Are we consistent in our understanding of this subject?

In principle, this subject appears to be quite simple; however, reality has demonstrated many inconsistencies in its application by the electrical designers and regulators.

Photo 1.

The biggest issue of such inconsistency relates to the fact that a technical enforcement of the requirements for electrical supervision of this electrically connected life safety equipment is done by various AHJs (sometimes by building inspection departments, sometimes by fire inspection departments, and occasionally – by electrical inspectors); and these various AHJs do not always use the same criteria for enforcement of such requirements.

But what about electrical designers? What do they know about these requirements and about where to find such information? And does this subject belong to the responsibility of the electrical designers? The answer is resounding “Yes.” Electrical designers are responsible for all aspects of electrical design, including design of application of the electrically connected life safety systems. They show such electrically connected life safety systems on the electrical drawings, and they must have a detailed knowledge of the relevant codes and standards regarding electrically connected life safety systems, including “electrical supervision.” Unfortunately, some electrical designers are not very clear on this subject as well.

So, what is “electrical supervision,” and which legally adopted codes and standards mandate it? Where can we find such mysterious “life safety systems”?

Let us start with the Canadian Electrical Code.

Subrule 46-002(2) of the Scope of Section 46 states that this Section applies to:

“46-000(2) This Section applies to the wiring between the emergency power supply and life safety systems that are required by the National Building Code of Canada to be provided with an emergency power supply.”

Although Scope of Section 46 does not appear to cover “electrical supervision of life safety systems,” it defines such life safety systems in Rule 46-002 as follows:

“Life safety systems — emergency lighting and fire alarm systems that are required to be provided with an emergency power supply from batteries, generators, or a combination thereof, and electrical equipment for building services such as fire pumps, elevators, smoke-venting fans, smoke control fans, and dampers that are required to be provided with an emergency power supply by an emergency generator in conformance with the National Building Code of Canada.”

If the CE Code is silent on electrical supervision of life safety systems, perhaps the logical approach would be to check the National Building Code of Canada (NBCC), which mandates use of such electrically connected life safety systems, and which provides references for electrical supervision of such life safety systems via a range of other relevant codes and standards.

A brief review of Article 3.2.4.10. of the NBCC will yield to the readers the following statement in Sentence 3.2.4.10.(1) “Electrical supervision shall be provided for a fire alarm system.” This fact is very encouraging. But what about other components of an electrically connected life safety system defined in Section 46 of the CE Code?

For example, what about electrical supervision of a sprinkler system or a fire pump? And how about the electrical supervision of smoke control or smoke venting fans? And should such electrical supervision be extended to the electromagnetic locks or to the electrically connected door holders installed on exit doors? And whether a signal to the fire department is required to be electrically supervised? And how about a heat tracing cable installed on a sprinkler system? And what about an emergency generator? And what about electrical supervision of a fire suppression system installed in a commercial kitchen? And what about monitoring emergency recall of elevators? And if such supervision is necessary, where is it supposed to be provided?

No wonder, this subject creates such confusion (and potential liability by all participating parties, when a fire investigation demonstrates that such electrical supervision has been absent).

Let’s deal with these questions step-by-step, by returning to Sentence 3.2.4.10.(1) of the NBCC mentioned earlier. This sentence of the NBCC mandates electrical supervision for a fire alarm system. But what does a typical fire alarm system consist of, and what components of a fire alarm system must be electrically supervised?

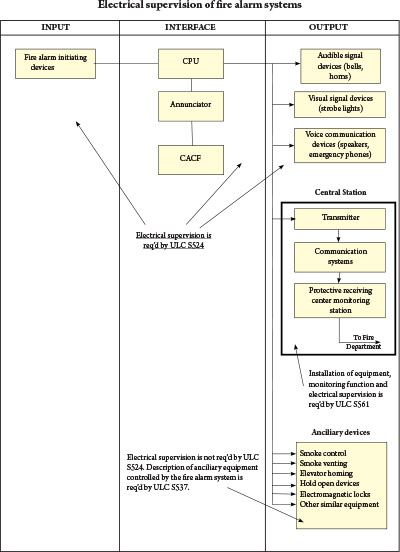

In order to answer this question, we need to check out Sentence 3.2.4.5.(1) of the NBCC. This sentence mandates that installation of a fire alarm system must comply with ULC S524 – standard for installation of fire alarm systems. ULC S524 elaborates on the equipment and field devices comprising a fire alarm system, on installation requirements of the fire alarm system components (on height, clearances, and specific location of such equipment and devices) and on electrical supervision of the wiring for devices and equipment included in a fire alarm system. Clause 3.3.1.1 of ULC S524 states that the following mandates electrical supervision of the wiring for the following components of a fire alarm system: manual stations, fire detectors, water flow devices for water based fire protection systems, NBCC required supervisory devices for water based fire protection systems, audible and visual signal devices, voice communication equipment including emergency telephone handsets, normal and emergency power supplies including power supply sources to the field devices, annunciators and control/display centre of a Central Alarm and Control Facility (CACF).

This ULC S524 requirement is very helpful in understanding that only equipment that represents components of a fire alarm system is subjected to the electrical supervision. Thus, a wiring to a typical manual station, a smoke detector or an audible signal device would have to be electrically supervised. Of course, the wiring between a control unit, annunciator and field devices must be subjected to the electrical supervision as well. All normal and emergency power supply sources would be required to be electrically supervised. The latter means that if an emergency generator is used as the emergency power supply source for a fire alarm system, it must be also electrically supervised. In fact, in addition to the requirement of Clause 3.3.1.1 of ULC S524, Clause 3.2.4.5 of this standard specifically states that a warning condition from the emergency generator safety control panel must initiate a trouble signal at the fire alarm control unit indicating a common generator fault condition, when an emergency power for a fire alarm system is provided from an emergency generator. Note: it is intended by this requirement that each other specific supervisory condition would be monitored at the emergency generator control panel in accordance with provisions of the CSA standard C282. Thus, a single common trouble signal at the annunciator is sufficient from an emergency generator.

It is interesting to note that Clause 3.3.1.5 of the ULC S524 states that “each circuit of a fire alarm system shall be installed such that open circuit faults or ground faults shall not interfere with the operation of other circuits of the fire alarm system, and such faults shall initiate a trouble signal.

Article 3.3.2 of ULC S524 provides additional requirements for operation of trouble signals (identification, audible and visual components, silencing, etc.). It should be noted that ULC S524 does not define a “supervisory signal” as a separate entity, but provides a definition of a “trouble signal” as “a visual and audible indication of equipment failure, circuit failure, fault condition or operational malfunction.” However, ULC S524 defines a “supervisory device” as “a field device to signal a condition that could prevent proper operation of a fire protection system,” and defines “tamper device” as “a device used to detect the removal or opening of a protective cover.” Thus, any abnormal condition such as a short or open circuit, or operation of a supervisory/tamper device must be indicated on a fire alarm annunciator in accordance with Clause 3.3.2.2 of ULC S524 by a distinctive trouble signal.

So, it is clear now that abnormal condition on field devices or equipment that comprises a fire alarm system must be electrically supervised. But what about electrical supervision of a building standpipe system? Is a standpipe system an integral part of a fire alarm system? The answer is “Yes.” Although operation of a standpipe system does not actuate fire alarm initiating devices and does not generate a fire alarm signal (a standpipe is operated by fire respondents, and a fire alarm signal is not necessary as a result of such operation), all valves controlling water supplies in a standpipe system must be electrically supervised at the annunciator of a building fire alarm system, and this fact is reflected by the requirement of Sentence 3.2.4.10.(2) of the NBCC.

A sprinkler system is an integral part of a fire alarm system; as in addition to being components of a fire suppression system, flow switches of a sprinkler system function as fire alarm initiating devices, and operation of each such flow switch must be indicated by a separate fire alarm initiating zone conforming to Article 3.2.4.16. of the NBCC. A fire pump also becomes a part of a sprinkler system, and electrical supervision of the fire pump is also required at the fire alarm annunciator. These requirements are articulated by Sentence 3.2.4.10.(3) of the NBCC as follows:

“3.2.4.10.(3) An automatic sprinkler system shall be electrically supervised to indicate a supervisory signal on the building fire alarm system annunciator for each of the following:

a) movement of a valve handle that controls the supply of water to sprinklers;

b) loss of excess water pressure required to prevent false alarms in a wet pipe system;

c) loss of air pressure in a dry pipe system;

d) loss of air pressure in a pressure tank;

e) a significant change in water level in any water storage container used for firefighting purposes;

f) loss of power to any automatically starting fire pump; and

g) a temperature approaching the freezing point in any dry pipe valve enclosure or water storage container used for firefighting purposes.”

It should be noted in accordance with NFPA 13, when portions of wet sprinkler system are subject to freezing, the pipe shall be protected against freezing by reliable heat-generating systems capable of maintaining a minimum temperature of 4.4 degrees C. The NFPA 13 recognizes use of heat tracing systems approved for application as means for the reliable maintenance of sprinkler systems at the required temperature level. Thus, a heat tracing system used for this specific application also becomes a part of the sprinkler system, and operation of this heat tracing system must be electrically supervised as well, in order to validate the fact that the wet sprinkler system is capable to perform as required.

Unfortunately, such requirement for electrical supervision is not reflected by any legally adopted code or standard, and the proposal to introduce this requirement into the CE Code has been submitted to Section 62 S/C of the CE Code.

Some municipalities, however, mandate such electrical supervision by directives or bulletins on clarification of the building code adopted in those municipalities. City of Vancouver, for example, published the dedicated Bulletin on application of the Vancouver Building By-law in this regard (Bulletin 2000-016), and this Bulletin mandates electrical supervision of a heat tracing system as follows:

“All heating circuits shall be thermostatically controlled and continuously monitored (electrically supervised) for:

a) loss of incoming supply voltage,

b) loss of control power,

c) ground fault,

d) continuity, and

e) open circuits.”

It should be also noted that a single common trouble signal from a fire pump may be sufficient for the purpose of paragraph 3.2.4.9.(3)(f) of the NBCC indicated above, provided that each separate condition mandated by the NFPA 20 is indicated on the fire pump controller, approved for “fire pump service.” Supervisory conditions mandated by the NFPA 20 are as follows:

a) “pump or motor running”;

b) “loss of phase”;

c) “phase reversal”;

d) “controller connected to alternate source.”

It is interesting to note that the NBCC mandates use of NFPA 96 as a standard for Ventilation Control and Fire Protection of Commercial Cooking Equipment in conjunction with commercial cooking equipment in Article 6.2.2.7. NFPA 96 states that where a commercial cooking operation is equipped with an automatic fire-extinguishing system, electrical supervision of this fire-extinguishing system must be provided on the annunciator of the building fire alarm system.

It looks like some of the questions posed at the outset of this article, slowly become answered, and the requirements for electrical supervision are no longer a complete mystery.

Where a unique supervisory condition is required to be identified by a common trouble signal on the fire alarm annunciator (as indicated in the examples above), it is a good engineering practice that the Registered Professional Electrical Engineer responsible for the design of the fire alarm system can demonstrate to the respective AHJ that such a grouping of these supervisory devices via a single common trouble signal will enable facilitation of efficient troubleshooting.

It is also interesting to note that although electrical supervision of elevators’ recall is not specifically mandated by the NBCC, Paragraph 3.2.6.7.(2)(c) requires that in a high building – Central Alarm and Control Facility (CACF) must be provided with means to “indicate visually that elevators are on emergency recall.”

Of course, electrical supervision of devices that are included in a fire alarm system must be subjected to the verification procedure of the fire alarm system in conformance with ULC S537, standard for verification of fire alarm systems. Why? you might ask. The answer is, because verification of each fire alarm system (required by Subsection 3.2.4. of the NBCC and installed in accordance with ULC S524) is, in fact, mandated by Sentence 3.2.4.5.(2) of the NBCC.

In light of the fact that such systems as smoke control and smoke venting fans and associated dampers, electromagnetic locks and hold open devices are not part of a fire alarm system, they are not subjected to electrical supervision at the annunciator of the fire alarm system, and their operation is not subjected to the verification in accordance with ULC S537. Such particular systems are considered by ULC S524 as “ancillary devices” ( i.e., equipment that has life safety implications) that are activated by a fire alarm system, but are not a part of it. Ancillary device is defined by the ULC S524. A typical verification report simply requires a description of ancillary devices activated by the fire alarm system and simply mandates only validation that upon activation of a fire alarm system, appropriate signals are sent (i.e., normally open contacts of a relay inside a fire alarm system control units have been closed in the circuits of ancillary devices — to activate such ancillary devices). However, operational/functional supervision of ancillary devices is outside of the scope of a typical fire alarm verification procedure.

Operation of such ancillary devices could be commissioned/tested in conjunction with operation of the fire alarm system, and such physical commissioning of integrated life safety systems is mandated by Article 3.2.4.6. of the NBCC in addition to the Code requirement for verification of fire alarm systems.

And what about electrical supervision of signals sent to the fire department by the building fire alarm system?

Can such supervision be provided at the fire alarm system annunciator? Let’s explore this important subject.

Where a signal to the Fire Department is required in conformance with Article 3.2.4.8. of the NBCC (assembly occupancy with occupant load exceeding 300, actuation of a first stage in a two stage fire alarm system, actuation of a fire alarm system in a sprinklered building), Sentence 3.2.4.8.(4) of the NBCC requires that signals to the Fire Department be provided by way of independent central stations conforming to CAN/UL-S561, Installation and Services for Fire Signal Receiving Centres and Systems.

ULC accredits central stations intended to provide notification of the fire department in conformance with Sentence 3.2.4.8.(4) of the NBCC under their listing in conjunction with the ULC Certificate Service, Fire Protective Signaling Systems DAYIC & DAYYC.

Each such central station is currently listed by ULC for full certificate service (monitoring and installation) or for shared (monitoring or installation) certificate service.

Every fire alarm verification report must provide name of the central station and elaborate whether the central station is listed by the ULC under a full certificate service or under “shared central station service.” When a shared central station service is used, the verification report must indicate the station which is listed for monitoring and the station which is listed for installation— for each particular site, as such central stations will assume complete responsibility for installation of a transmitter and communication system between the transmitter and the receiving center, and for monitoring/electrical supervision of the communication systems between the transmitter and the monitoring center. This means that the electrical supervision of such signal to the fire department will be done at the monitoring center in accordance with ULC S561. (see diagram 1).

Hopefully, all aspects of electrical supervision raised above have been clarified, and the mystery behind this subject has been resolved.

Diagram 1. Electrical supervision of fire alarm system devices

As usual, appropriate AHJs with jurisdictional authority for the subject of this discussion should be consulted before any design is ready for installation stage.

Find Us on Socials