The Sugar Cane Growers Cooperative of Florida is a 54-member sugar farmers’ cooperative that provides its members assistance with agricultural administration and processing operations for their more than 70,000 acres of sugarcane. At its Belle Glade plant, 24,000 tons of sugar cane is ground daily, producing 350,000 tons of raw sugar annually, on average. During the October through April harvest season, the plant operates 24 hours a day, seven days a week. Because sugar cane must be processed within a day of harvest, high throughput is essential.

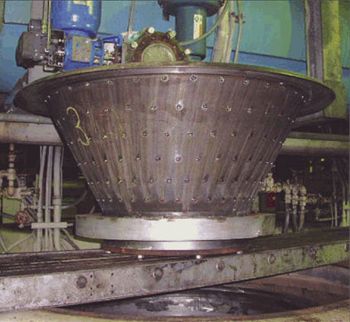

Key components in the multi-step process of converting cane into raw sugar are the sugar centrifuges, which separate crystals of sugar from sugar syrups. As the centrifuge spins at a rate of 45 to 1,200 RPM, the syrup (molasses) is forced out through perforations in the centrifuge wall, and raw sugar is left. The centrifuge’s drive controls the speed of the machine, ensuring maximum moisture is extracted.

After the 2003 harvest, the Sugar Cane Growers Cooperative decided to replace the drive control on a centrifuge, which has a 450 hp motor, one of the operation’s two largest centrifuges. The existing drive was outdated and was subject to frequent and expensive repairs, resulting in shutdowns that reduced production capacity. Because space was at a premium, they wanted a drive system with a compact footprint that would work with the existing OEM-supplied control configuration.

“Our previous unit failed at least once or twice a year, costing us thousands of dollars in replacement parts. Plus, when the centrifuge went down, it crippled the entire production line,” explains Jose Mena, chief electrical engineer at the Belle Glade plant. “We needed a drive system that was reliable, in addition to a drive that could re-harness the power lost when the centrifuge recycled.”

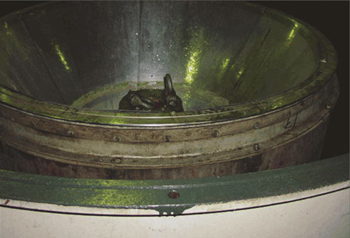

Photo 3. Scew conveyor inside the casing

The solution: a stand-alone industrial low-voltage drive for speed and torque control—the first of its kind installed in a sugar-processing facility. “We retrofitted with this drive, because it offered the Sugar Cane Growers processing plant everything they needed—a compact drive footprint, regenerative capability, and exact motor sizing,” says Chris Visage, an ABB Low-Voltage Drives territory manager at Hummel Industrial Sales (Ft. Lauderdale), the company commissioned to perform the retrofit. “The resulting improvement in cycle time will increase throughput and eliminate bottlenecks at the centrifuge, without adding a new larger motor,” he noted.

Shortened Cycle Time Means Increased Production

The drive provides precise, rapid motor-speed response based on exact variations of the centrifuge load—and this direct torque control immediately accelerated the centrifuge cycle time from 44 to 32 seconds, a 20 percent savings over the previous drive. Direct torque control enables the drive to calculate the torque and flux of the motor 40,000 times per second, quickly slowing the load down at end of cycle, saving seconds in unload/reload operations. Additional time and energy savings are realized, as the energy from the spinning centrifuge, which turns the motor into a generator, is recovered and transferred via the drive to an adjacent centrifuge. (This energy is dissipated as heat, in installations that do not utilize regenerative drives.)

Stable Ride Through Unstable Conditions

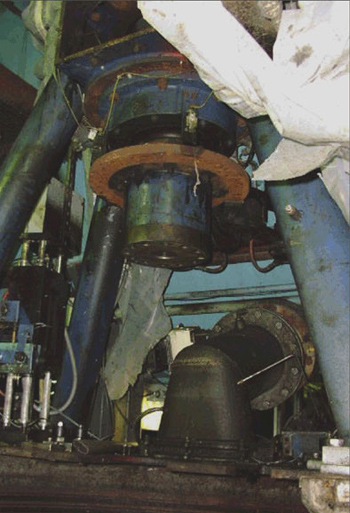

Photo 4. Motor mount above sugar centrifuge

The industrial low-voltage drive also enables motors to run at full power at full motor voltage in 80 percent brownout conditions. This ride-through ability means that, even when there’s a dramatic short-term reduction in voltage, the drive sustains full power for uninterrupted operation. In operating conditions where line voltage from a utility varies, this benefit helps ensure constant, optimum throughput. The industrial low-voltage drive employs an insulated gate bipolar transistor (IGBT) active front end, which is far more robust than traditional silicon-controlled rectifier (SCR) front ends. (SCR front ends are susceptible to inversion faults, which occur when the line power fails during a regenerative stop at the end of the spin cycle. It is not uncommon for such inversion faults to cause extended down times.) The IGBT front end, in conjunction with the microprocessor control of the industrial low-voltage drive, can be shut down safely, to prevent damage to the drive, should a power failure occur during a regenerative stop. The technology advance makes catastrophic inversion faults a thing of the past.

A Perfect Match to Existing Equipment

Because uptime is paramount during harvest, it was crucial to complete the retrofit installation before the season began. “We were able to install and test this system in five working days time, meeting the co-op’s deadline with a month to spare,” Visage says.

Photo 5. New ABB regenerative industrial drive installed

Installation time was shortened because ABB matched the existing control system from the OEM without using any relays, outside control interfaces, or power logic controllers (PLCs). “Our regenerative line was able to drive the motor and match the input power supply precisely, eliminating any additional spikes or fluctuations,” Visage says. “Because the throughput has increased, the co-op will be able to use the existing motor to the fullest, instead of dissipating much of the energy, which was the case with their prior drive.”

The drive cabinet is in a confined area, so a compact footprint was vital. The modular design provided a 40 percent savings in floor space over the previous unit, and the modular construction of the drive makes maintenance and repairs easier.

Software Aids Ease of Operation

Keypads and software designs facilitate smooth and accurate operation and maintenance, because they offer the capability to store programming within the removable keypad. This eliminates guesswork when the drive is reprogrammed after service. Parameters are simply downloaded from a unique user-saved position. In addition, exact run times are easily accessible by keypad, which promotes systematic maintenance scheduling and fewer secondary failures such as clogged filters.

“ABB has provided us a reliable product and an excellent service team,” Mena says. “Because we have other ABB products at the plant, we knew the reliability factor and anticipated no downtime with the retrofit.”

Local Support / Local Service

Sugar Cane Growers Cooperative worked closely with Miller Bearings, Inc., an industrial distributor for ABB products in Florida (http://www.millerbearings.com). Because the distributorship is factory certified DSS (Drive Service Station), providing maintenance and service for drive installations like these also is available, if needed. Throughout the project for Sugar Cane Growers Cooperative, a team consisting of Miller Bearings, ABB engineers and sales managers collaborated from start to finish, to size the drive, plan the installation, and commission the drive, ensuring total customer satisfaction. For further information about the products used in this project: seehttp://www.abb-drives.com.

Find Us on Socials