After I wrote an article about the selection of the overcurrent (O/C) protection and conductor sizes for transformers, I received significant feedback (questions and comments) from the readers.

Some questions in this feedback have been related to the Canadian Electrical Code, Part I (CE Code) requirements for loading (and overloading) of a transformer.

Let’s take a look at the applicable provisions of the CE Code in this regard. As was indicated earlier, a transformer is not a piece of utilization equipment. It is the piece of equipment that allows providing the necessary interface between supply and utilization voltages. As such, a transformer is inserted into a feeder or a circuit for a sheer purpose of such voltage interface and transformation. It means that a transformer is a part of a circuit or a feeder and that a continuous load connected to a transformer cannot exceed the rating of the circuit in which such a transformer is inserted.

Rule 26-258 of the CE Code states the following:

“26-258 Transformer continuous load (see Appendix B)

For the purpose of transformer overcurrent protection and conductor sizes selected in accordance with Rules 26-250 to 26-256, the continuous load as determined from the calculated load connected to the transformer secondary shall not exceed the values specified in Rule 8-104 5) or 6).“

Appendix B Note on Rule 26-258 offers the following clarification:

“Appendix B Note on Rule 26-258

The intent of this requirement is to provide for coordination between loads connected to a transformer secondary and the rating of the transformer circuit (i.e., rating of the transformer overcurrent device and ampacity of transformer conductors). Compliance with this requirement allows the proper selection of the minimum acceptable conductor size under the applicable provisions of Rule 26-256 and selection of the transformer overcurrent device under the applicable requirements of Rules 26-250 to 26-254.

Because selection criteria for the overcurrent devices and conductors are based on the rated (primary or secondary) current of the transformer, the actual calculated load connected to the transformer may not necessarily fully correlate with the transformer rated primary and secondary currents, in which case the intent of this requirement could be met by increasing the rating of the overcurrent device under the relaxation permitted by Rule 26-254 3). This Rule would also have to be considered when conductor size is permitted to be reduced under the provisions of Rule 26-256 3).“

It means that the load connected to the transformer shall not exceed the rating of the circuit (or feeder) in which the transformer is installed.

Subrules 8-104(1) and (2) provide the following statement regarding a rating of the circuit and correlation between the circuit rating and the maximum calculated load allowed to be connected to the circuit (and in this case – to the transformer, which is inserted into the circuit):

“8-104 Maximum circuit loading (see Appendix B)

1) The ampere rating of a consumer’s service, feeder, or branch circuit shall be the ampere rating of the overcurrent device protecting the circuit or the ampacity of the conductors, whichever is less.

2) The calculated load in a circuit shall not exceed the ampere rating of the circuit.“

Now is the perfect time to visit Rules 26-250 and 26-254 for the maximum allowable O/C protection of a transformer, and Rule 26-256 – for the minimum allowed ampacity of the transformer primary and secondary conductors.

Rule 26-250 applies to overcurrent protection for high voltage power and distribution dielectric liquid-filled and dry type transformer circuits, and Rule 26-254 covers overcurrent protection for low voltage dry-type transformer circuits as follows:

“26-250 Overcurrent protection for power and distribution transformer circuits rated over 750 V

1) Except as permitted in Subrules 2), 3), and 4), each ungrounded conductor of the transformer feeder or branch circuit supplying the transformer shall be provided with overcurrent protection

a) rated at not more than 150% of the rated primary current of the transformer in the case of fuses; and

b) rated or set at not more than 300% of the rated primary current of the transformer in the case of breakers.

2) Where 150% of the rated primary current of the transformer does not correspond to a standard rating of a fuse, the next higher standard rating shall be permitted.

3) An individual overcurrent device shall not be required where the feeder or branch circuit overcurrent device provides the protection specified in this Rule.

4) A transformer having an overcurrent device on the secondary side rated or set at not more than the values in Table 50 or a transformer equipped with coordinated thermal overload protection by the manufacturer shall not be required to have an individual overcurrent device on the primary

side, provided that the primary feeder overcurrent device is rated or set at not more than the values in Table 50.

26-254 Overcurrent protection for dry-type transformer circuits rated 750 V or less (see Appendix B)

1) Except as permitted in Subrule 2), each ungrounded conductor of the transformer feeder or branch circuit supplying the transformer shall be provided with overcurrent protection rated or set at not more than 125% of the rated primary current of the transformer, and this primary overcurrent device shall be considered as protecting secondary conductors rated at 125% or more of the rated secondary current.

2) Notwithstanding Subrule 1), a transformer having an overcurrent device on the secondary side set at not more than 125% of the rated secondary current of the transformer shall not be required to have an individual overcurrent device on the primary side, provided that the primary feeder overcurrent device is set at not more than 300% of the rated primary current of the transformer.

3)Where a value not exceeding 125% of the rated primary current of the transformer as specified in Subrule 1) does not correspond to the standard rating of the overcurrent device, the next higher standard rating shall be permitted.”

Rule 26-256 outlines criteria for a minimum allowed ampacity of primary and secondary conductors, connected to a transformer, as follows:

“26-256 Conductor size for transformers (see Appendix B)

1) The conductors supplying transformers shall have an ampacity rating

a) not less than 125% of the rated primary current of the transformer for a single transformer; or

b) not less than the sum of the rated primary currents of all transformers plus 25% of the rated primary current of the largest transformer for a group of transformers operated in parallel or on a common feeder.

2) The secondary conductors connected to transformers shall have an ampacity rating

a) not less than 125% of the rated secondary current of the transformer for a single transformer;

or

b) not less than 125% of the sum of the rated secondary currents of all the transformers operated in parallel.

3) Notwithstanding Subrules 1) and 2), primary and secondary conductors shall be permitted to have an ampacity rating not less than that required by the demand load, provided that they are protected in accordance with Rules 14-100 and 14-104.

4) Where the transformer overcurrent protection is selected in accordance with Rule 26-250 1) or 2) or 26-254 3), the primary and secondary conductors connected to the transformer shall be protected in accordance with Rules 14-100 and 14-104.

5) Where multi-rating transformers are used, the primary and secondary conductors shall have an ampacity rating not less than 125% of the rated primary and secondary current of the transformer at the utilization voltage.”

It means that when a dry-type low voltage transformer is selected for installation, O/C protection in the transformer primary cannot exceed 125% of the transformer primary current unless such O/C is allowed to be increased under the provision of Subrule 26-254(3).

Thus, for example, if a 100 A-rated O/C is selected in the primary of 75 KVA; 600 V:120/208 V transformer in accordance with Subrule 26-254(3), then (through the voltage ratio) this 75 kVA transformer with the secondary rated current of 208.43 A, would be allowed to be loaded to 288 A, if the primary 100 A-rated O/C is marked for continuous operation at 100% of the ampere rating of its overcurrent devices, as stated in Rule 8-104(5), or would be allowed to be loaded to 230.4 A if the primary 100 A-rated O/C is marked for continuous operation at 80% of the ampere rating of its overcurrent devices, as stated in Rule 8-104(6).

It means that in the worst case, this transformer would be overloaded by 139%.

It also means that the ampacity of primary and secondary conductors would have to meet provisions of Rules 14-100 and 14-104, as required by Subrule 26-256(4).

And considering the above-indicated provisions of the CE Code, what about loading of a HV dielectric liquid-filled transformer?

Rule 26-250 helps us to answer this question. If a primary circuit breaker is selected with a rating up to 300% of the transformer primary rated current, then (for example) a typical 2500 kVA dielectric liquid-filled transformer rated at 12.47 kV:347/600 V, with the primary (12.47 kV) circuit breaker rated at 300 A, could be loaded through the voltage ratio up to 6235 A on the transformer secondary, if this primary circuit breaker is marked for continuous operation at 100% of the ampere rating of its overcurrent devices, as stated in Rule 8-104(5). If, however, this primary circuit breaker is marked for continuous operation at 80% of the ampere rating of its overcurrent devices, as stated in Rule 8-104(6), then the maximum load allowed to be connected to the transformer secondary, would be 4988A.

It should be noted that a secondary rated current of such 2500 KVA transformer would be 2408.48.

It means that in the worst case, this transformer would be overloaded by 259%.

Of course, the ampacity of primary and secondary conductors connected to this 2500 kVA transformer, would have to meet provisions of Rules 14-100 and 14-104, as required by Subrule 26-256(4).

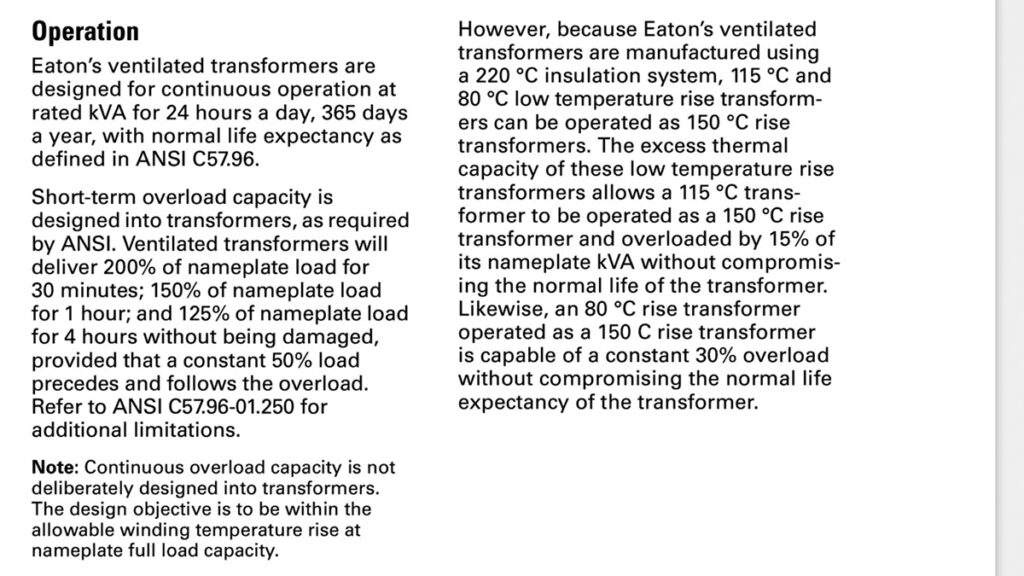

It should be noted that Eaton provides information on overloading of transformers in figure 1:

Some Code users, and particularly electrical inspectors, are concerned that the current provisions of the CE Code might create safety hazards due to the drastic overloading of the transformer in figure 1.

Electrical inspectors, however, cannot prevent installations demonstrated in the above examples, as compliance with Rules 14-104 and 8-104 is met under such design arrangements.

It should be noted that the proposal has been submitted to Section 26 S/C – to revise Rule 26-250.

Meanwhile, local AHJ’s should be consulted – to ensure that all safety provisions of the Code are met.

Find Us on Socials