The results of IAEI’s 2019 inaugural Workforce Survey are in.

More than 1,500 individuals participated in this workforce survey, which was conducted online in November 2019. IAEI received responses from 608 authorities having jurisdictions, 311 electricians, and 643 other electrical professionals who shared information on a variety of topics. We wanted to understand better how inspectors and other professionals felt about their careers in the industry and allow them to share valuable insight on which to make career decisions.

In the charts that follow, you’ll find details concerning salaries, professional development, and training, required licensing, and additional information from work-life balance to tips for career advancement. Average salaries are also broken down by industry average and region. Overall, electrical authorities are happy, feel well-compensated, and feel professionally challenged.

In part one, we’ll take a look at the local authority having jurisdiction — everything from their job duties and continuing education requirements to their reported annual salaries.

How do you stack up?

Updates through 12/4/2019 (n=1562)

What Is An AHJ?

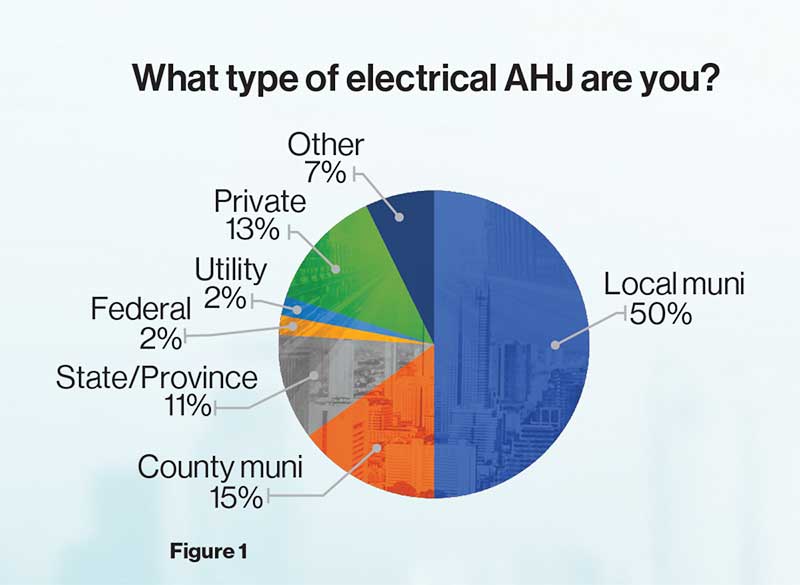

Authorities Having jurisdiction (AHJs), often known as inspectors or electrical inspectors, are responsible for approving installations, equipment, materials, or procedures and for enforcing the adopted code within a jurisdiction or company. Overall, AHJs report loving their jobs and helping to teach and enforce both electrical codes and electrically safe work practices. Of the 608 respondents, 78 percent work for a regional municipality, while other inspectors work for a private company, such as a third-party inspection agency (13%) or a utility (2%). Fifty percent of respondents work for a local city or village, 15 percent work for a county municipality, and 11 percent work for a state or provincial jurisdiction.

Departmental Overview

AHJs work in a variety of departmental names, with a few topping the list. The two most popular departments are the “Building Department” and “Inspection Services.”

Other popular names include:

- Electrical Safety Department

- Inspection Department / Building Inspection Department

- Building Department / Building Regulations

- Community Development

- Construction Services and Inspections

- Code Services Department

- Permit and Planning Department

- Code Enforcement

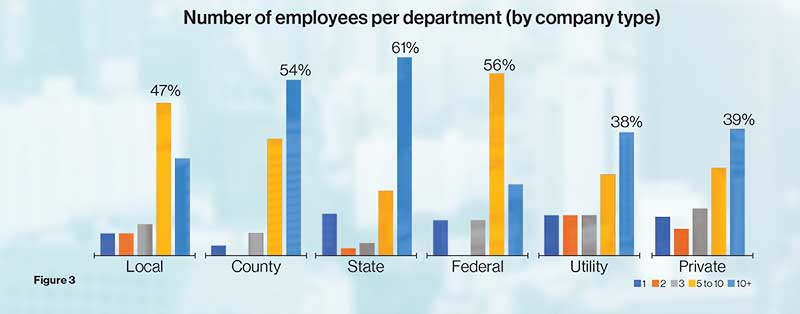

Seventy-seven percent of respondents indicated that their departments had five or more employees. Local municipalities report an average of 9.5 inspectors per department with a median number of 7.5 to offset some departments that report over 250 inspectors. One of the largest inspection supervisors oversees 400 combination inspectors who perform around 20 inspections per day per inspector.

The average number of inspectors for county municipalities is around 30 (due to some with larger numbers, especially in the Pacific states), with a median number of 10 inspectors per department.

State and provincial departments report an average of 40 inspectors, due to a few jurisdictions with over 100 inspectors, with a median count of 10.

The average number of federal employees per department is 6.

Private employers generally have a small number of employees at an average of 12, with a median of 7.5.

Overall, the average number of inspectors per department was 23, with a median number of 7.5 (to correct for the bottom and top figures). For departments with more than ten employees, the average was 46 employees per department or jurisdiction/company (with inspectors stretched across multiple departments) and a median number of 12.

Job Overview

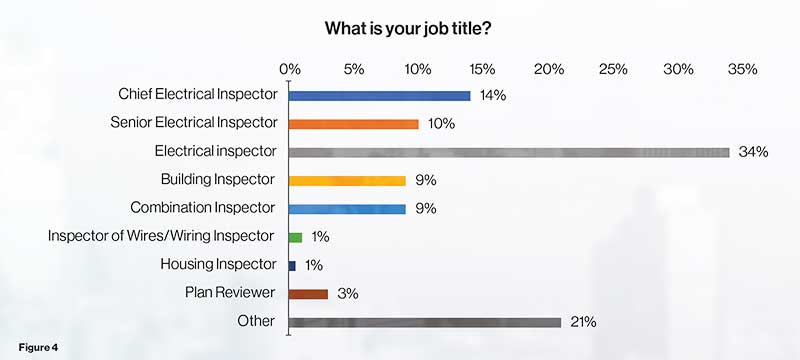

The typical authority having jurisdiction has a job title with a variation of the term electrical inspector (58%). Chief electrical inspector (14%), senior electrical inspector (10%), and electrical inspector (34%) were the most reported job titles among respondents. Building official, building inspector, or a baseline variety of it was the next most common job title among responders.

Other common titles include:

- Electrical Safety Manager / Inspector

- Quality Assurance

- Code Compliance Inspector / Code Enforcement Officer

- Insurance Inspector

- Master Electrician (especially among AHJs for private companies)

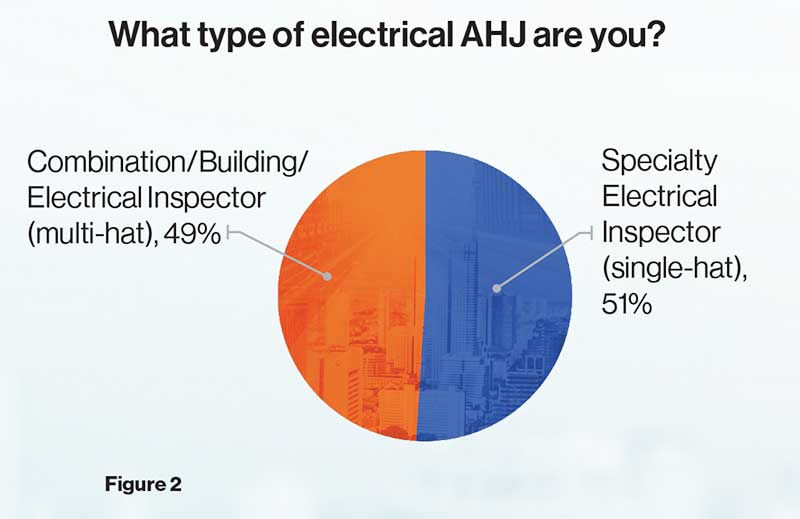

These electrical inspectors indicated that they are evenly divided among specialty inspectors and combination inspectors. The number of specialty electrical inspectors (51%) was only slightly higher than combination building inspectors (49%), but not enough to be statistically different. Interestingly, this number aligns with the 2016 survey of the same dataset of 539 responders, which indicated that 46% were single-hat, and 48% were multi-hat inspectors. The number of multi-hat inspectors was also higher in the Pacific states than in other regions of the country.

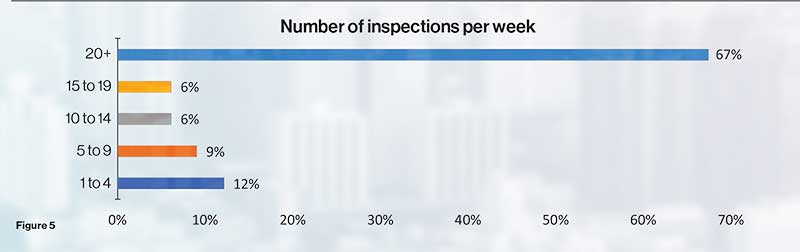

AHJs reported they often hear that most of their jobs comprise sitting in the office with little to no time out in the field. However, they are often in their trucks for most of the day going from site to site, often performing upwards of 10 inspections a day (this often means ten different stops). Even in a department with multiple inspectors, the majority of electrical inspectors (67%) report that they perform more than 20 inspections per week, with the average number of inspections per week being 66.

An AHJs Typical Workday

A common refrain among many of the inspectors is that sometimes their jobs feel like they are 75% paperwork and 25% inspections (with paperwork often being filled out in the truck).

The day often starts with office work (average 1.5 hours). Office work includes:

- answering phone calls, front counter questions, emails, and additional correspondence with engineers, building professionals, and fire professionals;

- answering code questions for citizens, contractors, and inspectors;

- reviewing plans;

- issuing permits; and

- performing mathematical calculations to determine appropriate fees and compliance of development plans with applicable requirements.

While getting ready to head out into the field, the inspector then picks up the schedule of inspections and put inspections in order of importance (a.m., p.m., and location) and verifies the technical documents.

Then they head out into the field to perform inspections. Drive, drive, drive (sometimes adding up to 1,000 or 2,000 miles per month on the truck). Inspect new and remodel construction during the day. Be aware while traveling of work going on that may not have permits to perform work. During an inspection, the AHJ often performs wall and ceiling rough, underground, power release, and final inspections, verifying that the equipment is utilized in accordance with its listing.

After they have finished, they provide reports to the contractors and office (sometimes this is done during breaks). The AHJ often closes out permits, authorizes energizations, and composes correspondence in the times between and after site inspections.

Short answer? The first hour is returning phone calls, answering emails, and doing paperwork. Then they review applications of permits, issue said permits, and head out for inspections. At some point, they go to lunch. After lunch, they inspect a few more installations and spend a few more hours out in the field. Finally, they often return to the office to enter reports from the daily inspections and start plan review.

Overall Responsibilities

The AHJ inspects electrical installations during construction or remodeling to enforce laws and ordinances establishing and maintaining minimum standards for residential, commercial, and industrial electrical installation and appliances. Their duties may include:

- Reviewing electrical plans and materials lists to interpret specifications and methods of installation.

- Verify loads, demand factors, and the number of circuits to ensure that circuits are capable of operating with overloads.

- Inspect electric wiring, fixtures, and equipment, and issue a notice to repair, remove, or refrain from using items found to be unsafe.

- Interpret legal requirements and recommend compliance procedures to contractors, craft workers, and owners.

- Keep records of inspections and prepare reports for use by administrative or judicial authorities.

- Perform electrical license investigations at random and in response to written complaints. If licensed violators are discovered, the incumbent is responsible for contacting the local authority and initiating proceedings for a court summons.

- Issue Stop Work Orders, which are posted when work is performed without permits within locality and correction notices.

- Inspectors also assist in fire alarm inspections and assist property maintenance inspectors.

- Investigate improperly installed or decaying electrical wiring systems and/or equipment that present a condition deemed hazardous to life or property and constitute an imminent danger.

- State or regional inspectors may also investigate and/or resolve complaints/disagreements of inspections performed by local electrical inspectors.

- Perform fire investigations. AHJs are often required to be qualified to determine cause and origin specializing in those of electrical cause.

What Do They Inspect?

What the AHJ may inspect can vary from residential to solar to high-rise installations and health-care facilities. The residential occupancies could be a 1-, 2-, or 3-floor home to any of the 5- to 8-story apartment complexes. These inspections may involve everything from the installation of a 15-amp garbage disposal circuit to 5000-amp switchgear or services. Local municipality inspectors may inspect residential, commercial, and industrial installations. Daily tasks are not just limited to permitted work.

Job Satisfaction

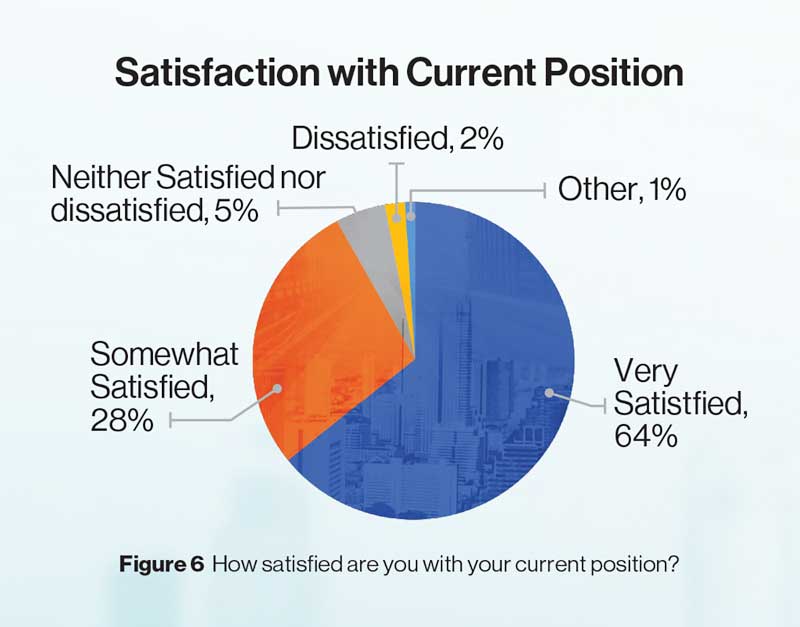

Most respondents find satisfaction with their position as an AHJ (92%), although some more so than others. Respondents expressed some slight dissatisfaction due to internal politics, corruption from within the system, confrontation over new code adoptions out in the field, austerity measures, and the sometimes 12-hour workdays where they “live in their truck.” Others report having to work additional positions to make up for limited municipal salaries. However, others report loving the position and having the opportunity to serve, teach, and help others within the community.

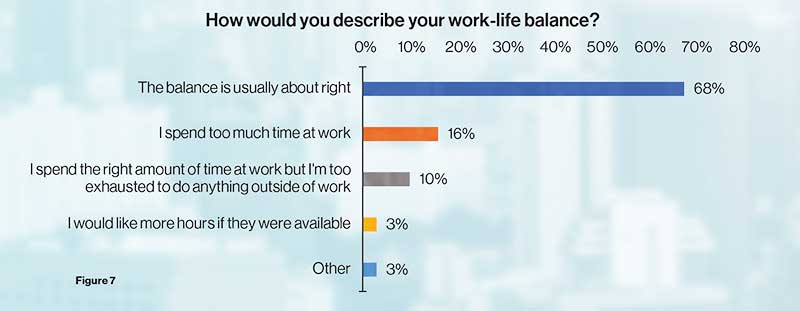

Part of their job satisfaction is also tied in with their work-life balance. The number of AHJs who reported that the balance was just about right was 68 percent, only one percent over those that are very satisfied with their job. An additional 16 percent report spending too much time at work while 10 percent note that they do spend the average day at work but are too exhausted to do anything outside of work once they are home. Only 3 percent report wanting additional hours if they were available, and many of these respondents worked in the more remote areas of the country. In addition to the time at work, respondents also report that their commute, which is sometimes up to 1.5 hours one way, is also hard on them.

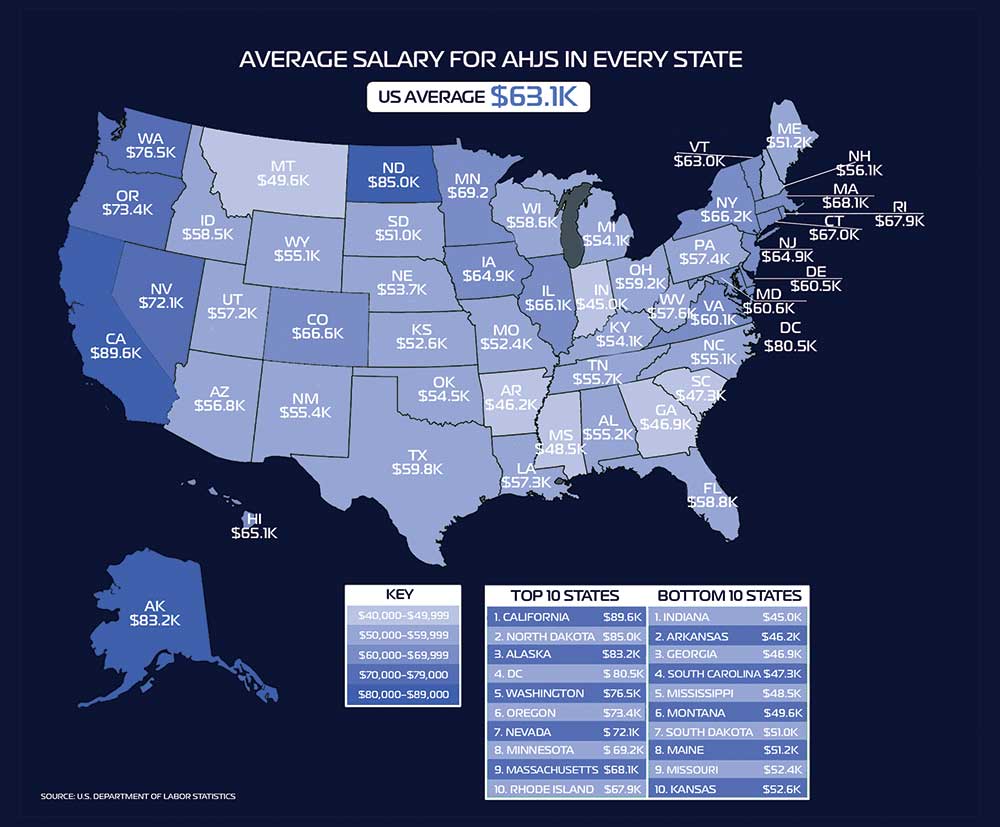

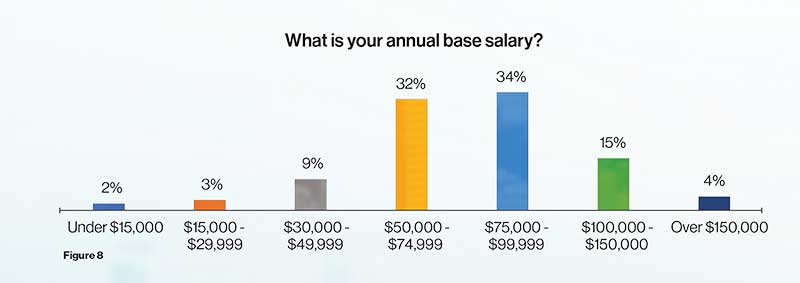

AHJ Salary

The annual salary of an electrician or electrical contractor often ebbs and flows based on the health of the building industry in the area. Many of the AHJs report that they enjoy working for a jurisdiction due to steady pay and benefits. A few do report that their pay is less than what they made as an electrical contractor or is less than what it should be considering the long work hours and duties. The survey reveals that the average 2019 base salary for electrical inspectors is $75,000. This amount exceeds the $63,150 annual base pay reported by the U.S. Department of Labor’s Bureau of Labor Statistics (BLS) for construction inspectors. The highest base was slightly over $150,000, primarily in the Pacific region of the country. The lowest base salary range was under $15,000.

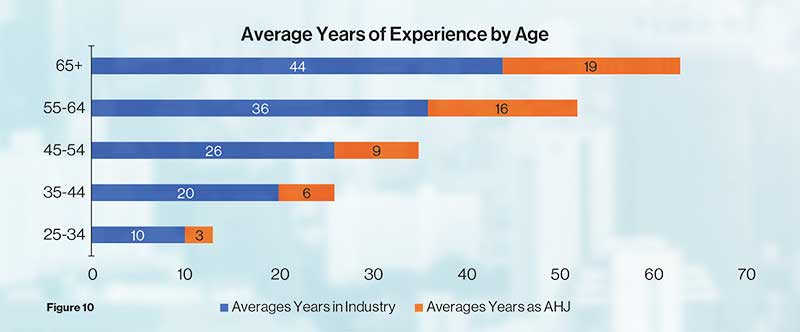

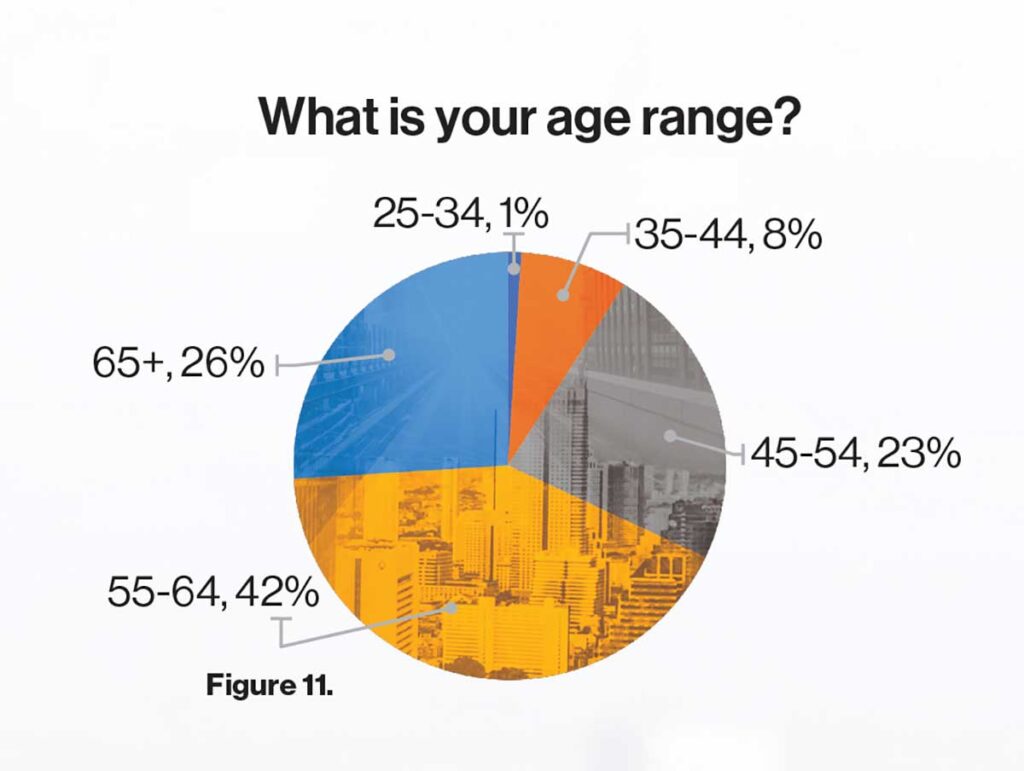

Average Age And Experience

AHJs report that many spend an average of 20 years in the electrical industry before becoming an inspector. Many begin as an apprentice, work their way up through the trade as a journeyman and a master electrician, and look to advancing into an inspector career. The average AHJ in our survey also notes that they have spent 15 years as an inspector by this time, and have over 35 years in the electrical industry. Not surprisingly based on the tenure in the industry, the average AHJ is between 55 and 64 years of age; only 9 percent of respondents are between the ages of 25 and 44.

How Did You Become An AHJ?

Short story?

Apprentice → Electrical Journeyman → Master Electrician → Electrical Inspector → Teacher?

The most common way to becoming an electrical inspector is through years of working in the electrical trade. Most respondents repeated the following story.

- The AHJ first went to an apprenticeship school and worked as an electrician.

- After completing an apprenticeship, the AHJ tested for the electrical journeyman license and then worked for two years as a journeyman electrician.

- After two years as a journeyman electrician, they take their master electrician license exam and work several years as a master electrician.

- After several years as a master electrician (average of 10 years), they then apply and get accepted as an electrical inspector.

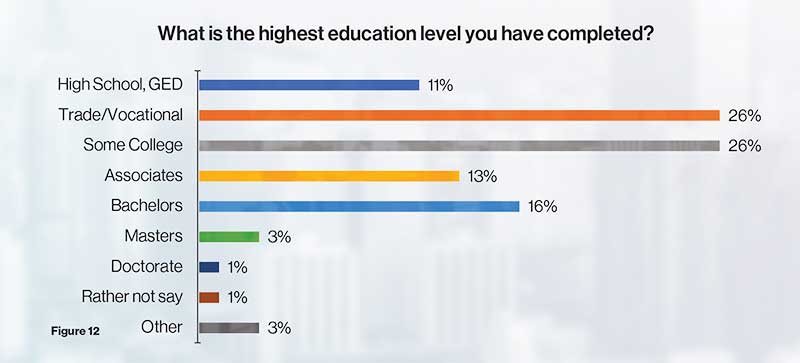

Only 20 percent of respondents indicate having a bachelor’s degree or higher level of education. The majority either came up through trade school and vocational training (26%), attended some college but received no degree (26%), or got an associate degree in a program such as construction management. Eleven percent indicated they had not received any formal training past high school but had gone through an on-the-job type mentorship program.

As far as getting hired for a position, many AHJs responded that they were asked to become one from the local AHJ. Multiple respondents noted that due to health reasons and wear-and-tear on their body (especially bad knees) from the physical challenges of installation, they thought about becoming an inspector as a second career following many years as a master electrician and/or electrical contractor. Other former electrical contractors reported that as work became scarce, they looked for the next step in their career with steady pay. Many of these respondents became inspectors during or around the 2008 construction crisis.

Often, the path to being hired is that they were working as a master electrician/electrical contractor and an AHJ who came out to inspect their work commented on their electrical installations. After the inspection, the existing AHJ would then ask if the electrician was interested in inspecting, and the electrician might then look into seeing what type of licensing or requirements are within that particular area. One installer worked for a county with no existing inspection department and, after repeated complaints about non-compliant installations due to lack of inspections, applied to the newly developed inspections department and was accepted.

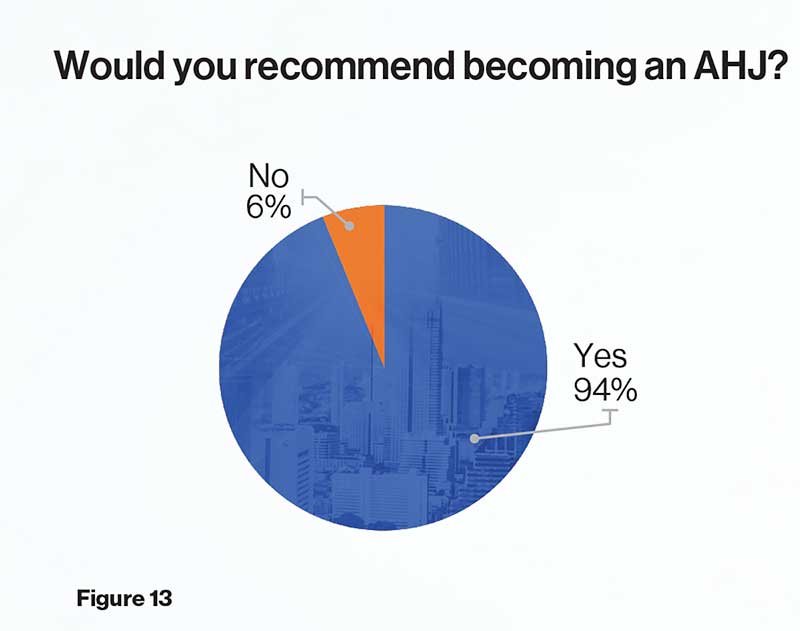

Recommend Being An AHJ To Others?

AHJs enjoy their jobs, and 94 percent recommend becoming an AHJ to others. They do acknowledge that the job is not for everyone and that people must have extensive code knowledge and excellent communication skills to do the job successfully. At least 10 to 15 years of experience are recommended for installers before going into the AHJ position. There is also no digging or pulling equipment by hand, and the position is often considered a good “post-retirement” job for former installers. That said, the workload can often be brutal and, while not physical, does demand much time on the road.

However, detractors note that local politics do heavily influence the job and that many of the municipalities are reducing the number of jobs and that their positions are not as protected as they used to be. Communication skills are stated as critical to navigating both the job responsibilities and the bureaucracy.

That said, only 27 percent of the AHJs report that they want to leave their current positions within the next year. Most of these noted that they are merely retiring due to their age, but others do note the increased workload and compensation. AHJs are also wanting to go back into the private industry as they could “be making more as a contractor.”

What would you recommend to an individual who is interested in becoming an electrical inspector?

The picture that emerges is a field of AHJs with years of experience working as electricians, contractors, and electrical engineers who are well-versed in the field of installations and the NEC. Inspectors recommend spending years in the electrical trade and studying hard, learning the requirements within the Code, and obtaining trade licenses. Acquiring technical skills is only the first step, respondents say, as it is critical to work on one’s people skills, work on having a non-aggressive personality, and develop a thick skin (“don’t argue, or go by what you think looks best or is common practice, let the Code decide”).

Here are a few other recommendations for people interested in becoming an electrical AHJ.

- Talk to other electrical AHJs in your area to learn the processes and to find job opportunities. As seen in the “How did you become an AHJ?” section, sometimes that comradery helps you land your next position.

- Keep in mind that everyone in the design, installation, and approval process is working on getting to the same place, a safe installation.

- Join an organization such as IAEI (meet the local AHJs); study the current versions of the NEC, IRC, or IBC; and get an ICC certification as an Electrical Inspector.

- Be courteous, respectful, and always look for a way to reject/fail an inspection without being condescending. Expect major push back and plan how to deal with that in advance. Keep a good attitude.

The main priority mentioned is to get your hands dirty and to do the work. Put in the time in the trenches of the actual install of work. Own the work. Learn how to effectively and proficiently lead others in the install aspect of the job. Lead by example. In your career, always teach others “how to check their work” and how to be thorough and what that looks like by physically showing them and by taking the time to walk each other through the “check your work together” philosophy. Teach teamwork and always teach covering your coworkers’ back for the betterment of the team.

Get as much exposure to all aspects of the electrical industry from single-family dwelling, multi-family dwelling, small retail, large retail, hospitals, office buildings, nursing homes, industrial — all of it if possible, both doing the work and leading the work. It’s a learning experience every day, and it’s interesting to see new methods, techniques, and products daily. Take advantage of all installation aspects of the electrical industry — residential, commercial, industrial, public safety buildings, and high voltage (underground and overhead).

Read and study the code. Strive to understand not only how something should be done but why it is done that way. Once you understand the why, you will be better equipped to understand the intent of the code and whether an installation can work, although it may not match the code exactly. Learn from the older generation how things have been done, but be open to new technology that has been properly tested and approved.

Learn time management and how to “always control the chaos.” Never let chaos control you. Plan your work and always work your plan, and always have backup plans for the backup plans because your plans will be destroyed by unforeseen circumstances. Be prepared to adapt quickly and always teach the rule book of the NEC, the specs and plans, and City Ordinances as well as the UL Listing processes and what the UL White Book is. It’s important to read through all of the blueprints, spec books, and product data — all of it. Know your jobs better than those who designed them. Know every aspect of your job installation. Never stop learning, teaching, and serving others in their quest to better themselves.

Licensing And Certification

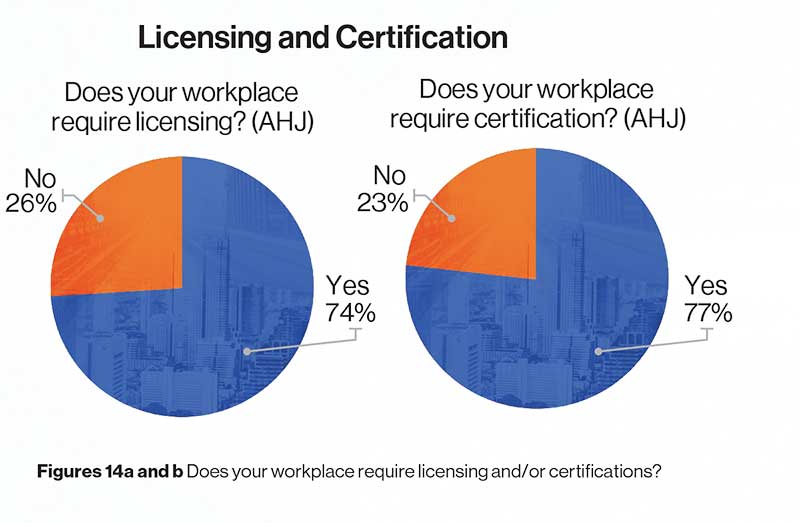

Licensing is a common requirement for most companies and jurisdictions. Slightly over 74% of respondents noted that their jurisdictions require licensing for their positions. Only 26% of the AHJs noted that their jurisdictions did not require licensing. Some jurisdictions that did not require licensing (especially in states with no licensing requirements) did require other pre-qualifications, such as a college degree.

Certifications are equally required by jurisdictions (77%). One caveat in the results is that some of the respondents listed their certifications as their type of license; therefore, many jurisdictions may require some form of credential, but it is hard to note from the results exactly what type is most common.

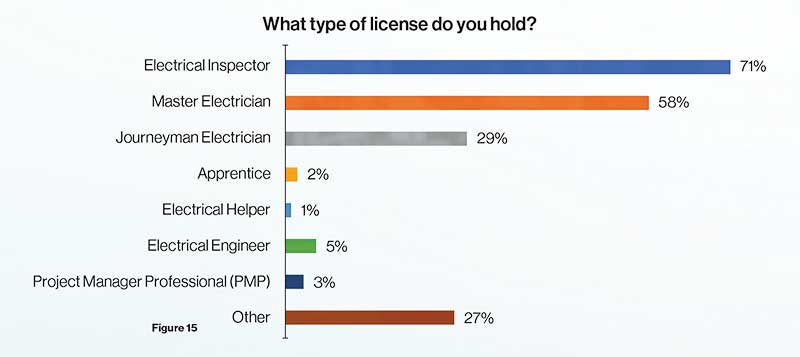

While jurisdictions can vary on what type of licensing is required, respondents said that they have either a current electrical inspector license (71%) or a master electrician license (58%). The sample responses also indicate that they have an ICC Certified Building Official or other form of ICC license/certification. (Some of the results had a mixture of licensing and certification answers.) Although electrical contractor was not initially given as one of the options on the chart, over 12% did respond that they also hold an electrical contractor license.

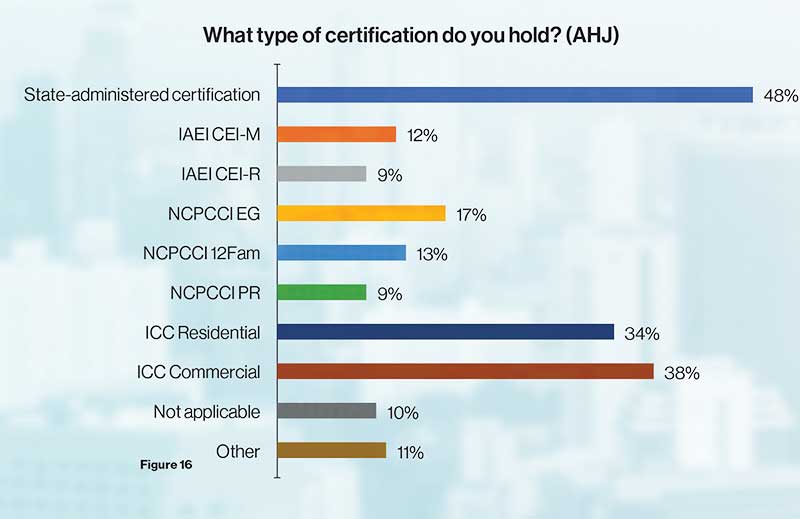

Slightly under half (48%) of the AHJs have a state-administered certification. ICC Certifications also feature heavily, as 34% currently hold an ICC Residential license and 39% have an ICC Commercial license. Just under 40% of the respondents also had some form of IAEI certification with NCPCCI, whether a general license, one- and two-family dwelling license, or one for plan review. The IAEI Certified Electrical Inspector certification, Master and/or Residential, is also held by 21% of respondents.

Certifications, such as the IAEI Certified Electrical Inspector program, often require continuing education credits every year or code cycle. A large portion of the AHJs report that their certification program requires continuing education credits (63%). A smaller portion report that their licenses (58%) or jurisdictions (34%) require CUEs. Only 6 percent report that no continuing education requirements exist at all.

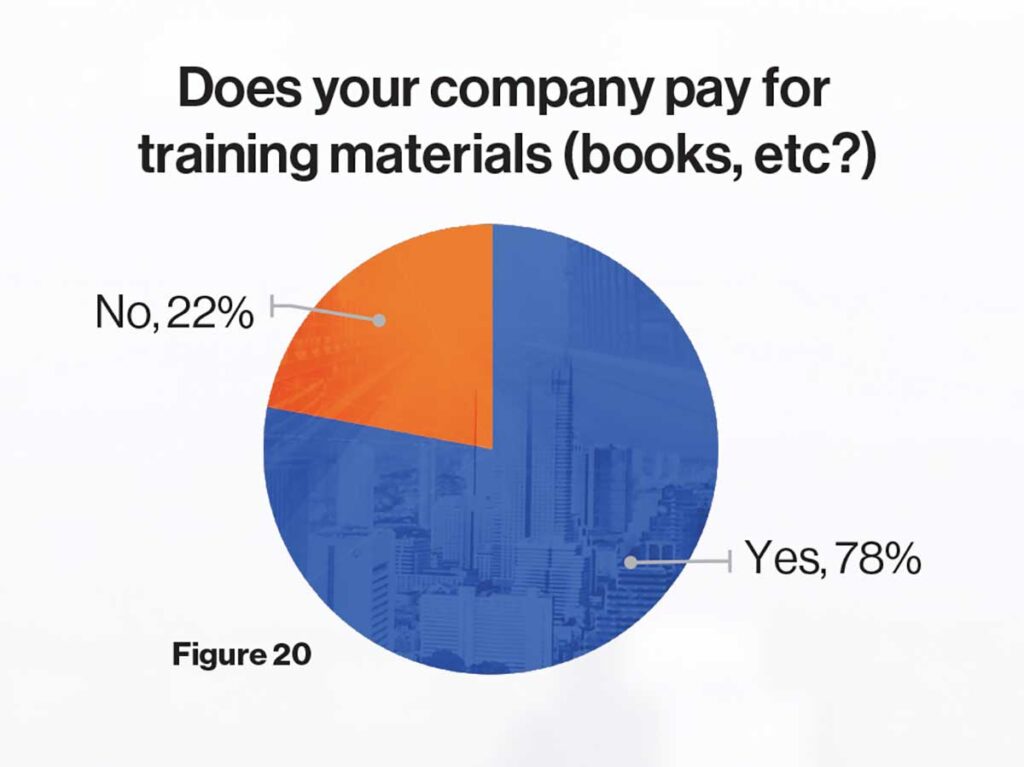

For the most part, jurisdictions do pay for training (80%), whether in full or reimbursed. A small portion of companies (6%) pay a percentage of the training while others require CEUs but do not reimburse (14%). The average amount that a jurisdiction is willing to pay annually per AHJ is $1000 per year per employee, which includes the fee for the training and any travel costs such as hotel, transportation, and food. Most of the respondents did not know the annual expenditure or noted that it varied upon the training being offered. Some respondents note that the amount used to be higher but that some jurisdictions were trimming the amount due to slower construction activity.

While a plethora of training can now be found online, over 86 percent of respondents still prefer classroom-style training. The majority (71%) prefer external classroom training to in-house (15%). On average, only 10 percent of respondents preferred online training. These numbers match up quite well to the current training styles being used, with only small variations. For example, while 71 percent of AHJs prefer external classroom training, only 63 percent are currently able to go off-site.

Not surprisingly, in such a varied field of continuing education providers, no one provider had a significantly large percentage in the field. Local IAEI chapter and division meetings account for 35 percent of attendees while 9 percent attend IAEI section meetings, and 8 percent get their CEUs from IAEI International training (both external and in-house). AHJs also get 20 percent of their training from ICC. Many inspectors also attend both in-house continuing education and ones that are provided by the state for local AHJs. Additional providers include local community colleges and trade schools, other local instructors, a local utility, in-house training, building inspector associations, online articles, and organizations such as ISO. AHJs primarily hear about these training opportunities via word of mouth (55%), email (11%), or by direct mail (8%). Non-listed avenues include hearing about it at work (mandatory training), radio advertisements, or by attending past events.

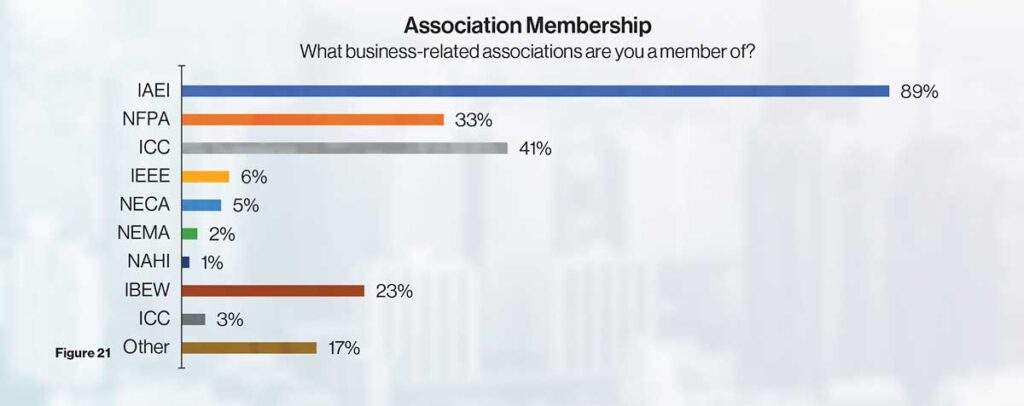

Association Membership

The majority of AHJs note that they were a member of a business association, with their company paying or reimbursing them for the most part (57%). IAEI membership was highest for the AHJs at 89 percent, followed by membership in ICC (41%), NFPA (33%), and IBEW (14%).

Educational Priority

AHJs are out in the field and inspecting the latest installations and renovations daily. Their unique perspectives provide us with an idea of what installers and inspectors would like in training and magazine articles. The majority of respondents requested information on 2020 NEC updates and interpretation of these articles related to electrical inspections. AHJs are also actively asking for “back to basics” — such as how to understand nameplates, sizing conductors, and overcurrent devices for equipment, and information on what installers and inspectors need to know. Some also note that the installation methods have changed since they were electricians and they are looking for updates on what is now standard practice. Healthcare and commercial facilities were also frequently requested. Other popular topics include inspections for high-rise and medium-rise occupancies, with people asking for information on service lines/feeder installation to the service equipment located in meter rooms on the individual floors of buildings.

Final Thoughts

AHJs, for the most part, love their trade and have a passion for electrical safety. This passion has them expressing concerns for the future of the electrical trade both in regard to knowledge of safe installation practices and the lack of installers to do the job. The need for younger individuals to take an interest in the building trades is a key concern as they are finding there are not enough people out there to perform the work. The AHJs find that those who are performing installations often need additional training, as they often see unqualified or unlicensed people performing “grunt work” like installing underground conduit. Inspectors report that they act more like a “training service” rather than an inspection service.

Their advice to new AHJs or those wanting to become one is simple: “Learn the Code.” One inspector said that he tells tradespeople that the NEC should be the last tool that goes into their toolbox because it should be the first thing to come out in the morning. Despite the sometimes-low pay, long hours, and politics, AHJs genuinely seem to enjoy their work and love the electrical industry.

Find Us on Socials