Although a few articles have already been written on this subject, numerous questions have been raised by industry stakeholders, including:

- What codes or standards mandate integrated fire protection and life safety systems?

- Of what does integrated fire protection and life safety systems consist?

- What is the extent of the required testing?

- Who should perform the testing?

- What is the scope of ULC S1001?

So, let’s clarify these questions accordingly.

Requirements for testing of fire protection and life safety systems

Requirements for testing of integrated fire protection and life safety systems are provided in Part 3 and Part 9 of the National Building Code of Canada 2015 (NBC) in respect to newly constructed buildings (or in respect to renovation of, or addition to, existing buildings) as follows:

3.2.9. Integrated Fire Protection and Life Safety Systems

3.2.9.1. Testing

1) Where fire protection and life safety systems and systems with fire protection and life safety functions are integrated with each other, they shall be tested as a whole in accordance with CAN/ULC-S1001, “Integrated Systems Testing of Fire Protection and Life Safety Systems,” to verify that they have been properly integrated. [See Note A-3.2.9.1.(1).]”

9.10.1.2. Testing of Integrated Fire Protection and Life Safety Systems

1) Where life safety and fire protection systems and systems with fire protection and life safety functions are integrated with each other, they shall be tested as a whole in accordance with CAN/ULC-S1001, “Integrated Systems Testing of Fire Protection and Life Safety Systems,” to verify that they have been properly integrated. [See Note A-3.2.9.1.(1).]”

Appendix A Note on the requirements of the above-referenced Articles the NBC is as follows:

A-3.2.9.1.(1) Testing of Fire Protection and Life Safety Systems. Building owners should verify that fire protection and life safety systems and their components (i.e. fire alarm systems, sprinklers, standpipes, smoke control, ventilation, pressurization, door hold-open devices, elevator recalls, smoke and fire shutters and dampers, emergency power, emergency lighting, fire pumps, generators, etc.), including their interconnections with other building systems, are functioning according to the intent of their design. CAN/ULC-S1001, “Integrated Systems Testing of Fire Protection and Life Safety Systems,” provides the methodology for verifying and documenting that interconnections between building systems satisfy the intent of their design and that the systems function as intended by the Code.

Clause 6.1.5 of CAN/ULC-S1001 allows the Integrated Testing Coordinator to accept documented evidence of any tests that have been performed on a system as part of its acceptance testing for the purpose of demonstrating compliance with the integrated testing requirements of that standard, so as to avoid duplication of work.

Requirements for testing of interconnections between fire protection and life safety systems in existing operational buildings also exists in the National Fire Code of Canada 2015 (NFC) as follows [see below Article 6.8.1.1. of the NFC and Appendix A note in this article]:

6.8.1.1. Testing and Maintenance

1) Interconnections between fire protection and life safety systems shall be tested and maintained in conformance with CAN/ULC-S1001, “Integrated Systems Testing of Fire Protection and Life Safety Systems.” [See Note A-6.8.1.1.(1).]

A-6.8.1.1.(1) Building owners must ensure that fire protection and life safety systems and their components (i.e. fire alarm systems, sprinklers, standpipes, smoke control, ventilation, pressurization, door hold-open devices, elevator recalls, smoke and fire shutters and dampers, emergency power, emergency lighting, fire pumps, generators, etc.), including their interconnections with other building systems, are functioning according to the intent of their design. CAN/ULC-S1001, “Integrated Systems Testing of Fire Protection and Life Safety Systems,” provides the methodology for verifying and documenting that interconnections between building systems satisfy the intent of their design and that the systems function as intended by the Code. Clause 6.1.5 of CAN/ULC-S1001 allows the Integrated Testing Coordinator to accept documented evidence of any tests that have been performed on a system as part of its acceptance testing for the purpose of demonstrating compliance with the integrated testing requirements of that standard, so as to avoid duplication of work.

So, if the 2015 edition of the NBC and 2015 edition of the NFC are adopted for a regulatory enforcement in any relevant jurisdiction, compliance with the applicable provisions of these legally adopted Codes is mandatory in new and existing buildings, and integrated testing of fire protection and life safety systems to ULC Standard S1001 would be certainly required, as this ULC standard is referenced in the above indicated provisions of the legally adopted NBC and NFC.

This is a reality which is unfortunately not fully embraced by the owners, designers, and regulators across the country.

It means that if, for example, any replacement of components on the existing fire alarm system (FAS) in a 20-year-old building would trigger verification of that portion of the FAS that was subjected to the modifications. If a central alarm and control facility (CACF) or a central processing unit/control unit of the existing FAS is replaced, then the entire fire alarm system would be subjected to a verification in accordance with ULC S537.

When the fire alarm system is verified, and it has been demonstrated that the fire alarm system operates as designed and has no deficiencies, then the additional integrated testing to ULC S1001 would not be warranted, as the verified FAS must continue to provide all existing outputs in respect to the operation of the existing life safety systems.

When the existing pieces of the electrically connected life safety systems have been upgraded or replaced, then operation of these replaced or upgraded pieces would have to be tested in accordance with ULC S1001.

Composition of fire protection and life safety systems

Article 3.2.4.5. of the NBC mandates that fire alarm systems must be installed in accordance with the standard ULC S524, and that upon completion of this installation, each FAS must be verified in conformance with ULC S537 by qualified persons acceptable to the authority having jurisdiction (AHJ).

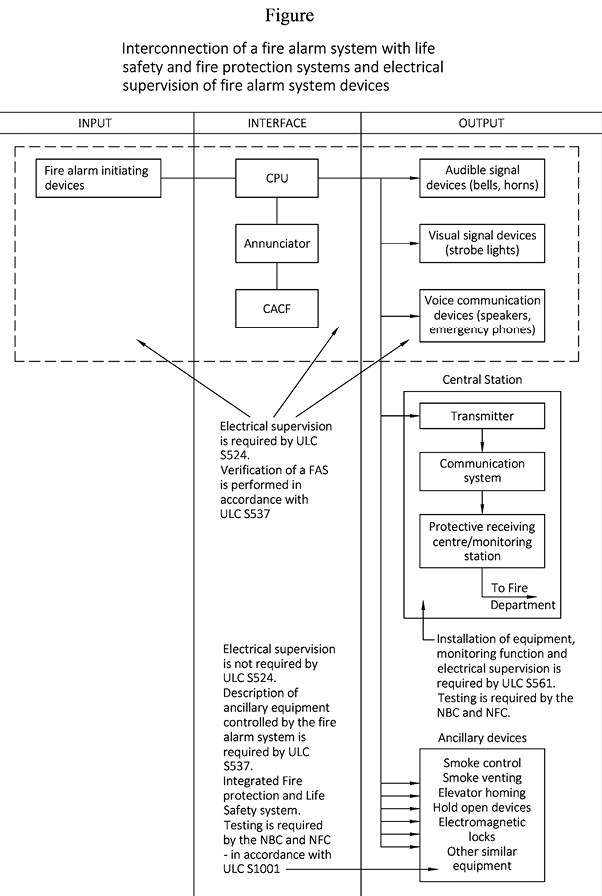

It should be noted that the extent of a verification is only limited to the equipment, wiring, and devices comprising a fire alarm system (i.e., to the fire alarm system components that are required electrically supervised by the NBC and by ULC S524) [see the top portion of the figure on the following page].

It should also be noted that the fire alarm system verification process includes validation that actuation of the FAS results in sending the necessary signals—to activate relevant auxiliary equipment indicated in Article 3.2.6.7. of the NBC.

This “auxiliary equipment” is represented in the ULC S524 as an “ancillary device.”

ULC S524 defines “ancillary device” as: “ANCILLARY DEVICE – A device which has a life-safety application, and is activated by the fire alarm system, but is not part of the fire alarm system.“

Such “ancillary devices” described by the ULC S524, or “auxiliary equipment” indicated in the NBC, are represented by the various pieces of electrically connected equipment that will be activated as the result of actuation of the FAS (i.e., elevator homing, hold-open devices release, release of electromagnetic locks, actuation of smoke control and smoke venting equipment, operation of fire dampers, signals to the fire department, etc.)

The extent of the required integrated testing

As it was indicated above, although the fire alarm system verification process includes validation that actuation of the fire alarm system results in opening or closing of certain output relay contacts inside the FAS control unit or CACF, it is impossible to know for certain by the verification of a fire alarm system if any opening or closing—such as relay contacts—actually results in activation of relevant life safety equipment (i.e., elevator homing, hold-open devices release, release of electromagnetic locks, actuation of smoke control and smoke venting equipment, operation of fire dampers, signals to the fire department).

Therefore, a functional ability of the listed life safety equipment to perform the intended designed functions could be determined and validated only by demonstrated testing in coordination with the fire alarm system.

It should be noted that such integrated testing of fire protection and life safety systems should also include testing of smoke control and smoke venting equipment required by Article 3.2.6.9. of the NBC, when a fire alarm system is installed in a high building, where this smoke control and smoke venting equipment is mandated by the NBC:

3.2.6.9. Testing

1) The systems for control of smoke movement and mechanical venting required by Articles 3.2.6.2. and 3.2.6.6. shall be tested to ensure satisfactory operation. [See Note A-3.2.6.9.(1)].

A-3.2.6.9.(1) Testing for Smoke Control. The efficiency of a smoke control system may be checked by measuring pressure differences and the directions of airflow around doors and through separating walls of compartments. A pressure meter can be used to measure pressure differences on either side of a door or partition. Where this is impracticable, a punk stick held near a crack will indicate the direction of airflow.

Measurements of airflow may be taken on the intake side of supply fans or in supply ducts to determine whether the specified airflow is being provided. In general, airflow should be from the spaces that may be occupied for various lengths of time during a fire emergency (e.g., vestibules, stair shafts, and elevator hoistways) toward the space in which the fire is assumed to have occurred. Measurements may be taken at certain critical locations to check the overall efficiency of the smoke control system.

In buildings where protection is obtained by venting corridors or vestibules to the outdoors, inspection of the building to determine whether the requirements have been met should be sufficient. Where service shafts are vented to the outdoors at the top, a check may be made of the wall between the shaft and the uppermost occupied floor areas to ensure that the direction of flow is from each floor area into the shaft, when the vent to the outside is open and the outdoor air temperature is significantly less than that indoors. Where mechanically pressurized vestibules are used, a check may be made to ensure that the pressure in each vestibule or area of refuge is greater than that in the adjacent floor areas at each floor level.

Doors to stair shafts, elevator hoistways, and vestibules in locations subject to pressure differences that may interfere with normal opening should be checked when the outdoor temperature is near the January design temperature, with the air injection system operating and a number of windows open to the outdoors on each floor in turn.”

Qualification required for integrated testing of fire protection and life safety systems

Preface to ULC S1001 states the following: “The requirements of this Standard contemplate that the integrated systems testing procedures described herein will be conducted by an organization other than the installing contractor.”

The AHJs responsible for acceptance of such coordinated testing usually apply their specific administrative requirements for persons who conduct this coordinated testing. In many instances, such responsibility is delegated to coordinated registered professionals (CRPs) who will establish testing protocols and will consult these protocols with the AHJ.

It is interesting to note that ULC S1001 provides the following criteria for participants of the integrated testing (but acceptance of this ULC S1001 criteria should always be verified with the local AHJ):

4.1 INTEGRATED SYSTEMS TESTING PARTICIPANTS

4.1.1 The person(s) identified in the integrated testing plan, who are required to participate in the integrated systems tests, shall be knowledgeable and experienced in the design, installation, and operation of their relevant fire protection and life safety system(s).

NOTE: Federal, provincial, territorial or other applicable regulations may exist for the licensing and/or certification of individuals as confirmation of their knowledge and experience.

4.2 INTEGRATED TESTING COORDINATOR

4.2.1 The integrated testing coordinator shall be knowledgeable and experienced in the design, installation, and operation of fire protection and life safety system(s), and the fire protection and life safety functions of building systems. Refer to Appendix A4.2.1.

4.2.2 The integrated testing coordinator shall have knowledge and understanding of:

A) The Codes and Standards that regulate the design and installation of fire protection and life safety system(s);

B) How individual and integrated fire protection and life safety system(s) are designed to operate during normal operating conditions and emergency conditions; and

C) Methods for validating the intended functionality of integrated fire protection and life safety system(s).

4.2.3 The integrated testing coordinator shall have all licenses and certifications if required by:

A) Federal, provincial, territorial or other applicable regulations; and/or

B) Contractual obligations.

Scope of ULC S1001

ULC S1001 Integrated Systems Testing of Fire Protection and Life Safety Systems was developed to specifically address the integrated testing protocol, and this Standard is referenced in the NBC and the NFC accordingly.

So, when the NBC and NFC are legally adopted for regulatory enforcement, compliance with ULC S1001 becomes mandatory.

The scope of this Standard states the following:

1. SCOPE

1.1 This Standard prescribes the methodology for verifying and documenting that all interconnections between systems provided for fire protection and life safety functions are installed and operating in conformance with their design criteria. Refer to Appendix A1.1.

1.2 This Standard is intended to satisfy the requirement for integrated systems testing in the National Building Code of Canada and the National Fire Code of Canada.

1.3 It is not the intent of this Standard that integrated systems testing ensure individual fire protection and life safety systems are functioning and installed in accordance with their design criteria or referenced Standards.

Hopefully, this article clarifies the subject at hand. The figure on the prior page intends to provide additional clarification on this issue. And, as usual, the local AHJ responsible for enforcement of the NBC and NFC should be consulted on this important (and not always well understood) subject.

Find Us on Socials