Let’s be honest, you probably don’t want to read another article about AFCIs. But here are two good reasons why you ought to read this one.

First, there were some significant changes made to Section 210.12 in the 2014 edition of the National Electrical Code® (NEC®). The states have been adopting the 2014 edition at a pretty rapid pace, so do you know what those changes are?

Second, there is, unfortunately, a lot of misinformation and misunderstanding out there regarding just how to comply with 210.12(A). Do you know how to make sure the jobs you install or inspect are Code-compliant?

For answers to these and other questions you may have, read on. I promise you won’t be disappointed. (Note: quotations from the NEC are shown in italics.)

DEFINITIONS

To fully understand the AFCI requirements in Section 210.12, it is important to first understand the definition of the some of the words used in the section, so let’s take a look at some definitions from Article 100.

Device. A unit of an electrical system, other than a conductor, that carries or controls electric energy as its principal function.

Dwelling Unit. A single unit, providing complete and independent living facilities for one or more persons, including permanent provisions for living, sleeping, cooking, and sanitation.

Outlet. A point on the wiring system at which current is taken to supply utilization equipment.

There are a few words we’ll encounter along the way that are not defined in Article 100, so let’s look at the definitions of those as well.

Home run – The home run is that portion of a branch circuit from the overcurrent device located in the load center (panelboard) to the first outlet box.

Parallel arc – A parallel arc is one which occurs between the line (hot) and the grounded (neutral) conductor or the equipment grounding conductor. It is called a parallel arc because it is in parallel with the load.

Series arc – A series arc is one which occurs due to a break in a conductor or connection. It is called a series arc because it is in series with the load.

CHANGES IN THE 2014 EDITION

Now let’s take a look at the changes to Section 210.12 that were made in the 2014 edition. The change to be discussed is shaded just like it is in the NEC.

210.12 Arc-Fault Circuit-Interrupter Protection. Arc-fault circuit-interrupter protection shall be provided as required in 210.12(A) (B), and (C). The arc-fault circuit interrupter shall be installed in a readily accessible location.

READILY ACCESSIBLE

AFCIs have test buttons, as do ground-fault circuit-interrupters (GFCIs). Pushing the AFCI test button periodically is important to verify that the device is still providing arc-fault protection. A device that is hidden behind obstacles or is in a hard-to-reach location will probably not be tested often, if at all. In recognition of the importance of periodic testing, the NEC now requires that AFCIs be installed in a readily accessible location, as is the case with GFCIs.

AREAS REQUIRING PROTECTION

(A) Dwelling Units. All 120-volt, single-phase, 15- and 20-ampere branch circuits supplying outlets or devices installed in dwelling unit kitchens, family rooms, dining rooms, living rooms, parlors, libraries, dens, bedrooms, sunrooms, recreation rooms, closets, hallways, laundry areas, or similar rooms or areas shall be protected by any of the means described in 210.12(A)(1) through (6):

Code-Making Panel 2 has continued its gradual expansion of areas in dwelling units that require AFCI protection by adding kitchens and laundry areas to the list in Section 210.12(A). In addition, devices located in these areas, not just outlets, must now be AFCI protected. This means, for example, that a basement lighting branch circuit with a switch located in the living room at the head of the stairs leading to the unfinished basement would require arc-fault protection. The same would be the case for a garage or outdoor lighting branch circuit when the switches controlling the lights are located in areas requiring AFCI protection.

In the 2011 edition, the protection means was to be a “listed arc-fault circuit interrupter, combination-type”, with two exceptions. In the 2014 edition more options were added and the exceptions were moved to positive text. Let’s look at the changes and how they impact new installations.

NEW INSTALLATIONS

Section 210.12(A) deals with new installations. It now lists six different ways to comply with the requirement to provide AFCI protection in specific dwelling unit areas. It is important to note that all of these methods are intended to protect the entire branch circuit, in addition to the cords plugged into it. While all of the text in Section 210.12(A) is new, only the new options have been shaded.

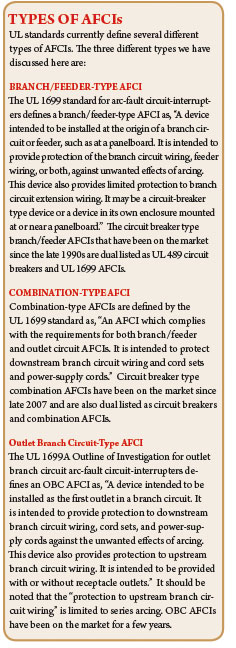

- Combination-type AFCI circuit breaker

(1) A listed combination-type arc-fault circuit interrupter, installed to provide protection of the entire branch circuit

This is the method that has been used for the past several years to meet the AFCI requirement in this section. The 2005 NEC first required the use of combination-type AFCIs effective January 1, 2008. Before that date, branch/feeder-type AFCIs could be used.

- Branch/feeder-type AFCI circuit breaker + outlet branch circuit-type AFCI receptacle

(2) A listed branch/feeder-type AFCI installed at the origin of the branch-circuit in combination with a listed outlet branch-circuit type arc-fault circuit interrupter installed at the first outlet box on the branch circuit. The first outlet box in the branch circuit shall be marked to indicate that it is the first outlet of the circuit.

The concept in this requirement is that:

- The branch/feeder-type AFCI circuit breaker located in the load center will protect the home run from parallel arcing.

- The outlet branch-circuit type arc-fault circuit interrupter (OBC AFCI) located in the first outlet box will protect the downstream conductors and any cords plugged into its face from both series and parallel arcing.

- The OBC AFCI will also provide series arc protection for the home run.

The purpose of marking the first outlet box at the time of rough-in is to insure that the OBC AFCI gets installed in it at a later time.

Branch/feeder-type AFCI circuit breakers were the devices that were used to provide AFCI protection prior to the Code requiring the use of combination type AFCIs.

- Supplemental arc protection circuit breaker + outlet branch circuit-type AFCI receptacle

(3) A listed supplemental arc protection circuit breaker installed at the origin of the branch circuit in combination with a listed outlet branch-circuit type arc-fault circuit interrupter installed at the first outlet box on the branch circuit where all of the following conditions are met:

- The branch-circuit wiring shall be continuous from the branch-circuit overcurrent device to the outlet branch-circuit arc-fault circuit interrupter.

- The maximum length of the branch-circuit wiring from the branch-circuit overcurrent device to the first outlet shall not exceed 15.2 m (50 ft) for a 14 AWG conductor or 21.3 m (70 ft) for a 12 AWG conductor.

- The first outlet box in the branch circuit shall be marked to indicate that it is the first outlet of the circuit.

The concept in this requirement is that:

- The supplemental arc protection circuit breaker located in the load center will protect the home run from parallel arcing. But in order for it to do so there must be sufficient arcing fault current to cause the circuit breaker to trip instantaneously, therefore, the home run may not exceed 50 ft for 14 AWG and 70 ft for 12 AWG conductors. Keep in mind that the arcing fault current will decrease the longer the wire run is due to the resistance of the wire.

- The OBC AFCI located in the first outlet box will protect the downstsream conductors and any cords plugged into its face from both series and parallel arcing.

- The OBC AFCI will also provide series arc protection for the home run.

The purpose of marking the first outlet box at the time of rough-in is to insure that the OBC AFCI gets installed in it at a later time. Requiring the home run to be continuous insures that all home run conductors will be protected by the OBC AFCI in the event of a series arc.

It should be noted that at the time of this writing, to the best of my knowledge, there are no supplemental arc protection circuit breakers on the market.

- System combination-type AFCI

(4) A listed outlet branch-circuit type arc-fault circuit interrupter installed at the first outlet on the branch circuit in combination with a listed branch-circuit overcurrent protective device where all of the following conditions are met:

- The branch-circuit wiring shall be continuous from the branch-circuit overcurrent device to the outlet branch-circuit arc-fault circuit interrupter.

- The maximum length of the branch-circuit wiring from the branch-circuit overcurrent device to the first outlet shall not exceed 15.2 m (50 ft) for a 14 AWG conductor or 21.3 m (70 ft) for a 12 AWG conductor.

- The first outlet box in the branch circuit shall be marked to indicate that it is the first outlet of the circuit.

- The combination of the branch-circuit overcurrent device and outlet branch-circuit AFCI shall be identified as meeting the requirements for a system combination–type AFCI and shall be listed as such.

The concept in this requirement is that:

- The branch-circuit overcurrent device (circuit breaker) located in the load center will protect the home run from parallel arcing. But in order for it to do so there must be sufficient arcing fault current to cause it to open instantaneously, therefore, the home run may not exceed 50 ft for 14 AWG and 70 ft for 12 AWG conductors.

- The OBC AFCI located in the first outlet box will protect the downstream conductors and any cords plugged into its face from both series and parallel arcing.

- The OBC AFCI will also provide series arc protection for the home run.

- Testing the branch-circuit overcurrent device and OBC AFCI together and listing them as a system combination AFCI will assure that the pair will provide arc fault protection for the home run. In other words, it will be the two devices working together that will provide arc fault protection for the entire branch circuit and all of the cords connected to it.

The purpose of marking the first outlet box at the time of rough-in is to insure that the OBC AFCI gets installed in it at a later time. Requiring the home run to be continuous insures that all home run conductors will be protected by the OBC AFCI in the event of a series arc.

It should be noted that at the time of this writing UL has yet to issue an Outline of Investigation for system combination-type AFCIs, not that they haven’t tried, thus there are none on the market.

- Outlet branch circuit-type AFCI receptacle + steel wiring method

(5) If RMC, IMC, EMT, Type MC, or steel-armored Type AC cables meeting the requirements of 250.118, metal wireways, metal auxiliary gutters, and metal outlet and junction boxes are installed for the portion of the branch circuit between the branch-circuit overcurrent device and the first outlet, it shall be permitted to install a listed outlet branch-circuit type AFCI at the first outlet to provide protection for the remaining portion of the branch circuit.

This was Exception No. 1 in the 2011 edition and was changed to positive text.

- Outlet branch circuit-type AFCI receptacle + concrete encasement

(6) Where a listed metal or nonmetallic conduit or tubing or Type MC cable is encased in not less than 50 mm (2 in.) of concrete for the portion of the branch circuit between the branch-circuit overcurrent device and the first outlet, it shall be permitted to install a listed outlet branch-circuit type AFCI at the first outlet to provide protection for the remaining portion of the branch circuit.

This was Exception No. 2 in the 2011 edition and was changed to positive text.

OTHER 210.12(A) CHANGES

Exception No. 3 in the 2011 edition is now simply titled “Exception” and remains otherwise unchanged. The Informational Notes have been updated.

BRANCH CIRCUIT EXTENSIONS OR MODIFICATIONS

An exception has been added to Section 210.12(B).

Exception: AFCI protection shall not be required where the extension of the existing conductors is not more than 1.8 m (6 ft) and does not include any additional outlets or devices.

This exception will make changing out a load center or adding a short extension to a branch circuit less burdensome.

DORMITORY UNITS

The requirements for arc fault protection have been extended to dormitory units.

(C) Dormitory Units. All 120-volt, single-phase, 15- and 20-ampere branch circuits supplying outlets installed in dormitory unit bedrooms, living rooms, hallways, closets, and similar rooms shall be protected by a listed arc-fault circuit interrupter meeting the requirements of 210.12(A)(1) through (6) as appropriate.

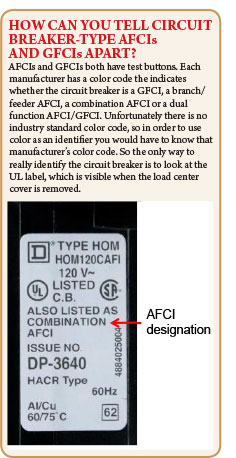

AFCIs AND GFCIs

As we’ve seen, the NEC now requires AFCI protection in kitchen and laundry areas. Of course the two small appliance branch circuits long required in kitchens need GFCI protection. But in the 2014 NEC, new Section 210.8(A)(10) now requires GFCI protection in laundry areas and new Section 210.8(D) now requires GFCI protection of the dishwasher branch circuit.

Are GFCIs and AFCIs compatible? Yes! GFCI receptacles can be fed from AFCI circuit breakers.

Will it be possible to buy a circuit breaker that provides both AFCI protection and GFCI protection? Yes! As of this writing, there are multiple circuit breaker manufacturers offering dual function AFCI/GFCI circuit breakers. They are listed as a UL 489 circuit breaker/GFCI and a UL 1699 combination AFCI.

INSPECTION CHALLENGE

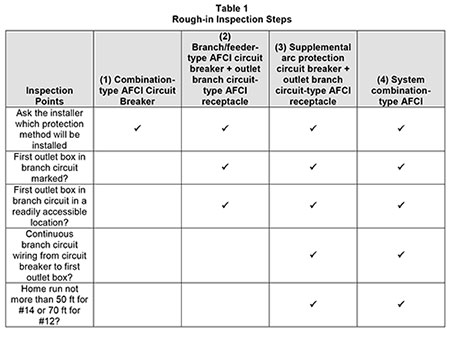

Now that there are six different ways that AFCI protection can be provided in new home construction, the inspection of homes may be more challenging and may take more time. Since options 5 and 6 in Section 210.12(A) are not really new, having appeared as exceptions in the 2008 and 2011 editions, let’s discuss the challenges in inspecting options 1 through 4.

Regardless of whether option (1), (2), (3) or (4) will be employed, the installer will have to inform the inspector at the time of the rough-in inspection of which option will be used. Why? Because the steps in the rough-in inspection will change, depending on the option to be installed later.

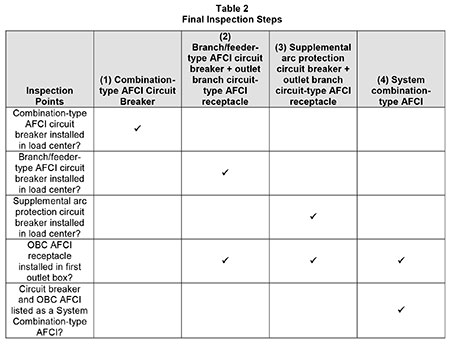

Table 1 shows what an inspector will need to look for during the rough-in inspection depending on the option to be installed.

Inspectors might want to consider asking installers using methods (3) and (4) to tag the home runs with their length to make the inspection task easier. This would also serve to emphasize to installers that the home run length is an important part of making sure that the installation will have the arc fault protection needed.

Table 2 shows what an inspector will need to look for during the final inspection depending on the option to be installed.

During the development of a UL standard for system combination-type AFCIs it has been proposed that the circuit breaker and OBC AFCI be labeled to indicate that they are part of a system and that specified devices would need to be used as replacements, should that ever become necessary. If that requirement comes about it would add another two final inspection points to check for option 4.

CONCLUSION

AFCIs play an important role in protecting the lives and property of homeowners and their families. But providing this added protection is not dependent only on the functioning of the device itself, it is also dependent on proper installation, and that’s where installers and inspectors come in. Installers must follow the Code to make sure that the final installation will have the needed protection and inspectors need to double check their work. If the team of device manufacturers, installers and inspectors work together, safer electrical installations will be the result.

In creating more options in Section 210.12(A), Code-Making Panel 2 has introduced opportunities for manufacturers to introduce new products to meet the AFCI protection requirements in the Code. However, in order for these new options to provide arc fault protection the products will need to be installed correctly. Inspectors will need to make sure that the work is done right so that people and their homes will be adequately protected from the risk of electrical fires.

Find Us on Socials