This series of articles is written with the intent of making the electrical inspector, the plan reviewer, and other authorities having jurisdiction (AHJs) as informed as possible on the National Electrical Code (NEC) aspects of and requirements for photovoltaic (PV) power systems. While these individuals may never be required to design or install a PV system, they should be more competent and knowledgeable in the application of the NEC requirements to the PV system than the PV system designer/installer. New technologies are here to stay

Are you ready? Here is a little test. Adults in the house should answer the following questions:

- Is there more than one flat-screen TV at home?

- Is it easy to program the cable DVR or satellite DVR for recording programs in advance?

- Are movies and other programs routinely streamed from the internet?

- Are files transferred from a desktop computer at home to the workplace desktop computer?

- Are there one or more tablets (iPad or equivalent) that are used both at home and at the workplace?

- Are the operating systems and virus detection systems up to date?

- Are all the features of a smartphone including texting and data transmission used regularly?

The answers to these questions will give some indication to the degree of technology competence and ability to deal with the technology age that is here. It will be ever more important and critical to job performance and the ability to ensure the safety of the public.

The Internet of things

The internet of things (IoT) is a concept that envisions microprocessors and other electronic devices installed in almost anything imaginable. Information is transmitted from the device in which they are installed to the internet to be processed in unimaginable ways. Right now, there are bracelets—and other similar devices like smartwatches—that can monitor your biometric functions including temperature, pulse rate, exercise, etc. and transmit this data to a local computer or the internet.

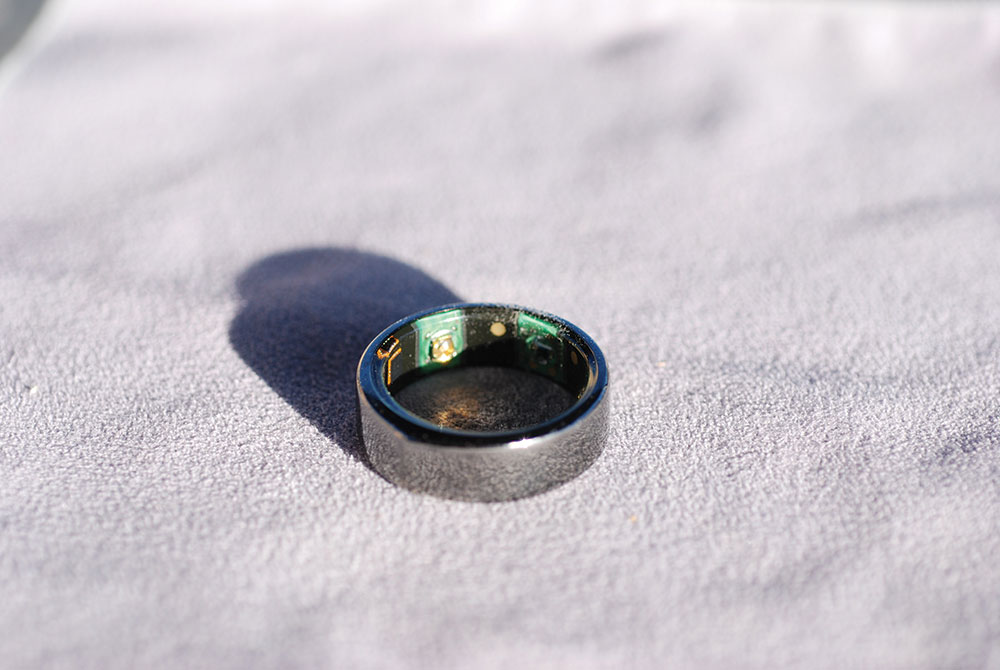

I am wearing a ring that has a gyroscope, an accelerometer, a pulse measuring system, and a temperature measuring device that takes my biometric data and transmits it to a tablet via Bluetooth. (See Photo 1.) The application in the tablet transmits the data to the cloud via Wi-Fi and the internet. Significant amounts of processing occur both in the tablet and in the cloud giving me a full picture of my biometric information and current state of health.

New refrigerators can read the barcodes on packaged foods and keep an inventory. And for a year or so, there have been refrigerators with interior cameras connected to the internet which allow for monitoring of the contents of your refrigerator on a smartphone from the store. Some large supercenters will take orders over the internet from the home, or elsewhere, bill the purchases to a credit card and have the order ready for pickup at a specified time. Other online merchants will take an order over the internet or phone app, deliver the products to a specified address, and—with a secure entry access system—stock the refrigerator or shelves in the home. In the near future, expect the newest refrigerators with sensors (cameras that can read barcodes) to automatically keep an inventory (specified by the system’s owner) and restock themselves.

The manufacturers of microprocessors and microsensors will be placing their devices in any possible location that they can think of, and those devices will be communicating with local computers or the internet. Vacuum cleaners will alert the operator when the bag needs emptied, and they will automatically order new bags. Brooms will automatically determine when they have reached the end of their lives. The cost of these microsystems—when produced in the millions—will become very inexpensive, and the manufacturers will see a market and will not be able to resist installing them in everything. Millennials will not resist buying them. Hence, the age of the internet of things is here.

How does this affect the AHJ and PV?

Electrical power systems for the first 100 years or so have been fairly basic, comprising conductors, disconnects, overcurrent protection, and transformers. The advent of power electronics and solid-state devices has changed all that. Certainly, we have the same conductors, disconnects, overcurrent protection, and transformers, but there are now numerous new technologies that have been added to the electrical power system. These include electronic motor start controllers, ground-fault equipment protectors, ground-fault circuit breakers, dimmers, and arc-fault circuit breakers, to name a few.

In more recent years, EV (electric vehicle) charging stations are being installed in residences and various commercial locations, and there are smart (internet linked) HVAC systems, internet-controlled lights and window shades, and energy storage systems that are being added to residences and commercial buildings. As these new systems interface with and become part of the building wiring and find their way into the NEC, the AHJ will have to inspect them. That implies additional education and training for the inspection force.

The PV industry is booming

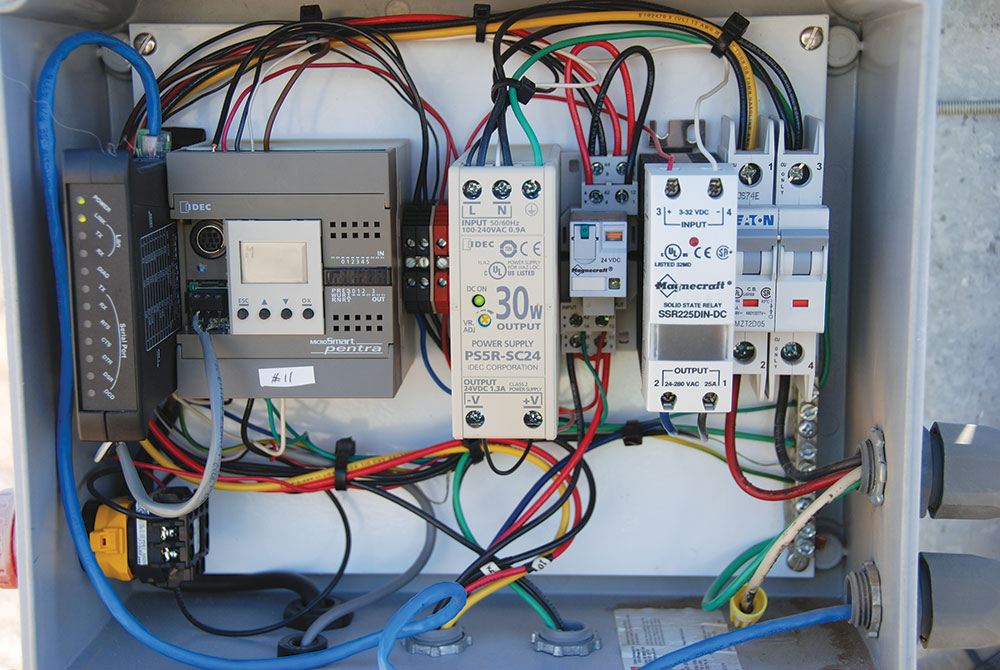

With the increasing importance of the issues associated with climate change and the continuing drop in the prices of PV systems, significant numbers of residential, commercial, and utility-scale PV systems are being installed throughout the country and indeed throughout the world. The PV system, of course, will typically include the utility-interactive inverter or—in the case of a standalone system—the charge controller and a standalone inverter. However, a host of other electronic devices have been incorporated into PV systems. Most of these devices are mentioned in the NEC, to some extent, establishing requirements for when and where they must be installed, but it provides little detail on the actual installation and adjustment requirements for these devices. (See Photo 2.)

Such devices include the DC–DC converter, which decouples the output of the PV module from the output of other PV modules. This decoupling invalidates the normal module and string calculations for voltage and current. (See Photo 3.) The instructions for these listed products (NEC 690.4) must be followed to ensure that they are correctly installed [NEC 110.3(B)].

A recent device—or better said, system—is the PV rapid shutdown system (PVRSS) required by Section 690.12. (See Photo 4.) First appearing in the 2014 NEC, the requirements changed in the 2017 NEC, and will change again in the 2020 NEC. Section 690.12 is fairly detailed and complex. A new UL Standard (expected for release in Summer 2019) called UL3741 The Standard for Safety for Photovoltaic Hazard Control is being developed to address the “inside the array boundary shutdown” NEC requirements that took place on January 1, 2019 [NEC 690.12 (B)(2)(2)]. Currently, AC PV modules and systems with microinverters—as well as many of the systems with DC–DC converters—have been certified to meet the PVRSS requirements, including the inside the array boundary requirements in the 2017 NEC.

There are a few systems coming to the marketplace that will meet the 2019 requirements for controlling voltages within the PV array boundary. These are relatively complex systems. They must be carefully installed to meet the life safety requirements for first responders who may be involved in firefighting operations where a PV system is located. The AHJ needs to be familiar with how these systems are to be installed (and each has its own peculiarities), verify that they are properly installed [NEC 110.3(B)], and, finally, have the installer activate the system to ensure that it is working properly.

Another relatively recent addition to the PV system is the PV DC arc-fault detection-interruption system (NEC 690.11). On smaller PV systems—such as a several kilowatt AC output system on a residence—the system may be entirely contained in the inverter. However, as the system size grows larger and the array becomes more complex in terms of number of strings and combiners, the PV DC arc-fault detection-interruption system may have components in the array itself, possibly in the DC combiners, in addition to detectors at the inverter.

The UL Standard for this device (UL 1699B) requires a manual or automatic self-test, that, if failed, shuts the inverter or charge controller down until the failure is repaired. There must be a visual indication of the success or failure of this test. And, the inverter or charge controller manual may have requirements on the size of the array and the number of strings that can be connected in parallel for the DC PV arc-fault function to work properly [NEC 110.3(B)]. This results in more homework for the safety-conscious AHJ.

As the proliferation of microprocessors associated with the IoT becomes more prominent in all phases of life, these devices will appear more frequently in PV systems. It may be self-monitoring inverters and charge controllers, fancy displays for the coffee table, and the microprocessors will definitely be linking the PV system to smartphones or tablets so that PV system performance can be monitored anywhere in the world. Other applications not currently envisioned will follow.

The game is afoot

There are ways to ensure high levels of productivity and efficiency in the world of PV systems. Here are a few suggestions for keeping ahead of all the burgeoning new technologies that are currently here and those that will appear in PV systems:

The jurisdiction should ensure that all permit applications for PV systems include manuals for all of the more complex electronic equipment that will be installed. That would include manuals for inverters, charge controllers, DC combiners, rapid shutdown systems, DC PV arc-fault circuit detection systems (if not included in the inverter), and any other electronic device that it is not adequately described in the Code. It would not be a bad practice to require both paper copies of these documents and electronic copies (on flash drives or CDs) that can be readily transferred to the office computer and to the tablet that is carried to the inspection site.

Tablets should have electronic copies of the permit, the schematics (system diagrams), all of the manuals associated with the system, and, of course, copies of the current (in the jurisdiction) National Electrical Code or better yet the National Electrical Code Handbook. Some aging eyes will find that smartphone screens, even the larger ones, are too small to effectively read and use this information. In fact, even the smaller tablets are a little too small to use during a field inspection, and a normal 13- to 15-inch display notebook computer could be a better solution. Small is not always beautiful.

As a final suggestion, frequent electronic contact should be maintained while in the field with the plan reviewer (assuming your jurisdiction uses plan reviewers), and electronic contact should include not only voice but also linkages from your field computer to the office field computer so questions concerning the installation can be effectively and promptly dealt with. If the jurisdiction does not use plan reviewers, then you should have access to individuals who can provide answers to questions that might arise. Those questions are usually best handled when both parties involved have access to the schematics and other technical information for the system. That indicates that all inspectors and plan reviewers should be familiar with how to transmit information from a tablet or field computer to the person who can answer those questions.

The Age of Technology is upon us. We will be immersed in it whether we like it or not. We will have no choice but to adapt our working environments to these new technologies. Continuing education is critical. It will be mandatory to use all available communication devices and advanced tools at our disposal to effectively plan, review, and inspect the current and next generation of PV systems. The safety of the public is paramount.

Find Us on Socials