Yet another swimming season has begun, and manmade dangers exist that have gone on record as taking the most precious of our family members, those whom we would give our lives to protect. Children love to swim, as do many grown-ups, as well. Unfortunately, electricity has been the cause of deaths in and around marinas and boatyards. As electrical professionals, we can make a difference. Whether you are an electrical inspector, installer, manufacturer, or other, we can make a difference together. I hope that this article will stimulate thought around electricity and those places where we dock and plug in boats. We will have a discussion around the potential risks of swimming in and around these areas, and how the NEC took a step forward to make a difference; but as you will see, we have a lot of work to do. Many boat docks and marinas exist across the United States that need our help. There are technical challenges ahead of us that deserve the greatest minds that our industry can supply.

Photo 1. Family events bring us closer to where water and electricity work in close proximity. As electrical professionals involved with these areas, we can help ensure they are electrically safe.

The Problem

Those locations where we dock our boats, large and small, present challenges for the electrical distribution system that is utilized to not only supply power for lights and tools but also to power the boat itself while docked. In addition to the presence of water and the elements surrounding it, electrical equipment can find itself in close proximity to fueling stations and on a structure that rises and sways with the waves. This mix can spell disaster for an electrical system that is not maintained or designed correctly. The electrical systems of concern are not only those on the docks or slips but also those on the boats that may “plug-in” to shore power while docked.

This problem is all too real.

Ten-year-old Noah and his eleven-year-old friend Nate died in the afternoon back in 2012 while swimming during a July 4th event. Noah died from the initial shock that he received, but Nate died the following day after being placed on life support.

Eighteen-year-old Michael jumped into the body of water at the end of a dock and immediately began to struggle due to electric shock. He struggled to swim back but when he grabbed what he thought was safety, a handrail, he was electrocuted. When others tried to save him, they immediately felt the current but luckily, no one else succumbed to the electricity that was flowing.

It was another boy named Lucas that got a gentleman I work with concerned and ultimately involved with changes in the National Electrical Code. On August 1, 1999, Lucas was with his parents at a boat dock and decided to go swimming with a group of his friends. Geared with their life jackets, they loved to enter the water at one end of the dock and ride the current downstream to the other end of the dock. To an eight-year-old boy, I am sure that was awesome. Suddenly, Lucas wanted to get out and so he called to his mother, and as he swam close to the ladder, he turned on his back gasping for air. His life jacket was doing its job and keeping his head out of the water. Lucas was not touching anything metal or any structure; he was just floating in the water. Still floating downstream others tried to swim in to help him, but they too felt a tingling sensation as they swam closer. Lucas’ mother dove into the water and took ahold of him. She immediately felt the effects of a strong electrical current that caused her to struggle to move as well; she was paralyzed by the electricity. She was saved, in turn, by others on the dock who pulled her to an area where she no longer felt the effects of the electrical current. On August 1, 1999, Lucas lost his life.

I encourage you to take a moment and listen to his story. Ask yourself what my friend Joe asked me: What can we do about this problem? (http://www.abycinc.org/whyabyc/safety.cfm and http://www.energyedcouncil.org/TLC_2014.html )

Unfortunately, these are not isolated cases. When a person succumbs to electricity while swimming, it is referred to as electric shock drowning (ESD). In putting this article together, I was not able to secure third-party statistics on this problem, but I found many cases documented in newspapers and on websites telling the story of children who died while swimming around boatyards and marinas. I have found websites and nonprofit organizations that are very concerned with this issue, as well. In many cases, the deaths that I read about could have been categorized as a drowning. Although that may be accurate in how the person died, the cause of the drowning just may have been electrical current. Lucas was wearing his life jacket. Had he not been, his death might have been categorized as a drowning. In fact, it was at first classified as a drowning until his father pressed the issue and discovered the real cause of his son’s death was electric shock drowning. The fact is that ESD happens too often, and we can do something about it.

When we hear of reports like those above, the immediate image that may come to your mind are those large marinas where many boats are present; however, smaller privately owned boat docks cannot be ignored. There are more than 8,000 large organized marinas across the U.S. and there many more that are privately owned.

Photo 2. Boats will obtain power from the shore. Conductors betwen shore equipment and the boat are frequently found in disrepair. The wiring on the boat itself can be in disrepair. This and all damage can create a hazard for the entire dock.

Fresh Water vs. Salt Water

As we all know, electricity and water do not mix and when they do by mistake, most often nothing good can come of it. Energized electrical currents will find their way back to the source through water. Water has a resistance usually referred to as “conductivity.” The conductivity of water is measured by applying a voltage between two electrodes and measuring the voltage drop between the probes. The drop in voltage is used to calculate the resistance. The resistance is then converted to conductivity.

Recall with me if you will some basic classes that you may have had years ago. Conductivity is calculated as

Conductivity = 1/Resistance (Mho)

Conductivity is the reciprocal to resistance and is presented as conductance over a specified distance, “Mho/cm.” Because the numbers are very small when it comes to the conductivity of water, you will see the terms “mili-” or “micro-” associated with the measurement of conductivity. Because conductivity is the reciprocal of resistance, the larger the conductivity, the smaller the resistance is. For example,

10 Ohms = (1 / 10) Mhos = 0.1 Mhos

0.10 Ohms = (1 / 0.10) Mhos = 10 Mhos

The conductivity of water is not something that I am going to dig into as a part of this article, but I can share with you what I have learned. First of all, it is not simple but rather quite complex and dependent upon what is in the water that you are addressing. The table below was obtained from the state of California, “The Clean Water Team Guidance Compendium for Watershed Monitoring and Assessment State Water Resources Control Board” (http://www.waterboards.ca.gov/water_issues/programs/swamp/docs/cwt/guidance/3130en.pdf). Take into consideration that larger conductivity numbers translate into smaller resistance values. The above-mentioned reference gave the following guidance.

| Water Type | Conductivity (umhos/cm) |

| Distilled water | 0.5 – 3.0 |

| Melted snow | 2 – 42 |

| Potable water in U.S. | 30 – 1500 |

| Freshwater streams | 100 – 2000 |

The more impurities you put in water, the more conductive it becomes. Saltwater offers a good conductive solution. Seawater, for example, can be upwards of 55,000 umhos/cm. When the resistance of a fluid around an object is less than the resistance of the object itself, current will take the path of least resistance—not through the object. When a human body is in fresh water that is energized because the fresh water has a high resistance and the human body offers a lower resistance, a potential can be measured and, hence, current can flow causing electrocution. This is why a boy like Lucas was electrocuted even though he was suspended in a body of water and not touching an energized piece of equipment or structure. Now, this does not mean that there is no electrical hazard for saltwater applications. As I noted above, the conductivity of water is not a simple matter. Many things can impact conductivity.

Hazards exist in many locations even beyond marinas and boat yards. Any location where water and electricity are in close proximity to each other poses a risk. A pond on a golf course, for example, may have employed pumps for fountain-like attractions. Fountains and even irrigation pumps are prime examples of where water can become energized.

Codes and Standards

Two key documents from an electrical perspective command your attention when addressing marinas and boatyards. NFPA 70, the National Electrical Code and NFPA 303, Fire Protection Standard for Marinas and Boatyards. I am not going to dig into other standards, but I will at least mention that the American Boat and Yacht Council (ABYC) offers safety standards focused primarily, if not entirely, on the boat.

Let’s begin with NFPA 303 (www.nfpa.org/303) as this document is the standard for marinas and boatyards and “. . . applies to the construction and operation of marinas, boatyards, yacht clubs, boat condominiums, docking facilities associated with residential condominiums, multiple-docking facilities at multiple-family residences, and all associated piers, docks, and floats.” This document addresses management, electrical wiring and equipment, fire protection, berthing and storage, and operational hazards. Reading through NFPA 303 reveals many types of hazards that demand attention at these types of locations. This document raised my awareness of the need for routine inspections at marinas, and that many of these boat docks include hazardous locations. Chapter 5 addresses “Electrical Wiring and Equipment.” It offers additional requirements to the NEC and specifically calls out Article 555, which is titled, “Marinas and Boatyards.” If you are involved with marinas and boatyards or anything similar, NFPA 303 is a must for your library.

When it comes to the National Electrical Code, chapters 1 – 4 apply generally, and chapters 5, 6 and 7 apply to special occupancies supplementing chapters 1 through 4. Chapter 5 is where we find Article 555 for Marinas and Boatyards. Article 555 was first introduced in NEC-1968 as “Boat Harbor Wiring” and consisted of Sections 555-1 through 555-6, taking up just about a half of a page. This article has seen attention since then, and NEC-2011 did not disappoint. It was during the 2011 code cycle that Section 555.3, “Ground-Fault Protection” was added.

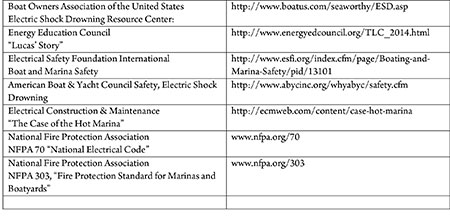

Figure 2. References

This new section of the NEC began with ROP 19-252 as a requirement for GFCI protection on the main or feeder circuits in a marina. ROP 19-252 proposed the GFCI protection language but was rejected by Code-making Panel 19 with the following panel statement.

“Although the recommendation has merit, additional technical substantiation and product development is needed. The use of GFCI for personnel protection is not prohibited by the current code. The proposed requirement for GFCI personnel protection (6 mA leakage) is not practical for all marina environments.”

A companion proposal made for Article 553, Floating Buildings, met a similar fate. The meat of this rejection was in the last sentence. During this cycle, many in the industry debated this topic; and I could argue that these debates brought to light the need for a change in marinas and boatyards even more so than it already was. The main concern was the realization that many boatyards have a considerable amount of leakage current, and it adds up in the main and/or feeder circuits.

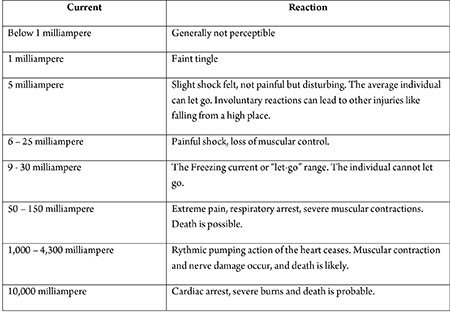

Figure 1. Effect of Current-Reaction

To address the concerns of the panel, the submitter crafted language that led to a requirement for equipment level ground-fault protection in the main, feeder, or branch circuits. An upper limit of 100 mA was established which removed the problem of product availability and enough concern about unwanted tripping for this comment to pass. It was a decent compromise because even equipment level ground-fault protection will detect, at a minimum, a problem in the wiring infrastructure that can lead to an electrocution. This language is not perfect, but it is a step in the right direction and achieves a goal of stimulating discussions that need to happen for progress in safety to occur. There is still room for improvement and development of technology that will prevent electrocution of a person suspended in water in and around a boat dock.

Ground Fault Protection

To get electrocuted three things are important: 1) the amount of current and 2) the path it takes through the body and 3) the amount of time the current is permitted to flow. A GFCI device does not know the path that current takes when it leaves the circuit, it simply detects the amount of current that is not returning over the neutral conductor and opens the circuit. UL 943 governs the response of a GFCI device. A GFCI device is designed to not trip for currents less than 4 mA and to always trip for currents above 6 mA.

To understand what this means to a person, the following table is used by many documents to describe the effect of current.

Lucas’ brother tried to swim and rescue Lucas when he was obviously in trouble. As he swam closer, he described what he felt; his first sensation was a pulsing in the water that to him was terribly strange; and as he swam closer, he described a tingling feeling on his body that caused him to back off immediately. As per the above table, it is around 1milliampere that we will begin to feel tingling.

The language of Section 555.3, Ground-Fault Protection, permits the use of a GFCI where product is available. On feeder circuits or at the main, any ground fault device that trips on current less than or equal to 100 mA would be permissible. A device that trips at these values greater than 6 mA but less than 100 mA will not prevent electrocution. Leakage currents that these devices detect are signs of disrepair. This is an early indicator, but there is still work to be done.

Photo 3. Power pedestals provide power for use by boat owners and those on shore. Inspect this equipment periodically to ensure it is free from damage and illegal field modification.

Moving Forward

At a bare minimum, we must recognize the need to inspect and hold our boat docks and marinas to high standards. This does not mean just those that are publically owned but also those that are privately owned. There are many precautions we can take, and technology is readily available to take us closer to mitigating occurrences of ESD. NFPA 303 tells us we need to perform routine inspections of the equipment in and around these boat docks. We need to address any hazardous location appropriately, and NFPA 70 now tells us that we not only have to provide GFCI protection for all 120V, 15A and 20A circuits in and around boat docks, but we also have to provide a level of ground fault on mains, feeders or branch circuits beyond these currents and voltages.

The Fire Protection Research Foundation (www.nfpa.org/research) has initiated a project to begin an effort to address the problem in and around marinas and boatyards and more. The title of this project is “Assessment of Hazardous Voltage/Current in Marinas, Boatyards and Floating Buildings.” The goal of the project is “. . . to identify and summarize available information that clarifies the problem of hazardous voltage/current in marinas, boatyards and floating buildings, and to develop a mitigation strategy to address identified hazards.” This type of attention can save lives. These efforts will make a difference.

Closing Remarks

Those who are involved or will be getting involved with marinas and boatyards must ensure they are qualified to do so. These locations can range from very simple to very complex bringing in many aspects of the NEC and other standards to ensure a safe installation. Periodic inspections are a must for those who circumvent safety to get a job done. Safety on a boat dock can change at any time so we must instill procedures to maintain the electrical infrastructure and keep it safe as time passes. These locations are harsh and very rough on electrical equipment.

Together we can make a difference.

As always, keep safety at the top of your list and ensure you and those around you live to see another day.

Find Us on Socials