This is the fourth of a series of articles detailing significant changes for the 2021 Canadian Electrical Code Part I (CE Code). A full copy of the CE Code is available at https://www.csagroup.org/store/.

This article will discuss the addition of energy storage system requirements in Section 64, starting with changes to the name and scope of the section to include energy production in addition to renewable energy and energy storage systems. The title now reads Renewable energy, energy production, and energy storage systems. This, along with the same addition to the scope of Section 64, was the first step needed to find a home for energy storage system requirements in the CE Code.

For the next step, a task force was established to develop requirements for energy storage systems. As part of our work, we looked at existing requirements in the Ontario Electrical Safety Code, the National Electrical Code, the requirements then being developed for NFPA 855, Standard for the Installation of Stationary Energy Storage Systems, and the product requirements in UL 9540, Energy Storage Systems and Equipment.

Early on in the process, the task force recognized a conflict between the rules for storage batteries in Section 26 and the existing rules in Section 64. The first action by the task force was to submit a code proposal to move these rules from Section 26 to Section 64. Once completed, the task force started wording on an amalgamation of the requirements for storage batteries and removal of duplications, including revised and new definitions.

The definitions for “sealed cell or battery” and “storage battery” were changed to:

Battery — an assembly of more than one cell connected in series, parallel, or both.

Sealed cell battery — a battery that has no provision for the addition of water or electrolyte, nor for the external measurement of electrolyte specific gravity.

With the most significant change being the deletion of “storage” and the addition of a new definition for a “cell”:

Cell — an electrochemical device used to receive, store, and deliver electrical energy.

A new Appendix B note provides a clarification that an assembly of cells forming a battery are part of the standard for batteries in UL 1973, Standard for Batteries for Use in Stationary, Vehicle Auxiliary Power, and Light Electric Rail (LER) Applications.

Rule 64-002 Special Terminology also has the following new definitions regarding energy storage systems:

Energy storage system — a system capable of supplying electrical energy to local power loads or operating in parallel with a supply authority system or any other power sources.

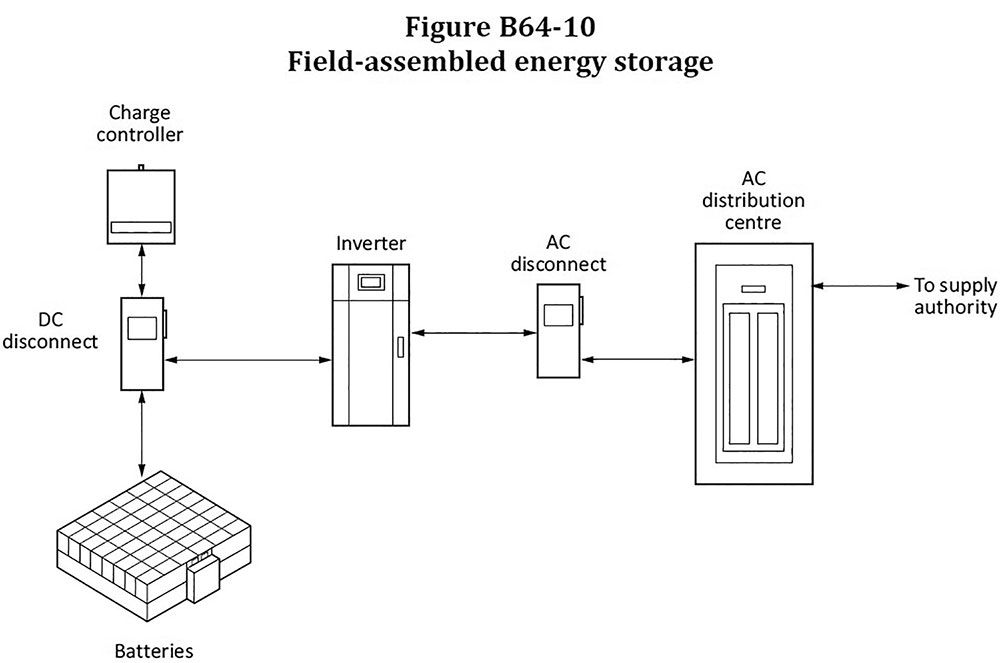

Field-assembled energy storage system — a system with storage capacity not exceeding 1 kWh (3.6 MJ) that has not been evaluated in accordance with UL 9540.

Non-residential use energy storage system — an energy storage system that is not marked as being suitable for residential use.

Residential use energy storage system — an energy storage system that

-

- a) is marked as being suitable for residential use; and

- b) conforms to the requirements of UL 9540.

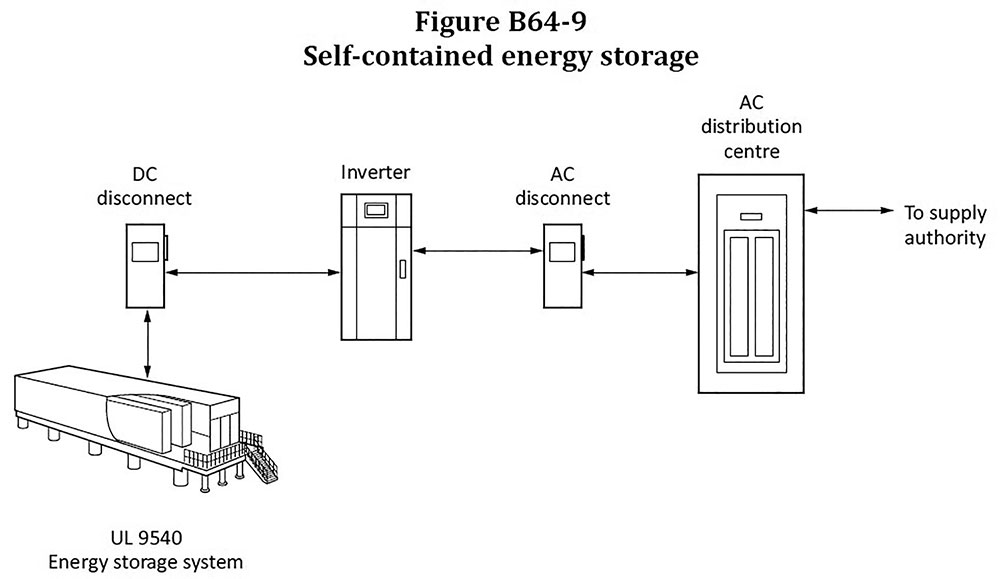

Self-contained energy storage system — a system that conforms to the requirements of UL 9540.

Appendix B Figures B64-9 and B64-10 have also be added at Rule 64-900 to help show the difference between a self-contained energy storage system and a field-assembled energy storage system.

Keep in mind that a field-assembled energy storage system is limited to 1 kWh (3.6 MJ)

An Appendix B note for “energy storage system” provides clarification that an uninterruptible power system (UPS) that is approved to CSA Standard C22.2 No. 107.3 An uninterruptible power system is not considered an energy storage system.

The easiest way to understand the difference between an energy storage system is to look at the direction of power.

Uninterruptible power systems

Supply —> UPS —> Load

Energy storage system

Supply /Load <—> Energy storage system

The next rule change was the addition of energy storage systems to Rule 64-050 General that will allow energy storage systems to supply a building.

Rule 64-060 Disconnecting means was also expanded to require a disconnecting means that will simultaneously disconnect all ungrounded conductors from batteries.

Rule 64-074 Warning notice and diagram now requires the same marking and diagram requirements for energy storage systems as previously required for renewable energy systems.

Subrule 4) of Rule 64-112 Interactive point of connection has been expanded inserting a new Item e) that reads: e) notwithstanding Items c) and d), the sum of the ampere rating of the overcurrent devices shall be permitted to exceed the rating of the busbar or conductor where means are provided to limit the input and output current of the interconnected systems to ensure the busbar or conductor cannot be overloaded;…

This is a significant change for both renewable energy systems and energy storage systems. This change was intended for the very large systems that incorporate control systems to prevent the distribution bus from being overloaded.

Rules 64-800 to 64-814 for storage batteries in the 2018 CE Code, as mentioned previously, have been changed to installation of batteries in 64-800 to 64-820 removing the word storage as unnecessary wording. With the amalgamation of the battery requirements from Section 26, the rules look deferent, but this article will focus on the technical changes.

The requirement for ventilation for rooms or areas containing batteries now covered in Rule 64-802 is limited to only batteries vent hydrogen to the atmosphere. Subrule 2) that addresses temperature limitation is not limited to only lead-acid batteries.

Rule 64-804 Installations previously Rules 26-510 and 64-800 has a new Subrule 1) that mandates batteries to be suitable for the purpose. This means batteries are now required to be approved; this recognises the product standard for batteries UL 1973 Standard for Batteries for Use in Stationary, Vehicle Auxiliary Power, and Light Electric Rail (LER) Applications. The second change for installations is that the output voltage for batteries in dwelling units has been raised from 48 V dc to 50 V dc. This was changed to provide consistency with existing allowances in Section 64. The final change is a new Subrule 6) that requires batteries to be spaced in accordance with the manufacturer’s installation instructions to align with the product standard.

The only change to Rule 64-808 Disconnection of series battery circuits (previously Rule 64-806 was to increase the voltage from 48 V dc to 50 V dc for consistency.

Rule 64-810 Bonding of battery installations is new, requiring bonding in accordance with Section 10. Bonding in Section 10 was already a requirement; this rule was added as a concern raised by inspectors that bonding of battery installations was being missed. Adding the rule may highlight the need for bonding to code users.

Rule 64-812 Battery interconnections has two changes; the first is the replacement of the “flexible cable” reference to insulated conductors or cables of the fine strand type. This is also similar to requirements in Section 480.4 of the National Electrical Code. The second change is to allow insulated or bare busbar to be used for battery interconnection.

Rule 64-814 Wiring from batteries to other equipment is a new rule including requirements from Rule 26-512 and 64-810 and adding a new Subrule 2) that mandates conductors extending more than 3 m from battery terminals to be in a wiring method in accordance with Section 12, and be treated as tap conductors in accordance with Rule 14-100 b).

Rule 64-816 Wiring methods and installation of equipment in battery rooms moved from Rule 26-514 only had one small change replacing the words “dry location” to “ordinary location” to be consistent with the definition in Section 0.

The only change for Rule 64-820 Diversion charge controller previously Rule 64-814 was to remove the reference to renewable energy systems from Subrules 1) and 2) making these requirements applicable to battery installation and renewable energy systems.

Energy storage systems rules have been added as new rules from 64-900 to 64-928 covering the installation of self-contained and field-assembled energy storage systems.

Rule 64-902 Marking has two subrules, first mandates the plaque or directory in Rule 64-074 to be provided to indicate the building or structure contains an energy storage system and the location of all energy storage system disconnecting means. Subrule 2) requires field-assembled energy storage systems to have a nameplate in accordance with Rule 2-100 at a readily accessible location at the disconnecting means for the energy storage system. The nameplate requirements for the self-contained energy storage systems is part of the product requirement.

Rule 64-904 Voltage of energy storage systems limits the voltage of a field-assembled energy storage system installed in or on a dwelling unit to 50 V dc.

Subrule 2) limits the output circuits for self-contained energy storage system installations in or on a dwelling unit to 600 V, provided that all energized parts in the energy storage system circuits over 150 volts-to-ground are accessible only to qualified persons.

Similar to Rule 64-202 for photovoltaic source and output circuits, Subrule 3) has an exception for the interlocking and visible isolation requirements in Rules 36-204, 36-208, and 36-214 for the dc portion of energy storage systems with maximum voltages higher than 750 V dc but not exceeding 1500 V dc provided that:

the installation is serviced only by qualified persons,

the part of the installation exceeding 750 V dc is inaccessible to the public,

and enclosures in which circuits exceeding 750 V dc are present are marked with the word “DANGER” followed by the maximum rated circuit voltage of the equipment.

Rule 64-906 Insulated conductors and cables aligns with the product standard requiring insulated conductors and cables used for the interconnection and connection of energy storage systems to have a minimum temperature rating of 90°C.

Similar to Rule 64-212 for photovoltaic circuit Rule 64-908 Insulated conductors marking or colour coding requires insulated conductors for dc circuits to be colour coded or marked as follows:

a) for a 2-wire circuit,

i) red for positive and black for negative;

ii) insulated conductors, other than green or white, with permanent marking at terminations and splices in accordance with Item i); or

iii) insulated conductors manufactured with permanent surface printing indicating the polarity on the insulated conductor; and

b) for a 3-wire circuit (bipolar circuit),

i) white or white with a coloured stripe for the mid-wire (identified as the centre tap), red for positive, and black for negative;

ii) insulated conductors, other than green or white, with permanent marking at terminations and splices in accordance with Item i); or

iii) insulated conductors manufactured with permanent surface printing indicating the polarity on the conductor insulation.

Rule 64-910 Installations has two subrules, first to align with the product standard Subrule 1) mandates self-contained energy storage systems to be installed in accordance with the manufacturer’s installation instructions. Subrule 2) requires mechanical protection where an energy storage system may be subject to the risk of physical damage or vehicular impact.

Rule 64-912 Overcurrent protection mandates that dc overcurrent protection must be marked for use on dc circuits, and each ungrounded conductor of an energy storage system must be protected in accordance with Rules 14-100 and 14-104. When establishing the location and size of overcurrent protection, Subrule 2) requires that each source of supply be considered where equipment or conductors are energized from both directions.

Rule 64-914 Disconnecting means for energy storage systems requires disconnecting means that complies with Rules 14-414 and 14-700 for all ungrounded conductors supplied from an energy storage system and that the disconnecting means can not be connected in any grounded conductor if the operation of that disconnecting means would cause the grounded conductor to be in an ungrounded and energized state. This rule also mandates that the disconnecting means have a warning that the terminals on both the line and load sides could be energized when the disconnecting means is open and that a disconnecting means installed for a fuse is required to disconnect all sources of supply if the fuse is energized from both directions unless the fuse can be readily and safely de-energized. Subrule 8) requires that a disconnecting used on dc circuits be rated for dc applications.

In addition, all energy storage systems require a disconnecting means that is:

a) be capable of being energized from both sides;

b) indicate whether it is in the open or closed position;

c) have provision for being locked in the open position;

d) be in accordance with Section 14;

e) be capable of being opened at rated load;

f) be capable of being closed with a fault on the system; and

g) be located within sight of and within 9 m of the equipment or be integral to the equipment. This includes a self-contained energy storage system that does not include an integral output disconnecting means.

Rule 64-916 Bonding requires that the bonding conductors be sized in accordance with Section 10 based on the largest overcurrent device protecting the circuit conductors. This is significant where conductors are energized from both directions without individual overcurrent protection at each end of the conductor. An Appendix B note was also added to help explain this that reads: Energy storage systems are bi-directional, and fault current can be available from more than one source. Energy storage system circuits connected in parallel can all contribute to a fault; therefore, bonding conductors should be sized according to the largest overcurrent device in the circuit. This rule also mandates that in addition to bonding all non-current -carrying conductive parts of electrical equipment in accordance with Section 10, metal objects such as battery racking, cable management systems, structures, and enclosures housing field-assembled energy storage equipment, etc., must be made electrically continuous and bonded to non-current-carrying conductive parts of electrical equipment.

Rule 64-918 Location and separation requirements for energy storage systems can be divided into three topics: self-contained energy storage systems, general requirements, and installation in dwelling units. To align with the product standard, self-contained energy storage systems must be installed in accordance with the manufacturer’s installation instructions. The general requirements for energy storage systems location and separations are in Subrule 2), 3), 7), 9), and 10). These subrules limit installations in accordance with the spacing from gas equipment covered in Rule 2-238, do not allow energy storage systems to impede egress from a building does not allow energy storage systems to be located closer than 3 m from a path of egress and entrance or exit doors, and do not allow battery energy storage systems installed below a grade of higher than 23 m unless installed in an electrical equipment vault. In addition, Subrule 7) states:

Energy storage systems

a) directly mounted to a building surface shall have

i) for a single energy storage system, a storage capacity not exceeding 20 kWh; and

ii) for multiple energy storage systems, a spacing of not less than 1 m apart and an

aggregate storage capacity not exceeding 40 kWh; or

b) installed in or on a detached garage, storage building, or free-standing structure, shall have

i) for a single energy storage system, a storage capacity not exceeding 20 kWh; and

ii) for multiple energy storage systems, a spacing of not less than 1 m from a dwelling unit and an aggregate storage capacity not exceeding 80 kWh.

Dwelling unit installations are covered by Subrules 4), 5), and 6).

Subrule 4) and 5) do not allow energy storage systems installed outside of a dwelling unit and not to be installed within 1 m of any window, door, or ventilation opening, and do not allow energy storage systems with a storage capacity greater than 1kWh or utilizing lithium-ion batteries to be installed in dwelling units, and any living space of a residential occupancy including clothes closets, storage rooms, bathrooms, stairways, or any other similar undesirable places.

Subrule 6) does permit residential use energy storage systems to be installed in garages of dwelling units, provided that:

a) the storage capacity of any single energy storage system does not exceed 20 kWh; or

b) aggregate storage capacity of multiple energy storage systems does not exceed 40 kWh and the energy storage systems are spaced not less than 1 m apart.

An exception for Subrules 6) and 7) allows energy storage systems to exceed the limitations above provided the systems are marked with “THIS EQUIPMENT MEETS THE CELL LEVEL PERFORMANCE CRITERIA OF UL 9540A.”

Rule 64-920 Battery installations has two subrules, first for self-contained energy storage systems that mandate that the batteries be installed in accordance with the manufacturer’s installation instructions. The reason for this subrule is that large self-contained energy storage systems are typically shipped without the batteries installed. As part of the certification, the self-contained energy storage systems have specific installation instructions for the batteries. Subrule 2) requires batteries installed as part of field-assembled energy storage systems to be installed in accordance with Rules 64-800 to 64-820.

Rule 64-922 Diversion load controllers prohibits the use of the supply authority system as a diversion load as the primary means of regulating the stored kinetic energy of an energy storage system.

Rule 64-924 Ampere rating of energy storage system circuits considers an energy storage system interconnected with a supply authority system to be a continuous load for the application of Rule 8-104. Where the output of an energy storage system supplies dedicated loads or other power systems, the continuous load can be determined in accordance with Rule 8-104 3). Subrule 1) of Rule 64-924 provides direction on how the energy storage system circuits maximum current is established as follows:

a) for an inverter output circuit, the inverter continuous output current rating;

b) for an inverter input circuit, the continuous inverter input current rating when the inverter is producing rated power at the lowest input voltage;

c) for the output of a dc-to-dc converter, the dc-to-dc converter continuous output current rating;

d) for a charge controller, the input current while charging; and

e) for a self-contained system, the rated current indicated on the energy storage system nameplate(s).

Rule 64-926 System charge control mandates that field-assembled energy storage systems have equipment to control the charging process, limited access by qualified personnel to adjustable settings for the control of the charging process and that diversion charge controllers be installed in accordance with the requirements of Rule 64-820

Rule 64-928 Working space and accessibility to energized parts mandates that energy storage systems meet the working space rules in Section 2 along with Rule 2-202 that covers guarding of live parts. In addition, field-assembled energy storage systems installed in dwelling units are not allowed to have exposed energized parts. The working space requirements internal to self-contained energy storage systems are covered by the product standard; as such, the self-contained energy storage systems must be installed in accordance with the manufacturer’s installation instructions.

The next article will continue with changes in Section 30.

Find Us on Socials