Question

When installing a supply-side bonding jumper, what are the requirements for installing such a conductor both inside and outside a raceway?What type of conductive material is suitable for a supply-side bonding jumper and how is it sized? EJ

Answer

The term supply-side bonding jumper first appeared in the 2011 National Electrical Code as a result of a CMP-5 Task Group regarding the proposed revisions to Section 250.30 for grounding separately derived systems.

This revision created a new definition that was added to Section 250.2. “Bonding Jumper, Supply-Side. A conductor installed on the supply side of a service or within a service equipment enclosure(s), or for a separately derived system, that ensures the required electrical conductivity between metal parts required to be electrically connected.”

Previously, we identified all bonding jumpers the same, whether they were on the supply side of an overcurrent device or if they were on the load side of an overcurrent device. By designating it as a supply-side bonding jumper, it is easier to understand how the conductor is used and how to size it properly. A bonding jumper on the supply side of an overcurrent device is sized from Section 250.102(C), which takes you to Table 250.66. The size of the supply-side bonding jumper is based on the ungrounded phase conductors. An equipment bonding jumper on the load side of an overcurrent device is sized from 250.102(D) based on Table 250.122, similar to sizing an equipment grounding conductor from the rating of the overcurrent devices protecting the conductors of the branch circuit or feeder.

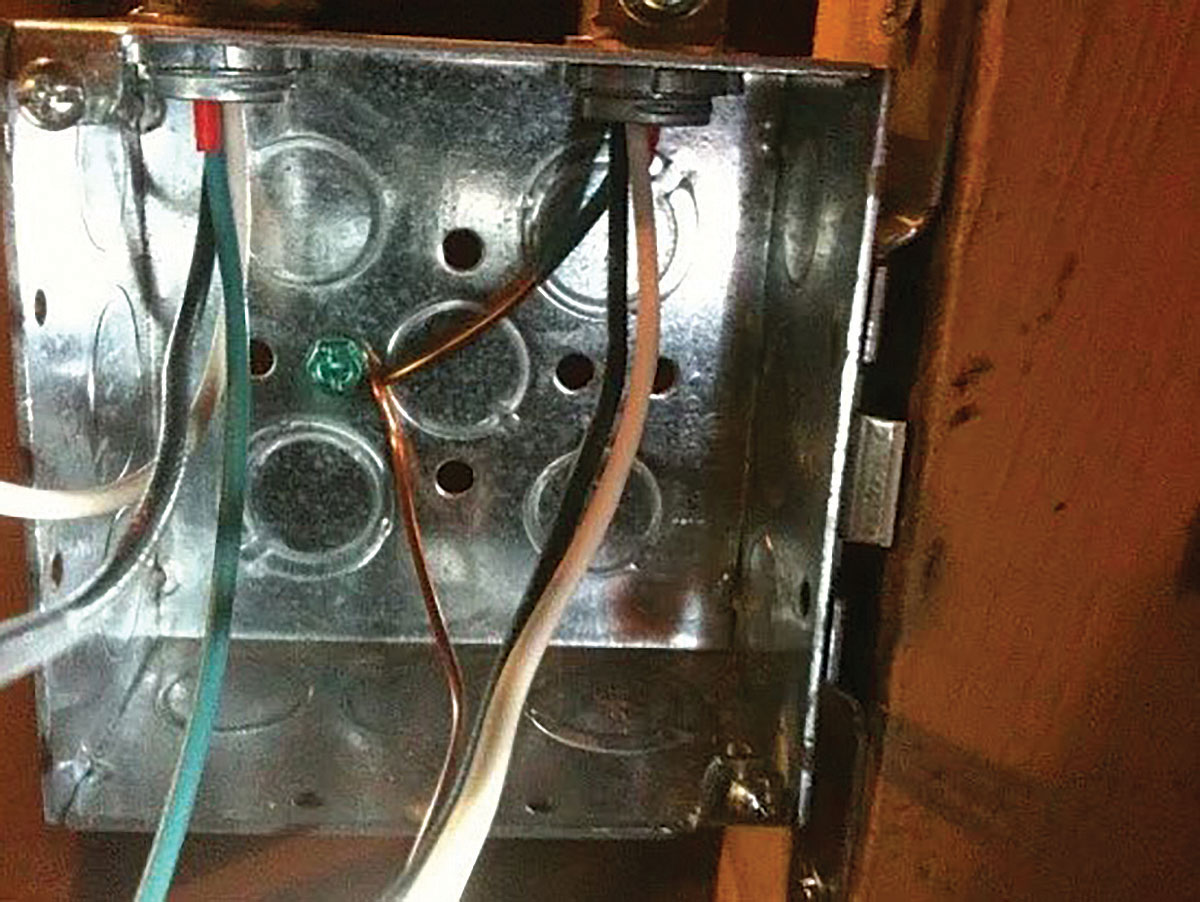

A supply-side bonding jumper installed on the inside of a raceway must be installed with the circuit conductors from the source enclosure to the first disconnecting means. Section 250.104(E) governs how the bonding jumper is to be installed: (1)inside the raceway, it must comply with 250.119: bare, covered, or insulated. If covered or insulated, it must be green or green with yellow stripe(s); (2)outside the raceway or enclosure, it generally cannot exceed 6 ft in length and must be routed with the raceway or enclosure. There is an exception for outside pole locations allowing the jumper to be longer than 6 ft for isolated sections of metal conduit or raceway.

The supply-side bonding jumper is sized per Table 250.66 based on the size of the ungrounded phase conductors. It is not required to be larger than the ungrounded phase conductors. Section 250.102(A) states that bonding jumpers may be of copper or other corrosion-resistant material, and may be a wire, bus, screw, or similar suitable conductor.

Find Us on Socials