Few of us are comfortable with change. It is difficult to let go of the familiar. I actually overheard a lady sitting behind me on a plane the other day say, “I welcome change, as long as nothing is altered or different.” I had to think about that for a moment. At an IAEI event in 2018, while preparing to discuss some significant Code changes, I heard my good friend Jim Dollard quote W. Edward Deming by saying, “It is not necessary to change, as survival is not mandatory.”

John F. Kennedy’s famous quote concerning change stated that “Change is the law of life and those who look only to the past or the present are certain to miss the future.” Motivational speaker Robin Sharma said, “Change is hard at first, messy in the middle, and gorgeous at the end.” Pastor Rick Godwin is quoted as saying, “One reason people resist change is because they focus on what they have to give up instead of what they have to gain.” Albert Einstein made this statement on change, “The world as we have created it is a process of our thinking. It cannot be changed without changing our thinking.” And finally, my favorite quote concerning change comes from comedian George Carlin who said, “I put a dollar in one of those change machines … nothing changed!

If you are involved with the electrical industry and the National Electrical Code (NEC), change in our world is inevitable. The Code is changed and updated every three years. With changing technology and improving safety and work practices, it is imperative that the NEC evolves to engulf these innovative techniques. With that backdrop in mind, this article will look at some of the more noteworthy changes that are being proposed for the 2020 NEC.

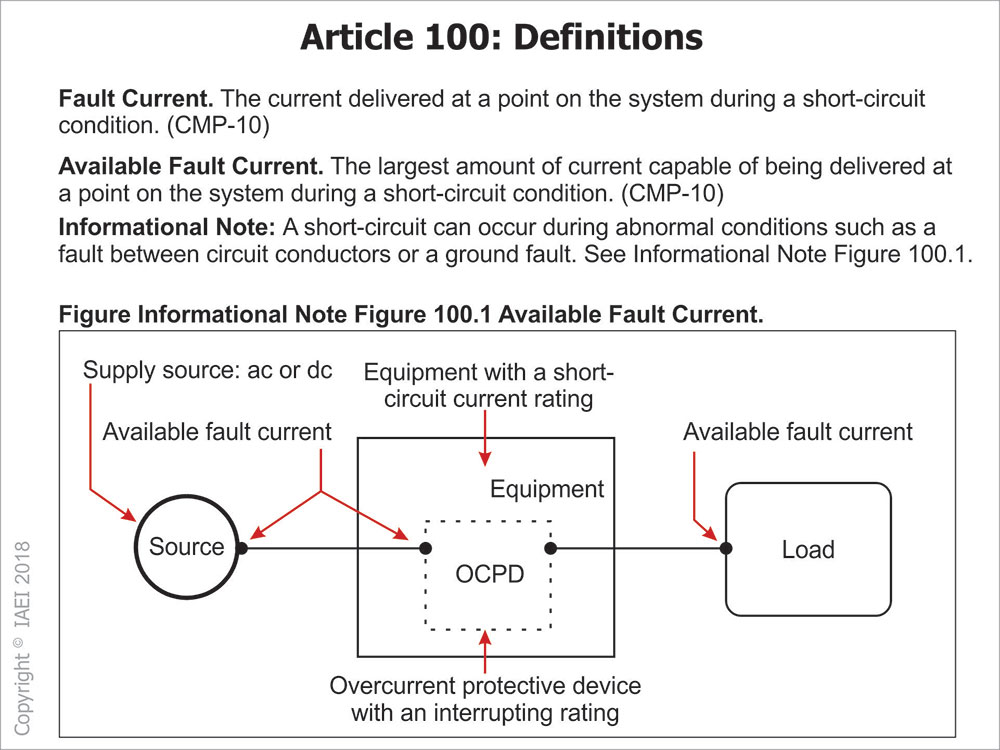

Figure 1: Reproduction of new NEC Informational Note Figure 100.1.

Figure 1: Reproduction of new NEC Informational Note Figure 100.1.

New 2020 NEC Articles

Four new articles have been proposed for the 2020 NEC:

- Article 242 Overvoltage Protection (CMP-10) This new proposed article provides the general, installation, and connection requirements for overvoltage protection and overvoltage protective devices. Part II covers surge-protective devices (SPDs) permanently installed on premises wiring systems of not more than 1,000 volts, nominal. Part III covers surge arresters permanently installed on premises wiring systems over 1,000 volts, nominal. A lot of this information was relocated from existing Articles 280 and 285.

- Article 311 Medium Voltage Conductors and Cable (CMP-6) This article will cover the use, installation, construction specifications and ampacities for medium voltage conductors and cable (Type MV). Medium voltage requirements that were previously found in Articles 310 and 328 were consolidated into one article to improve the usability of the Code.

- Article 337 Type P Cable (CMP-6) This newly proposed article will cover the use, installation, and construction specifications for 600-volt Type P cable (armored and unarmored) for use in hazardous (classified) locations. Based on cable performance and requirements for some land-based operations, Type P cable has been proposed to be added to the 2020 NEC for hazardous area applications.

- Article 805 General Requirements for Communications Systems (CMP-16) This Chapter 8 article is intended to cover communications circuits, community antenna television and radio distribution systems, network-powered broadband communications systems, and premises-powered broadband communications systems, in addition to the specific requirements in Articles 800, 820, 830, and 840. This article will combine common requirements currently found in Articles 800, 820, 830, and 840 into a new “general” article that applies to all of these articles while removing redundant requirements throughout Articles 800, 820, 830, and 840.

Article 100 Definitions: Fault Current, Available Fault Current

Two new definitions are being proposed for Article 100 for Fault Current and Available Fault Current. These new definitions were added primarily based on actions of an NEC Correlating Committee task group that reviewed the use of the terms “fault current,” “short circuit current,” and the qualifiers “maximum,” and “available” used throughout the previous editions of the NEC. The new definition for available fault current includes the term, “largest amount of current,” to clarify that a “short circuit” as used in this definition is of negligible impedance. This action was part of a global effort to increase clarity in the use of these terms.

110.12(C) Mechanical Execution of Work — Cables and Conductors

A new Item (C) is being proposed for 110.12 to coordinate with potential actions to relocate the content concerning mechanical execution of work at 760.24, 770.24, 725.24, 800.24, 820.24, 830.24, and 840.24 to a new home in Article 110 (General Requirements). This action was primarily due to recommendations of the Correlating Committee Usability Task Group to improve the usability of Chapters 7 and 8 by removing redundant requirements historically repeated in most of the Chapter 7 and 8 articles. This action supports consolidation of these repetitive requirements and relocating them into a new general rule in Article 110. This action supports the newly proposed Article 805 for combining common requirements currently found in Articles 800, 820, 830, and 840.

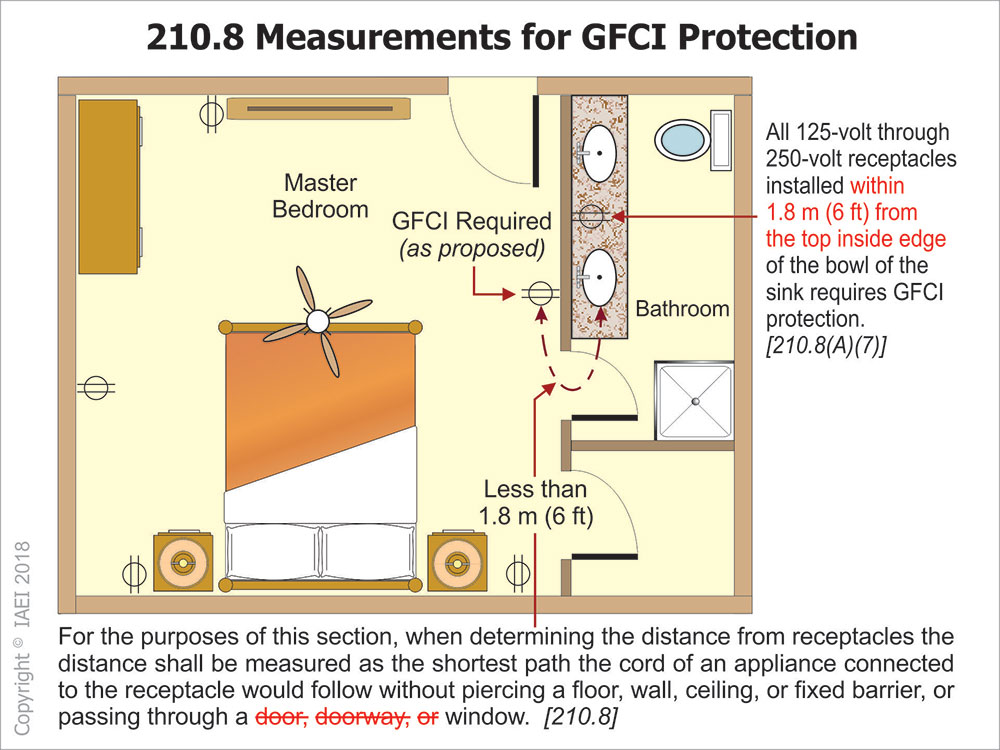

210.8 GFCI Protection for Personnel (Measurement Requirements)

The parent text of 210.8 was revised to add clarity to the distance requirements for ground-fault circuit interrupter (GFCI) protection. The word “supply,” as in “supply cord” was added to be consistent with the language in 680.22(A)(5) for measurements for receptacle outlets around swimming pools. When a distance was referenced in conjunction with GFCI protection [such as “receptacles installed within 1.8 m (6 ft) from a sink”], previous editions of the Code stated this distance was to be measured as the shortest path an appliance supply cord would follow “without piercing a floor, wall, ceiling, or fixed barrier, or passing through a door, doorway, or window.” The words “door” and “doorway” have been removed from this reference to address the confusion that a cabinet “door” or other door is not intended to eliminate GFCI protection for something like a receptacle outlet installed inside the cabinet under a kitchen sink. This revision should make it clear that GFCI protection is required for receptacle outlets that are within 1.8 m (6 ft) from the potential hazards described in 210.8(A) and (B), regardless of any intervening doors or doorways of any kind.

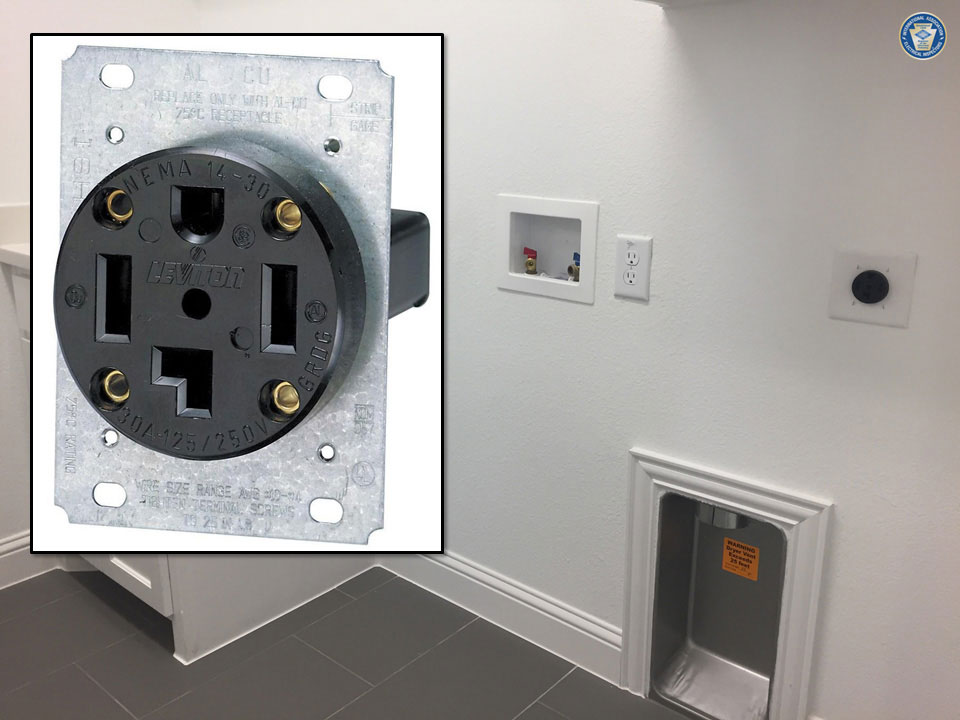

210.8(A) GFCI Protection for Personnel — Dwelling Units

Revisions proposed at 210.8(A) will result in all 125-volt through 250-volt receptacles installed at dwelling units supplied by single-phase branch circuits rated 150 volts or less to ground to be provided with ground-fault circuit-interrupter protection for personnel. This new addition of 250-volt receptacles and the removal of any amperage limitation will provide for GFCI protection to most receptacles commonly used in the specified areas of 210.8(A)(1) through (A)(11). These specified areas (bathrooms, kitchens, laundry areas, etc.) have been shown to justify the need for GFCI protection for 125-volt, 15-and 20-ampere receptacle outlets. 250-volt receptacle outlets (dryer and range receptacles) present similar shock hazards.

210.8(B) GFCI – Other Than Dwelling Units — Kitchens and Other Areas

Additional language was added to 210.8(B)(2) to clarify that non-dwelling unit areas (other than a kitchen) with a sink and permanent provisions for either food preparation or cooking have the same potential for shock hazards as a kitchen. Current Code text only requires GFCI protection at a non-dwelling unit “kitchen,” with a kitchen defined in Article 100 as “an area with a sink and permanent provisions for food preparation and cooking.” Ice cream parlors, coffee shops, smoothie stores, etc. currently do not require GFCI protection since there is no stove or oven (permanent provisions for food preparation and cooking). Areas with stainless steel refrigerators and freezers that are also being used as countertops with moisture and condensation deserve GFCI protection, as well.

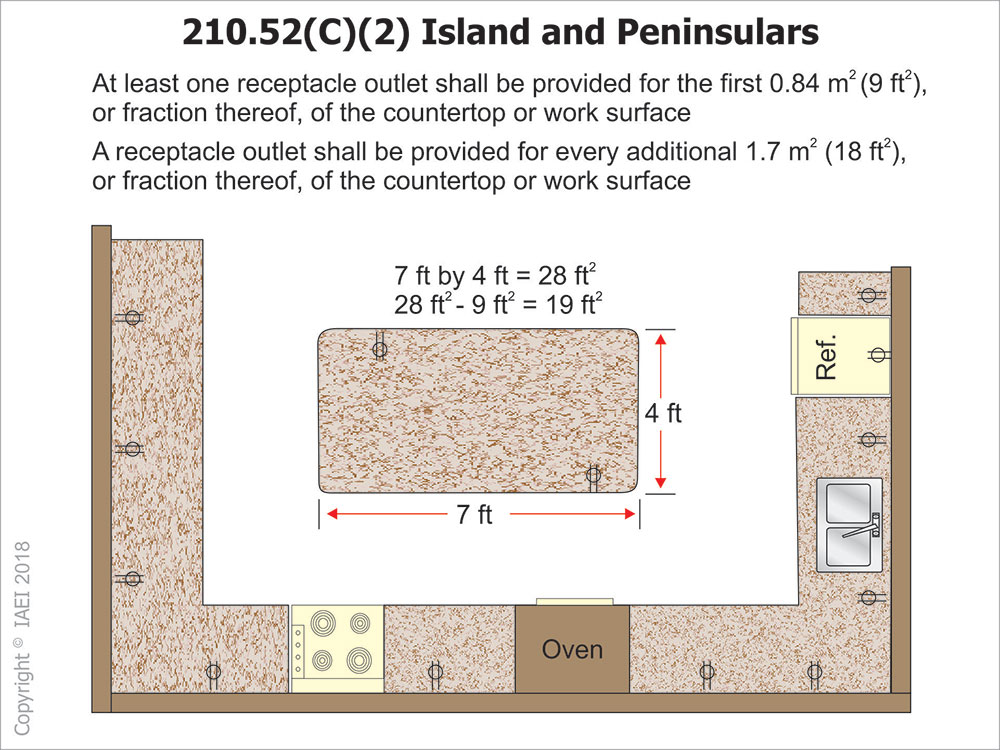

210.52(C)(2) Island and Peninsular Countertops and Work Surfaces

The method for determining the minimum number of 125-volt, 20-ampere receptacle outlets required to serve a dwelling unit island or peninsular countertop/work surface has been revised. In previous editions of the Code, one would simply take a measurement across the countertop to determine if the rule of one required receptacle was required. If the measurement consisted of a long dimension of 600 mm (24 in.) or greater and a short dimension of 300 mm (12 in.) or greater, one receptacle was required to serve the island or peninsula. This one required receptacle was Code compliant regardless of the size of the countertop or work surface.

Figure 3: Minimum of two receptacle outlets could be required for larger islands and peninsula countertops.

Figure 3: Minimum of two receptacle outlets could be required for larger islands and peninsula countertops.

For the 2020 NEC, it is being proposed to replace the long and short dimension measurements with a square foot calculation to determine the number of receptacles required. This was an attempt to provide additional receptacles for very large islands found in many of today’s dwelling units. At least one receptacle outlet would be required for the first 0.84 m2 (9 ft2), or fraction thereof, of the countertop or work surface. An additional receptacle outlet(s) would then be required for every additional 1.7 m2 (18 ft2), or fraction thereof, of the countertop or work surface. As an example, this would result in a total of two required receptacle outlets at a kitchen island that measured 2.1 m (7 ft) by 1.2 m (4 ft) [2.6 m2 (28 ft2) – 0.84 m2 (9 ft2) = 1.76 m2 (19 ft2)]. At least one receptacle outlet will also be required to be located within 600 mm (2 ft) of the outer end of a peninsular countertop or work surface. Additional required receptacle outlets can be located as determined by the installer, designer, or building owner.

215.9 GFCI Protection with Feeders

Revisions are being proposed to allow feeders to be protected by a GFCI protection in lieu of the provisions for such GFCI protection as specified in 210.8 and 590.6(A) for branch circuits. These revisions provide correlation with GFCI protection requirements in 210.8 by removing the existing GFCI limitations to 15- and 20-ampere branch circuits. According to the substantiation for these revisions to feeder GFCI protection, there is no practical reason to limit GFCI protection of a feeder where hard-wired outlets are supplied.

220.12 Lighting Load for Non-Dwelling Occupancies

Section 220.12 and Table 220.12 are proposed to receive extensive revision for the 2020 Code cycle. Table 220.12 (General Lighting Loads by Occupancy) has received minimal revisions since the 1970s. The proposed revisions will result in reducing the lighting loads in some of the occupancies identified in the table based on technology enhancements over an almost 50-year period of time from the inception of this lighting load table. Comprehensive data has historically not been available to support a revision to this table. Energy codes adopted across the country have created further discussion around the appropriate values in Table 220.12.

The development of the lighting power densities in the energy code have been established through case studies of various occupancies from the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE), which provided the foundation for the revisions to the new proposed values in Table 220.12. Some of the highlighted revisions to 220.12 and Table 220.12 include expanding and aligning the list of occupancies in the NEC with those found in ASHRAE Standard 90.1-2016 —Energy Standard for Buildings Except Low-Rise Residential Buildings and the International Energy Conservation Code.

Dwelling and multi-family dwelling units will be moved out of Table 220.12 and referenced in a new 220.14(J). The newly proposed values in Table 220.12 were also established from ASHRAE Standard 90.1 data. The lighting power density (LPD) values from ASHRAE Standard 90.1 (2000 cycle) establishes a minimum margin of 25 percent between the maximum values determined through field studies and the new values for Table 220.12. All but four occupancies are reduced to more closely align with actual use based on the field case studies conducted by the ASHRAE Lighting Committee.

The lighting load values for four occupancies were increased (gymnasiums, manufacturing facilities, religious facilities, and warehouses). Information for floor area calculations has been relocated from 220.12 to a new 220.11, which addresses both non-dwelling occupancies in 220.12 and dwelling occupancies in 220.14(J). The existing Exception No. 1 to 220.12 is being converted to positive text with a new 220.12(B) titled “Energy Code.” Finally, language was added at the parent text of 220.12 to indicate that a motor load where the motor is rated less than 1/8 HP and connected to a lighting circuit will be considered and included in the general lighting load as these loads are minimal and can be safely served using the unit loads from Table 220.12.

230.67 Surge Protection for Dwelling Units

A new requirement is being proposed to necessitate a surge protection device (SPD) on all services in dwelling units. This requirement is intended to address the recognized need for surge protection to protect sensitive electronics and systems found in most modern appliances, safety devices (AFCIs, GFCIs, and smoke alarms) and equipment used in modern dwelling units. The expanded use of distributed energy resources (DERs) within electrical systems often results in more opportunity or greater exposure for the introduction of surges into electrical systems.

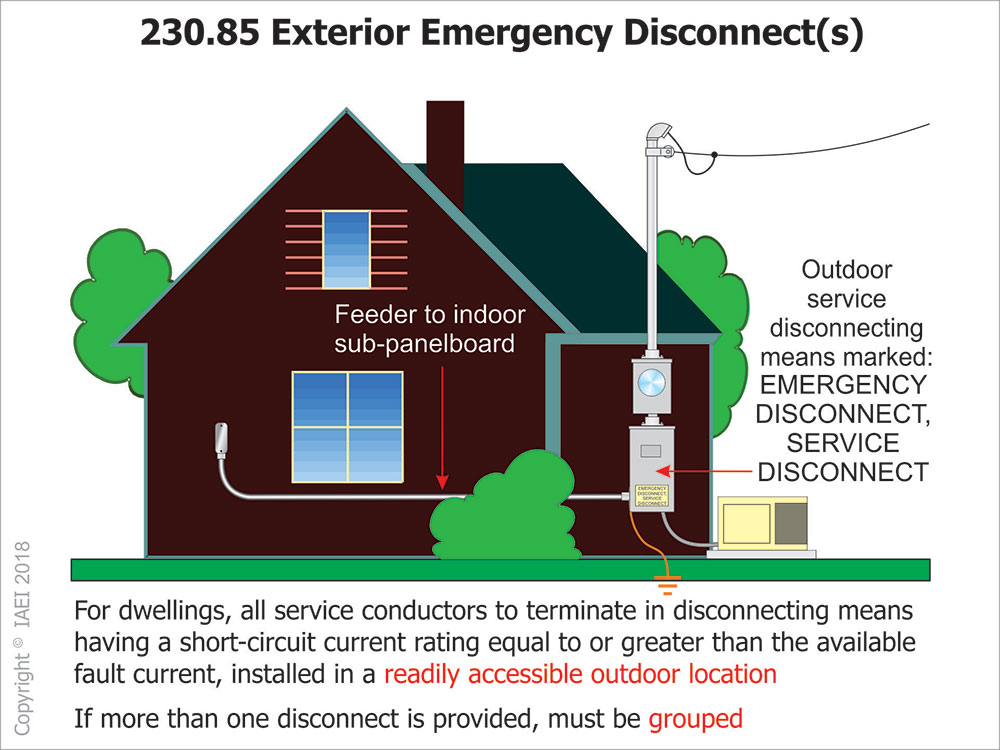

230.85 Outdoor Emergency Disconnects for Dwelling Units

New Code language is being proposed that would require an emergency disconnect at a readily accessible outdoor location for all dwelling units. This outdoor disconnect requirement recognizes the need for an outdoor disconnect for first responders of emergencies such as a house fire. According to CMP-10, these proposed emergency disconnect requirements are practical, feasible, and provides installers with multiple options. Currently, first responders and utility personnel do not have a way to safely remove power from a structure without the servicing utility company removing power from the entire structure. This emergency disconnect can consist of (1) the actual service disconnect, (2) a meter disconnect installed per 230.82(3), or (3) other listed disconnect switch(es) or circuit breaker(s) on the supply side of each service disconnect that are suitable for use as service equipment. Marking requirements that accompany these emergency disconnects and the marking requirements must comply with 110.21(B).

250.25 Grounding Systems Permitted to Be Connected on the Supply Side of the Disconnect.

New Section 250.25 is being proposed to cover the requirements for grounding of systems and disconnects permitted to be connected on the supply side of a service disconnect. This was originally proposed to cover service type supply-side disconnects with a definition of a supply-side disconnect, but comments received by CMP-5 identified the fact that not all equipment connected to the utility is considered a service, such as parallel power production equipment. However, it should be grounded and bonded with the same requirements. In some instances, such as solar installations, the parallel power production equipment is connected in parallel with a service and in some cases connected directly to the utility solely for power production to the utility with no service equipment in parallel.

Systems such as solar, wind, fuel cells, and interconnected power production systems do not fall under current requirements for grounding and bonding of services and separately derived systems when connected in a line-side connection as permitted by 230.82. The addition of 250.25—which in most cases point to the appropriate parts of 250.24—ensures that supply-side equipment is connected to a grounding electrode system, has an effective fault path whether it be a grounded service conductor or supply-side bonding jumper, and is bonded with the more robust requirements of 250.92 and 250.102(C).

250.68(C)(3) Grounding Electrode Conductor Connections (Rebar)

New text is being proposed to clarify that the rebar system in a footing or foundation is not suitable as the conductor to interconnect other grounding electrodes. No substantiated evidence has ever been submitted to support the rebar being used as a conductor for interconnection of different components of the grounding electrode system. Confusion on this issue may have arisen because of where this rebar-type metal structure section was placed in the 2017 NEC along with metallic water piping that can be used to interconnect electrodes as well as in-ground support structural metal that is permitted to be used to interconnect various grounding electrodes. Current Code text implies that rebar-type structural steel that might encircle a building or structure is also suitable to be used as a conductor to interconnect various electrodes. A similar sentence was also added at 250.53(C) as this section contains the rules for bonding jumper interconnection of electrodes.

250.121 Restricted Use of Equipment Grounding Conductors

A new sub-section (B) is being proposed to be added at 250.121 that will prohibit the structural metal frame of a building or structure from being used as an equipment grounding conductor. This rule already exists, but it is being relocated from the existing last sentence of 250.136(A) (Equipment Secured to Grounded Metal Structure). By moving this requirement to its new proposed home at 250.121. it will clarify that this requirement applies to all equipment and not just equipment secured to a grounded metal structure.

Article 310 Conductors for General Wiring

Article 310 has been proposed to receive extensive reorganization to increase its usability. The ampacity requirements over several Code cycles have become increasingly difficult to use, which in turn made Article 310 more difficult to use. Some of the noteworthy changes proposed for Article 310 include moving the Type MV Cable requirements from Article 310 into a new Article 311 (Medium Voltage Conductors and Cable) which also includes moving the requirements out of Article 328 (Medium Voltage Cable) to remove redundant text. The ampacity tables in Article 310 will simply be titled as Table 310.16 through Table 310.21. As an example, Table 310.15(B)(16) will revert back to its original numbering of Table 310.16. The requirements for single phase dwelling services and feeders was moved from its current home of 310.15(B)(7) to a new 310.12.

A new Table 310.12 will be added that was located at Informational Annex D, Example D7 and previously located at Table 310,15(B)(7) prior to the 2014 NEC. A new note was added at the bottom of new Table 310.12 stating that the table is permitted to be used if there are no temperature correction or adjustment factors required. New text has also been added at 310.15(A) to allow for the inclusion of ampacities for sizes not found in the ampacity tables under engineering supervision. The word “allowable” was removed from the term “allowable ampacities” in some text and also in the titles of the ampacity tables to provide clarity to Code users. The Conductor Applications and Installations table was moved from Part III [currently Table 310.104(A)] to Part II [proposed Table 310.4] for clarity and usability. The recently added conductor types (first recognized in the 2017 NEC) XHHN, XHWN, and XHWN-2 were added to the list of acceptable wire types for dry and damp locations at 310.10(B), wet locations at 310.10(C), as well as the ampacity tables based on appropriate temperature ratings.

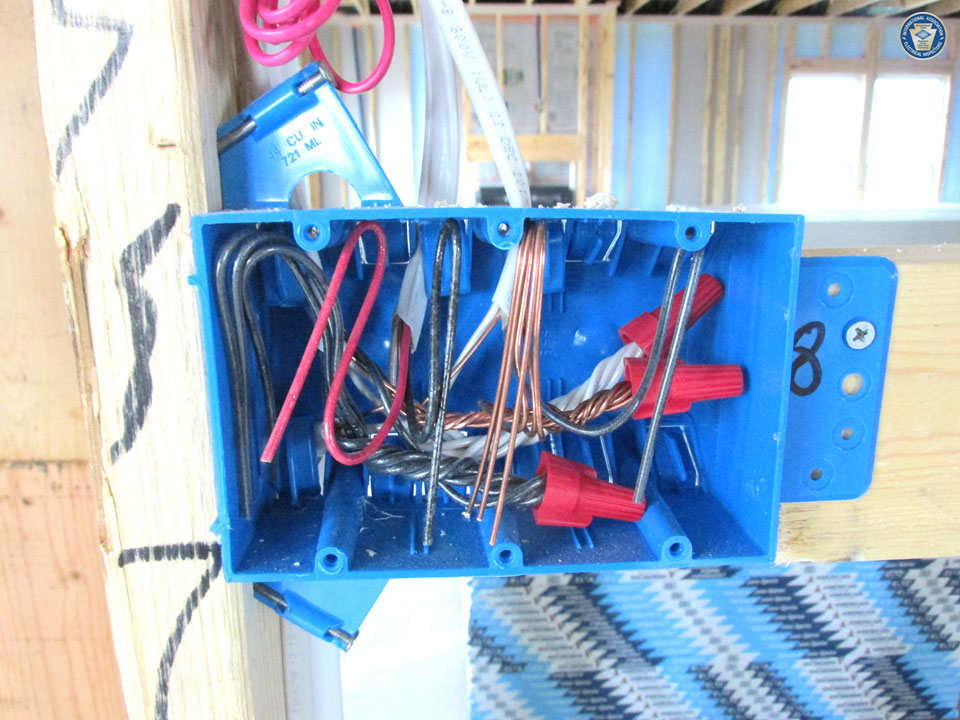

314.16(B)(5) Equipment Grounding Conductor Fill

The box fill volume allowance for equipment grounding conductors (EGC) and equipment bonding jumpers have been revised. The new revisions will add an additional ¼ volume allowance to the existing volume allowance of a single conductor volume allowance based on the largest equipment grounding conductor or equipment bonding jumper entering the box. This new ¼ volume allowance will be counted for each EGC installed in the box for more than four EGCs or equipment bonding conductors. In multiple gang boxes, taking only one volume allowance based on the largest EGC is not adequate in many cases resulting in significant undue crowding of conductors and not enough free space to allow heat to dissipate from the contained conductors. This change eliminates the need to specifically address the EGCs for isolated ground receptacles permitted by 250.146(D).

314.27(C) Boxes at Ceiling-Suspended (Paddle) Fan Outlets

Revisions will now require all outlet boxes mounted in a location acceptable for the installation of a ceiling-suspended (paddle) fan in the ceilings of habitable rooms of dwelling units to be listed for the sole support of ceiling-suspended (paddle) fans or supported by the structural framing, and independent of the outlet box. This revision will eliminate the requirement that a spare separately switched ungrounded conductor be present in order to require a listed fan box for future installations. Ceiling-suspended (paddle) fans can now be installed on outlet boxes with two current-carrying conductors with the advent of the remote-controlled paddle fans because the box will already be rated to support a ceiling-suspended (paddle) fan. This revision will not require a listed “fan box” in installations where the ceiling fan is installed, and the box is not used as the sole support of the ceiling fan as the structural framing can still support the ceiling-suspended (paddle) fan. This will need to be verified by the Authority Having Jurisdiction.

Coming up

This has been a look at just a few of the significant changes being processed for the 2020 NEC Chapters 1-3. In Part II, we will look at changes being projected for Chapters 4-8. These articles can serve as a frontrunner for IAEI’s Analysis of Changes — 2020 NEC textbook and PowerPoint.

Find Us on Socials