EXECUTIVE SUMMARY:

Copper-clad aluminum (CCA) wire is growing in popularity across the United States, but some people may have questions about best practices for terminating these wires. This article addresses these common questions and explains how the UL 486C standard continues to provide a high margin of safety. The discussion concludes with practical guidance for inspectors and authorities having jurisdiction (AHJs) on spotting wire connectors specifically designed to provide corrosion and thermal protection in CCA installations.

WHY IS COPPER-CLAD ALUMINUM GROWING IN POPULARITY TODAY?

Copper-clad aluminum is currently experiencing a resurgence driven by modern copper shortages and the accelerating global trend toward electrification. Propelled by new electric technologies, copper prices have surged by nearly 75% since 2020 [1].

![Figure 2. Splicing using twist-on wire connectors. Image Credit: IDEAL Electrical]](https://iaeimagazine.org/wp-content/uploads/2025/08/Fig2_CCASplicing.png)

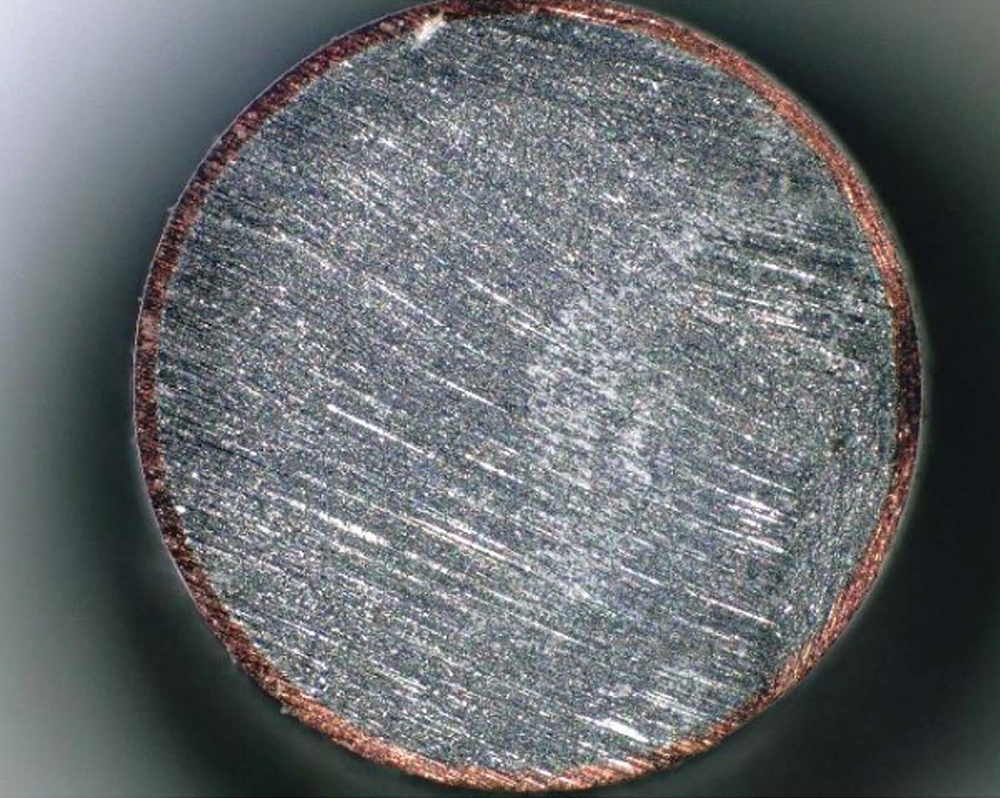

To conserve copper supplies and save costs, copper-clad aluminum wire is re-emerging as a copper wire substitute. Today’s CCA is a bimetal product composed of a core of AA-8000 series aluminum that is metallurgically bonded to an exterior coating of high-purity copper [2]. CCA is manufactured by removing the aluminum oxide layer in a controlled environment before bonding the remaining aluminum to a layer of 99.8% O2-free copper [2]. NEC guidelines require this copper layer to equate to at least 10% of the total cross-sectional area of the conductor [3].

Proponents of copper-clad aluminum emphasize both its economic and practical advantages. CCA today is consistently cheaper to purchase than copper wire. Additionally, aluminum is approximately 70% lighter than copper, making CCA easier to transport, handle, and install [4].

![Figure 3 – [Copper-clad aluminum is composed of an aluminum core surrounded by a layer of copper. Illustration Credit: IDEAL Electrical]](https://iaeimagazine.org/wp-content/uploads/2025/08/Fig3_CCAIllustration.jpg)

- How to maintain code compliance when splicing copper-clad aluminum conductors

- Address the concern of the long-term reliability of copper-clad aluminum splices

- What specialty wire connectors exist for copper-clad aluminum

HOW TO MAINTAIN CODE COMPLIANCE WHEN SPLICING CCA

The 2023 edition of the National Electric Code (NEC) covers splicing conductors in electrical installations in Section 110.14(B). This section specifically notes that “conductors shall be spliced or joined with splicing devices identified for the use…”, which typically means that such a device must be certified by an independent testing agency (i.e. UL, ETL, CSA, or another Nationally Recognized Testing Lab) and that this certification is to a UL standard or equivalent [5]. The standard used by the NEC for splicing connectors is UL486C, Splicing Wire Connectors.

UL486C testing protocols and requirements for copper-clad aluminum have remained largely unchanged since the introduction of CCA in the 1970s. The 2023 standard for splicing copper-clad aluminum conductors retained its backwards compatibility and essentially tests CCA to the same rigorous standards as pure aluminum wire. This approach is intentionally conservative and provides an extremely high margin of safety.

The combination of advanced wire connector designs with continued strict UL standards ensures that modern connector types are carefully engineered and tested to avoid the potential overheating risks once associated with aluminum. For even greater peace of mind, inspectors and AHJs can look for wire connectors that are not only UL-listed for CCA but specifically engineered to accommodate a higher level of thermal protection when connecting wires with an aluminum core. Most twist-on and push-in connectors on the market are rated for 105°C, but others are rated up to 125°C for additional thermal tolerance and enhanced confidence in installations where CCA may run hotter than pure copper wiring.

DOES A COPPER-CLAD ALUMINUM SPLICE HAVE LONG-TERM RELIABILITY?

Another question surrounding copper-clad aluminum involves galvanic corrosion, also known as bimetallic corrosion, which occurs when two dissimilar metals with different electrochemical potentials contact each other [6]. When the two metals are electrically connected via an electrolyte, the more reactive of the two metals (the anode) will begin to corrode at a faster rate [7]. The less reactive (the cathode) corrodes at a slower rate than it would otherwise.

The risk of galvanic corrosion may increase when CCA conductors are spliced in environments with high humidity or salt exposure. This is a particular concern as CCA adoption is higher in the southern and coastal regions of the United States – the exact places where humid or sea-salt air is the norm.

In the case of a twist-on connector, the method of applying a spring force to the splice connection can impact the corrosion resistance. To understand why, it helps to first understand the design and function of twist-on connectors. Twist-on connectors are the norm in US residential electrical work to splice wires together. They are typically designed with an internal, coiled steel spring that “bites” on the conductors as they twist together within the insulating outer shell. This biting is necessary to ensure a firm grip and the security of the internal metal-to-metal contact between wires.

The plating material on the coiled spring is an important design feature to consider for long-term reliability. Most twist-on wire connectors use zinc-plated steel springs, where a zinc coating is applied to the steel via an electrolyte solution during the manufacturing process [8]. This process shields the steel from exposure. The zinc serves as a sacrificial anode to the steel’s cathode, meaning the zinc corrodes first and protects the underlying steel against oxidation-related damage such as rust and corrosion.

![Figure 4 – [A visual representation of how the zinc-plated spring of a wire connector may pierce the aluminum core of a CCA conductor. Illustration Credit: IDEAL Electrical]](https://iaeimagazine.org/wp-content/uploads/2025/08/Fig4_ZincSpring.jpg)

In that scenario, the aluminum can come into direct contact with the zinc coating on the spring. Introducing a third metal (zinc) into the mix of copper and aluminum may increase the risk of galvanic corrosion around the connector area and lead to the eventual degradation of the connection, particularly in humid or salty environments.

![Figure 5 – [A visual representation of how a copper-plated spring may pierce the aluminum core of the CCA conductor but maintain copper-to-copper contact. Illustration Credit: IDEAL Electrical]](https://iaeimagazine.org/wp-content/uploads/2025/08/Fig5_CopperSpring.jpg)

![Figure 6 – [A side-by-side comparison of a twist-on wire connector with a zinc-plated spring (left) versus a copper-plated spring (right). Illustration Credit: IDEAL Electrical]](https://iaeimagazine.org/wp-content/uploads/2025/08/Fig6_SpringComparison.jpg)

WHAT WIRE CONNECTORS EXIST FOR COPPER-CLAD ALUMINUM?

Twist-On Style

Twist-on connectors remain the most popular type of connector for North American electricians. Twist-on connectors can be UL-Listed for usage with copper-clad aluminum and pass intensive testing to ensure safe usage with both copper-clad aluminum and copper conductors. Additional features, such as thermal protection up to 125°C and copper-plated springs, can provide enhanced protection against corrosion and give AHJs and inspectors added peace of mind when inspecting copper-clad aluminum terminations.

![Figure 7 – [Twist-on wire connectors with a copper-plated spring. Image Credit: IDEAL Electrical]](https://iaeimagazine.org/wp-content/uploads/2025/08/Fig7_TwisterConnector.png)

Push-In and Lever Style

Push-In and Lever Connectors can also be UL-listed for copper-clad aluminum connections. In these connectors, the CCA conductors are pressed against a conductive buss with a stainless-steel spring that provides the clamping force needed to keep the connection stable. The spring will typically not penetrate the outer copper layer of CCA in such a scenario, meaning the risk of galvanic corrosion is very low.

![Figure 8 – [Lever connectors resting on a junction box. Image Credit: IDEAL Electrical]](https://iaeimagazine.org/wp-content/uploads/2025/08/Fig8_LeverConnectors.png)

COPPER-CLAD ALUMINUM WIRE AND THE FUTURE

Copper wire will remain the backbone of electrical installations. But as copper shortages intensify, copper-clad aluminum provides a reliable and code-compliant solution when paired with the right materials and installation practices. Understanding its capabilities and the latest connector innovations is key to navigating the future of electric wiring.

REFERENCES

[1] Macrotrends. “Copper Prices – 45 Year Historical Chart.” Macrotrends. https://www.macrotrends.net/1476/copper-prices-historical-chart-data.

[2] Carr, Stephen. “The Comeback Kid: Copper-Clad Aluminum Returns as an Alternative.” Electrical Contractor Magazine, June 15, 2021. https://www.ecmag.com/magazine/articles/article-detail/your-business-comeback-kid-copper-clad-aluminum-returns-alternative.

[3] Mello, Chuck. “Important Performance Differences between Copper-Clad Aluminum and Aluminum.” IAEI Magazine, September 27, 2023. https://iaeimagazine.org/electrical-fundamentals/important-performance-differences-between-copper-clad-aluminum-and-aluminum/.

[4] Helukabel. “The Advantages of Aluminum as a Conductor Material.” Windpower Engineering & Development, June 1, 2020. https://www.windpowerengineering.com/the-advantages-of-aluminum-as-a-conductor-material/.

[5] National Fire Protection Association. NFPA 70: National Electrical Code. 2023 ed., National Fire Protection Association, 2022. Article 110.14(B).

[6] Ahmad, Zaki. “Chapter 4 – Types of Corrosion: Materials and Environments.” Principles of Corrosion Engineering and Corrosion Control, Butterworth-Heinemann, 2006, pp. 120–270. ScienceDirect, https://doi.org/10.1016/B978-075065924-6/50005-2.

[7] Komaspec. “Galvanic Corrosion: Why It Happens and How to Avoid It.” Komaspec, December 15, 2023. https://www.komaspec.com/about-us/blog/galvanic-corrosion-why-it-happens-and-how-to-avoid-it/.

[8] OneMonroe. “Zinc Plated vs. Galvanized Steel: What’s the Difference?” Monroe Engineering Blog, April 29, 2021. https://monroeengineering.com/blog/zinc-plated-vs-galvanized-steel-whats-the-difference/.

![Figure 1 – [Twist-on connectors specifically designed for copper-clad aluminum splicing. Image Credit: IDEAL Electrical]](https://iaeimagazine.org/wp-content/uploads/2025/08/Fig1_CCATwister.png)

Find Us on Socials