A new safety standard in Canada for high-density polyethylene conduit (Type HDPE conduit) and HDPE conduit with conductors has been developed known as CSA Standard C22.2 No 327 HDPE conduit, conductors in conduit, and fittings. This new standard is scheduled to be published early this year.

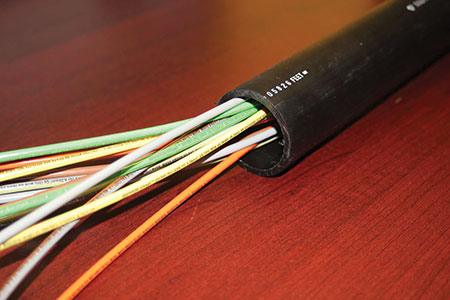

High-density polyethylene conduit (Type HDPE conduit) is defined as a non-metallic, coil-able, smooth-wall conduit of high density polyethylene for direct burial or encasement in concrete or masonry. This type of conduit will be available with or without conductors or cables already installed in the conduit.

The scope of this new standard will cover HDPE (high-density polyethylene) conduit without conductors, and, HDPE conduit with conductors, and fittings, intended to be installed in ordinary (non-hazardous) locations, and intended for direct burial or encasement in concrete or masonry. The seed document for the standard was based on CSA Standards C22.2 No 211.0 General Requirements and Methods of Testing for Nonmetallic Conduit and C22.2 No 51 Armoured Cables.

The compound used for HDPE is required to have a specific cell classification to meet or exceed the physical properties specified in ASTM D3350. The conduit diameter and wall thickness is specified in Table 1 of the standard. This typical diameter can be used to establish conduit fill and is intended to create the percentage of conduit fill data found in the appropriate Table 9 of the Canadian Electrical Code.

To align this new standard with the existing requirements in the CE Code, the maximum number of conductors in one conduit is limited to 200. In addition the maximum number of conductors or multi-conductor cables in one conduit shall be such that the conductors or cables and their coverings will not result in a greater conduit fill than that specified in Table 8 of CE Code.

Conductors or cables rated less than 5 kV, used in HDPE conduit, are required to be suitable for 90°C and have moisture resistant insulation in accordance with Table 19 of the CE Code. Cables rated 5 kV and higher are mandated to meet the requirements of CSA standards C68.5 or CSA C68.10.

The colour coding of conductor requirements in the standard are similar to the provisions of the CSA Standard C22.2 No 51 Armoured Cables. As an example, insulated bonding conductor used in HDPE conduits with conductors is required to be coloured green or green with yellow stripes.

Where bonding conductors are mandated, the size of the bonding conductor is required to be in accordance with Table 16A of the CE Code.

The markings on HDPE conduit are required to include:

- the manufacturer’s name, trademark, or other recognized symbol of identification;

- “HDPE CONDUIT 90*C”;

- the metric designator and trade size;

- the date of manufacture or the manufacturer’s code;

- “CSA C22.2 No. 327”;

- “maximum pulling tension _____N”

In addition to the marking mandated for HDPE conduit, HDPE conduit with conductors is required to include:

- the trade size and number of conductors;

- the maximum rated voltage;

- for aluminum conductors, “ALUMINUM”, “ALUM”, or “AL”. “ACM” may also be marked;

- for single-conductor cables, “CONCENTRIC CONDUCTOR TO BE USED ONLY FOR BONDING”;

- for compact strand conductors, “COMPACT STRAND”;

- for HDPE conduits containing 2-conductor with red and black insulated conductors, “RED — BLACK CONDUCTORS”;

- for HDPE conduits containing 3-conductor with red, black, and blue conductors, “RED — BLACK — BLUE CONDUCTORS”;

- the neutral conductor size (AWG or kcmil), if larger than the phase conductors.

Testing as part of the certification process for HDPE conduit includes impact resistance, crush resistance, coupling crush, residual stress, chemical resistance, joint tightness, stiffness, pullout, compression , bore, and resistance to sag testing.

As part of the standard development process, the C22.2 No 327 Subcommittee submitted a proposal to add specific rules into the CE Code for HDPE conduit and HDPE conduit with conductors. Although the National Electrical Code covers installation requirements for HDPE, there are no similar provisions in the CE Code. The plan is to add new definitions to Section 0 to include HDPE conduit and HDPE conduit with conductors, and a new subsection to Section 12 starting with new rule number 12-1250. The new rule will cover the use permitted, restrictions on use, temperature limitations, fittings, maximum number of conductors, method of installation, and provision for bonding continuity.

The proposal will allow HDPE conduit and HDPE conduit with conductor to be used for installation underground. In addition, HDPE conduit and HDPE conduit with conductors could be installed in walls, floors, and ceilings where encased or embedded in at least 50 mm of masonry or poured concrete. The reason for the restriction on the installation of HDPE conduit and HDPE conduit with conductors is that the current compound used for HDPE conduit would not pass the UV and FT4 testing required for installations above ground or in buildings.

The temperature limitations are similar to the existing requirements for PVC conduit in existing Rule 12-1104. Other similar requirements to PVC installations include a rule not allowing HDPE conduit and HDPE conduit with conductors to be threaded; the maximum number of conductors to be in accordance with Rule 12-910; a requirement for all cut edges shall be trimmed to remove rough edges; and a separate bonding conductor to be installed in HDPE conduit in compliance with Rule 10-404 where bonding is required.

The final CE Code change as part of the subcommittee proposal is to revise the title of Table 9C to read: Cross-sectional areas of rigid PVC conduit and Type HDPE conduit.

Find Us on Socials