If you are involved with the electrical industry and the National Electrical Code (NEC), change in our world is inevitable. The Code is changed and updated every three years. With changing technology and improving safety and work practices, it is imperative that the NEC evolves to engulf these innovative techniques. With that backdrop in mind, this article will look at some of the more noteworthy changes that are being proposed for the 2020 NEC.

Editor’s note: This is Part II of a two-part series. Read Part 1

406.5(G)(2) Receptacle Orientation Under Sinks

In the first part of this series, we looked at some of the more substantial changes being proposed for Chapters 1–3 of the 2020 National Electrical Code (NEC). In this article, we will explore some of the more significant changes being discussed for Chapters 4–8 of the 2020 NEC.

New text is proposed that would prohibit receptacle outlets from being installed in a face-up position in the area below a sink. Receptacle outlets are currently prohibited from being installed in a face-up position in or on countertop surfaces or work surfaces unless listed for countertop or work surface applications and in seating areas and other similar surfaces. Dripping water or other unwanted objects could easily enter a receptacle outlet installed in the face-up position under a sink area.

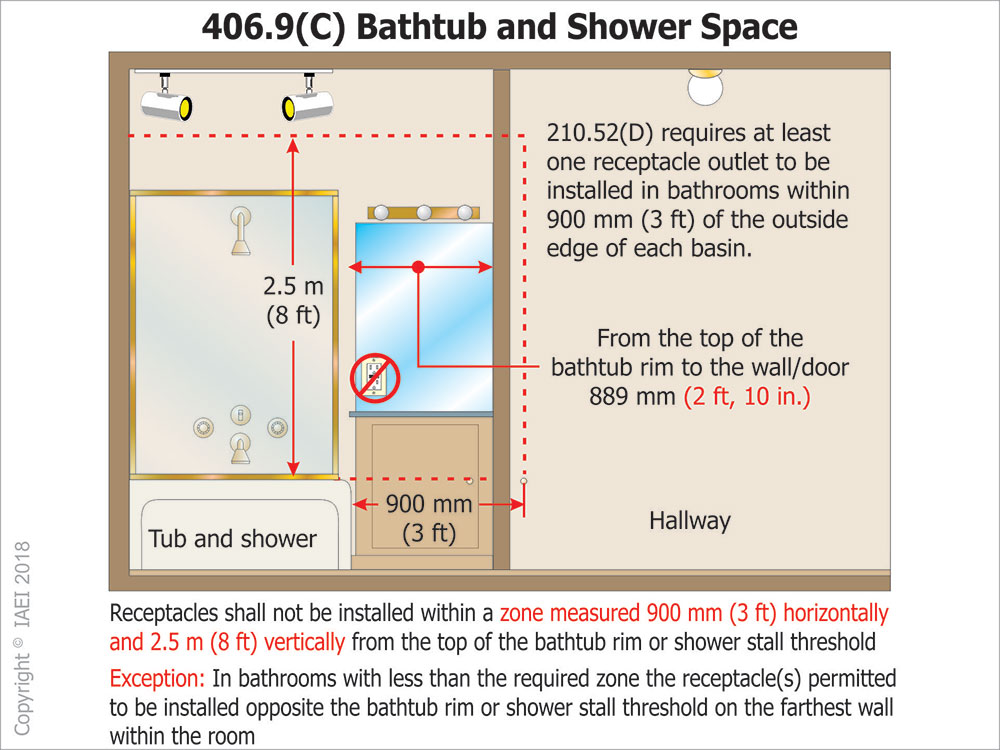

406.9(C) Bathtub and Shower Space Receptacles

Receptacle outlet(s) located in the area around a dwelling unit bathtub or shower stall have been revised to include a restricted “zone” similar to luminaires in said areas. The 2017 NEC text in this section indicates that a receptacle outlet cannot be located “within or directly over a bathtub or shower stall.” What constitutes the bathtub or shower space? Is the bathtub space the outside dimensions of the tub or the inside of the tub? Does it mean the walls enclosing the tub or shower?

Some users of the Code consider this language vague, leading to confusion and varied interpretation. New language has been proposed for this section dealing with receptacles similar to what is found at 410.10(D), which provides specific dimensions for electrical installations near bathtubs and shower stalls for luminaires, fans, etc. The new proposed language would prohibit receptacle outlets from being installed within a zone measured 900 mm (3 ft.) horizontally and 2.5 m (8 ft.) vertically from the top of the bathtub rim or shower stall threshold. This zone would be all-encompassing and include the space directly over the tub or shower stall. An exception would allow a receptacle outlet within this 900 mm (3 ft.) by 2.5 m (8 ft.) zone in smaller bathrooms where the proposed zone measurements could not be achieved due to limited space. In these cases, the receptacle outlet would be required to be installed on the farthest wall within the room that is opposite the bathtub rim or shower stall threshold. Consideration was also given to 552.41(F) for park trailers, which states the following: “A receptacle outlet shall not be installed in or within reach [750 mm (30 in.)] of a shower or bathtub space.” (See Figure 1.)

408.4(A) Circuit Directory or Circuit Identification

Revisions are being proposed to allow the circuit directory for a panelboard to be located in an “approved location adjacent” to the panel door. Current Code text only permits the circuit directory to be located on the face or inside of the panel door in the case of a panelboard. Inside the lid of a panelboard is experiencing scarce real estate due to things like schematics, specifications and instructions, inspection stickers for many different permits and trades, arc-fault ratings, and lists of circuits controlled by energy management systems. The more detail that is provided in a circuit directory the better in terms of meeting safety objectives. By only allowing the circuit directory on the face or inside of the panel door may cause some frustration due to a lack of space. Adjacent approved locations [approved by the authority having jurisdiction (AHJ)] could include a prominently labeled notebook of circuit directories for adjacent panels that might even include graphics.

408.6 Short-Circuit Current Rating for Switchboards, Switchgear, and Panelboards

New requirements were added to Article 408 requiring available fault current and the date the calculation was performed to be documented and made available to the AHJ for switchboards, switchgear, and panelboards (other than dwelling units). These new provisions also require switchboards, switchgear, and panelboards to have a short-circuit current rating not less than the available fault current. This is vital in determining the suitability of an installed piece of equipment with regard to the short-circuit current rating. Currently, if the data is even available, it may be several years old and may have changed greatly since original calculation. With this new requirement, the installer and inspector can judge the suitability of the equipment based on a value derived at the time the equipment was installed.

The NEC clearly addresses short-circuit current ratings for specialized equipment such as industrial control panels (409.22), elevators (620.16), and industrial machinery (670.5). The Code should also include available fault current for switchboards, switchgear, and panelboards. The present available fault current field marking requirement of 110.24(A) assumes that switchboards, switchgear, and panelboards should be rated at or above the available fault current, but it is not clearly indicated. Available fault current ratings are not on the forefront of most installers’ minds and it is sometimes hard for the field inspector to enforce without this vital link in the short-circuit current rating process.

408.43 Panelboard Orientation

New provisions are being proposed for Article 408 to prohibit panelboards from being installed in a face-up position. The practice of mounting a panelboard in the face-up position increases the likelihood that contaminants accumulate on the circuit breakers and panelboard bussing. Additionally, such mounting orientations result in a challenge with applying workspace requirements. Panelboards mounted in the face-up position were becoming somewhat common in the photovoltaic (PV) world. It was also not uncommon to find a panelboard mounted in the face-up position at a medium vestibule between rows of washing machines at a laundromat.

422.5(A) GFCI for Appliances

A few changes are being proposed for ground-fault circuit-interrupter (GFCI) protection for appliances. Currently, in order for GFCI protection to be required for automotive vacuum and tire inflation machines, they must be “provided for public use.” For the 2020 NEC, the “provided for public use” condition has been removed for both automotive vacuum machines and tire inflation machines. The potential risk of electric shock is similar whether the appliance is used for public use or not (e.g. used within an automotive garage by mechanics). Sump pumps have also been added to the list of appliances requiring GFCI protection in recognition of the potential for handling these appliances when both the user and the appliance are wet. GFCI protection was added for bottle fill stations and drinking water coolers as they are often integral with or installed adjacent to each other. These two related appliances present similar risk for an electric shock hazard.

430.122(B) Output Conductors for Motors

New provisions are proposed to be added in Article 430 to require the conductors between motor power conversion equipment and the motor to have an ampacity equal to or larger than 125 percent of the motor full-load current as determined by 430.6(A) or (B). An exception to this rule will allow the ampacity of the minimum conductor size marked on the power conversion equipment if the power conversion equipment is listed and marked as “Suitable for Output Motor Conductor Protection.” The technology for motor drives can provide output conductor short-circuit and ground-fault protection. UL 61800-5-1, Standard for Safety for Adjustable Speed Electrical Power Drive Systems, has been updated to allow an alternating current (AC) drive to be marked for protecting its output conductors in individual-motor installations. This change permits the use of such a drive to decouple the output conductor sizing from the branch-circuit short-circuit ground-fault protective device sizing. These new provisions for motor output conductors are related to proposed changes to 430.130(A)(1) (Branch-Circuit Short-Circuit and Ground-Fault Protection for Single Motor Circuits Containing Power Conversion Equipment).

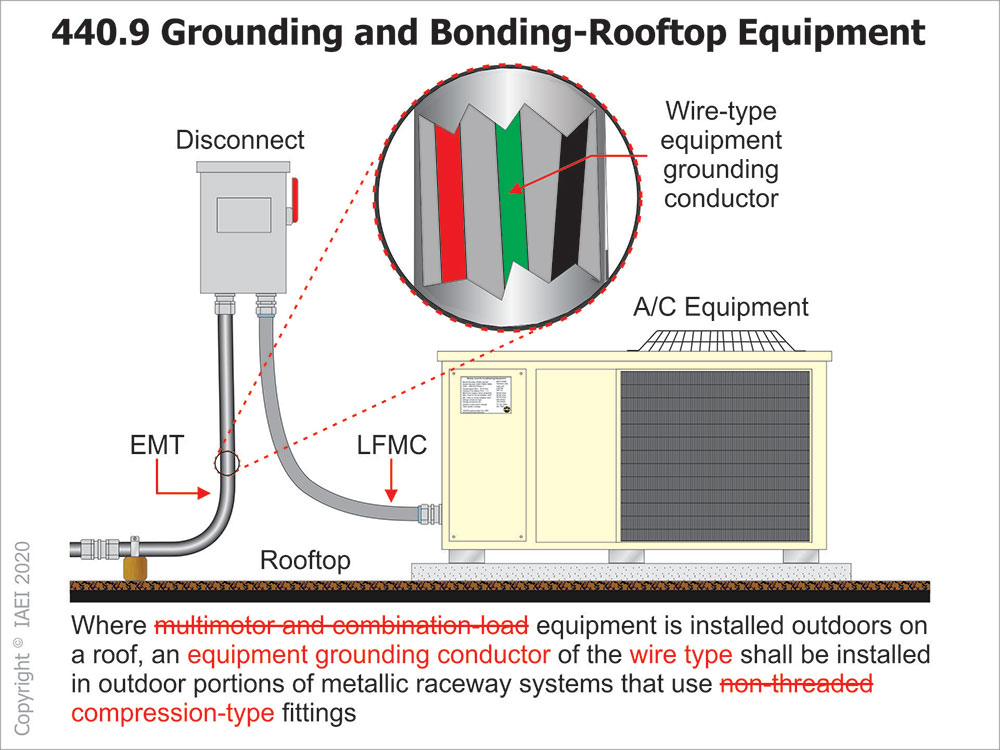

440.9 Grounding and Bonding of HVAC Equipment on Rooftops

Revisions were made to 440.9 to require an equipment grounding conductor of the wire type to be installed in outdoor portions of metallic raceway systems that use non-threaded compression-type fittings at HVAC equipment installed outdoors on a roof. New wording replaces “non-threaded” fittings with “compression-type” fittings for improved clarity. This requirement, introduced in the 2017 NEC, was intended to require a wire type equipment grounding conductor (EGC) in any metallic raceway system that does not use threaded fittings such as threaded rigid metallic conduit. It was intended to require the EGC wire type for “slip-type” fittings that could come apart such as electrical metallic tubing (EMT). It was quickly pointed out by users of the Code that an EMT compression-type fittings (such as a coupling or connector) has threads, but not the type of threads intended in the original text. These revisions will help clarify the type of metallic raceway systems and fittings that would require a wire type EGC to be installed with equipment mounted outdoors on a rooftop. (See Figure 2.) The 2017 NEC term “multimotor and combination-load” equipment was removed because this requirement is intended to include all air-conditioning and refrigeration equipment located outdoors on a rooftop.

445.18(D) Generator Emergency Shutdown in One- and Two-Family Dwelling Units

New requirements are proposed to require an emergency shutdown device to be located outside all one- and two-family dwelling units at a readily accessible location (for other than cord-and-plug-connected portable generators). This emergency shutdown device was deemed necessary for fire service and other first responders to secure on-site power sources during emergencies such as a house fire. This requirement is similar to the new requirements being proposed in 230.85 requiring an emergency disconnect at a readily accessible outdoor location for dwelling units.

450.9 Transformer Tops as Storage

A new sentence is being proposed to be added at the end of 450.9 to assist the installer and inspector in keeping the tops of transformers from being used as storage shelves. This new requirement will necessitate some signage or markings at transformer top surfaces that are horizontal and readily accessible to prohibit storage. It has become an all too common practice to find the tops of transformers being used for storage of tools, cleaning products, and anything else stored near the transformer. This can create excess heat and constitute a fire and/or electrical hazard due to poor ventilation. This practice is also a detractor to proper maintenance of the transformer.

511.12 GFCI Protection for Commercial Garages

Revisions are being proposed to align GFCI requirements for commercial repair garages to the GFCI requirements of 210.8(B). The current text in 511.12 requires all 125-volt, single-phase, 15- and 20-ampere receptacles installed in areas where “electrical diagnostic equipment, electrical hand tools, or portable lighting equipment are to be used” to be provided with GFCI protection for personnel. Pointing Code users to 210.8(B) will require all single-phase receptacles rated 150 volts to ground or less, 50 amperes or less and three-phase receptacles rated 150 volts to ground or less, 100 amperes or less in the commercial repair garage to have GFCI protection without the qualifier that the receptacle outlet be used for “electrical diagnostic equipment, electrical hand tools, or portable lighting equipment.” By simply pointing 511.12 back to 210.8(B), these two sections will then be in alignment with one another. Similar changes are being proposed in 513.12 for aircraft hangers.

517.10(B) Not Covered (Health Care Facilities)

New text and revisions are being proposed to clarify what areas are not covered by the wiring and protection methods of Article 517, Part II for health care facilities. Text is being planned to clearly indicate that areas used exclusively for intramuscular injections (immunizations), psychiatry and psychotherapy, alternative medicine, and optometry are areas not applicable to Part II of Article 517. If an area of a health care facility must comply with Part II of Article 517, the wiring method must consist of a metal raceway system or a cable having a metallic armor or sheath assembly that qualifies as an equipment grounding conductor in accordance with 250.118 and an insulated copper equipment grounding conductor. This is sometimes referred to as a “redundant” equipment grounding system.

With varied interpretations, there was a need to provide additional clarification as to when the more restrictive wiring methods in Part II are applicable and when they are not. As an example, some AHJs were requiring pharmacies that give flu shots to comply with Part II of Article 517. Shock hazards are greatly reduced with no invasive procedures performed and no electro-medical equipment connected to the body or patient. (See Photo 1.)

Article 545 Manufactured Buildings and Relocatable Structures

A new Part II is on the verge of being added to Article 545 for “Relocatable Structures” with a definition of the term added in 545.2. This addition of requirements for mobile structures other than “mobile” and “manufactured” homes is necessary to properly address other structures such as mobile office units, mobile classrooms, mobile restrooms and shower facilities, mobile break rooms, mobile training centers, and other non-dwelling types of mobile structures. Currently, there is only limited language in Article 550 related to these mobile structures. The requirements for “mobile homes used as other than dwelling units,” formally covered in Article 550, have been incorporated into the new Article 545, Part II. (See Photo 2.)

The term “relocatable structures” was chosen as it is already a commonly used industry term that still identifies the portable nature of these units. This term also distinguishes these structures from other manufactured buildings. These new provisions and the relocation of these requirements to Article 545 will make it clear that Article 550 only covers mobile and manufactured homes and mobile home parks that are intended to be used as dwelling units.

555.35 Ground-Fault Protection of Equipment (GFPE) and Ground-Fault Circuit-Interrupter (GFCI) Protection at Marinas, Boatyards, and Docking Facilities

The ground-fault protection requirements of marinas, boatyards, and docking facilities are being revised for the 2020 NEC. These GFP requirements (previously located at 555.3) were divided into three parts to provide clarity for these important ground-fault requirements. Section 555.35(A)(1) will address shore power receptacles with individual GFPE not to exceed 30 milliamperes (mA). Section 555.35(A)(2) will address 15- and 20-ampere receptacles for other than shore power with Class A GFCI protection (4 to 6 mA) being provided in accordance with 210.8. Section 555.35(A)(3) will address feeder and branch-circuit conductors that are installed on docking facilities to be provided with GFPE set to open at currents not exceeding 100 mA with coordination with downstream GFPE permitted at the feeder overcurrent protective device. An exception was added that would exempt transformer secondary conductors of a separately-derived system [to exceed 3 m (10 ft.)] installed in a raceway from this GFPE protection as it would be difficult to provide ground-fault protection on the conductors from the transformer to the first panelboard where the transformer resides on the docking facility. (See Photo 3.)

It was noted in the substantiation that 50 percent of the electric shock drowning (ESD) incidents could be avoided by the 30 mA protection at the shore power receptacles whereas the existing overall 30 mA ground-fault protection for the entire marina was too low for most marinas. Informational notes will also be added to address the concerns regarding vessel testing to alleviate potential leakage current that contributes to ESD as test data has shown that a great deal of the stray current in the water around marinas comes from the boats (vessels) themselves. As pointed out in the scope of the NEC, the Code does not have jurisdiction over the vessels at marinas. While the NEC rules cannot demand that the vessels be tested for current leakage, language will be put in place to require leakage current measurement devices to be in place and available at marinas and boatyards where more than three receptacles supply shore power to boats.

600.35 Retrofit Kits for Signs

A new section addition has been proposed for Article 600 to bring requirements for retrofit kits for signs. The existing definition in Article 100 defines a retrofit kit as “a general term for a complete subassembly of parts and devices for field conversion of utilization equipment.” While this definition explains what a retrofit kit is, a definition is not a Code requirement. Specific regulations for retrofit kits were needed and will be added to Article 600 with the installation requirements.

These proposed requirements are intended to address a safety deficiency that is prevalent with the installation and use of sign retrofit kits. Some of the provisions addressed by this new section will include what a “complete subassembly of parts and devices for field conversion of utilization equipment” would consist of such as Class 2 power supplies or transformers, the light-emitting diodes (LEDs), the LED mounting means, associated equipment including fittings, devices, suitably rated Class 2 power-limited cable, and installation instructions required for field conversion of a host sign, wiring methods, inspection for damage and parts, and field conversion workmanship.

680.2 and 680.50 Splash Pads

A new definition for “Splash Pads” is currently being proposed to be added in 680.2. Provisions added at 680.50 will allow for future revisions to more accurately target installation requirements for these recreational units. A splash pad will be defined as “a fountain with a pool depth 25 mm (1 in.) or less, intended for recreational use by pedestrians.” This definition is not intended to include showers intended for hygienic rinsing prior to use of a pool, spa, or other water feature. Splash pads typically incorporate one or more water spray jets and/or above ground water spray features. (See Photo 4.) A typical splash pad has zero depth with the structure flush with the surrounding perimeter surface. Not only will splash pads be required to comply with Part I (general) and Part V (fountains), these designs will be required to comply with Part II (permanently installed pools). Splash pads and similar installations present the same potential risk of electric shock as do the areas around swimming pools, which should demand similar equipotential bonding requirements.

680.35 and 680.45 Immersion Pools

Two new sections covering immersion pools are proposed to be added to provide requirements for a newly added definition at 680.2. Immersion Pools are currently included in the scope of Article 680, but their unique characteristics are not specifically addressed in current Code language. These new requirements and definition will provide needed clarity to applications where listed prepackaged units are not used. The new definition added to 680.2 will indicate that an immersion pool is “a pool for ceremonial or ritual immersion of users, which is designed and intended to have its contents drained or discharged.” These structures are typically installed in a building such as a church and are generally installed indoors but may be installed outdoors, on the ground or supporting structure, or in the ground or supporting structure. They typically contain integral interior steps and may be equipped with a heater and/or pump. They can even employ an underwater luminaire. Portable heaters and pumps may be utilized even with permanently installed immersion pools. New 680.35 will deal with requirements for Storable and Portable Immersion Pools, and new 680.45 will be added for Permanently Installed Immersion Pools.

690.31 Wiring Methods (Solar Photovoltaic Systems)

The section on wiring methods permitted for solar photovoltaic (PV) systems is expected to receive extensive revisions applied throughout this section and its subsections. Some of the revisions include a section title change from “Methods Permitted” to “Wiring Methods” to align with other similar sections of the Code. Existing Table 690.31(A) [now Table 690.31(A)(a)] received extensive revision by only including correction factors for 105°C and 125°C as all other temperature and correction factors that were in the existing table can be found in Article 310. The ambient temperature columns were expanded up to 120°C (the existing table only went to 80°C) and the temperature ranges are now given in 5°C increments. A new ampacity table for ampacities of insulated conductors rated up to and including 2,000 volts, for 105°C through 125°C (221°F through 257°F), and not more than three current-carrying conductors in raceway, cable, or earth, based on ambient temperature of 30°C (86°F) was also added as new Table 690.31(A)(b).

Section 690.31(B) (Identification and Grouping) has been revised to make it clear that PV system direct current (DC) circuits and Class 1 remote control, signaling, and power-limited circuits of a PV system are permitted to occupy the same equipment wiring enclosure, cable, or raceway. However, these PV DC circuits are prohibited from occupying the same equipment wiring enclosure, cable, or raceway just as other non-PV systems or inverter output circuits, unless the PV system DC circuits are separated from other circuits by a barrier or partition. This will address a common application of this requirement for enforcers with the installation of inverter DC input conductors and AC output conductors in the same wireway below an inverter.

A new exception was added at 690.31(B) for other multiconductor cable assemblies listed for the application in the same wiring method. New marking requirements for DC conductor polarity was added to 630.31(B)(1) (Identification)similar to existing language from Articles 210 and 215 on polarity markings. Current text at 690.31(G) was moved to 690.31(D) (Photovoltaic System Direct-Current Circuits on or in a Building). The 2017 NEC basically required all PV system DC circuits to be installed in a metallic wiring method when installed inside a building. Revisions will limit the metal raceway provisions to PV system DC circuits that exceed 30 volts or 8 amperes. This will allow low voltage and power circuits (30 volt or less and 8 amperes or less) as a feasible design option. (See Photo 5.)

700.5 Transfer Equipment

Language was added at 700.5 to clarify that meter mounted transfer switches are not permitted for use in emergency systems. Meter mounted transfer switches are currently readily available and are being installed to facilitate emergency systems, optional standby systems, etc. at dwelling units on a fairly consistent basis. There was—and currently is—a need for the NEC to recognize the use of these transfer switches and build additional requirements necessary to ensure the safe installation and use of this type of installation. It is imperative that these switches be listed to meet product standard UL 1008M, Transfer Switch Equipment, Meter Mounted, the same as other types of transfer switches that are currently being used in emergency systems, optional standby systems, etc. These transfer switches that are operated automatically must be suitable for switching the entire load supplied by the service (located directly in line with the utility meter). If the transfer switch is non-automatic, manual intervention is required and will be necessary to disconnect those branch circuits that are not part of the emergency system.

Article 805 Communication Circuits

This new article has been proposed for Chapter 8 and would combine common requirements currently found in Articles 800, 820, 830, and 840 into a new “general” article that applies to all of these. This would include such things as mechanical execution of work, abandoned cables, and spread of fire or products, if combustible. This proposed new article for communication circuits significantly improves clarity and usability while removing redundant requirements from each of the articles throughout NEC Chapter 8.

In this and the last issue of IAEI News magazine, we have taken a sneak peek at some of the more noteworthy changes being proposed for the 2020 NEC. The next step in the process is approval of these proposals at the National Fire Protection Association (NFPA) annual Conference & Expo June 17-20, 2019, in San Antonio, TX. Once approved, the 2020 NEC should be ready for publication the later part of August 2019.

These IAEI News articles are just a taste of what is to come from the International Association of Electrical Inspectors (IAEI) Analysis of Changes—2020 NEC textbook and PowerPoint decks. Look for these products from IAEI in late-2019.

Find Us on Socials