Does the equipment bonding conductor for a metal device box have to be a separate conductor from the equipment grounding conductor from one of the branch-circuit conductors?

Can the branch circuit equipment grounding conductor be bonded to the box and then extended out to be spliced to the other equipment grounding conductor(s) and equipment bonding jumper to the wiring device?

The information provided below is based on the 2020 edition of the National Electrical Code. There are no changes in the 2023 edition of the NEC that would modify this response.

Questions, such as those above, have been raised on the methods that are allowed to comply with section 250.148 when installing branch circuit wiring with devices in metal device boxes. The wiring method could be non-metallic, such as an NM-B cable, or metallic, such as an AC cable, MC cable, or conduit with circuit conductors installed.

The 2020 NEC applicable requirements found in 250.148 are as follows:

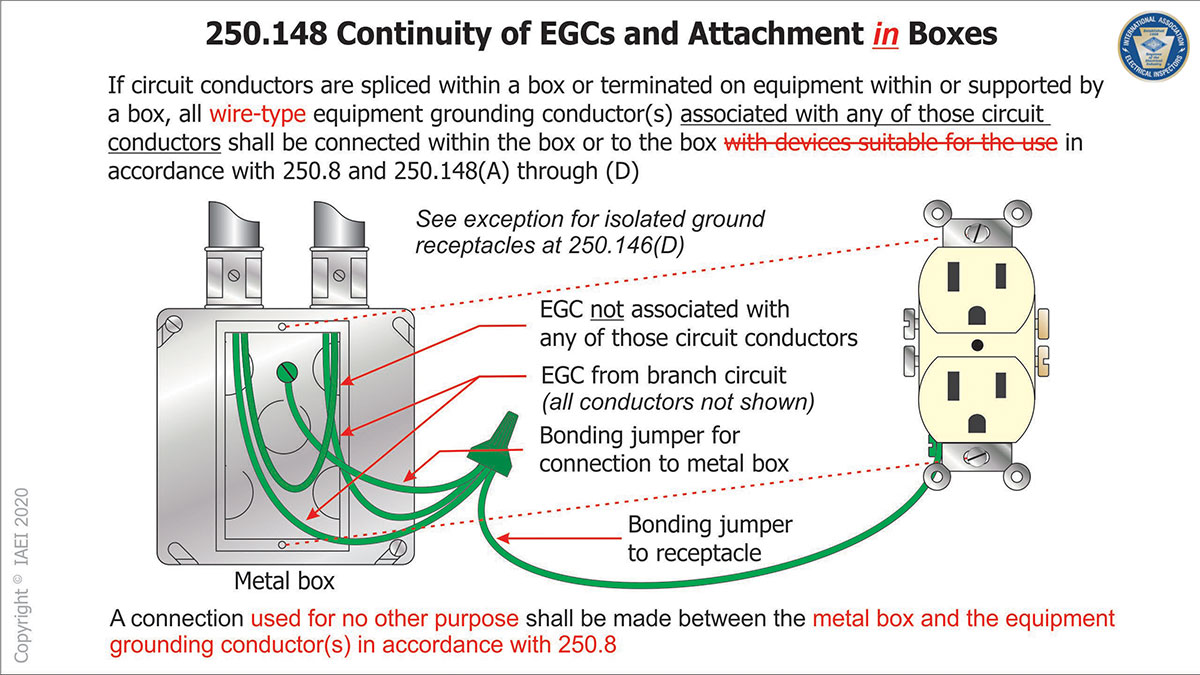

“250.148 Continuity of Equipment Grounding Conductors and Attachment in Boxes.

If circuit conductors are spliced within a box or terminated on equipment within or supported by a box, all wire-type equipment grounding conductor(s) associated with any of those circuit conductors shall be connected within the box or to the box in accordance with 250.8 and 250.148(A) through (D).”

“(B) Equipment Grounding Conductor Continuity. The arrangement of grounding connections shall be such that the disconnection or the removal of a luminaire, receptacle, or other device fed from the box does not interrupt the electrical continuity of the equipment grounding conductor(s) providing an effective ground-fault current path.”

“(C) Metal Boxes. A connection used for no other purpose shall be made between the metal box and the equipment grounding conductor(s) in accordance with 250.8.”

Over the past several NEC code cycles, the basic requirements have remained the same, with the main changes being which sets of equipment grounding conductors are to be bonded together. The requirement to bond the metal box has not changed.

As can be seen from the code text, the requirement is to ensure the bonding of all the related equipment grounding conductors, equipment bonding conductor(s), and the metal box where used. The code does not specify a single method, or single connector to be used. There are many ways to complete the installation to be compliant with the NEC. Figure 1 from the 2020 IAEI Analysis shows an example of one method, but what is shown is not the only method permitted (see Figure 1).

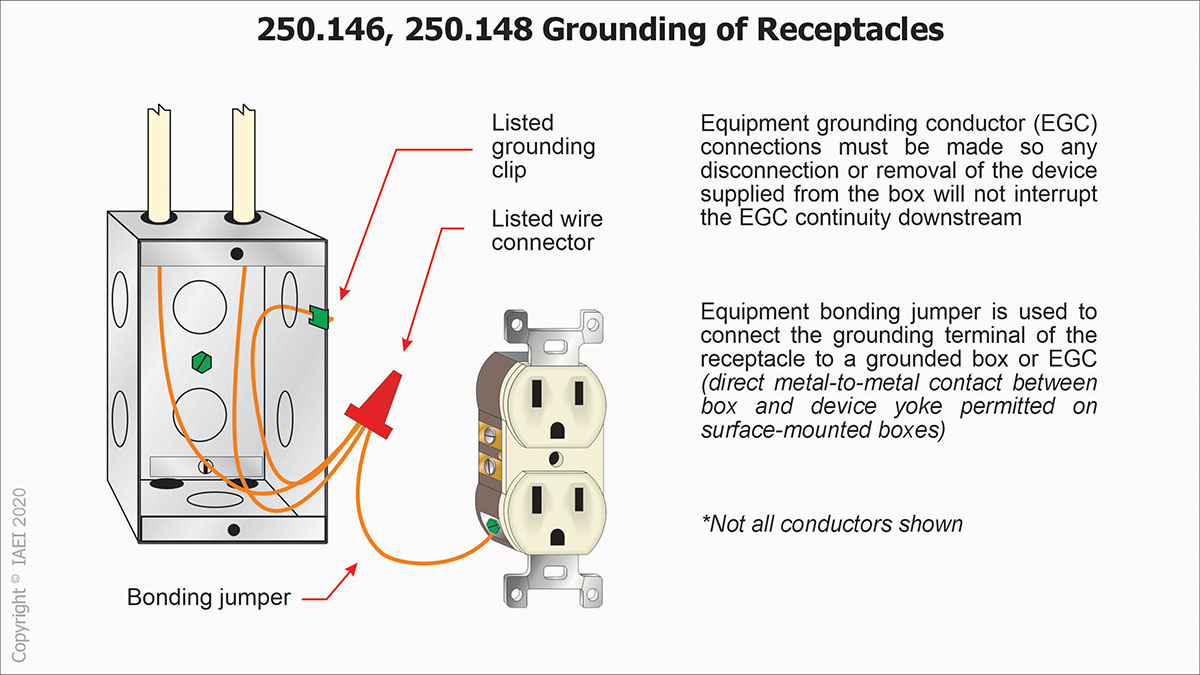

The text in 250.148(C) indicating “for no other purpose” applies to the connection means to the metal box. The 2017 NEC had limited this to a “screw”, but this was broadened and clarified in the 2020 edition to allow any connector permitted in 250.8. This connection device can be the green screw commonly used, but as now allowed in the main text of 250.148, the connection can be any of the devices or hardware listed in 250.8. This would include standard machine screws with or without a nut, listed grounding clips that attach to the wall of the metal box, see Figure 2, or other listed devices. The reason behind the “no other purpose” requirement is to prohibit a fastener for a device or equipment, such as the receptacle 6-32 mounting screws or the screw for the internal cable clamp, from being used to connect the equipment bonding jumper to the metal box. If the receptacle or mounting device were to be loosened or removed, then that safety circuit continuity is lost and a hazard can be created.

Figure 2.

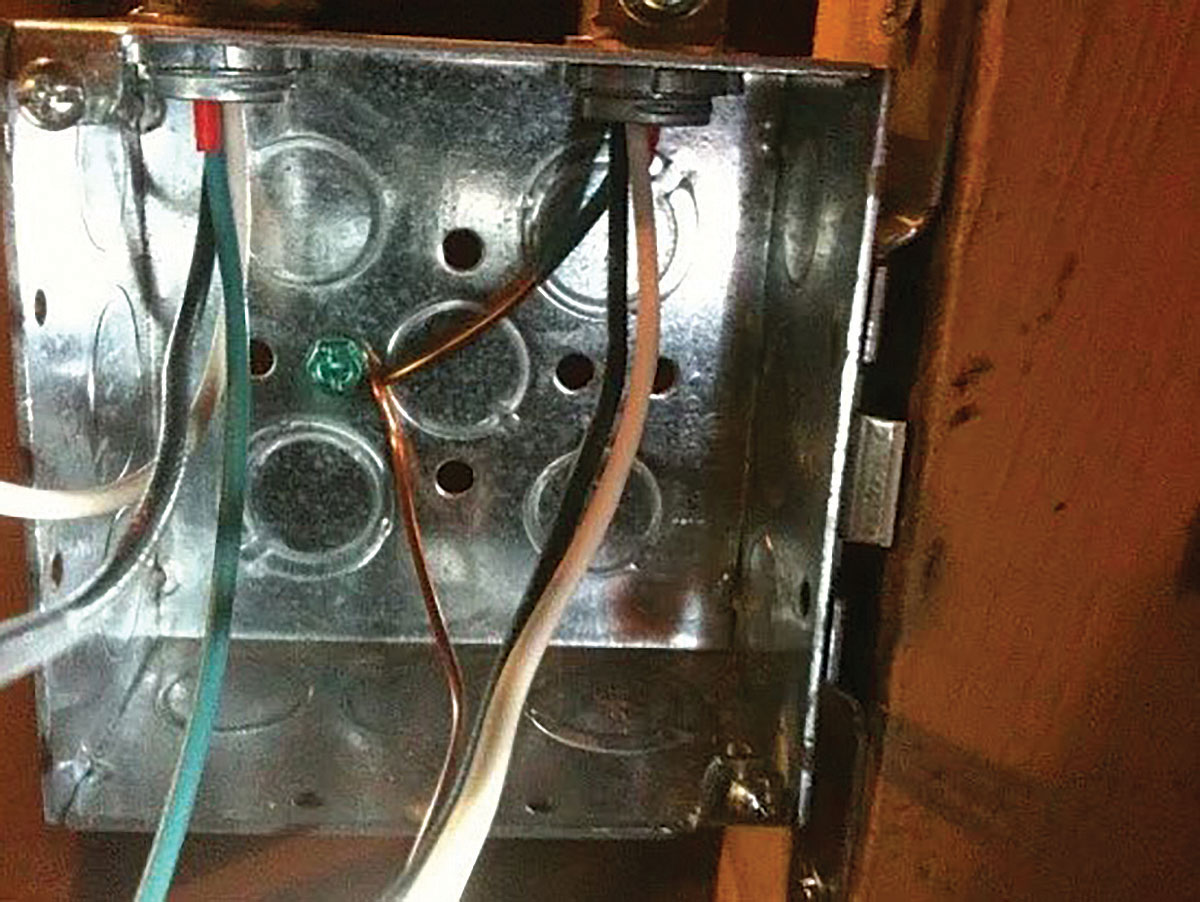

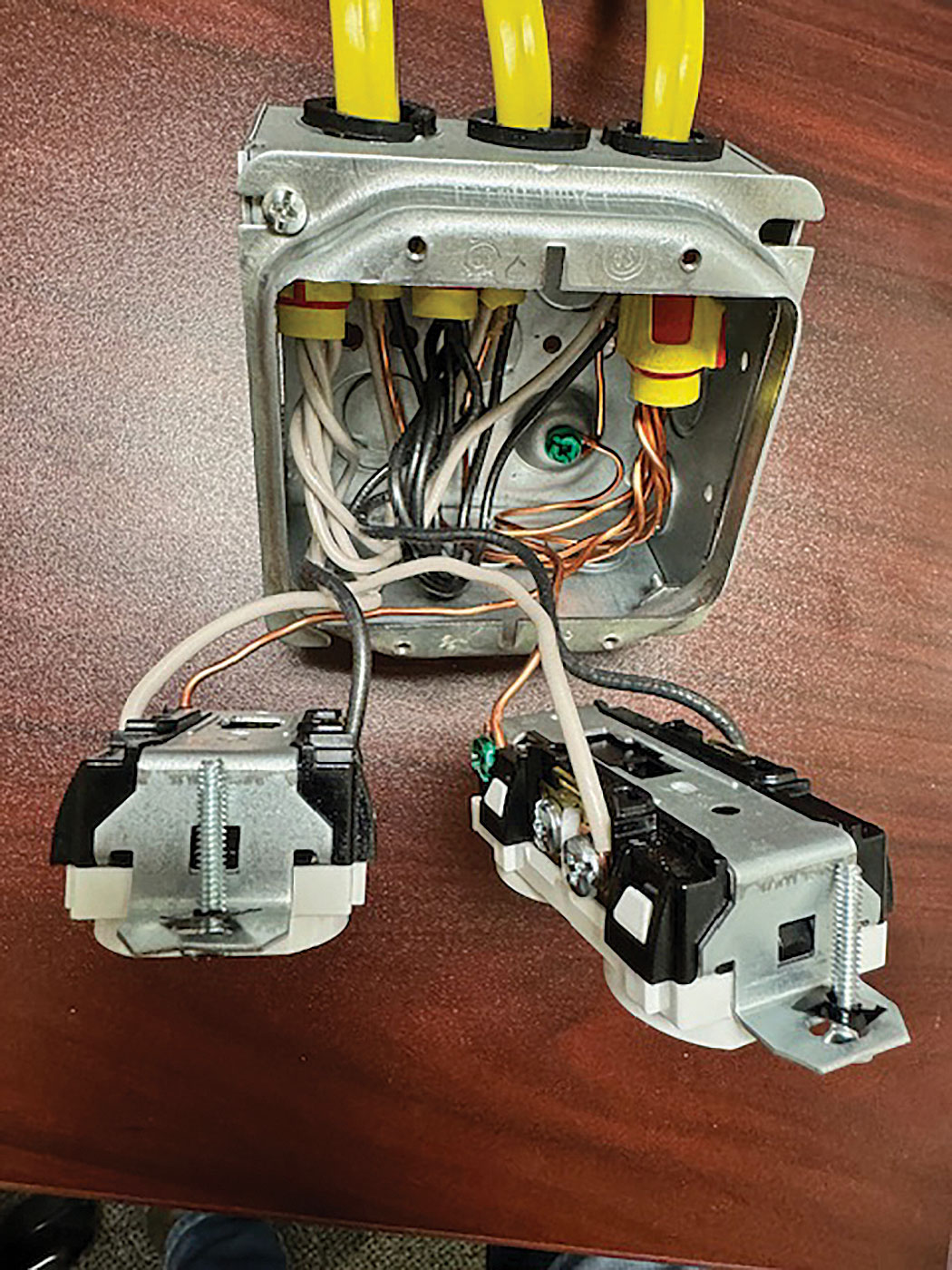

Can the NM-B bare equipment grounding conductor be installed directly to the metal box, by creating a loop around the screw and under the head to provide a secure attachment, then extended with the minimum 6 inches of length for making the splices? As shown in figure 3, photos 1 and 2, and referencing the text from 250.148, the answer is yes. There is nothing in the NEC prohibiting this as a method of installation and it has been a well-used method by electricians for many decades.

Figure 1.

Photo 1.

Photo 2.

When installing or inspecting an installation, caution must be exercised to follow or exceed the requirements in the NEC. There are generally many ways to complete a compliant installation. Remember that explanatory materials, graphics, or other methods used to explain code requirements may only provide an example and are not necessarily the sole means to be code-compliant. The text of the code is the requirement, and that is what must be met.

The information provided here is the opinion of the author and is not a formal or informal interpretation from NEC code-making panel 5 or the NFPA.

Find Us on Socials