Two types of ground-fault protection are required by the Code: ground-fault circuit interrupter protection (GFCI) and ground-fault protection of equipment (GFPE). A ground-fault circuit interrupter is intended to protect persons against shock and electrocution. As implied by its name, ground-fault protection of equipment protects equipment from damaging line-to-ground faults. More detailed definitions of these devices are found in Article 100:

Ground-Fault Circuit Interrupter.A device intended for the protection of personnel that functions to de-energize a circuit or portion thereof within an established period of time when a current to ground exceeds some predetermined value that is less than that required to operate the overcurrent device of the supply circuit.1

Ground-Fault Protection of Equipment.A system intended to provide protection of equipment from damaging line-to-ground currents by operating a disconnecting means to open all ungrounded conductors of the faulted circuit. This protection is provided at current levels less than those required to protect conductors from damage through the operation of a supply circuit overcurrent device.2

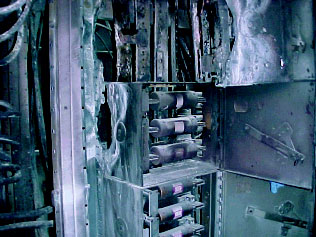

Figure 1. Zero frequence ground system

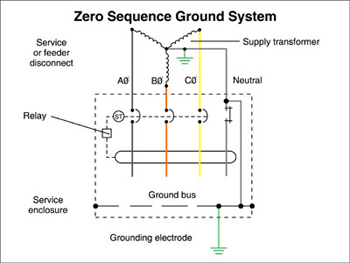

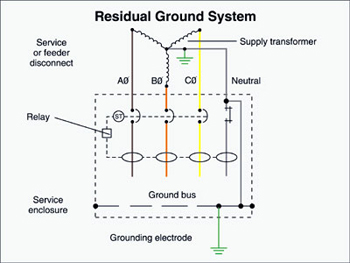

There are essentially three types of ground-fault protection schemes for equipment utilized in the electrical industry. The zero sequence, the residual, and the neutral ground strap types. (See figures 1, 2, and 3.) The residual and zero sequence work to measure balanced current flow and will operate or trip and determined setting levels if current does not return through the current transformer in balanced fashion. The neutral ground strap type of GFP operates when ground fault current flows over the main bonding jumper in the equipment at a predetermined current pickup level. The tripping bands on this equipment are set at predetermined levels below the maximum levels specified in Section 230-95(a). Performance tests require an actual current injection through the current transformer (CT) and the time and current levels are both measured as part of this test. If the GFPE operates at less than the maximum ampere value and within the time required by 230-95, then it is a successful performance test and meets the requirements of Section 230-95. Many designers or engineers recommend the settings for the GFP equipment based on the conditions of use. Where multiple levels of ground-fault protection are installed, coordination of the devices is required.

Figure 2. Residual ground system

Requirements for GFPE

Although requirements for GFCIs, found not only in NEC Section 210-8 but also in many other articles and sections, have expanded greatly in the past few code cycles, this article will focus on ground-fault protection of equipment. While several articles contain GFPE requirements, one should begin research in Article 230 for services. “Ground-fault protection of equipment shall be provided for solidly grounded wye electrical services of more than 150 volts to ground, but not exceeding 600 volts phase-to-phase for each service disconnect rated 1000 amperes or more.”3 This refers to the rating of the disconnecting means, not to the rating of a fuse of a lesser rating, which may be inserted into a disconnecting means rated at 1000 amperes or greater.

Two exceptions from the requirement of providing ground-fault protection of equipment exist: first, “for a continuous industrial process where a nonorderly shutdown would introduce additional or increased hazards,”4 and, second, for fire pumps. The language in the exceptions is mandatory, indicating that the ground-fault protection provisions of Section 230-95 shall not apply to these particular loads. They may be supplied by standard overcurrent protective devices because of the increased hazards that might be created by the operation of the ground-fault protective devices.

Figure 3. Neutral ground strap

Section 215-10 requires “each feeder disconnect rated 1000 amperes or more and installed on solidly grounded wye electrical systems of more than 150 volts to ground, but not exceeding 600 volts phase-to-phase,” to “be provided with ground-fault protection of equipment in accordance with the provisions of Section 230-95.”5 There are three exceptions to this rule: Exceptions 1 and 2 are identical to the exceptions in Section 230-95 concerning GFPEs for service disconnects; Exception 3 states that the provisions of Section 215-10 “shall not apply if ground-fault protection of equipment is provided” in the service disconnect “on the supply side of the feeder.”6

Photo 2

Another section that requires ground-fault equipment protection is 240-13:

Ground-fault protection of equipment shall be provided in accordance with the provisions of Section 230-95 for solidly grounded wye electrical systems of more than 150 volts to ground but not exceeding 600 volts phase-to-phase for each individual device used as a building or structure main disconnecting means rated 1000 amperes or more.

The provisions of this section shall not apply to the disconnecting means for the following:

(1) Continuous industrial processes where a nonorderly shutdown will introduce additional or increase hazards

(2) Installations where ground-fault protection is provided by other requirements for services or feeders

(3) Fire pumps installed in accordance with Article 6959

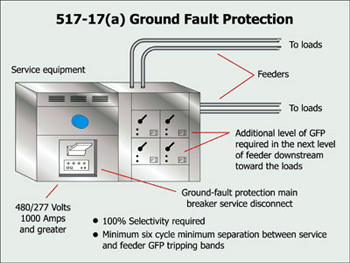

Figure 4. Ground fault protection

There are other requirements for GFPE found in Section 517-17 and specifically when the service disconnect for the healthcare facility is equipped with a GFP main service disconnect. “Where ground-fault protection is provided for operation of the service disconnecting means or feeder disconnecting means as specified by Sections 230-95 or 215-10, an additional step of ground-fault protection shall be provided in the next level of feeder disconnecting means downstream toward the load. Such protection shall consist of overcurrent devices and current transformers or other equivalent protective equipment that shall cause the feeder disconnecting means to open.”8 This protection is required to localize the fault and prevent the entire electrical service from being interrupted by the tripping of the service ground-fault protective device. This additional level of protection downstream of the service disconnect is to assure continuity of service to the health care facility and to trip out only the load that is in trouble. The devices are to be fully selective and have a minimum six-cycle separation between the tripping bands of the feeder and the service. These devices are required to be performance tested when first installed on site in accordance with Section 230-95(c), and the tripping band and six-cycle separation should be verified during the test. (See figure 4.)

Photo 3

Each of the above sections requires that where the ground-fault protection equipment is installed, it must meet the provisions of Section 230-95. This includes both setting and performance testing provisions.

GFPE settings

Minimum settings are required for ground-fault protection devices specified in this section. “The maximum setting of the ground-fault protection system shall be 1200 amperes, and the maximum time-delay shall be one second for ground-fault currents equal to or greater than 3000 amperes.

“If a switch and fuse combination is used, the fuses employed shall be capable of interrupting any current higher than the interrupting capacity of the switch during a time when the ground-fault protective system will not cause the switch to open.”9 (See photo 3, photo 4, photo 5, and photo 6.)

Performance testing is required

Photo 4

Section 230-95 requires that each ground-fault protective device “be performance tested when first installed on site”10 in accordance with the manufacturer’s installation and testing instructions. Section 110-3(b) also requires this for listed equipment. Many qualified electrical testing organizations are available to perform these tests. “A written record of” the performance test of the ground-fault protective device “shall be made available to the authority having jurisdiction.”11 Many jurisdictions require these test results or records to verify compliance with Section 230-95(a) prior to issuing a utility power clearance to energize the service equipment. Many also require that the testing be performed by an independent qualified testing organization that is equipped to perform such tests.

Photo 5

This is much more than a push-button test. These tests include a removal of the neutral disconnect links to verify that no ground connections to the grounded conductor are downstream of the main bonding jumper, as required by Section 250-24(a)(5). A current is injected through the ground-fault protection equipment zero-sequence current transformer (CT) to simulate a ground fault. The amount of pick-up amperes and the time it took to trip the device are also measured. This data is then written in a record, which Section 230-95(c) requires to be made available to the authority having jurisdiction.

FPN No. 1 of Section 230-95 emphasizes that “Ground-fault protection that functions to open the service disconnect will afford no protection from faults on the line side of the protective element. It serves only to limit damage to conductors and equipment on the load side in the event of an arcing ground fault on the load side of the protective element.”12

Summary

The NEC requires ground-fault protection for service and feeder disconnects that are rated at over 150 volts to ground and not over 600 volts phase-to-phase and have an ampere rating of 1000 amperes or greater. This protection is required to help protect equipment from damaging line-to-ground faults that can be destructive and self-sustaining. Ground-faults at these voltage levels produce an ionized gas which is conductive and, often times, can turn from a line-to-ground fault into a line-to-line short circuit, manifesting into major damage and sometimes leading to the total destruction of the equipment. (See photo 1.)

Photo 6

Performance testing is required in Section 230-95(c) and is not just a button test or a test at the place of manufacture. Ground-fault protection equipment is required to be tested when it is first installed on site. Testing organizations and equipment are available for this performance testing. Results are to be reported in the form of a written record, which is then made available to the authority having jurisdiction. Local amendments to the minimum requirements set forth in the National Electrical Code may be required. Therefore, one should always consult the local authority having jurisdiction as to any additional requirements over and beyond the rules in the NEC.

1 NFPA 70, National Electrical Code, 1999 Edition, (Quincy, MA: National Fire Protection Association, 1998), p. 69.

2 NFPA 70, p. 22.

3 Ibid

4 NFPA 70, p. 68.

5 NFPA 70, p 69.

6 NFPA 70, p. 47.

7 Ibid

8 NFPA 70, p. 73.

9 NFPA 70, p. 362.

10 NFPA 70, p 69.

11 Ibid

12 Ibid

Find Us on Socials