The Electrical Utility Risk Assessment Practice #250 is a best practice developed to define and evaluate the risk associated with working with medium—and high-voltage activities in the DOE complex.

Why was the best practice used? Electrical utility tasks involve high-hazard activities where the risk is often undefined. This best practice is developed to assess the risk of high hazard activities to assist DOE contractors in implementing controls to reduce risk. These controls follow the hierarchy of control methods defined in ISM and NFPA 70E. Additionally, human performance indicators and tools are utilized to address the human element of risk.

What are the benefits of the best practice? Using this best practice will allow DOE contractors to evaluate their high-hazard tasks in order to reduce risk to an acceptable level. This best practice provides a common, systematic approach for all DOE contractors to evaluate their Electrical Utility Operations. Making use of this systematic approach will enable each site to implement adequate work control to ensure the proper rigor, staffing, and work method controls are in place and implemented for appropriate high-risk activities.

What are the benefits of the best practice? Using this best practice will allow DOE contractors to evaluate their high-hazard tasks in order to reduce risk to an acceptable level. This best practice provides a common, systematic approach for all DOE contractors to evaluate their Electrical Utility Operations. Making use of this systematic approach will enable each site to implement adequate work control to ensure the proper rigor, staffing, and work method controls are in place and implemented for appropriate high-risk activities.

What problems/issues were associated with the best practice? NFPA 70E requires electrical activities to go through a risk assessment process; however, Electrical Utility Operations are exempted from those requirements. Electrical Utility Operations are among the highest hazard activities performed on DOE sites. This is developed to evaluate the risk of EUO high hazard tasks and provide methods for implementing risk control.

How was the success of the Best Practice measured? This best practice was developed using several experienced EUO personnel from multiple DOE sites.

Description of process experience using the Best Practice: The known operating experience to date is limited to a few sites associated with the development of this product that have successfully employed some or all of the components of this Best Practice at their respective sites.

Scope and Applicability

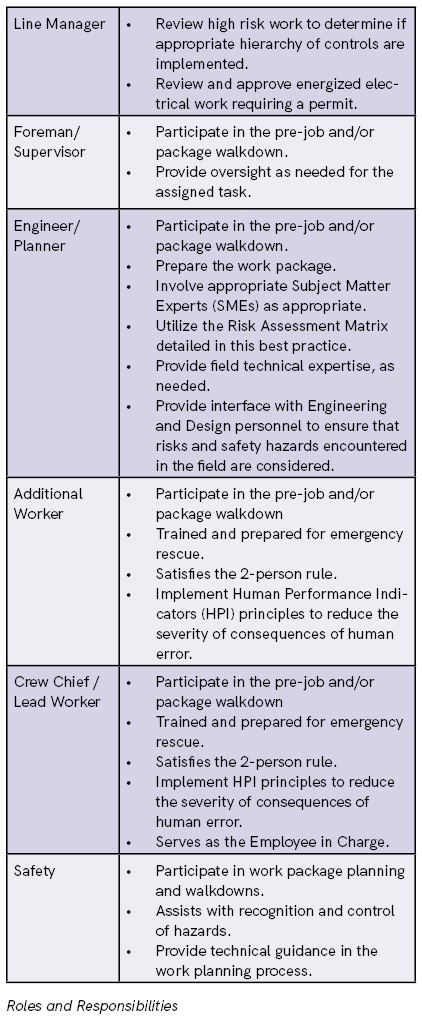

The best practice applies to Electrical Utility Operations (EUO) at United States Department of Energy (DOE) sites. The risk assessment herein covers the scope of high hazard electrical work not covered by NFPA 70E Electrical Safety in the Workplace. [See Roles and Responsibilities]

Note: The information provided is intended to be modified by each facility to meet their applicable mission, roles, staffing, and tasks.

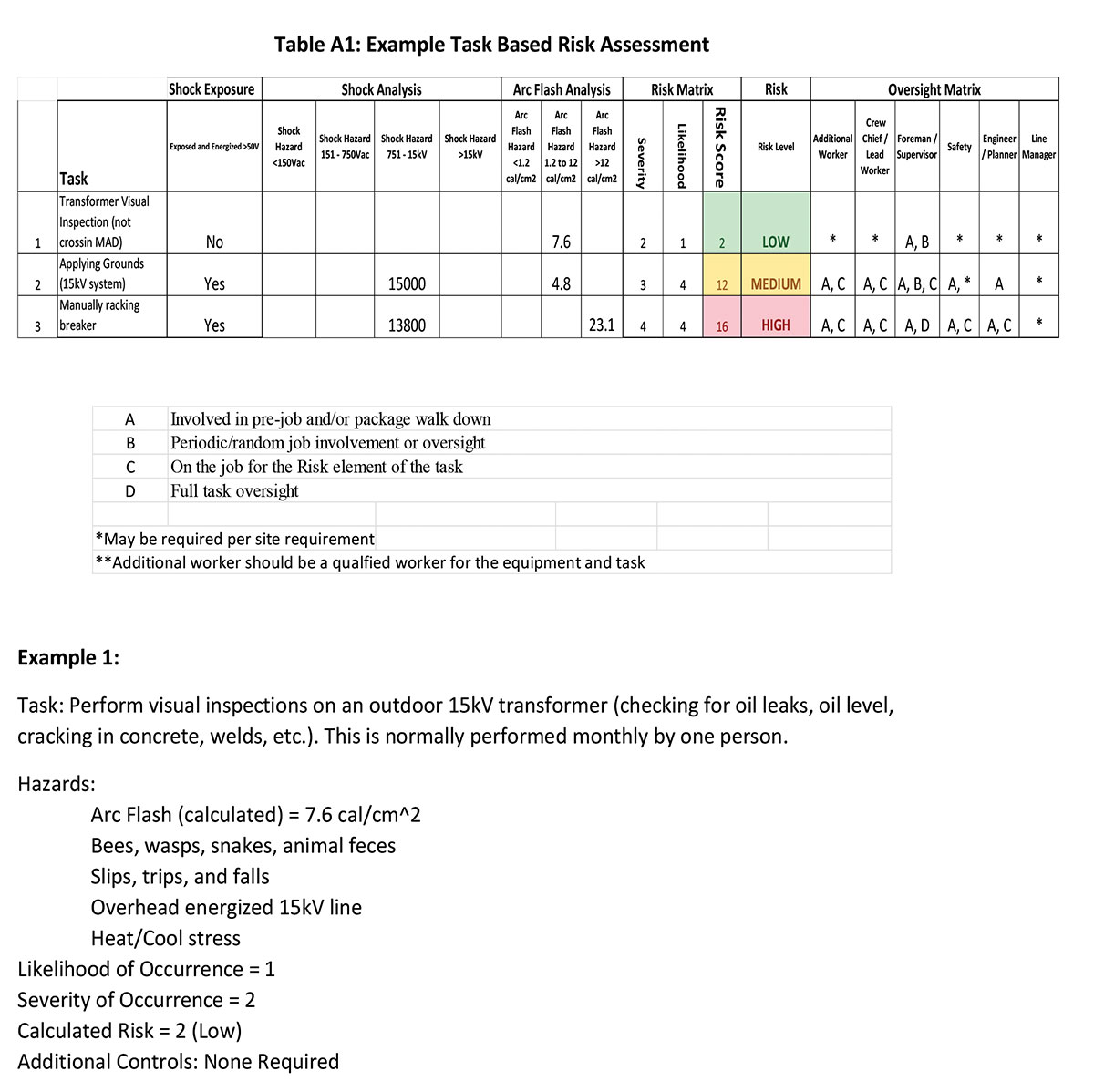

Performing a Risk Assessment for High Hazard Electrical Utility Operation Tasks:

Identify the Scope and Hazards

- Identify the scope of work that will be assessed for risks.

- Perform a planning walk-down and/or table-top to identify hazards (shock, arc flash, environmental, chemical exposure, work from heights, etc.) associated with the task(s). Involve appropriate SMEs, as needed.

- Identify possible situations that could develop into accidents during work task, considering serious/high-impact, but credible, scenarios.

Categorization

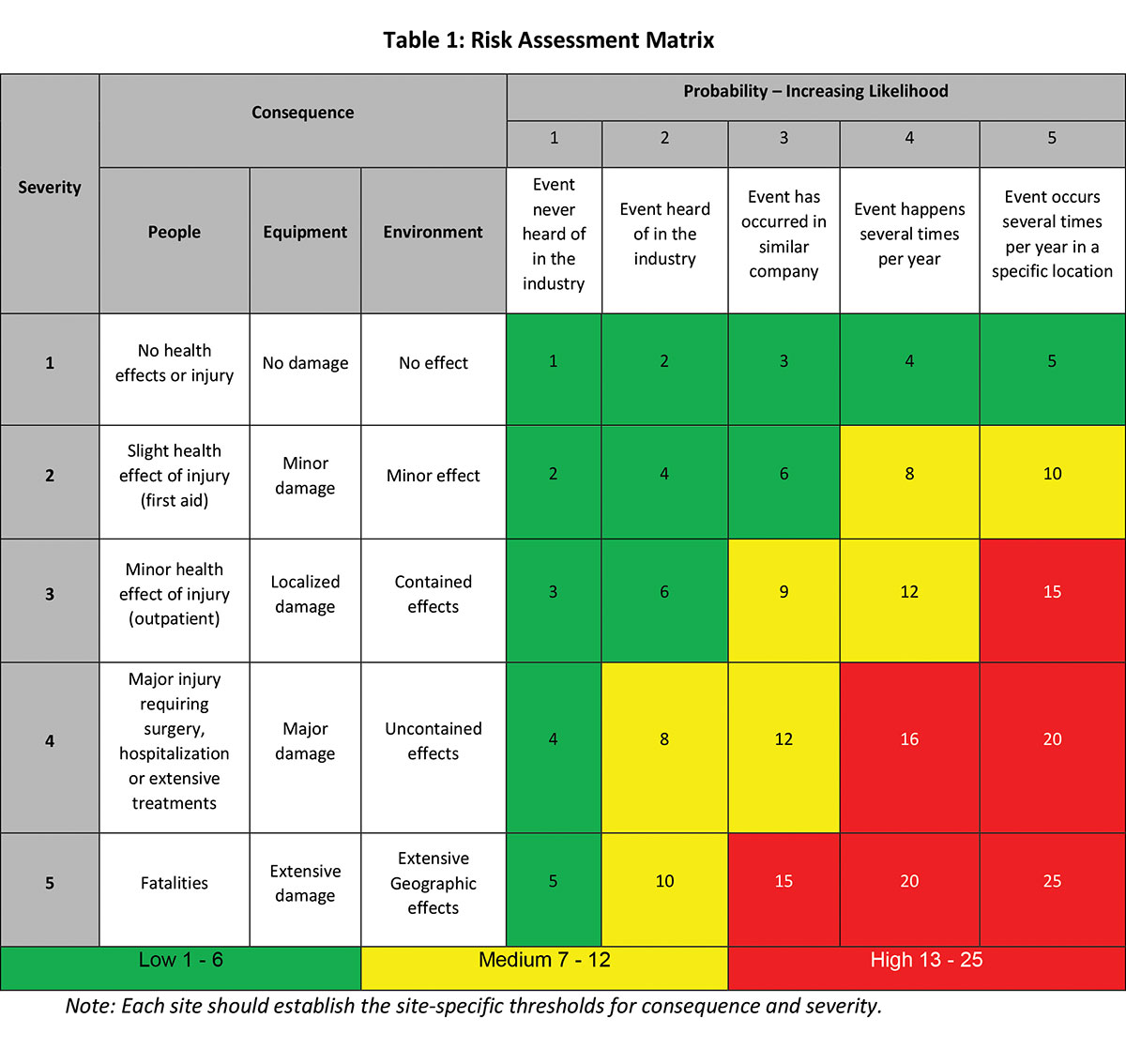

- Using Table 1, organize scenarios into one of the following three categories according to what would be impacted by an accident: More than one may apply.

- People

- Equipment – including critical system operational function

- Environment

Assign Consequences and Severity

- Review the Consequence and Severity Definition of Scale.

- Select the most appropriate severity using:

- Site-documented events

- DOE documented events

- Electrical Utility industry documented events.

- Document the severity for the selected scenario.

Estimate Likelihood

- Select the most appropriate likelihood using:

- Site-documented events

- DOE documented events

- Electrical Utility industry documented events.

- Document the likelihood for the selected scenario.

Utilize the Risk Assessment Matrix and Implementing Controls

- Calculate risk. Risk = Severity × Likelihood.

Example: Environmental Release that has previously occurred at the facility

Severity (4) × Likelihood (3) = Total Risk (12) - Record the risk score of current work practice controls.

- If the evaluated risk is unacceptable, utilize the hierarchy of risk control methods to implement additional controls to reduce risk. Examples of hierarchy of risk control methods are below:

- Elimination

- Conductors and/or circuit parts are de-energized, have a visible open, and are equipotentially grounded

- Substitution

- Remote device operation

- Reduce energy to below hazardous energy thresholds

- Engineering

- Adjusting relay protection

- Arc flash reduction maintenance switch

Controls below this should have redundancy in implementation

Consider utilizing HPI tools/concepts

- Awareness

- Signs, barricades, barriers

- Labels

- Attendant/Spotter

- Administrative

- 3-part communication for switching

- Training

- Procedures

- Personal Protective Equipment (PPE)

- Shock and arc flash PPE

Human Performance

- Utilize site HPI program to provide an avenue for worker and work evolution success.

- See NFPA 70E (2018) and DOE HPI Handbook Vol. 1 and 2.

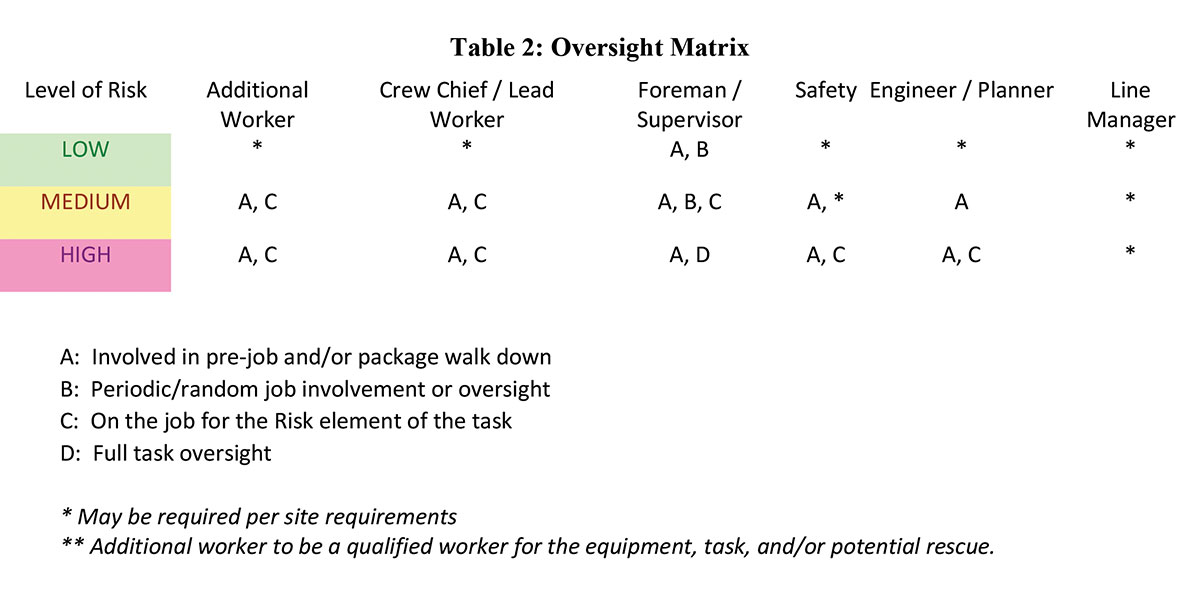

Oversight Matrix

- Implement Oversight Matrix per determined level of risk.

References

- OSHA 29 CFR 1910.269, Electric Power Generation, Transmission, and Distribution

- DOE Human Performance Improvement (HPI) Handbook Volumes I & II

- NFPA 70E (2018) Standard for Electrical Safety in the Workplace

- NFPA 70E (2018) Standard for Electrical Safety in the Workplace

ABOUT THE SAFETY WORKING GROUP

The Safety Working Group (SWG) is chartered to support member companies in attaining and maintaining the highest levels and regulatory performance in the operation of DOE/NNSA facilities/projects. The SWG achieves this by:

- Advocating for strong, effective implementation of Integrated Safety Management across departmental activities.

- Seeking out, developing, and promoting best management and operating practices.

- Facilitating the exchange of operating experiences and information on safety/regulatory programs and their effectiveness and designing studies and developing position and technical papers to inform DOE/NNSA regulations and directives processes where appropriate.

- Providing DOE/NNSA and member companies with access to a network of subject matter experts.

- Assisting member companies in cost effective implemetnation of effective safety and regulatory programs through peer reviews and consultations.

- Arranging for training, exercises and/or awareness workshops to enhance the competency of safety professionals.

Find Us on Socials