At some point in our life we have all heard, or perhaps stated, variations of the common phrase, “Don’t worry about things you can’t control.” With respect to workplace electrical safety, there has been little change over the past 10 years in non-fatal injuries due to electricity; and the issue isn’t a lack of awareness or intent or budget, it is a lack of effective action, it’s a lack of control!

When considering the arc flash hazard there are two questions we need to ask (the same two questions for any hazard): What is the likelihood it will happen? and How severe will the impact be?

What is the likelihood an arc flash will happen?

US Bureau of Labor Statistics indicate that there were nearly 6,000 fatal electrical injuries to workers in the US between 1992 and 2013.

BLS data also indicates there were 24,100 non-fatal electrical injuries from 2003 – 2012.

National Safety Council reported in its 2014 edition of Injury Facts that there were 961 fatal injuries from 2008 through 2010 due to exposure to electric current.

A study of electrical injuries over a 20-year period at a Texas burn center found that 40% of burns were electrical arc injuries.

How severe will the impact be?

Washington State Department of Labor and Industries “Burn Injuries Facts” reported that worker’s compensation costs for 30 serious arc flash or blast burn injuries that took place between September 2000 and December 2005 were in excess of $1.3 million.

OSHA in 2014 estimates a value of $62,500 per non-fatal injury for workers performing electric distribution work (direct costs only).

American Society of Safety Engineers estimates that indirect costs may be as much as 20 times higher than direct costs.

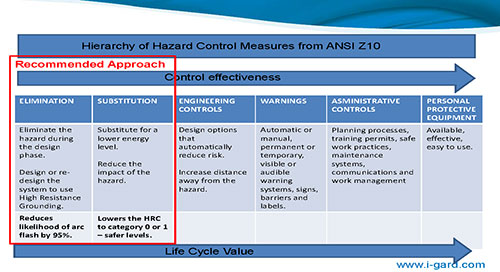

Recent changes to NFPA 70E and CSA Z462 aligning these standards with the Hierarchy of Risk Control in ANSI Z10 support the approach of directly answering and addressing the two questions.

NFPA 70E Annex 0 General Design Requirements 0.2.2 Design option decision should facilitate the ability to eliminate hazards or reduce risk by doing the following:

- Reducing the likelihood of exposure

- Reducing the magnitude or severity of exposure

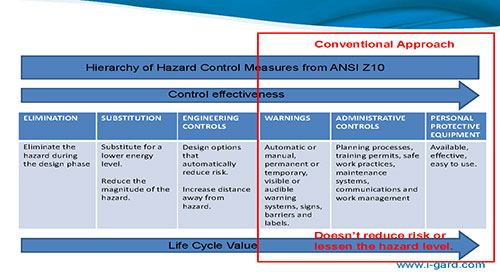

The conventional approach to workplace electrical safety has been to conduct an arc flash study after the installation is complete, calculate the incident energy levels, post warning signs and labels, provide training on safe work practices then purchase appropriately rated PPE, job done.

Posting warnings, conducting awareness training, purchasing and issuing PPE does not in any way reduce the likelihood of an arc flash event nor does it reduce the magnitude of the arc flash.

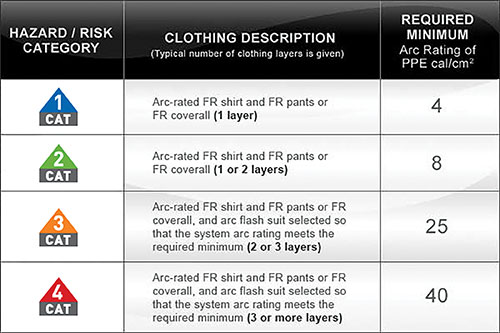

For those professing that PPE does reduce the severity of exposure, let’s pause and consider what it means to wear ARC rated clothing — there is a 50% probability of receiving second degree burns. Surely we can’t accept this is safe.

Electric arcing may produce temperatures as high as 35,000 degrees and in addition to causing severe burns there is the real possibility of hearing loss, eye injuries as well as lung damage and blast injuries from the pressure wave.

The positive news is that we can control both the likelihood of exposure as well as the magnitude of exposure with technology that is proven, readily available and already being used by enlightened companies leading the way in improving workplace electrical safety.

Control the Likelihood of Exposure

The first and obvious step is to de-energize the electric circuit before conducting any work whenever practical. If this isn’t practical or safe, then consider options that reduce the likelihood of an arc flash event occurring.

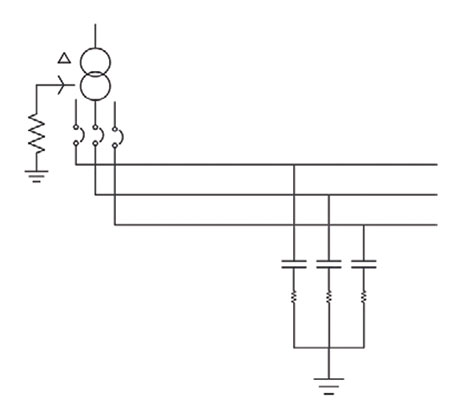

Again referring to NFPA70E, Annex 0 clause 0.2.4 3) states, “A great majority of electrical faults are of the phase-to-ground type. High-resistance grounding will insert an impedance in the ground return path and below (at 5 kV nominal or below), leaving insufficient fault energy and thereby helping reduce the arc flash hazard level.”

This is consistent with statements in the Industrial Power System Grounding Design Handbook which states that 95% of all electrical faults are phase-to-ground faults and IEEE141-1993 Recommended Practice for Electric Power Distribution for Industrial Plants 7.2.2 which states “there is no arc flash hazard (on HRG systems) as there is with solidly grounded systems, since the current is limited to approximately 5 amps.”

In FM Global Standard 5-18 Protection of Electrical Equipment Single-Phase and Other Related Faults it states “Sustained arcing faults in low voltage apparatus are often initiated by a single-phase fault to ground which results in extensive damage to switchgear and motor control centers.”

If we already understand that the vast majority of arcing faults start as single phase-to-ground faults, whether the specifics are 95% or the great majority, and that by employing High Resistance Grounding, a technology that has been around for 50 years and used in all manner of industries from petro-chemical to food processing to automotive to paper manufacturing to data centers tech, we can reduce the exposure to the hazard significantly, then the question needs to be asked why is this not the standard practice for grounding industrial facilities? HRG as a technology is recommended by IEEE, it is recognized by NFPA 70E, it is promoted by FM Global, and yet it is still not the default option when making the grounding decision for industrial facilities.

Of course High Resistance Grounding does not protect against phase-to-phase faults nor does it lower the incident energy calculation and, therefore, additional control steps must be taken to ensure an electrically safe workplace.

Reduce the Magnitude of Exposure

Again referring to NFPA70E, Annex 0 clause 0.2.4 2) states, “Arc flash relay. An arc flash relay typically uses light sensors to detect the light produced by an arc flash event. Once a certain level of light is detected the relay will issue a trip signal to an upstream overcurrent device”

An arc is developed in milliseconds and leads to the discharge of enormous amounts of energy. The energy discharged in the arc is directly proportional to the square of the short-circuit current and the time the arc takes to develop, i.e., energy = I2t

The damage resulting from the arc depends on the arcing current and time and of these two factors time is the most easily controlled and managed. Rules of thumb for different arc burning times are:

- 35 ms or less – no significant damage to persons or switchgear which can often be returned to use after checking for insulation resistance

- 100 ms – small damage to switchgear that requires cleaning and possibly some minor repair. Personnel could be at risk of injuries.

- 500 ms – catastrophic damage to equipment and personnel are likely to suffer serious injuries.

The goal of arc mitigation technology is to protect personnel and property and to effectively accomplish this we must first detect the arc and then cut the flow of current to the arc in as short a time as possible. As noted above the target is to achieve a total reaction time of 100 ms or less from detection of the arc to isolation of the circuit.

Arcs produce light at intensity levels that exceed 20,000 lux. This can be detected through special arc detection optical sensors connected to a relay system that has a typical operating time under 1ms and is the fastest arc flash detection technology currently available. The operating time is independent of the fault current magnitude since any current detector elements are used only to supervise the optical system.

With optical arc protection technology installed, the relay operating time is essentially negligible compared to the circuit breaker operating time; and the cost is fairly low since current transformers are only needed on the main breakers. If we sum up the circuit breaker operating time and the optical arc detection time, we are well below the goal of 100 ms regardless of the age and speed of the circuit breaker and have mitigated the damage to a lower and safer level.

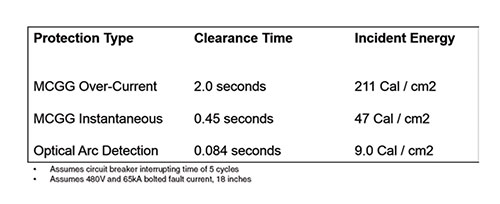

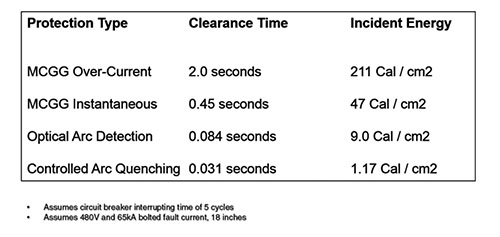

Simply changing from standard coordination and instantaneous settings on the relay (suggested by some consultants as sufficient) to a protection system which uses optical arc detection that incident energy levels are reduced substantially.

NFPA70E, Annex 0 clause 0.2.4 1) states “Energy-reducing active arc flash mitigation system. This system can reduce the arcing duration by creating a low impedance current path, located within a controlled compartment, to cause the arcing fault to transfer to the new current path, while the upstream breaker clears the circuit. The system works without compromising existing selective coordination in the electrical distribution system.”

Arc quenching has been used in Europe for more than 30 years but due to concerns over the mechanical stresses caused by initiating a 3 phase bolted fault, it is a technology yet to be fully embraced in North America.

The solution may be as simple as modifying the approach to add an impedance into the circuit so that as the arc is detected by an optical detection relay, a signal is sent to initiate the arc quenching device which closes onto a resistor placed between the quencher and each phase of the bus bar. The high levels of fault current are dampened and controlled by a resistor on each phase eliminating the concern over mechanical stresses.

The addition of arc quenching technology, controlled through an impedance could result in lowering the incident energy levels in the event of an arc flash to very low and safer levels.

A safer workplace can easily be achieved if we simply change our approach by conducting risk assessment during the design phase of a project. Then we move forward and conduct the arc flash study, define the risk, and quantify the hazard.

Next we employ elimination technology (High Resistance Grounding) then technology to lower the hazard level (arc flash detection relay or active arc mitigation system), redo the study, re-quantify the risk and the hazard (which will be much lower), then post the warning labels, purchase the PPE conduct the training.

A workplace where the likelihood of an arc flash is 95% lower, where the impact of an arc flash can be minimized to very low levels is possible today—we just need to take control and use technology already available.

Find Us on Socials