Last issue we made it through the “g” definitions in Article 100. In this article, we will finish reviewing selected definitions. Our first definition is in sight from(within sight from, within sight). These variations of phrase are used in various parts of the code, but would likely engender many arguments over meaning if the Code did not include a clear definition. When we use one of these phrases, we are usually talking about the location of equipment in relation to the location of the disconnecting means. This definition specifies that the referenced equipment must be visible, and it must also be less than fifty feet away (see photo 1). Until recently, I thought this was a pretty simple concept and an easy-to-apply code requirement, but then I observed an installation involving a motor on a large conveyor system. The motor was located about 30 feet in the air on a platform, and the disconnect for the motor was located on a second platform (which also had another motor and associated disconnect). The two platforms were about 40 feet apart, but to get from the first platform to the second, you had to climb down the 30 feet, walk over about 40 feet then climb the stairs up 30 feet to the disconnect. Was the letter of the code met? Perhaps, but the intent of this requirement is that the disconnect is close at hand and easily accessible in case you need to operate it quickly and also that a worker can see the disconnect and maintain a level of safety when working on equipment. Now with OSHA requirements, we have taken this up a level with lockout tagout procedures.

Last issue we made it through the “g” definitions in Article 100. In this article, we will finish reviewing selected definitions. Our first definition is in sight from(within sight from, within sight). These variations of phrase are used in various parts of the code, but would likely engender many arguments over meaning if the Code did not include a clear definition. When we use one of these phrases, we are usually talking about the location of equipment in relation to the location of the disconnecting means. This definition specifies that the referenced equipment must be visible, and it must also be less than fifty feet away (see photo 1). Until recently, I thought this was a pretty simple concept and an easy-to-apply code requirement, but then I observed an installation involving a motor on a large conveyor system. The motor was located about 30 feet in the air on a platform, and the disconnect for the motor was located on a second platform (which also had another motor and associated disconnect). The two platforms were about 40 feet apart, but to get from the first platform to the second, you had to climb down the 30 feet, walk over about 40 feet then climb the stairs up 30 feet to the disconnect. Was the letter of the code met? Perhaps, but the intent of this requirement is that the disconnect is close at hand and easily accessible in case you need to operate it quickly and also that a worker can see the disconnect and maintain a level of safety when working on equipment. Now with OSHA requirements, we have taken this up a level with lockout tagout procedures.

Locations

Location is separated into three distinct areas depending on the level of exposure to weather or moisture. First, we have dry location, which is a

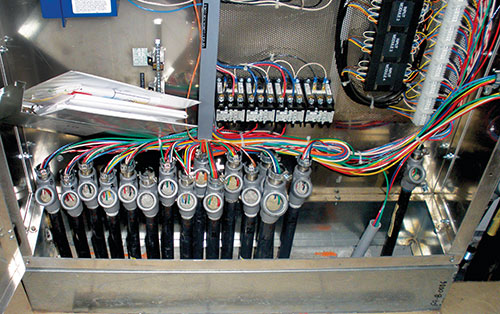

Photo 1. Disconnects located in sight of the equipment they control

location not normally subject to dampness or wetness. This location may temporarily be damp or wet, especially during construction. The next level is damp location, which covers areas not subject to saturation with water or liquids, but subject to moderate degrees of moisture. This could include areas under eaves, or open covered porches, especially in areas of the country that have very high levels of humidity. The last definition is wet location, which covers those locations subject to saturation with water or other liquids and also those areas underground, in concrete or in masonry in direct contact with earth. Two examples of areas that fit into this category might be car washes and exposed exterior locations. Please keep in mind, not all of the wet location areas covered by this definition are exterior to a building, it is certainly possible to find areas inside buildings that are subject to all degrees of moisture or wetness (see photo 2).

Listed and Labeled

The next two terms to cover work together, and actually need to be reversed to help make sense. First we will cover listed, which means that the equipment, materials, or services are evaluated by an organization acceptable to the authority having jurisdiction (AHJ). This service is generally done by a nationally recognized testing laboratory (NRTL). Most commonly this is done by organizations recognized by OSHA as a NRTL. However, you will notice that the actual code language states “acceptable to the authority having jurisdiction,” so it is really up to the AHJ to determine which organizations are accepted. The second term is labeled, which is usually the after-effect of listing. Once an item is listed, a label is affixed to the equipment stating it has been inspected and listed to a standard for that type of equipment. The listing and labeling requirements are often overlooked in many areas or jurisdictions. This is due to the fact that many of us are not familiar with the requirements for listing and labeling. This would include unique, custom-fabricated, or modified equipment. My personal recommendation is to establish a contact with a knowledgeable resource who works with a listing agency (or agencies) who will be willing to answer questions you may have if you see something that just doesn’t look right.

Overcurrent and Overload

We’ll jump to overcurrent and overload. While these appear to go together, they are unique concepts and I will explain why. An overcurrent is any current in excess of the rating of any equipment or conductor. On the other hand, an overload is the operation of equipment or conductor in excess of its full load rating, which if it is not stopped, will eventually cause damage or dangerous overheating. A short circuit or fault to ground are not overloads, however, they are overcurrents. Overloads usually have a longer duration and result in a thermal reaction of an overload device in order to shut off the circuit.

Raceway

Photo 2. This receptacle may be in a wet location, while the light fixture is located in a damp location.

Our next definition is raceway, which is simply an enclosed channel designed specifically for holding wires, cables or busbars. Sometimes there is confusion with this concept since we have several types of raceways that look very similar to manufactured cable assemblies. Cable assemblies are generally manufactured and listed to a UL Product Standard that contains very specific requirements for the design of the cable, and come as a complete system with the conductors inside. Alternatively, a raceway will have conductors installed in the field. The fill factors and installation requirements for cable assemblies and raceways that look similar may be quite different.

Separately Derived System

Separately derived system is premise wiring that comes from a source other than the service provided to the premises by the utility, and it does not have a direct connection to the service. In the past, this system was usually generators or transformers, but now we have many alternative energy systems which can qualify as a separately derived system. These systems may trigger many specific code requirements, which will be covered as we get into the body of the code.

Service

Photo 3. These light bulbs would be considered utilization equipment.

The next four terms are all related: they are service, service drop, service equipment and service lateral. Let’s start with service drop and service lateral; these are the wiring methods used from the street main or transformer to the premises service equipment. The difference between a drop and a lateral is the service drop is run overhead, whereas laterals are underground. Both types are covered under the general term service conductors; it is just their location that gives them different names. Most new construction, if it is in or around metropolitan developments, is now required to run as much as possible underground, so the term service lateral has become the norm for a high percentage of construction. Also, the service drop conductors and laterals may be owned by the utility; if so, they are outside the scope of the NEC. Let’s move on to service equipment, which is usually one or more circuit breakers or fused switches located near the point of entrance of the supply conductors. It is usually located at a point close to the meter. Now to put this all together, the combination of the items in this paragraph constitute the service; sometimes it’s just easier to start at the bottom of a list and work your way up, as is the case with the service definitions.

Short-Circuit Current Rating

Short-circuit current rating (SCCR) is a term that was largely overlooked for many years. The installer would size the wire, size the overcurrent protection device for the wire size, the load and voltage, and then head down the road. However, in the last decade, we’ve become enlightened and realize that we need to address the SCCR as well. The SCCR is the rating that equipment must have to withstand the maximum current which could possibly flow to that device. The reason we’ve heightened our awareness of this is to prevent catastrophic failures which result in the loss of property and possibly life. With the increased legal activity and OSHA enforcement which may occur after any large failure, we now pay a lot more attention in enforcement to make sure the installation can handle the available fault current. This involves several steps and calculations depending on the equipment, the fuses or breakers involved and the wire. The first step before any of these items can be calculated is the determination of the fault current available at the service point. You must find out what that value is from the serving utility. If the inspector does due diligence in verifying the values and calculations during plans check and field inspections, all equipment that is installed will be sized for the fault current available. In the event of a fault of any kind the equipment will operate as intended and avoid catastrophic failures. This is a newer concept that I’ve had to add to most classes just in the last few years, but it is a very important concept to introduce early in the course of study and is essential to safety.

Switches

Photo 4. Weatherproof

Sometimes we have a simple term such as switch, which we all know is just a little device in the wall that turns on a light or some device. However, at this point I will encourage you to once again get your code book out and notice that a switch might not be just a switch in every application. Once you review all the different types of switches, you will see that it is a good example of the many items in every trade that we may think of in a certain way (an apple is an apple). However, the more we learn the more we find out that we need to take the time to learn the nuances of even simple terms and to understand when there may be a variety of meanings (is that a Granny Smith or a crab apple?).

Thermally Protected

Thermally protected is the next term I usually cover to those new to the electrical code. It’s applied to motors, and it means that the motor has a device in it which senses the current the motor draws. If for some reason the motor starts to pull too much power, the thermal protector will open the circuit to protect the motor. The best example to illustrate this is the push button on the bottom of your garbage disposal. I usually ask my class if they have ever jammed their disposal and had to reset the button on the disposal. This example usually rings a bell.

Utilization Equipment

The next term we’ll cover is one of my most memorable. The reason it is memorable was the circumstance where I came across it. I remember during a Master’s test I got to a simple question which stated, “Something that utilizes electricity?” It almost stumped me, as I had just answered over 100 questions of every type throughout the code book and suddenly I went blank — was it in Article 430, or was it 440, maybe 424? After what seemed like a long time, I finally decided to look in Article 100, and there it was, word for word in the definition for utilization equipment. Ever since that question, I make sure people understand that something that uses or consumes electricity is utilization equipment (see photo 3).

Voltage

Voltageis the next term to cover, and it has three unique definitions under the headings voltage(of a circuit),voltage, nominal and voltage to ground. Each represents a slightly different application. To start with, let’s take nominal voltage, which is the voltage reference used for equipment and code language to identify the voltage system we are working with. For instance, frequently we say 110 volts when in fact you won’t find this in the code, since the nominal voltage in the code is 120 volts. In Article 430, you will find unique nominal voltages for motors. Voltage of a circuit is identified as the maximum voltage between any two conductors of a circuit; so for a 120/208 system the circuit voltage would be considered 208 volts, which is the maximum possible between two conductors. The last voltage term is voltage to ground, which is the maximum voltage between any one conductor and ground. This voltage will vary on systems depending on how we’ve grounded the service. We will cover more on this later when we discuss services. Voltage to ground is commonly used when we are working on the height clearances for conductors over streets, yards or buildings.

Watertight and Weatherproof

The last two terms for us to cover in the definitions also go together, they are watertight and weatherproof, which are similar but have two levels of construction. The first is watertight which very simply means that moisture will not enter the enclosure under a specific test standard. Weatherproof has a little different concept which actually allows moisture to enter an enclosure, as long as it doesn’t interfere with the successful operation of the enclosed equipment. With this in mind, most equipment that is weatherproof is designed with a topside and has small weep holes in the bottom to allow any moisture which might accumulate within that enclosure to drain out (see photo 4).

This concludes the major definitions which I have always used as the basis for teaching the NEC. We will from time to time refer to other items in Article 100; however, the ones pointed out in this and the previous article will give us a good start. Once again, I would encourage you to review the other items in Article 100, as it can only help with the process of learning the electrical code. In the next edition, we will actually get into the meat of the code with Article 110, which often doesn’t get the attention it deserves since wire sizing and overcurrent or raceway installation issues often get most of the coverage. However, Article 110 covers a variety of the simple rules which are often overlooked and lead to code violations, which can come as a rude surprise to an installer. Hope you are hanging in there and are ready for the next issue.

Find Us on Socials