In the electrical industry, there is hardly a subject that appliesmore often than the issue of bonding and grounding. And yet, this matter remains one of the most discussed, argued and misinterpreted by the electrical designers, contractors and inspectors.

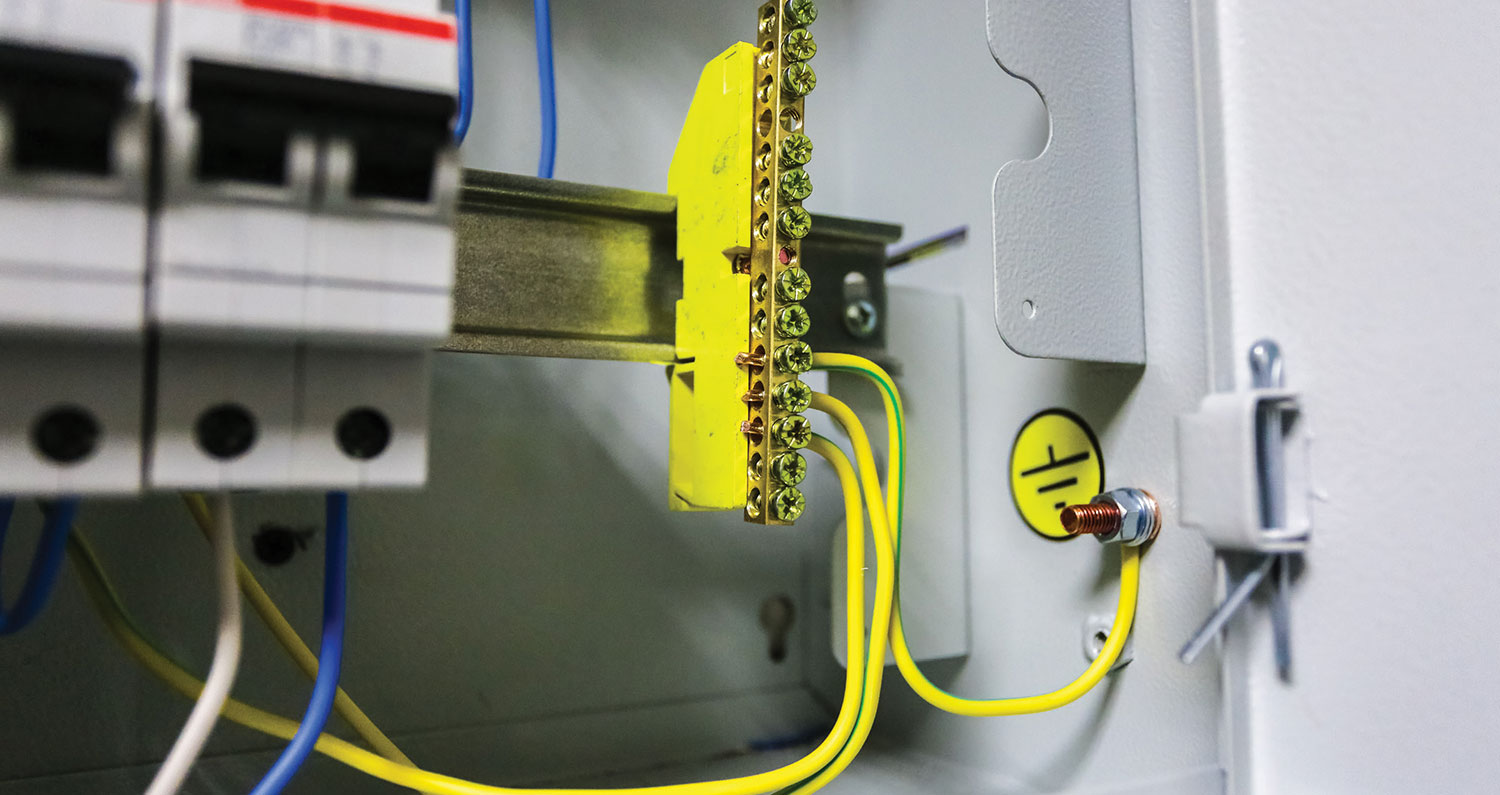

Photo 1. Inspectors might note that the bonding and grounding equipment shown in this photo (a clamp) has no certification monogram indicating that it is “approved” or “listed” for the application in accordance with the relevant CSA standard in Canada or with the UL standard in the USA. Thus, such equipment may be code non-compliant in some jurisdictions.

Let’s revisit this subject from the CE Code perspective and confirm a few undisputed facts.

Section 10 of the CE Code covers general requirements for the bonding of electrical equipment (including bonding of conductor enclosure), for connecting of bonded equipment to groundand for grounding of electrical systems. Provisions of Section 10 are referenced throughout all relevantsections ofthe Code, where bondingof the specific equipment (installed under rules of those sections)is necessary.

In addition to Section10, Section 36(which deals with High Voltage Installations) addresses particular requirements for bonding and grounding of electrical equipment within boundaries of a HV station and connection of the equipment and structures forming part of the station to the station ground electrode.

Section 10 also providesthe Code users with a clear and transparent object for bonding and grounding as follows:

“10-002 Object

(1) The object of bonding metal parts and metal systems together and to the grounded system conductor is to reduce the danger of electric shock or property damage by providing a low impedance path for fault current back to the source and to establish an equipotential plane such that the possibility of a potential difference between metal parts is minimized.

(2) The object of grounding the electrical system and non–current-carrying metal parts is to connect the earth to the equipotential plane, thereby minimizing any potential difference to earth.

(3) The object of using an ungrounded system or a system incorporating neutral grounding devices is to provide an alternative to a solidly grounded system, thereby limiting the magnitude of fault current and minimizing the damage resulting from a single fault.”

Section 0 of the CE Code offers the following definitions related to the subject of bonding and grounding:

“Bonding– a low impedance path obtained by permanently joining all non–current-carrying metal parts to ensure electrical continuity and having the capacity to conduct safely any current likely to be imposed on it.

Bonding conductor– a conductor that connects the non–current-carrying parts of electrical equipment, raceways, or enclosures to the service equipment or system grounding conductor.

Ground– a connection to earth obtained by a grounding electrode.

Grounded– connected effectively with the general mass of the earth through a grounding path of sufficiently low impedance and having an ampacity sufficient at all times, under the most severe conditions liable to arise in practice, to prevent any current in the grounding conductor from causing a harmful voltage to exist

(a) between the grounding conductors and neighbouring exposed conducting surfaces that are in good contact with the earth; or

(b) between the grounding conductors and neighbouring surfaces of the earth itself.

Grounding– a permanent and continuous conductive path to the earth with sufficient ampacity to carry any fault current liable to be imposed on it, and of a sufficiently low impedance to limit the voltage rise above ground and to facilitate the operation of the protective devices in the circuit.

Grounding conductor– the conductor used to connect the service equipment or system to the grounding electrode.

Grounding electrode– a buried metal water-piping system or metal object or device buried in, or driven into, the ground to which a grounding conductor is electrically and mechanically connected.”

So, after being acquainted with the Code objective for bonding and grounding and afterbeing reminded of the Code definitions on thissubject, one could say that the bonding is a deliberateinterconnection of all exposed, non–current-carrying metal parts of electrical equipment by means of a conductor that would be able to carry a fault current back to the source. When the bonding action is completed, all such non–current-carrying metal parts of electrical equipment would be kept at the same potential. It could be said that grounding is a deliberate action of connection of the electrical system or service equipment to earth, so the neutral point of the electrical system and the enclosure of the service equipment would be kept at the potential of earth. Accordingly, bonding to ground is a deliberate action of connection of all bonded non–current-carrying metal parts of electrical equipment to earth at the service equipment via a grounding conductor, so that equipotential plane between allbonded equipment would be equal tothe potential of earth.

So, this matter appears to be quite simple. Whydoes it remain a subject of inconsistency and occasional confusion? Perhaps, the main reason for confusion is lack of appreciation for different functions of bonding and grounding. Experience has demonstrated that the main issues appear to relate to some of the following questions (we’ll limit the list to ten such questions): (1) Does a neutral conductorcarry a fault current? (2) Can grounding be done on the load side of the service disconnecting means? (3) What should be the size of a grounding conductor and does a grounding conductor carry a fault current? (4) What material could be used for bonding and grounding conductors? (5) Can a neutral be used for bonding? (6) Is isolated ground required by the Code? (7) Is the bonding conductor required to run with service conductors that incorporate a neutral conductor?(8) How to ground separate systems located in a building? (9) How to deal with bonding and grounding in buildings supplied from a single service installed in a remote building? (10) Does a ground loop around an outdoor pad-mounted transformer with HV primary and a typical LV (120/208 V or 347/600 V) secondary have to be extended to the LV service equipment in the building?

Of course, the list of the questions is not necessarily limited to these ten. But based on the practice, the Code users indeed respond to these listed questionsquite differently and apply the Code provisions in a not very consistent way.

So, let’s elaborate on the posed questions by briefly discussing each of them.

1. Does a neutral conductor carry a fault current? The neutral (or grounded conductor) that runs to each service, becomes an extension ofbonding conductors, as all bonding conductors terminate in the service enclosure, and the grounded service conductor (which is connected to the grounding conductor at the service) also terminates at the service enclosure. Rule 10-204(2)(b) of the CE Code recognizes the fact that such grounded service conductor functions as a bonding conductor (i.e., it carries a fault current between the service equipment and the source). Rule 10-624(4) further acknowledges this fact by allowing the neutral/grounded service conductor to be used for bonding of the service equipment (bonding screw is in).

2. Can grounding be done on the load side of the service disconnecting means? Except as permitted by Rule 10-208 (when more than one building is supplied from a single service, see answer to question 9 below), grounding or connection to earthis not permitted on the load side of the service disconnectingmeans. After a neutral conductor is terminated in the service equipment, is connected to a grounding electrode via a grounding conductor and is connected to the service equipment enclosure (usedfor bonding of the service equipment), the neutral conductor is no longerpermitted to be connected to ground. Rule 10-208 provides such exceptions for installations, where such neutral conductor is also run to thebuildings that are supplied from the single service.

3. What should the size of a grounding conductor be? As a grounding conductor only serves as means of connection for the neutral in the service equipment and for the bonded enclosure of the service equipment to a grounding electrode (to earth), 6 AWG copper conductor is deemed to be sufficient for this purpose. Rule 10-812 is abundantly clear on this subject. A grounding conductor is not intended to carry a fault current (a fault current will be carried by a bonding conductor to the service enclosure, and then — by the grounded service conductor/neutral — directlyto the source). The fault current will not go back to the source via a grounding conductor, grounding electrode and earth, as the impedance of this path would be much higher than the impedance of the service grounded conductor/neutral.

4. What material could be used for bonding and grounding conductors? Let’s start with grounding conductors. Rule 10-802 mandates use of copper for grounding conductors.Material for bonding conductors could vary, as long as the bonding means will provide a reliable low impedance path. The CE Code requires use of copper bonding conductors in HV installations (Rule 36-308), in patient care areas under provisions of Section 24 (Rule 24-104) and in fire alarm systems (Rule 32-100). However, in general Rule 10-804 states that bonding conductors could be “of copper or other corrosion-resistant material, insulated or bare.” This rule also recognizes that a busbar, steel pipe, metal raceways and metal cable sheath or armour could be used as bonding conductors under specific conditions.

5. Can a neutral be used for bonding? Neutral conductor is a grounded circuit conductor. Except for situations when a neutral conductor from a single service runs to the services in other buildings supplied from that single service (see Rule 10-208), neutral is not permitted to be used for bonding on the load side of the service disconnecting means. The neutral conductor is intended to carry a load current in a typical 2-wire circuit, or an unbalanced current in a single-phase, 3-wire system or 3-phase,4-wire system.However, when the neutral conductor is used in a supply or consumer’s service, it is allowed to be used for bonding of a meter mounting device and the service enclosure, as this neutral/grounded service conductor functions as a bonding conductor.

6. Is isolated ground required by the Code? This subject creates lots of misconception. The CE Code does not specifically mandate use of isolated bonding conductor. However, such approach is permitted under Rule 10-906(9) as follows: “10-906(9). Notwithstanding Rule 10-808, electronic equipment rated to operate at a supply voltage not exceeding 150 volts-to-ground and that requires a separate bonding conductor shall be permitted to be bonded to ground by an insulated conductor extending directly back to the distribution panel, provided that (a) the separate bonding conductor is enclosed in the same raceway or cable containing the circuit conductors throughout the length of that cable or raceway; (b) the separate bonding conductor is sized not less than a given in Table 16 for each leg of the run, determined by the size of the overcurrent protection for the circuit conductors; and (c) the bonding requirements of Rules 10-304 and 10-400 are met.”

7. Is bonding conductor required to run with service conductors that incorporate a neutral conductor? A separate bonding conductor should not be run with the service conductors that incorporate a neutral/grounded service conductor, since the grounded service conductor/ neutralfunctions as the bonding conductor between the upstream transformer (or other source) and the service equipment. In fact, if a separate bonding conductor runs in parallel with the service neutral, such approach may conflict with provisions of Rule 12-108 for installation of conductors in parallel. Answer to question 5 above also could be used in dealing with this subject.

8. How to ground separate systems located in a building? Each new electrical system is derived from a secondary of a transformer or from another source of power supply (i.e., a generator). There are numerous situations, where in addition to the main service in the building (i.e., 347/600 V), a number of step-down transformers is used to establish various electrical systems such as 277/480 V or 120/208 V, etc.Quite often, a building is also provided with an emergency or a back-up generator. Each new solidly grounded system must be connected to a grounding electrode via a grounding conductorin accordance with Rule 10-204(1)(a). Therefore, a separate grounding electrode would have to be installed for each new solidly grounded system that (in addition to the main service) exists at the building. However, Rule 10-206(2) of the CE Code allows use of the single grounding electrode of the main serviceas an alternative to the requirement of Rule 10-204(1)(a). This grounding electrode of the main service would become a common tie point between neutrals of different solidly grounded systems that exist in a building.

9. How to deal with bonding and grounding in buildings supplied from a single service installed in a remote building? Rule 10-208 allows for two options. Under first option, the neutral conductor running from the main service to a building supplied from this main service would function as a bonding conductor. In this case, no separate bonding conductor (between the main service and the service in any building supplied by the main single service) would be required, and the service in each building supplied from the main single service would have to be grounded in accordance with Rule 10-204(1)(b).Under the second option, each new service in the building supplied from the main single service would be considered as part ofdistribution system. In this case, noconnection to ground would be made at each such building, as the only connection to ground would be allowedat the main single service. The neutral conductor whichruns to each suchbuilding supplied from the single service, would be isolated from the service enclosure (it would be used only to carry a load current in a 2-wire circuit or an unbalanced current in a multi-wire circuit), and a separate bonding conductor would have to run from the main single service to each building supplied from this single service to bond the service equipment in each such building.

10. Does a ground loop around an outdoor pad-mounted transformer with HV primary and a typical LV (120/208 V or 347/600 V) secondary have to be extended to the LV service equipment in the building? Ground loop is required by Rule 36-302(1)(c) around high voltage station only. Such ground loop would have to be installed around the outdoor pad-mounted transformer and around all relevant HV equipment comprising high voltage station. However, such ground loop does not have to be extended from the low-voltage secondary of this outdoor transformer into the low-voltage service supplied from this transformer andlocated in the building. Such typical low-voltage service is originated from a new low-voltage system, and provisions of Section 36 of the CE Code for station ground electrode would not be applicable for such low-voltage installation.

It looks like the typical questions raised in this article in relation to the issue of bonding and grounding have been adequately answered. But there is no doubt that the nature ofthis subject will continue generate questions from the Code users. And, of course, the best way to deal with these questions (aside from reading the Code), is to discuss them with relevant electrical safety regulatory bodies.

Find Us on Socials