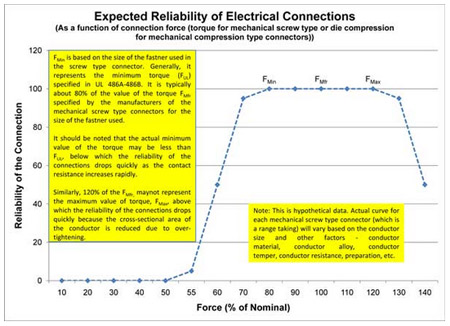

When it comes to terminating electrical conductors, Ms. Hunter’s field study, “The Difference between Success and Failure: How a Torque Wrench Improves System Reliability” published in July/August 2010 issue ofIAEI News, demonstrates the importance of doing it right the first time.The expected reliability of electrical connections can be described by a curve shown in figure 1.

Figure 1. Expected Reliability of Electrical Connections

The contact force applied to make the connection—either from torque required for a screw type mechanical connector or from the die pressure required for a compression type mechanical connector— needs to be within acceptable limits for a given connector. Undertightening below some minimum value will make the connection unreliable because the contact resistance between the connector body and the conductor will increase rapidly when the power is turned on to serve the load. Overtightening above some maximum value will make the connection unreliable because the excessive force has reduced the conductor area under in the connection, which in turn will increase the contact resistance between the connector body and the conductor. Conductor properties, connection preparations, and heat cycling from the power on and off will exacerbate the performance of the connections that are undertightened or overtightened beyond acceptable limits.

The reproducibility and repeatability of such studies is difficult and expensive. Further, it is not the point of the study to develop a precise torque level for connections. Other studies, cited by Ms. Hunter, have demonstrated that the electrical connections perform very well over a wide range of the tightening force. However, installers should not take their skills for granted. Like many participants in this study, I believed that the professional installers would be able to tighten the connections with more precision without the aid of a torque wrench; this study has demonstrated that the professional installers should not rely on how they feel when terminating conductors. Good installers follow the procedures and welcome the third party verification.

We endorse the requirements for “Listed” products. Conductors are listed, connectors are listed, and tools are certified. So, how do we list installers? The answer is through certifications or licenses that are always up-to-date. I hope that the industry organizations, such as IAEI, will continue to embrace and inculcate the requirements for installation methods in their training programs for installers and verifiers to ensure safe and high-performing installations.

—Ravi Ganatra, Engineering Manager

CME Wire & Cable, Inc.

Find Us on Socials