.

Continuing with the article layout, 3xx.30 deals with Securing and Supporting. One thing to keep in mind here is the difference between securing and supporting. The code language states that you will securely fasten the raceway within a certain distance of any box, cabinet or other termination. This is pretty easy to picture, as it will require some type of device that is designed and properly installed to make the raceway secure. Securing prevents motion between the connection point and the raceway, which might lead to a loss of solid contact. If we have a loosening of this type, it could create a faulty ground path for the system, which could then lead to overcurrent devices not operating or a fire hazard. Let’s consider the difference between support and securement. Picture this: if you hold your hand up in the air and simply create a saddle with your hand to hold something without grasping it tightly in your hand, you are supporting it. However, you are not securing it, only offering support. When you are running a conduit on a vertical wall, the supports and securement methods may be one and the same; however, when running through framing members that have openings provided or drilled, then support will be provided by these openings, but not securement.

Photo 4. Here is a photo of both sides of a PV system showing the inverters and the panel they feed; notice here that the raceways used to transition from the underground raceway system to the various pieces of equipment are all Liquidtight Flexible Metal Conduit.

Continuing in the articles, we come to the 3xx.42, 46 and 56, which give you the information needed to enforce Couplings and Connectors, Bushings, and Splices and Taps. These will vary according to each raceway system, so review these and become familiar with the requirements for the systems you most commonly see. This is a good opportunity to review all of the systems at least once, and then you can always check the code book when you come across a new method in the field. Don’t feel like you need to memorize each part of every raceway system. If you are not sure of the requirements while you are on site, just excuse yourself for a moment, go out to your vehicle, get your code book out and double check. Once you know the layout of these articles, it makes it very easy to find your information quickly. If you really want to have some fun, ask your contractor if they have a code book so you can check something. You might be surprised at the answers you get. I’ve had contractors offer me code books that are over a decade old and others that just don’t have one close by. I wonder what they do if they have a question on an installation or code application issue?

If any of the raceways have an added requirement for grounding, it should be mentioned in 3xx.60 of the respective article. This section will also tell you if the raceway itself is suitable for grounding.

The last general article layout item I want to mention is Part III of each article, which deals with Construction Specifications. Marking requirements will be covered here, and this may be a lot of help if you have a question when you see something that just doesn’t look right or is a method you haven’t seen before. Also, Part III may give you additional information related to such things as standard lengths of the respective conduit system.

Now we’ll look at a few specific raceway types.

We will start with Articles 342 and 344, Intermediate Metal Conduit (IMC) and Rigid Metal Conduit (RMC). While very similar as far as applications, I will point out the differences between the two and then go into the code applications. Intermediate Metal Conduit was developed in the 1970s. It is a less expensive alternative to RMC due to its reduced wall thickness. It has an external galvanized coating for protection, and the interior has an organic coating for corrosion protection. Both IMC and RMC have a 3/4 inch per foot tapered thread, which makes the fittings interchangeable.

Rigid Metal Conduit may be made of steel, stainless steel, aluminum or red brass. Several acronyms are used, some of them are RSC (Rigid Steel Conduit), ERSC (Electrical Rigid Steel Conduit), GRC (Galvanized Rigid Conduit), and of course RMC (Rigid Metal Conduit). Rigid Steel Conduit is the heaviest-weight and thickest wall conduit. It is generally protected by a zinc-based coating. For more details on these conduit systems, you may visit the Steel Tube Institute website.

Photo 5. Here is a good example of EMT installed in a headwall of a hospital emergency room. Notice the use of colored EMT to identify the different systems within the facility.

The next raceways we’ll cover are found in Articles 348 Flexible Metal Conduit (FMC), 350 Liquidtight Flexible Metal Conduit (LFMC), 356 Liquidtight Flexible Nonmetallic Conduit (LFNC), 360 Flexible Metallic Tubing (FMT), and finally 362 Electrical Nonmetallic Tubing. The one thing all of these methods have in common is that they are a flexible raceway system. Early on in the electrical business, they recognized that there was a need for a flexible conduit system, so along with this recognition came the need for standardization of products for use in the electrical industry. As a result, Underwriters Laboratory established the first UL Standard (UL 1) for Flexible Metal Conduit in February of 1924.

Each of these flexible raceway systems will have a few unique requirements and applications. One of the major uses for these systems is providing the needed flexibility for connection to equipment that needs isolation from vibration or equipment that requires movement as a function of its design. However, each of these methods may have requirements you need to be aware of, especially related to such things as grounding and bonding. Some of them may be acceptable for grounding up to certain lengths and others not at all; some may absolutely require an additional grounding conductor, depending on the application. Again, you will need to review the exact article related to the system used.

Sometimes, you may have a local code requirement which requires a separate wire-type equipment grounding conductor in certain wiring methods, usually for wiring methods that are flexible metallic type or have non-threaded couplings. If so, this is done to provide an even more reliable ground-fault current path.

Next we’ll review the nonmetallic raceway systems, including: 352 Rigid Polyvinyl Chloride Conduit (PVC), 353 High Density Polyethylene Conduit (HDPE), 354 Nonmetallic Underground Conduit with Conductors, 355 Reinforced Thermosetting Resin Conduit (RTRC), and a repeat from the flexible list would also include 362 Electrical Nonmetallic Tubing (ENT).

First of all, these conduit systems require a grounding conductor when used in applications where grounding is required, as they are made of nonmetallic materials. Therefore, there is no way the raceway itself will provide a grounding path back to the origin of the circuit. Another item to be concerned with is the support of these wiring methods. When run above ground, you will have to check the requirements for each method. For instance, PVC requires support according to the diameter being installed.

One of the issues you need to address with nonmetallic raceways is thermal expansion, which can be exacerbated when installed in areas subject to large temperature changes. If installing PVC, refer to 352.44 for the code requirements and Table 352.44 for the data, which will give you the expansion coefficient per 100 feet of raceway based on your temperature swing.

Article 354 Nonmetallic Underground Conduit with Conductors is a system you may not have seen. I haven’t seen it installed within the portion of the systems we are required to inspect, in others words downstream of the point of service. However, I have seen thousands of feet of this used by the utility on the service side of the meters. The utility commonly calls it CIC, or conductors in conduit, and it will come in large reels and be installed per the utility regulations.

Another issue related to nonmetallic raceways is that you have to be aware of the temperature limitation of the raceway itself; this will be part of the labeling or listing requirement. The point of concern here is that we shall not install a conductor with a load that would result in it operating at a temperature that will exceed the rating of the raceway. A good example of the code language addressing this is found in the PVC article 352.10(I), Uses Permitted, Insulation Temperature Limitations. If we were to have an installation where the conductor operates at a temperature higher than the raceway, it would overheat the raceway. This could lead to off gassing from the conduit, embrittlement of the conduit, or further overheating issues if the conductor becomes encased in additional melted PVC.

The last article we will address is probably the most common raceway system we see used, Electric Metallic Tubing (EMT), which is covered in Article 358. One notable fact is that EMT is not a conduit, it is a tubing. Therefore, elsewhere in the code if there is a requirement related to conduit, it may not apply to EMT. It is unique in the fact that it cannot be threaded, which results in special fittings just for EMT. It has several advantages, some of which include price compared to RMC or IMC, weight (it is much lighter), and it is very easy to do field bends. It meets the requirements for an equipment grounding path when properly installed. EMT has fittings which allow it to be used in both dry and wet locations, depending on the listing of the fittings. One area of concern with EMT is that where run outside and exposed to temperature variations, make sure the connectors and couplers are tight. The last thing we want is to have this raceway system loosen up and come apart when used as our equipment grounding conductor.

I’ve taken a different approach to discuss raceways in the code, describing the arrangement of the Articles, pointing out a few items of concern, some of the issues regarding different materials, and some of the inspection items to watch for. Again, I have not gone item by item within each article, as I expect you to have and use your code book when reading these article. The only way to learn the code is to use it and apply it.

Find Us on Socials