Batteries are crucial across an array of industries as they power all kinds of industrialized machines, such as forklifts. Without them, manufacturing in the modern world would look very different — and much less efficient. There are several types of industrial batteries, and each one requires safety measures to protect those working with them.

COMMON TYPES OF INDUSTRIAL BATTERIES

There are several types of batteries within specific design purposes. The following are the most commonly used for a wide range of applications.

1. Lead Acid batteries

Lead-acid batteries are the most common type of battery in use today. They power everything from golf carts to forklifts and automobiles. They are mostly rechargeable and work via chemical reactions between lead plates or coils, electrolytic compounds, and sulfuric acid.

THERE ARE TWO SUB-CATEGORIES AVAILABLE:

Starting, Lighting, Ignition (SLI)

These are mostly automotive batteries. They use only about three percent of their overall capacity during ignition and startup. An alternator charges the battery during the continuous operation of the vehicle.

They are completely sealed and require no form of maintenance. However, the battery’s charging cycle is limited.

Deep-cycle batteries

These chargeable, continuous-usage batteries provide power for forklifts, golf carts, and other battery-powered vehicles. Due to their design, they require more maintenance than car batteries.

Dangers

Overcharging a lead-acid battery can cause it to explode if the cells inside fail to vent excess gas. An explosion in the cell is possible, causing a chain reaction. The likely result is a failure of the battery casing, which will cause the acid to spew out along with the casing fragments.

The sulfuric acid contained in lead-acid batteries is highly toxic and corrosive. It can cause skin irritations and burns. If contact is made with the eyes, it can quickly burn through the cornea, causing permanent blindness.

2. Nickel cadmium batteries (Ni-Cd)

Ni-Cd batteries were once very popular in the early 1980s but are slowly being replaced by cheaper alternatives. They are now used mostly for aircraft, backup power for telecommunications networks, and mass transit. These batteries have a special relief system that allows gas to vent in case of overheating. This feature is essential for aircraft batteries due to continuous usage.

Ni-Cd batteries work through a chemical reaction between nickel oxide hydroxide and metallic cadmium. Their biggest advantage is high continuous performance as well as being able to recharge at relatively low temperatures.

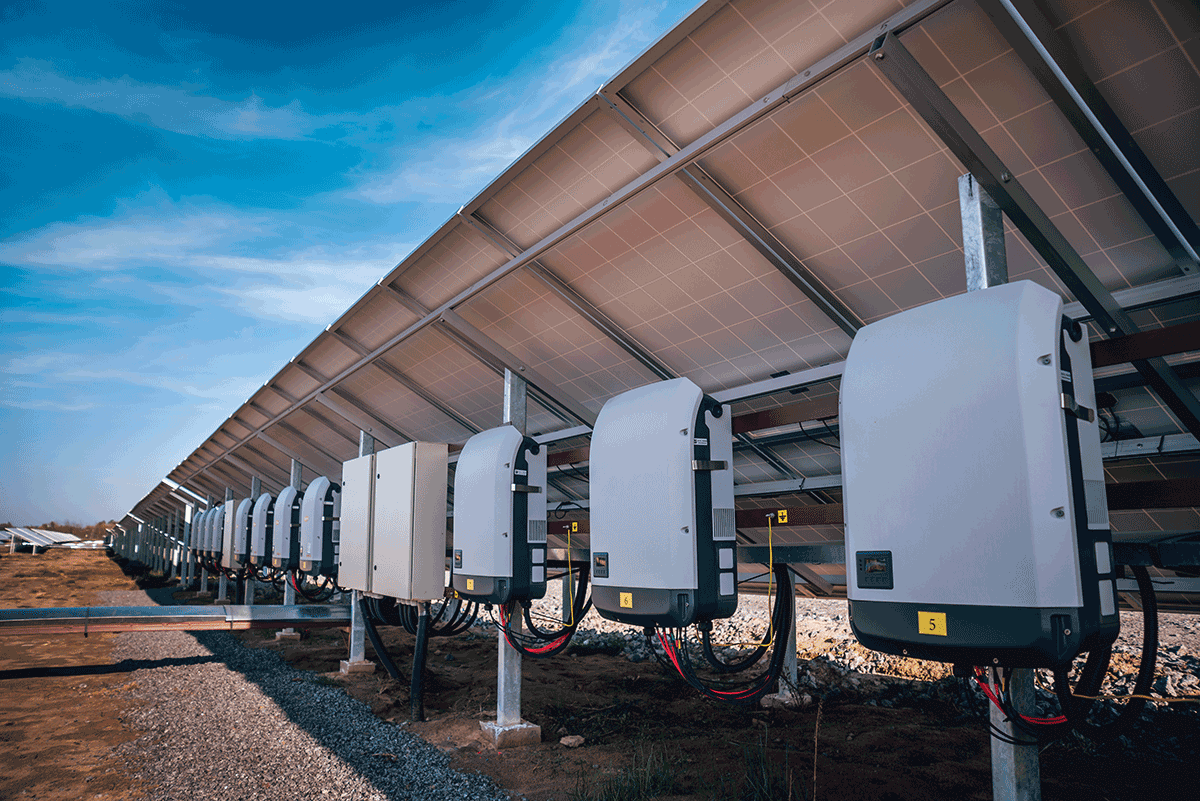

3. Lithium-ion batteries (Li-ion)

Li-ion batteries use a complicated process of energy transfer. It is similar to how other batteries work: There is a chemical reaction between a negative electrode through an electrolyte to a positive electrode. The process is reversed for charging the battery.

In the case of Li-ion batteries, the negative electrode is made up of lithium-ion cells composed of carbon. The electrolyte is typically constructed from lithium salt in an organic solvent. Finally, the positive electrode is made of a metal oxide compound.

Uses for Li-ion Batteries

Here are some of the more common applications for Li-ion batteries:

- Electric vehicles

- Smartphones

- Laptop computers

- Power tools

- Grid energy storage

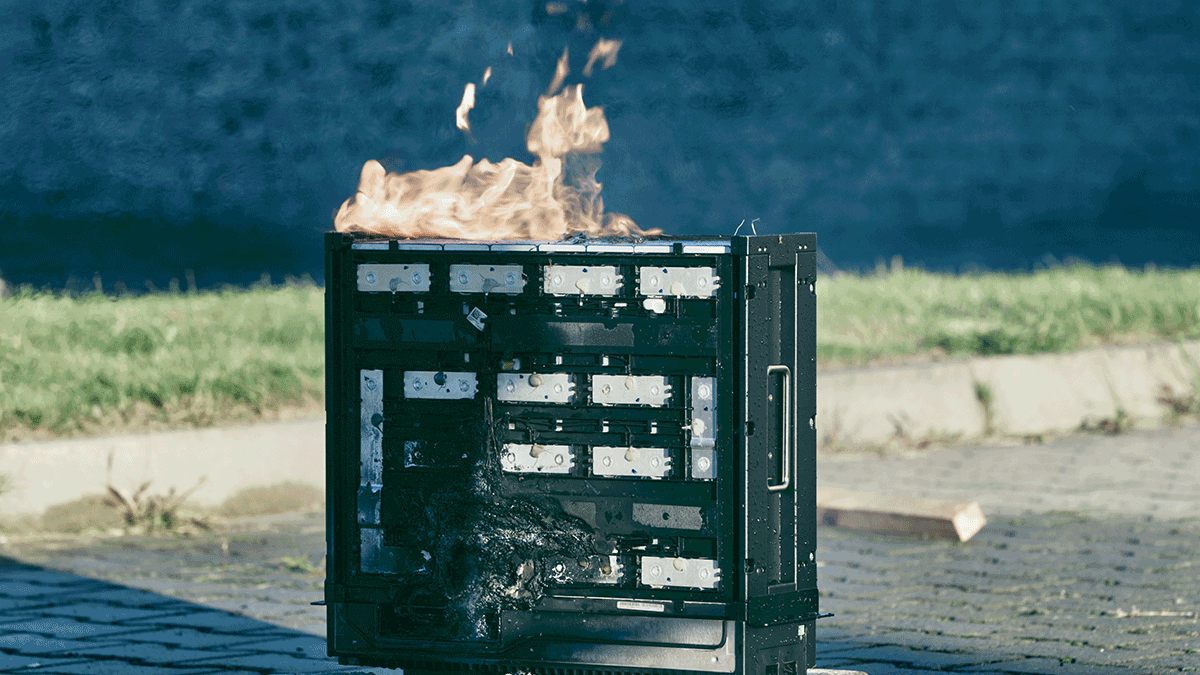

Dangers

There are some specific hazards to be aware of when storing, using, and charging Li-ion batteries. These are the most typical ones:

- Overcharging, leading to fire hazards

- Thermal runaway resulting in an explosion

- Overheating

- Short-circuiting due to metal contamination

GENERAL SAFETY PRECAUTIONS

First, safety and warning signs should be posted in designated work areas and charging stations. All personnel who work with industrial batteries should be trained in the proper handling, storage, safety precautions, and first aid before starting work. They should also be trained in the proper use of personal protective equipment (PPE) while working with batteries.

PPE should be readily available, kept in good working order, and free from defects. PPE includes:

- Long sleeve shirt

- Fog-resistant safety goggles

- Full face shield that covers the sides as much as possible

- Apron

- Rubber gloves

- Acid-resistant safety shoes or boots

Eye-wash stations

OSHA-approved emergency eyewash stations should be available throughout the work area, especially where batteries are maintained. OSHA requirements mandate that these stations be available at least within 25 feet of any battery handling areas or charging stations.

Fire prevention

No-smoking signs should be visible at various locations throughout the work areas. Welding equipment and other open flame sources should be kept well away from battery storage and charging stations.

Fire suppression equipment such as fire extinguishers should also be readily available, and all personnel should be trained in their proper use.

Safe handling procedures

When picking up large industrial batteries, a flexible back brace is useful for preventing back injuries. Bend at the knees when picking up large batteries from low places or lifting them out of a forklift.

Remove watches and other jewelry while handling or performing maintenance. When metal objects come into contact with terminals, they can create a spark, causing a fire hazard when mixed with gases and other chemicals.

Static electricity can also be a hazard. Be sure to ground all charging equipment properly before using it.

PRECAUTIONS WHILE CHARGING BATTERIES

- Lead-acid batteries emit hydrogen gas when charging. Under normal conditions, it is not a problem; however, if the battery is damaged in any way, it can become excessive. A hydrogen gas detector should be mounted close to the charging station and regularly checked to ensure it is working properly.

- Only charge batteries in well-ventilated, designated areas free from clutter, vehicles, and hydrocarbons such as gasoline, oil, and hydraulic fluid. Before charging, check the battery for obvious damage such as cracks, bulges, and fluid leakage. Report any problems immediately.

- Any equipment that can contact battery terminals or cell connectors should be properly insulated to avoid sparking hazards.

- Position forklifts and other vehicles in the proper position with parking brakes applied.

- Avoid overstretching charging cables.

- Keep battery covers open while charging to facilitate hydrogen gas venting, especially in confined areas.

- Always attach the positive clamp first and then the negative clamp second.

- Keep the tops of batteries clean and free of debris while charging.

- Check for heat buildup. If the battery becomes hot, stop charging immediately.

- To increase the battery’s life and avoid damage that could lead to injury, charge the battery when it lowers to 20-30% capacity. Be sure to leave it charging until it reaches 100%, but do not overcharge.

- To avoid electrical shock, always turn off the charger before disconnecting the clamps from the battery.

PRECAUTIONS DURING ROUTINE BATTERY MAINTENANCE

- Lead-acid batteries contain sulfuric acid. Avoid contact with the skin. It can also lead to permanent blindness if even a small amount gets into the eyes.

- All personnel should wear the proper PPE as outlined above when handling and maintaining batteries to avoid exposure to acid spills.

- Make sure to have at least a gallon of acid spill neutralizing liquid available near the workstation. This emergency acid absorber can be a simple solution of one pound of baking soda to one gallon of water. Commercial spill compounds are also readily available.

- Wash hands before and after handling batteries. Never touch the face or eyes right after working with any batteries or battery charging devices.

WHAT TO DO IN THE EVENT OF AN ACID-SPLASH EMERGENCY

Knowing what to do in the event of an emergency is essential to preserving lives and equipment. Every industrial workplace should have at least a few employees highly trained in first aid and CPR.

Here are some first-aid procedures to follow in case of an acid-splash emergency:

Skin contact

Remove affected clothing immediately and flush the skin with clean water for at least 15 minutes. If the skin is irritated or burned, seek medical attention.

Eye contact

Carefully remove any eyewear or goggles. Flush with clean water for 15 minutes using an approved eyewash station. Seek medical help immediately.

Accidental ingestion

- Even if a small amount of sulfuric acid finds its way into an open mouth, it can cause considerable damage to the lips, tongue, and intestinal tract.

- Give the victim milk to drink. It will help neutralize the acid. If milk is not available, rinse the mouth with a solution of 2 tablespoons of baking soda in a glass of water. Do NOT induce vomiting.

- Seek immediate medical attention.

- If the victim appears to be unconscious, call 911, remove the victim from the area, and provide fresh air. Provide CPR if the victim is not breathing and continue until emergency medical personnel arrive.

LITHIUM-ION BATTERY SAFETY PRECAUTIONS

Due to their high-density output and flammable materials, lithium-ion batteries are susceptible to varying degrees of fire hazard and explosion. These hazards can be broken down into four categories in order of severity.

- The battery gets heated to a point where smoke and toxic fumes are present.

- The next stage is where the battery turns into a virtual flare. The effect can last a few seconds to several minutes.

- In this stage, the battery catches fire. It can last for a few seconds to several minutes.

- The battery completely burns up while admitting a noxious plume of toxic vapors into the air that is extremely hazardous to humans.

EXPLOSIONS

If a lithium-ion battery gets hot enough, it can explode. The user may not know it is about to happen until it is too late.

STORING LITHIUM-ION BATTERIES

Store large quantities of batteries in industrial warehouses or storage units, not in small office spaces. Inspect batteries for damage before storage and discard any that might present a hazard. It is best to keep batteries charged to at least 50% capacity and to store them in metal containers. Always keep combustible materials away from stored batteries.

SAFE HANDLING

Avoid damaging the battery casing and connections during use; if a part does get damaged, make sure to set it aside to be repaired before further use. Keep batteries away from water and other conductive materials as well as open flames, and never smoke nearby. Before charging, allow the batteries to cool. For some of the larger vehicle batteries, welders gloves may be necessary to remove heated cells.

PRECAUTIONS WHILE CHARGING

It’s important never to overcharge batteries. Disconnect the battery from the charger immediately if there is excessive heat, smoke, or toxic fumes present. Never try to charge a disposable battery since they are not designed to be recharged. After charging is complete, promptly remove batteries from the charger to avoid excessive heat buildup.

SAFE BATTERY DISPOSAL

Environmental concerns over improper disposal of the various types of batteries are warranted. Toxic chemicals used in battery production can leach into the soil and groundwater. The result could lead to drinking water contamination and damaged crops. It can become a complicated mess to clean up.

LEAD-ACID BATTERY DISPOSAL

Thankfully, 98% of all lead-acid batteries in the US become either recycled or reconditioned. Not only does this practice help the environment, but it also saves the operator thousands of dollars each year by making batteries more cost-effective.

A local recycler is probably the best place to start. They can provide information concerning the safe transport and delivery to the recycling plant. They may even be able to help schedule the pick-up of old batteries.

NICKEL-CADMIUM AND LITHIUM-ION BATTERY DISPOSAL

Like lead-acid batteries, Ni-Cd and Li-ion batteries are recycled at a very high rate in the US. The difference here is that it may be more challenging to find a local recycler to handle Ni-Cd since there are fewer of them.

However, batteries used in laptops and cell phones are simpler to recycle. Most large, big-box retailers have a collection area for discarded batteries. They, in turn, call for recycling pickup by large industrial recycling plants. But it is somewhat harder to find local recyclers for industrial-use Ni-Cd and Li-ion batteries.

This is where universal waste handlers come in. They pick up from industrial sites all over the United States and are tightly regulated by the EPA. Some of their services include transport, re-use, and reclamation of industrial materials.

Conclusion

Training and preparing workers for dangerous situations that may occur when working with industrial batteries will reduce the number of workplace injuries and ensure OSHA requirements are being met. With the proper PPE, procedures, and emergency precautions, any warehouse can maximize the amount of work that gets done each day while providing a safe and efficient working environment.

For more information on the safe handling of batteries, visit https://powrparts.com/

Find Us on Socials