Whenever I travel across our great country, I never cease to be amazed that the receptacles in my hotel room, in the meeting rooms, in the airports or wherever I go are always the same shape and size. The ungrounded, grounded and equipment grounding slots or “smiley face” are always in the exact position, and the dimensions never change. The power cord for my laptop computer plugs right in every time with no problem. This has to be sheer coincidence, right? No, this is no coincidence at all. All these receptacles are built to a product standard (UL 498) that will ensure our electrical products will be compatible, regardless of our location around the country. As long as the electricity is available when we plug into a receptacle, we tend to take these devices for granted. It’s difficult to improve on these reliable devices, but in this article we consider a few changes in the upcoming 2014 National Electrical Code.

Article 100 of the NECdefines a receptacle as “a contact device installed at the outlet for the connection of an attachment plug.” Article 406 of the NEC is titled, “Receptacles, Cord Connectors, and Attachment Plugs (Caps).” Let’s look at some of the changes in Article 406 and other places that affected our little “smiley face” friends we call receptacles.

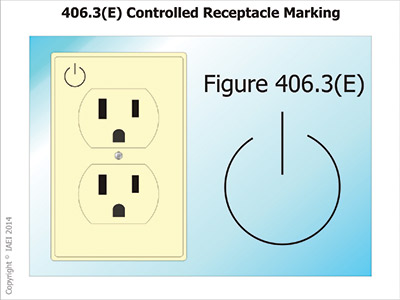

406.3(E) and Figure 406.3(E)

Controlled Receptacle Marking

A new subdivision titled “Controlled Receptacle Marking” was added to 406.3, Receptacle Rating and Type. This new subsection will now require a new marking symbol for all nonlocking-type, 125-volt, 15- and 20-ampere receptacle outlets controlled by an automatic control device or by an automatic energy management system. A new symbol was also added in new Figure 406.3(E). An exception follows this rule to indicate that this marking is not required for receptacle outlets controlled by a wall switch to provide the required room lighting outlet(s) as permitted by 210.70(A)(1) Ex. No. 1.

New energy management codes are currently being widely adopted. One such energy management code is ASHRAE 90.1 Energy Standard for Buildings except Low-Rise Residential Buildings. This code requires that up to 50 percent of all 125-volt, 15- and 20-ampere receptacles be automatically controlled. The control could be an energy management system, timer or sensor. The occupant or end user needs to know which receptacle outlets will be automatically controlled and which receptacles will be energized continually. This will avoid loads such as a refrigerator appliance being plugged into the receptacle and then being unintentionally turned off for a time. Automated systems typically control identified loads such as lighting or HVAC equipment with the consequences known and understood. The uncertainty of what is plugged into a controlled receptacle outlet can raise concerns regarding safety as well as convenience; thus, it is essential to be able to identify, readily, receptacle outlets that will be powered on and off automatically.

Figure 1. Receptacles controlled by an automatic control means must be so marked.

406.4(D) Readily Accessible Location for Replacement Receptacles

This new requirement for replacement of receptacles was initiated to align the readily accessible requirements for GFCI devices stated at 210.8 with the rules for GFCI and AFCI protective devices required at 406.4(D). The readily accessible requirement for GFCI receptacles governed at 210.8 was added to the 2011 NEC. Justification for the readily accessible rule at 210.8 was primarily related to occupant or user accessibility to the monthly testing and to the features of the reset device. Just like GFCI protection, AFCI protection can also be accomplished by circuit breaker types or outlet-type devices which have the same monthly testing and reset features. Ready accessibility to these protective devices for replacement receptacles should not be different from that for GFCI devices covered at 210.8.

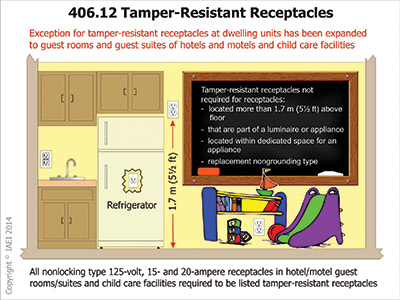

Figure 2. Exception for tamper-resistant receptacles

was expanded for the 2014 NEC.

406.5(E) Receptacles in Countertops and Similar Work Surfaces

Receptacles are prohibited from being installed ina face-up position in countertops, or similar work surfaces; this prohibition applied only to dwelling units prior to the 2014 NEC. The words “in Dwelling Units” were removed from the title of 406.5(E) to make it clear that receptacles cannot be installed ina face-up position, in countertops or in similar work surfaces, of any type occupancy, not just in dwelling units. If there is a concern about receptacles installed in the face-up position at dwelling units countertops or similar work surfaces for such things as liquid spillage, these same concerns exist at countertops or similar work surfaces of non-dwelling units, as well. Section 406.5(E) also now recognizes “listed receptacle assemblies” for countertop applications. ANSI/UL 498-2012 Standard for Safety for Attachment Plugs and Receptacles in Sections 143, 144 and 146, and ANSI/UL 943-2012 Standard for Safety for Ground-Fault Circuit-Interrupters in Sections 6.28 – 6.29 specifically evaluate and list receptacle assemblies and GFCI receptacle assemblies for countertop applications.

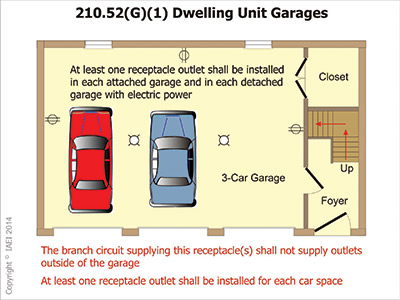

Figure 3. Receptacle outlet is required for each car space.

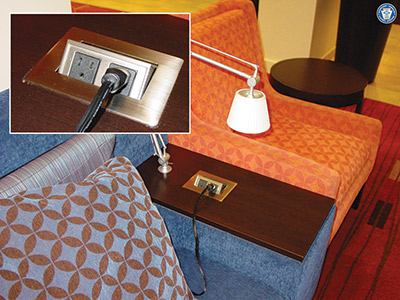

406.5(F) Receptacles in Seating Areas and Other Similar Surfaces

Receptacles are presently not permitted, according to 406.5(E), to be installed in a face-up position in countertops, or similar work surfaces. In recent times, benches and seating areas in public locations such as airports are being installed with receptacles installed in and on the seating areas. These are typically installed so that someone can sit on these benches and use the supplied 125-volt receptacle outlet for a laptop computer or to charge a cell phone or other electronic hand-held device. In some cases, these receptacles are installed in the face-up position. This represents a hazard in waiting as it is possible in some cases to sit right on the receptacle itself. Spillage — of water, soft drinks, etc. — is another issue involving these “face-up” receptacles. Where there is a need to install such receptacles in benches or other similar surfaces, it should be done with an assembly listed for the application to prevent damage and potential exposure to energized conductors or circuit parts. For the 2014 NEC, strict language was adopted at 406.5(F) that will require receptacles in seating areas or similar surfaces not to be installed in the face-up position unless the receptacle is part of an assembly listed as a furniture power distribution unit (if cord-and-plug-connected) listed to UL Product Standard 962A; or is part of an assembly as household or commercial furnishings listed to UL Product Standard 962. These seating-mounted receptacles can also be listed as a receptacle assembly or as a GFCI receptacle assembly for countertop applications or installed in a listed floor box.

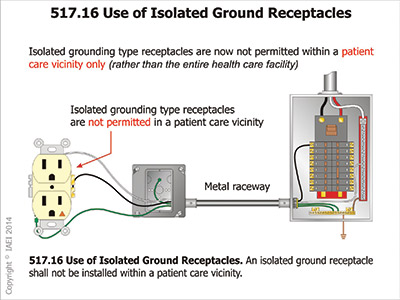

Figure 4. Isolated ground receptacles are not permitted in a patient care vicinity.

406.9(B)(1) 15- and 20-Ampere Receptacles in Wet Locations

Revisions to 406.9(B)(1) have leveled the playing field for dwelling units and non-dwelling unit wet locations as far as “extra duty” enclosures and covers are concerned. The “in-use” covers for wet location, 15- and 20-ampere, 125- and 250-volt receptacles must all be of the extra duty type regardless of its occupancy type location. The requirements for these more rigidly-constructed extra duty covers or hoods at in-use covers for receptacles installed in wet locations was instituted in the 2011 NEC, but at that time, the extra duty cover provision only applied to “other than one- or two-family dwellings.” The durability of the nonmetallic in-use cover hoods provided for compliance with these wet location requirements has been found to be less than desirable, especially on construction sites. Breakage and hinge failure to these nonmetallic hood covers has been reported at dwelling units and non-dwelling units as well, leaving the receptacles exposed to all weather conditions. The more rigorous performance requirements in UL Product Standard 514D, Standard for Cover Plates for Flush-Mounted Wiring Devices, for of these extra duty in-use outlet box hood covers has improved the general durability of all listed in-use covers.

Another revision calls for these extra duty covers at all wet location 15- and 20-ampere, 125- and 250-volt receptacles, not just the ones that are supported from grade. If the receptacle is installed in a wet location, it should make no difference how the enclosure or device box is installed or supported when determining the need for an extra duty hood cover.

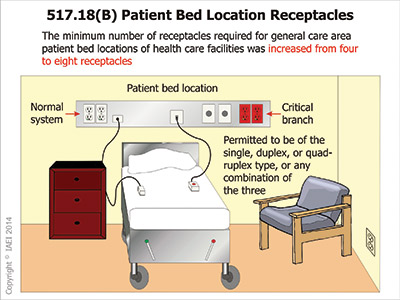

Figure 5. The minimum number of required receptacles was increased at health care facilities.

406.12 Exception for Tamper-Resistant Receptacles

The exception for tamper-resistant receptacles (with four specific locations or areas) that applied only to dwelling units in the 2011 NEC, now applies to dwelling units, guest rooms and guest suites of hotels and motels, and to child care facilities. Tamper-resistant receptacles for dwelling units were introduced in the 2008 NEC in an effort to prevent small children from inserting foreign objects (paper clips, keys, etc.) into energized electrical receptacles. An exception (with four areas) was added to the requirement for tamper-resistant receptacles in the 2011 NEC. Tamper-resistant receptacles requirements for guest rooms and guest suites of hotels and motels and for child care facilities were added to the 2011 NEC, as well. These three sections for tamper-resistant receptacles were combined into one section with three subsections, with the exception that applied to dwelling units being moved to apply to all three occupancies for the 2014 NEC. The exception with the four specified locations that was added to the 2011 NEC for dwelling units was warranted, but these exceptions are also needed for guest rooms and guest suites of hotels and motels and for child care facilities. These exempted locations — whether in a dwelling, hotel room, or a child care facility — are out of reach of small children and should be exempted for tamper-resistant receptacle provisions.

406.15 Dimmer Controlled Receptacles

A new section was added at 406.15 to permit specific receptacles to be controlled by a dimmer under specific conditions. A receptacle supplying lighting loads can be connected to a dimmer if the plug/receptacle combination is a “nonstandard configuration” type and is specifically listed and identified for each such unique combination. The electrical industry is starting to see 120-volt cord- and plug-connected lighting, such as rope lighting, being installed under shelving or under cabinets. To power this lighting, conventional 120-volt receptacle outlets are being employed. The concerns begin when the occupant complains that the lighting is too bright, and he wants to control this cord- and plug-connected lighting with a dimmer. Some of the manufacturers of these lighting sources provide a dimming feature that is listed with their product. Clear and concise Codelanguage was needed to ensure that standard grade receptacles cannot be controlled from any dimming or voltage dropping device. This new provision will require a receptacle supplying lighting loads from a dimmer only if the plug/receptacle combination is a nonstandard configuration type and is specifically listed and identified for each such unique combination.

Photo 1. New provisions were added that prohibit receptacles, unless they are part of an assembly listed for the application, from being installed in a face-up position in seating areas or similar surfaces.

Other noteworthy changes in the 2014 NECinvolving receptacles include the following.

210.52(G) Dwelling Unit Garage Receptacle Outlets

A receptacle is now required for each car space in a garage. The garages encountered today at most dwelling units have gone from a simple place to park vehicles out of the elements in a bygone era to “do-it-all” locations where homeowners service their vehicles and/or convert a portion of the garage space to serve as a workshop. In previous editions of the Code, one convenience receptacle outlet was required in this garage location regardless of the size of the garage or the intended use of same. In many instances, this one required receptacle outlet may very well be located behind a large appliance such as a freezer or refrigerator. It is not uncommon in these situations for the homeowner to resort to running an extension cord from this receptacle outlet behind the appliance or from the garage door receptacle outlet, stapling the cord to the ceiling and down the wall to have an additional outlet for convenience use for such things as hand drills, car vacuum cleaners, etc. The majority of dwelling units built today is constructed with two- or three-car garages. This new provision which will now require an additional receptacle outlet for each car space will reduce the use of extension cords currently being used to extend the branch circuit wiring and will provide a safer environment for the homeowner.

Photo 2. “Extra duty” covers are now required for all 15- and 20-ampere, 125- and 250-volt receptacles installed in a wet location (not just for those supported from grade), including dwelling unit wet location receptacles, as well.

210.64 Receptacle at Electrical Service Areas

At least one 125-volt, single-phase, 15- or 20-ampere receptacle outlet is now required to be installed within 15 m (50 ft) of all electrical service areas. There is also an exception added for this rule to exempt one- and two-family dwelling services from this requirement. This new rule is similar to the requirement for a service receptacle outlet to be installed within 7.5 m (25 ft) of all heating, air-conditioning, and refrigeration equipment at 210.63. At the service equipment, there is sometimes a need for connecting portable electrical data acquisition equipment for the qualitative analysis of the electrical system. Test equipment is frequently needed for monitoring and servicing electrical equipment in service areas, as well.

517.16 Use of Isolated Ground Receptacles

The requirement to prohibit isolated ground receptacles in health care facilities was condensed to prohibit these receptacles to a patient care vicinity only of a health care facility. The previous language at 517.16 would prohibit the use of isolated ground receptacles in the entire health care facility. Section 517.16 is located in Part II of Article 517 and, as such, applies to the entire health care facility. The 2012 edition of NFPA 99 Health Care Facilities Code affirms the use of isolated ground receptacles in health care facilities while continuing to forbid their use only within patient care vicinities [see NFPA 99 6.3.2.2.7.1(A) and 6.3.2.2.7.1(B)]. Listed cord- and plug-connected medical instrumentation used in health care facilities outside of patient care vicinities (typically at nurses’ monitoring stations) often requires connection to isolated ground receptacles to insure measurement accuracy by mitigating electrical noise or interference, which is essential to patient medical safety. Allowing isolated ground receptacles away from a patient care vicinity would allow this mitigation against equipment interference without affecting patient safety.

Article 517 Receptacles at Health Care Facilities

The minimum number of receptacles required for general care area patient bed locations of a health care facility was increased from four to eight receptacles at 517.18(B). The minimum number of receptacles required for critical care area patient bed locations of a health care facility was increased from six to fourteen receptacles at 517.19(B). The minimum number of receptacles required for an operating room of a health care facility is now required to be a minimum thirty-six receptacles at 517.30(B). This was an effort to align the NECwith NFPA 99 Health Care Facilities Code. The 2012 edition of NFPA 99 underwent some major modifications, one of which eliminated all occupancy chapters within the document and adopted a risk-based approach as far as the patient is concerned. A new process detailing building systems categories in healthcare facilities was introduced. Category 1 covers facility systems in which failure of such equipment or system is likely to cause serious injury or death of patients or caregivers. Category 2 is facility systems in which failure of such equipment is likely to cause minor injury to patients or caregivers. Category 3 is facility systems in which failure of such equipment is not likely to cause injury to patients or caregivers but can cause patient discomfort. Category 4 is facility systems in which failure of such equipment would have no impact on patient care. These categories are determined by documenting a defined risk-assessment procedure found in NFPA 99.

680.22(A)(1) Required Receptacle(s) at Swimming Pools

At least one 125-volt, 15- or 20-ampere receptacle on a general-purpose branch circuit must be located not less than 1.83 m (6 ft) from, and not more than 6.0 m (20 ft) from, the inside wall of all permanently installed pools. This requirement was expanded to all permanently installed pools, not just dwelling unit permanently installed pools. The title was revised from, “Dwelling Unit(s)” to “Required Receptacle, Location.” For permanently installed pools, at least one 125-volt, 15- or 20-ampere receptacle must be installed in the vicinity of the pool. This receptacle must be GFCI-protected, on a general purpose branch circuit, and must be located not closer than 1.83 m (6 ft) and not farther than 6.0 m (20 ft) from the inside wall of the pool. This receptacle shall be located not more than 2.0 m (6½ ft) above the same floor, platform or grade on which the pool is installed. Prior to the 2014 NEC, this required receptacle was only required at permanently installed pools at dwelling units. This receptacle outlet(s) that service the pool area is commonly used for ordinary devices such as radios, electric grills, bug zappers, etc. This receptacle’s primary function is to limit the use of extension cords around and near the pool’s water edge.

Find Us on Socials