The protection afforded by the ground-fault circuit interrupter (GFCI) has existed for many years. Some electrical professionals can remember a world without this type of protection. But many have grown up seeing this protection in our kitchens, bathrooms, and outside their homes. This article will take the reader through the history of this protective device.

What is a GFCI protective device?

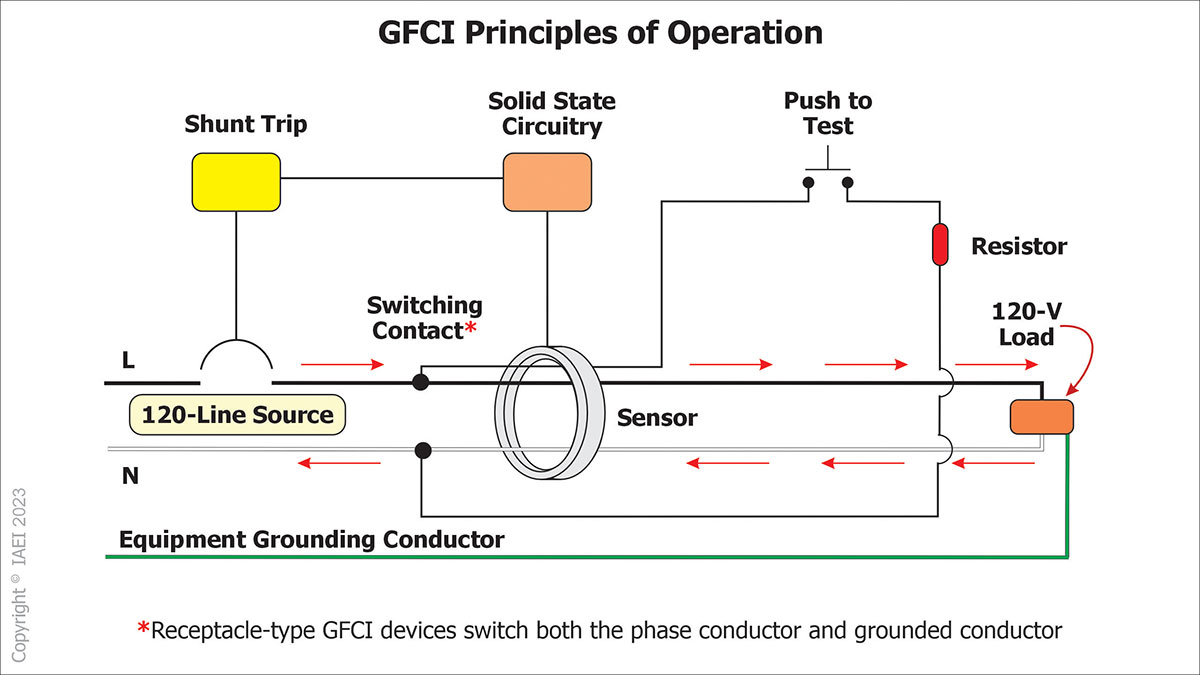

A GFCI is a defined term in the National Electrical Code (NEC) and is found in Article 100. It is a device intended for the protection of personnel, not equipment. It functions to de-energize a circuit when the current to ground exceeds an established value. For a Class A GFCI device, this value to ground is 6 milliamperes (mA) or higher. However, the device will not trip when the current to ground is less than 4 milliamperes (mA). For additional information, see UL 943, Standard for Ground-Fault Circuit Interrupters.

Who Developed this Technology?

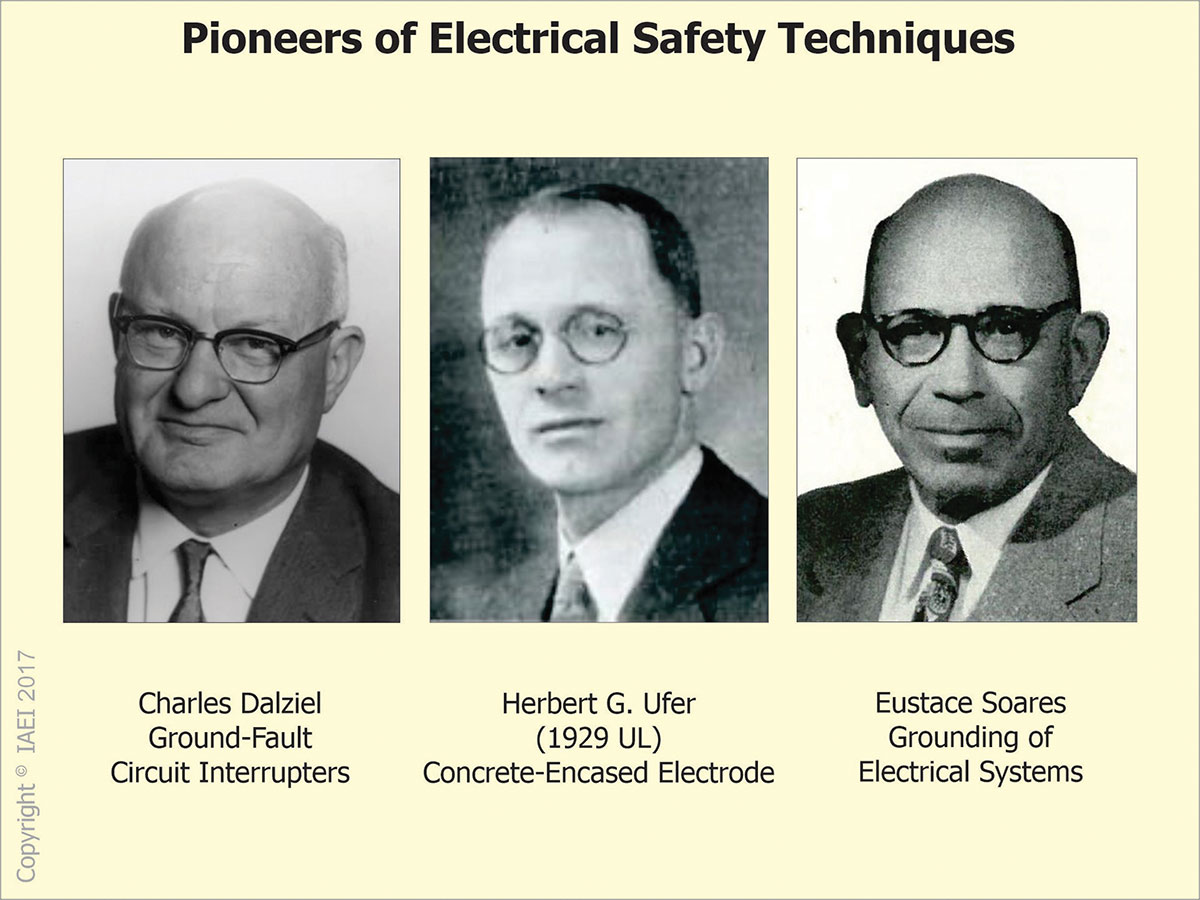

A professor by the name of Charles Dalziel is credited as the father of GFCI protection. Professor Dalziel taught at the University of California in Berkley where he conducted experiments with electricity. A paper was published detailing his work entitled Deleterious Effects of Electric Shock and was showcased at the Meeting of Experts on Electrical Accidents and Related Matters in Geneva, Switzerland, October 23-31, 1961.

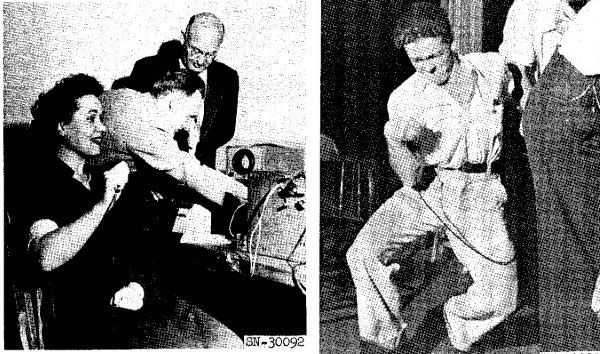

So many are wondering how he developed this protection. He was in a perfect situation. He was surrounded by starving college students eager to make an extra buck. These students, both male and female, would volunteer to undergo electrical testing to see what effects electricity had on the human body. These tests were specifically to find out the “let-go threshold” for the human body. At what current does the body (or hand) no longer have the ability to “let go” of an energized conductor? Even though your body is feeling the effects and wanting to let go. Are there differences between the let-go thresholds of men and women? What about children? How did we arrive at 4-6 milliampere GFCI protection?

What the Research Showed

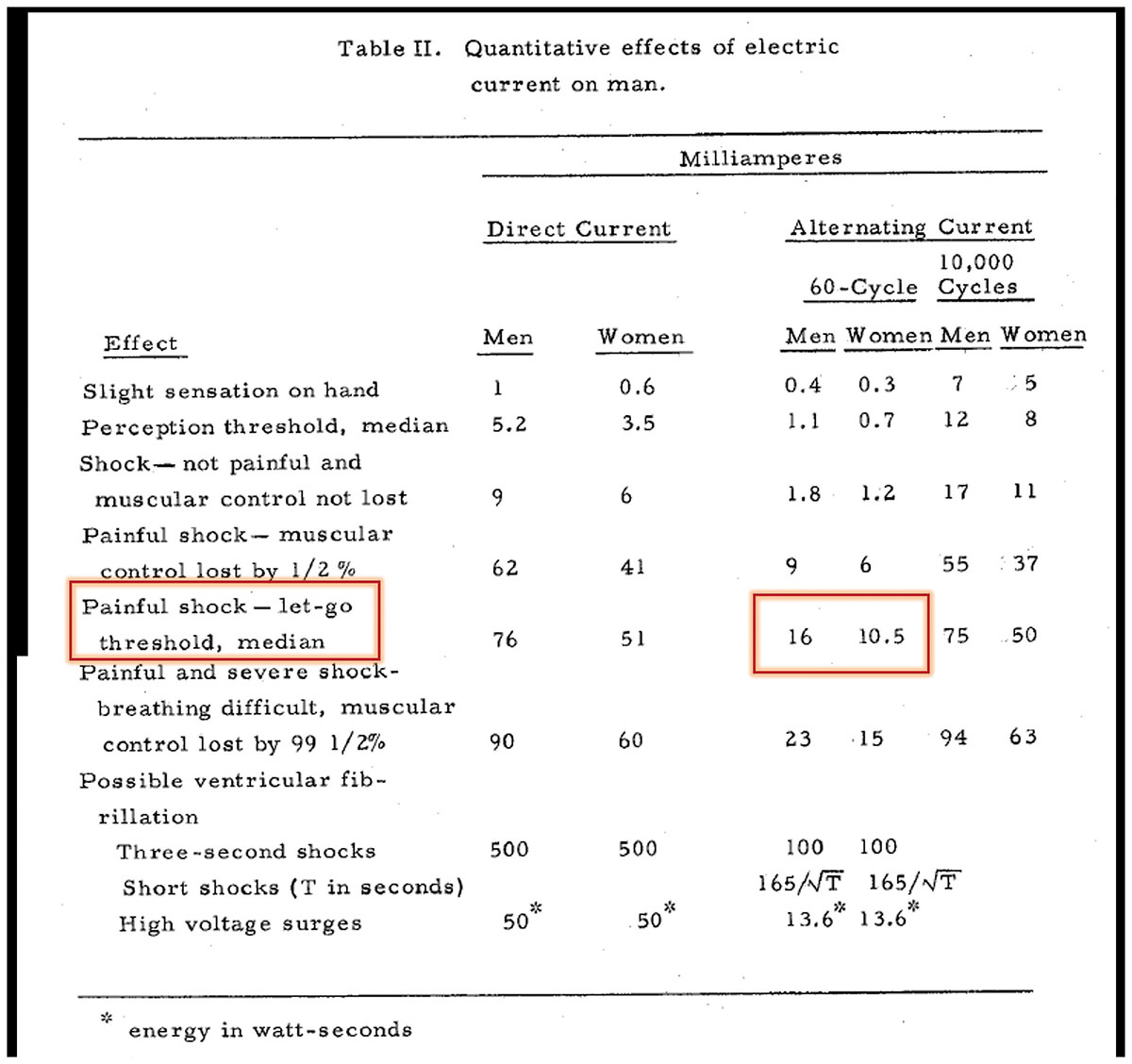

Through testing conducted by Professor Dalziel on college students, it was discovered that there was a difference in the let-go thresholds of men and women. He attributed this difference to the difference in the body mass and weight that existed between men and women. Men were typically taller and weighed more than the women subjects.

You can see from Table 4 that men typically reached their let-go threshold at 16 milliamperes while women reached their let-go threshold at around 10.5 milliamperes. This difference would allow Professor Dalziel to extrapolate the let go threshold amount for a typical 2-year-old toddler. So, no, Professor Dalziel did not test children to obtain their let-go threshold tolerances to electrical current. He used the art of science and math to make sure the GFCI protective devices kept all types and ages of people safe.

GFCI History in the NEC

We will focus on GFCI protection for dwelling units in this article. Unless otherwise stated, this GFCI protection is for the typical 15-20 ampere receptacle the end user would use to plug in electrical devices or equipment.

The first GFCI requirements in the NEC were exactly where one would think GFCI protection needed to be located. In an environment where water and electricity are purposefully mixed. In this instance, it appeared in the 1968 NEC for underwater lighting fixtures in swimming pools. Along with this requirement found at 680-4(g), the definition of a GFCI was introduced.

In 1971, the NEC required protection for receptacles located within 20 feet of swimming pools. This NEC edition is where the first requirements were introduced for GFCI protection for construction site receptacles. If you are constructing a house and using electrical tools in the rain and mud, this makes a lot of sense. Construction professionals need protection from the ill effects of electricity, too! Lastly, GFCI protection was introduced for outdoor receptacles.

In the 1975 NEC, bathroom receptacles were required to be provided with GFCI protection. We closed out the 1970s in the 1978 NEC; garage receptacles were required to be GFCI-protected.

The decade of the 1980s brought about additional GFCI protection requirements. For the 1981 edition of the NEC, spas and hot tubs were added to the list of items requiring GFCI protection. In the 1987 edition, GFCI protection was required for hydromassage bathtubs, boathouse receptacles, and basement receptacles. Kitchen requirements were modified to reflect that GFCI protection was needed within 6 feet of the sink and above countertop surfaces.

Moving into the decade of the 1990s, we find that in the 1990 edition of the NEC, crawl spaces were added as an area needing GFCI protection. This makes a lot of sense because of the damp environment often found in these locations. In this edition basement locations were clarified to mean an unfinished basement.

During the 1993 code cycle, receptacles for wet bar locations were added to the items in a dwelling unit requiring GFCI protection. This edition also introduced the requirement to provide GFCI protection where receptacles were being replaced in an area where the Code now requires GFCI protection. An example would be for a dwelling unit built in the 1960s where GFCI protection was not required for the receptacle serving the kitchen countertop within 6 feet from the sink. If or when that receptacle is replaced, GFCI protection is now required for that receptacle.

For the 1996 NEC code cycle, accessory building receptacles were required to have GFCI protection. There was also an exception added to exempt from GFCI protection outdoor electric snow-melting and deicing equipment. This made sense for folks who get a lot of snow in their area of the country. If the equipment was not doing its job to remove snow and ice (the GFCI had tripped removing electricity), the weight of the snow and ice over time could cause the roof to collapse. Modifications were made in kitchens to require GFCI protection for all receptacles serving the countertop locations. Finally, for the 1999 NEC edition, electrically heated floors were added to the locations requiring GFCI protection. This included electrically heated floors with conductive floor coverings in bathrooms, hydromassage bathtubs, spa, and hot tub locations.

Now, we are moving into the decade of the 2000s. Many users of the Code will remember when some of these GFCI requirements became part of the NEC as you were either installing or inspecting with these code requirements. In the 2005 edition we find requirements for GFCI protection afforded to laundry receptacles, utility room receptacles, and boat hoist outlets. Only the receptacles within 6 feet of the outside edge of a laundry, utility or wet bar sink required GFCI protection.

In the 2011 NEC, GFCI devices were required to be installed in a readily accessible location. It would seem to reason that if someone needed to reach the GFCI device to reset it, one should not have to move the refrigerator or freezer to do so. There is also a requirement to test a GFCI device monthly. Now be honest and let me know if you do this in the dwelling you reside in on a monthly basis? Is the average homeowner even aware of this requirement? We also find that receptacles at sink locations (other than kitchen sinks) throughout the dwelling unit require GFCI protection. Electrically heated floor areas in kitchens would now also require GFCI protection.

In the 2014 NEC, it was clarified that all receptacles within 6 feet of dwelling unit sinks would require GFCI protection. GFCI protection was also extended to bathroom and shower stall areas, laundry areas, and dishwashers. Dishwasher manufacturers were noticing an end-of-life failure in these appliances that could cause possible electrocution or death to the end user. To protect the end user as well as reduce legal exposure to the manufacturers, GFCI protection was required for these specific appliances.

What is an indoor wet or damp location? What if the dwelling has an area that is not a bathroom or laundry area with a sink near the floor to wash pets? Do receptacles installed in these locations need to have GFCI protection to protect the person in that area from the effects of electricity? The 2020 NEC addressed that question by stating that all 125-volt through 250-volt receptacles supplied by a single-phase branch circuit be protected by GFCI protection. This further clarifies that the rating of the branch circuit be 150 volts or less to ground.

The 2017 and 2020 NEC also recognized electrical issues that have arisen at outdoor HVAC outlets. Electrical shock and deaths have occurred from individuals coming into contact with these units. HVAC technicians that provide service to these units will commonly do so when the unit is energized. GFCI requirements have been discussed and debated over the past two code cycles. A future effective date of September 2026 has been agreed upon to allow manufacturers to address issues with these HVAC units that, in some cases, will not operate while being protected by GFCI protection.

Are There More Changes to Come?

This was an attempt to provide the reader with a 30,000-foot history review of the GFCI requirements found in the NEC. There are bound to be additional requirements placed into the NEC as the need arises. Your input in the development of the NEC is crucial to providing a safe electrical environment.

And with a review of this type, not everything may have been included in this article during this history lesson. I highly encourage you to visit the NFPA Link or drag out your NEC code book and review these GFCI requirements, as many modifications and changes have occurred these past 50-plus years.

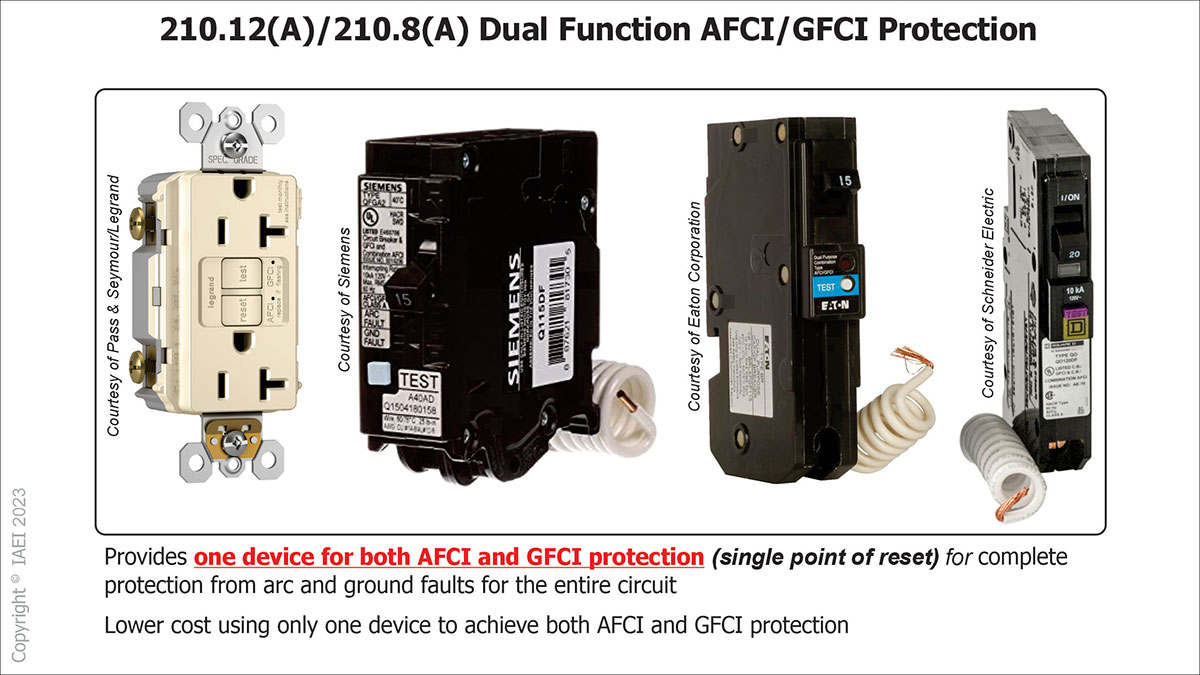

Remember that there are several ways that electrical manufacturers have provided the electrical professionals and the homeowner to provide this protection. These include GFCI devices and circuit breakers.

I hope you have found this information useful. Many of today’s electrical installers may not be aware of the vast amount of time and discussions that have taken place over the many years to ensure the electrical safety that many sometimes take for granted. I hope this article has, in some small way, exposed you to the history of GFCI protection. I hope you are a better electrician or inspector for knowing this history. Feel free to share this information with your friends and colleagues, and together, we can continue to keep families electrically safe.

Find Us on Socials