The Code Making Panels’ (CMPs) discussions for the National Electrical Code (NEC)-2023 revisions will be starting soon. Some changes will be to clarify existing requirements, others to remove obsolete requirements, and, most importantly, changes to incorporate new or revised requirements to account for new technologies.

One of the strengths of the NEC is the CMPs’ attention to those technologies on the horizon, ensuring the indispensable lifeblood of the NEC is properly considered. This vision is part of what gives the NEC its strength and vitality – understanding what hazards exist and then looking ahead to what is next to ensure safety is improved and keeping the NEC up to date.

Several fundamental principles exist to achieve what should be a “safe” electrical installation. The safest electrical installation, strictly from an electrical hazard perspective, is one that never gets energized. But in reality, power is turned on; therefore, we have the next best thing – an installation designed and installed to or above the NEC. Since we are going to turn on the electrical energy, some safety principles need to be applied. One principle is to “engineer” out an identified hazard as a first choice. On the other end of the spectrum, using administrative controls, such as labels or markings, requiring a person to comply should be the last resort. An example of this for electrical safety is to have insulated conductors instead of bare exposed conductors that can be contacted.

Another principle is the example of the four-legged stool, where each leg needs to be fully present for the stool to stand up and be stable. In electrical safety the four legs are:

- Qualified designers (engineers) for products and facilities;

- Certified products to recognized industry standards;

- Qualified installers; and

- Proper inspections by qualified inspectors to verify the installation.

The underlying and most widely accepted standard for safe electrical installations is NFPA 70®, the National Electrical Code® (NEC), and it is a foundation for safe electrical installations. The NEC® serves as the minimum set of requirements for safe electrical installations. These requirements include modifications to existing systems and application of new technology. These updates create a pathway to ensure future editions of the Code appropriately anticipate and address new and evolving technologies. A good representation of these concepts and how they’re folded into the code can be seen in figure 1.

New technologies are being developed to “engineer out” hazards; product standards are being reviewed and updated for the new technologies or better techniques to test existing products; and continuing education for engineers, installers, and inspectors is a must to keep abreast of what is going on. One of the main reasons the NEC is updated every three years is because some new technology has come along and needs to be included either to acknowledge that new technology or to improve existing installation methods and practices. Many times, a new technology has a “soft introduction” to allow time for the industry to adapt and accept its application. Other times it needs to be implemented right away because of the severity of the identified hazard.

Historical Introduction of New Technology. One example of this gradual introduction was the grounding-type receptacle that most all of us take for granted today. For many decades knob and tube wiring and the early versions of nonmetallic sheathed cable (NM) had only two conductors, and a two-wire non-polarized receptacle was the norm. It was understood that in many locations, having some sort of “grounding” of appliances and equipment increased the safety from electrical shocks. How to achieve that practically and economically was the question. The grounding-type receptacles, along with adding an equipment grounding conductor in the NM cable, raceway, or using the raceway, came about in the mid-1950s. In the 1959 NEC, Section 210-22(b) introduced grounding-type receptacles and the requirement they be installed in laundry rooms, open porches, breezeways, basements, cellars, workshops, garages, and on the exterior surfaces of outside walls or like locations. This was where equipment might be plugged in, and the user was standing on the ground (earth) or grounded conductive material.

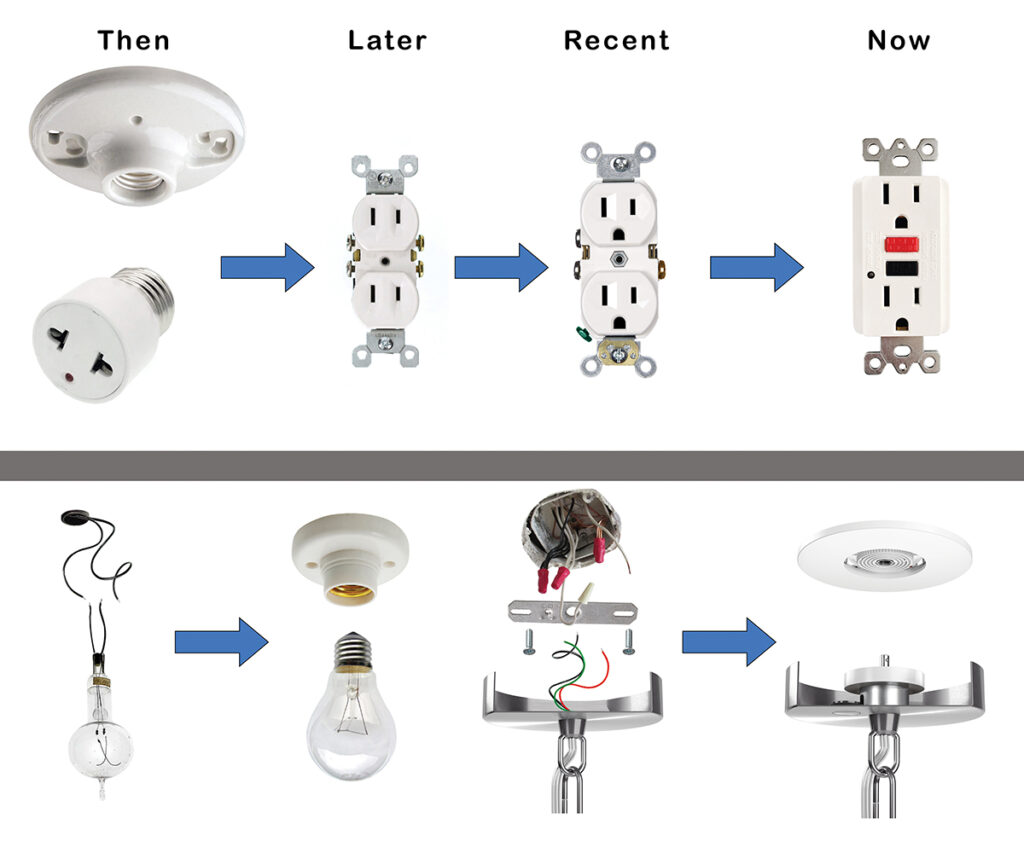

In the 1962 edition, the requirements were moved to Section 210-21(b) and made it mandatory that all 15- and 20-ampere receptacles on branch circuits have to be the grounded-type device. From the grounding-type receptacle, the evolution has now come to the ground-fault circuit interrupter (GFCI) receptacle that not only provides the advantages of a grounding and bonding connection, but a protection means when a low-level ground fault occurs. The result of these technology changes and mandatory Code requirements have been documented to have greatly reduced incidents of electrical shocks and injuries even with the increased use of electrical appliances and equipment, see figure 2. There are many other examples where technology was developed to mitigate a hazard and that technology becoming part of the Code. As we continue to evolve, more new technologies are being introduced or expanded in application.

The National Fire Protection Association (NFPA) process is a consensus process of the industry as a whole. The initial actions are by the public with inputs, now called Public Inputs, to propose additions or changes to the present Code. For the 2023 edition, those public inputs had to be submitted by September 10, 2020. The Code Panel members then review, debate, and decide on what changes are to be made in a multi-step process; they are the experts who call “balls and strikes” about what goes in the Code. Ultimately, the general membership of the NFPA determines the final outcome. If asked what belongs in the Code, each panel member would have their own version of an answer similar to the following, “…any requirement needed to prevent or lessen the likelihood of shock, fire, injuries or death arising from the use of electricity.” Does that fully answer the question, or does it raise more? Yes, in part, but those decisions are not always black and white. This article seeks to shed some light on the considerations of how the panel decides what topics are added and become mandatory, or are added as an option, or discarded altogether. It will also provide a glimpse of some new technology that is in the pipeline to be considered during the NEC-2023 cycle that is now underway.

Each revision cycle, there are thousands of Public Inputs submitted. These Public Inputs are separated and assigned to each of the 18 panels for consideration. When considering new requirements, sometimes, a Panel’s answer includes something to the effect: “…this requirement will not be added, as the NEC is a minimum standard…” After decades of the authors watching Code meetings, it becomes clear that what should be mandatory is in the eye of the Panel members.

In some cases, a good “engineering argument” will be persuasive enough for the panel members to act favorably. In other cases, serious injuries or reported deaths, have often resulted in new requirements. Injury data from the Consumer Product Safety Commission (CPSC) and Occupational Safety and Health Administration (OSHA) have been successfully used to substantiate a number of requirements. The Panel members are some of the world’s most renowned experts in the electrical field. They have a history of developing practical solutions. The NEC revisions are done in a consensus process, so a 2/3 majority of the panel members need to be convinced that the proposed action is necessary. Someone has to make the judgment call, so there’s no one else’s judgment that is better.

As some new technologies are introduced into the Code, they become either optional or very limited mandatory application. For example, although GFCI protection is a proven life-saving technology, it has been rolled out slowly over many code cycles because it needed to be justified for each application.

PERSUASIVE PUBLIC INPUT (PI) SUBSTANTIATION

What are common arguments to make a requirement mandatory, and what are some common Panel responses? Let’s discuss some of the factors they consider.

A good PI must have a persuasive substantiation – the reasons the changes are warranted with facts and data. In the substantiation text, it’s important to be as concise as possible and to put the reasons that will persuade the Panel to agree to make the change. Often additional information such as fact-finding reports or other data is included as an attachment to the public input or comment. Let’s look at a few examples of general substantiations types.

Substantiation that Would be Ineffective: For example, “the proposed change requires all dwelling units to have a 400-amp service to provide for future growth”. (To be clear, nobody has proposed this change and it is for demonstration purposes only). The Code deals with hazards and mitigating hazards; it doesn’t take into account what might be the “best” way to do something. More capacity isn’t necessarily better. Requiring a 400-amp service for all dwellings would be unreasonable since that exceeds any reasonably expected load. In some cases, options are added to the Code to complete an installation because these options provide equivalent safety. However, sometimes an option that is believed to be inefficient, and not used in practice is still added since that method does provide for a safe installation.

This approach of considering all installation options in a requirement is consistent with Section 90.1(B) Adequacy; requirements are in the NEC that are necessary for safety. The requirements don’t take into consideration the efficiency, convenience, or if it is adequate for good service or future expansion.

Compelling Substantiation: “The addition of this requirement would reduce the risk of fires, deaths or injuries by installing ‘x.’” This is the best reason to add or modify requirements in the NEC. One must ponder, are we talking about a rare minor injury, one or more serious injuries, one death, or more than that? Would a single death or serious injury be a reason to make a requirement mandatory? The answer, as it so often is with code questions, is “…it depends”. It depends if the death was due to an unusual circumstance identifying a hazard not foreseen by the Code, or a condition like not following the Code or some misuse by an untrained person. It depends on if the hazard could happen again or is foreseeable that it will happen again. There have been cases where a single death has resulted in the addition of a new requirement. Those cases involved a death from a hazard that could reasonably be expected to occur again.

In some cases, the deaths or injuries were caused by a previously unrecognized existing hazard. In other cases, the deaths or injuries are caused by a known hazard, but there was no available technology to mitigate or eliminate the hazard. This is where new technology comes in. The new technology becomes an integral part added to the Code to ensure that the Code does not stand in the way of progress, but rather embraces it, particularly when it will result in improved safety.

Compelling Substantiation: “This new text recognizes a new technology that needs requirements to ensure safe application.” It is well known that the Panel members loathe to stand in the way of state-of-the-art technology. If the new technology isn’t presently considered in the Code, and by omission, the new technology might not be permitted, this is a reasonable argument to add requirements into the Code. Additionally, if a new technology is not addressed, then designers, installers, and users may have no basis to judge the installation to be safe. An example of needing to address new technologies is the rapid changes occurring in renewable energy systems. The new requirements ensure the new technology is permitted to be used, along with the requirements to keep it safe. This is a great argument to add mandatory requirements into the Code. A good example of this is the Power over Ethernet (PoE) requirements added in the 2017 NEC in Articles 725 entitled Class 1, Class 2, and Class 3 Remote-Control, Signaling, and Power-Limited Circuits and Article 840 entitled Premises-Powered Broadband Communications Systems.

WHAT’S ON THE HORIZON?

Many examples of new and evolving technology that could arise in future Code cycles were discussed at the Fire Protection Research Foundation’s Electrical Data Summit; Impact of Data in the Electrical World; discussions are included in its proceedings1 that were published in April 2020. Some of these advanced technologies are discussed below:

Class 4 (CL4) Power Systems. In the world of high tech, there are talks of a potential new type of power system. You may have heard of it by one of many names: smart transfer system, pulsed power, packet energy transfer, digital electricity, fault managed power, or several other names. Although there have been no decisions made yet, there’s talk of calling it a Class 4 power system; so, for simplicity, we will use that term, hereafter CL4.

The theory behind CL4 is that these power systems must be able to detect a range of faults that far exceed existing types of protection and must remove hazardous energy fast enough to prevent fire or shock. One such implementation of CL4 transmits the power in small pulses that do not individually deliver sufficient energy to ignite a fire or be a shock hazard. When the pulses are added together at the receiving end, sufficient energy can be delivered to operate the equipment. A sampling period takes place after each pulse, and if there is a problem, the intelligent monitoring and protection system identifies it and prevents the next pulse from being transferred.

It’s essentially a system that monitors the circuit for faults and controls the power transmitted. It will detect if there is a problem along the circuit, all the way from the source to the receiver (that could be an appliance) and will essentially cease the flow of electricity “instantaneously” when a fault is detected. This interruption of the energized circuit would occur if there were a frayed wire, if the power load wasn’t appropriate for the appliance if the appliance got dropped in water, human skin contact with energized parts, a malfunction or any other abnormal condition. It has been described as an “electronic handshake” to verify that the powered device is present and operating correctly before power is applied or power continues to be applied.

If this technology proves to be all it promises, the number of shocks and electrocutions should plummet, as would the instances of equipment being overloaded. Many details have yet to be fleshed out. Still, at a minimum, the Panel will first need to properly define how to maintain the integrity and reliability of this power, including safety requirements.

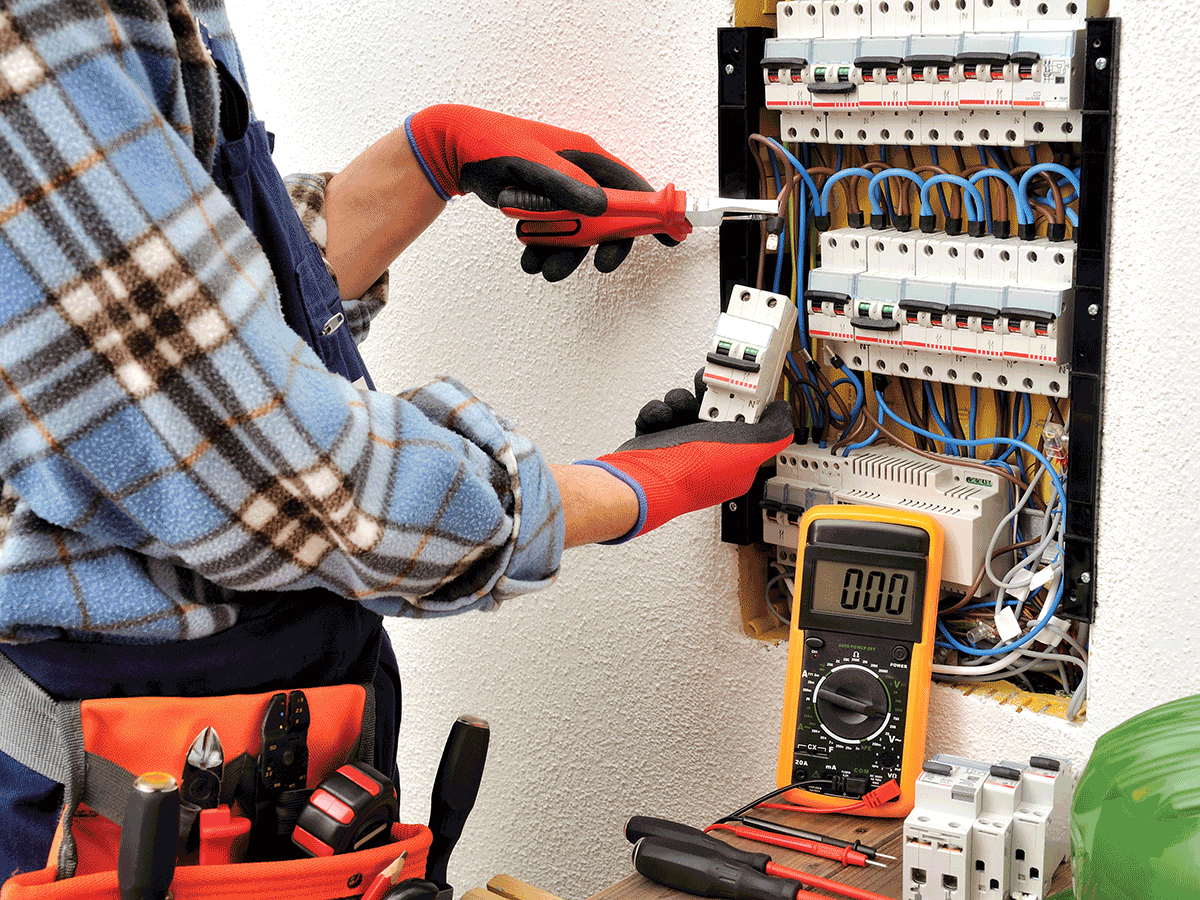

Whole-Home Electronic Failure Monitoring. Another new technology in development monitors the home’s entire electrical network for precursors to electrical fires (micro-arcs and sparks) by measuring the electromagnetic data with incredible granularity at 30 million samples a second. It also alerts on power quality issues such as outages, surges, and sags, see figure 3.

When considering the detection of power quality issues as a sole substantiation, it might be considered non-persuasive based on Section 90.1(B) Adequacy. But what about the potential to save lives? The insights from the data collected could uncover a variety of electrical hazards in the home and provide safety beyond the power quality aspects. This type of technology offers very interesting possibilities beyond the single homes they are protecting, like watching the grid for possible points of concern during wildfire season.

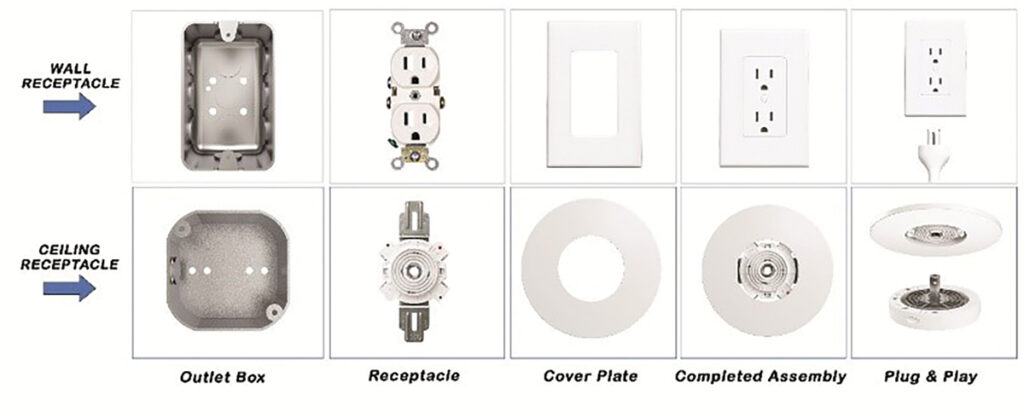

Weight Supporting Ceiling Receptacle (WSCR) (“plug and play”). When general lighting in dwellings is going to be installed, why does the initial luminaire installation or future luminaire change-outs have to be hard-wired? The answer is, “…because it always has been”. Is this the safest way to make the installation? In fact, the data regarding injuries and deaths while doing these types of wiring installations is available, and the benefit analysis of this technology is compelling. The current wiring installation method is not necessarily in the best interests of the homeowner or professional, nor is it necessarily in the best interests of safety. Therefore, the WSCR was added to the 2017 and 2020 editions of the Code in ten areas as an option for installing a luminaire and is referred to as “locking support and mounting receptacle.” Luminaires are often changed after their initial installation. In fact, in new construction, lighting units are often changed after the final electrical inspection when the buyer does a walk-through and insists on a change. That replacement is often not performed by an electrician and rarely if ever, re-inspected. As homes age or there is new homeownership, subsequent luminaire replacements are often installed. Many times, these installations are completed by non-electricians, including homeowners, handymen, painters, or carpenters who may introduce hazards due to their lack of training.

Now, if the initial installation included a weight-supporting ceiling receptacle, as shown in figure 4, the electrical connections can be installed one time to a light-weight receptacle by the professional electrical installer. In addition, a device exists to now simply and safely verify the polarity of the receptacle connections, which is an added benefit that is not available with current luminaire installations. After the initial installation of the receptacle, any future luminaire replacements will not require any electrical work or contacting energized conductors because the weight supporting receptacle was installed by an electrical professional, and the polarity verified. The luminaire can simply be disconnected and replaced for servicing. With the installed WSCR, the luminaire can simply be “plug and play” to allow replacing the luminaire, for relamping, cleaning, or painting the ceiling. All this, without contacting energized conductors as well as significantly minimizing the time spent on ladders while installing or servicing luminaires. See the safety issue in Figure 5. According to the Centers for Disease Control and Prevention (CDC), falls are the number one cause of accidental injury in virtually every age group2. This is an ongoing safety issue that can be significantly mitigated by applying this technology.

Safety in the NEC is a continuing evolution. When the screw shell lamp holder design was standardized, why wasn’t a weight supporting the “plug and play” option for luminaires and paddle fans also included? Simply put, because the technology didn’t exist at that time. Today, that technology does exist, as shown in figures 2, 4, and 6.

When looking around the home, most electrical equipment advanced from some level of hard-wired connection to essentially “plug and play”: appliances plugging into a receptacle, landline phone, home internet, and satellite TV. Why not for ceiling luminaires and paddle fans? Again, because the technology to bear the weight didn’t exist before, but now does exist, see Figure 6. Figure 7 shows the comparison of concepts – the installation of a grounding-type receptacle in a wall box and the similar installation of the weight supporting ceiling receptacle in a ceiling box.

This technology makes the installation of a replacement light safe, quick, and efficient. Also, most importantly, safety is improved by not having to contact energized conductors or spend a long time on a ladder. To be successful, the substantiation to require this technology would need to include data on injuries and deaths associated with the traditional wiring installation that is mitigated by the new method. It is possible that a benefit analysis could provide a compelling justification.

SUMMARY

The three technologies discussed are great innovations. The Weight Supporting Ceiling Receptacle (WSCR) is the only one that is presently in the Code. The WSCR has all the ingredients in the Safety Cycle, as shown in figure 1: the hazards identified were falls, shocks, and electrocutions; the innovative technology was developed; it was introduced in the 2017 Code, and lastly, it improves safety. It is understood that the Class 4 power system will be introduced in the 2023 NEC, whereas it is presently unknown if the whole house monitoring will be proposed to enter the Code.

Advancements in technology, coupled with the need to improve safety, are powerful motivations for keeping the NEC up to date. As technologies are introduced and evolve, they will likely make their way into the Code, ensuring the NEC continues to be at the forefront of innovation.

References

- Grant, Casey, et al. Fire Protection Research Foundation, Apr. 2020, Electrical Data Summit Impact of Data in the Electrical World at https://www.nfpa.org/News-and-Research/Data-research-and-tools/Proceedings/Electrical-Data-Summit-Impact-of-Data-in-the-Electrical-World, pages 23-33 (CL4) and pages 31-33 (residential voltage monitoring).

- WISQARS Leading Causes of Nonfatal Injury Reports. (n.d.). Retrieved August 17, 2020, fromhttps://webappa.cdc.gov/sasweb/ncipc/nfilead.html

The authors are independent consultants presently engaged by Sky Technologies, Inc.

Find Us on Socials