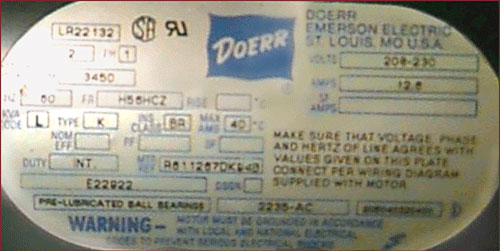

Your day starts with an early morning phone call: “Hi, This is Phil’s Auto Repair on Chestnut Street. What information do you need to have a permit drawn for installing an automotive service lift?” Your first thought, as an electrical inspector, is to ask, “Is it listed?” You are assured it is, so a permit for the installation is filed, and a final inspection is scheduled. When you arrive for the inspection, the building owner proudly shows off his new lift, and points to the “listing” mark on the lift motor.

Everything seems to be in order, and you sign off on the final inspection—but is everything in order?

You should be aware that most automotive lifts are required by the International Building Code (IBC) Chapter 30 to meet the requirements of ANSI/ALI ALCTV-1998 Standard for Automotive Lifts – Safety Requirements for Construction, Testing, and Validation. As with fire fighters’ life safety equipment, this standard requires third party certification and third party marking for compliance with the standard. This compliance means much more than having a listing label on the motor. The ANSI/ALI ALCTV-1998 standard requires that all electrically powered automotive lifts have a valid maintained-current electrical listing with an OSHA designated nationally recognized testing laboratory (NRTL) to ANSI/UL 201 Standard for Safety, Garage Equipment. Conversely, the ANSI/UL 201 standard requires that all electrically powered automotive lifts be evaluated to the requirements of ANSI/ALI ALCTV.

Photo 1. Typical recognition marks

Does this sound mutually inclusive? It is.

Both of these standards have been developed to keep the user of the lift safe from harm, whether the lift is electrical or mechanical. Simply attaching a “recognized label”1 to the motor or “hydraulic power unit”2 of an automotive lift does not necessarily make it electrically suitable; indeed, it could make it an extreme hazard to life and property.

A knowledgeable electrical inspector would have concerns related to the new lift at Phil’s Auto Repair, such as:

1. Does the lift incorporate all of the mechanical safety devices required?

2. Does the lift structure meet accepted industry strength factors?

3. Will the location of the power unit be such that it will be installed in a hazardous (classified) area?

4. Is the power unit operating within the parameters for which it was designed—will the insulation get hot enough to break down and cause an electrical fault?

5. Will the lift stop prior to contacting an overhead structural part of the lift, causing vehicle or lift damage and possible collapse?

6. Is the operational control system correct for this application?

7. Will the lift structure support the weight that the power unit is capable of lifting? If a power unit can produce 3000 psig, and a lift will lift its rated capacity utilizing only 2000 psig, then that power unit is capable of lifting a load 50% in excess of the rated structural capacity of the lift. Further, if the hydraulic system has a design pressure of 2000 psig, the 3000 psig pressure capability could also rupture hoses, cylinders, or fittings.

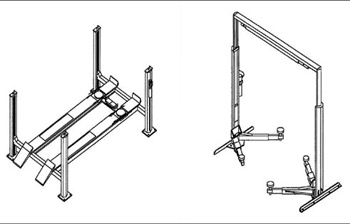

Figure 1. Typical four- and two-post automotive lifts

Each of these items is a critical question that can only be satisfied if the total lift design has been tested and certified.

Your only proof of a certified lift is a marking indicating it has been evaluated, it has been tested, it is under follow-up, and it is part of a program administered by a NRTL. The following label is exemplar of one offered by the Automotive Lift Institute.

Often, code officials are consulted by specification writers for new construction incorporating automotive lifts, and sometimes for replacement lifts involved in a renovation. Typical bid wording should read, “Lift(s) must be certified to the requirements of ANSI/ALI ALCTV.” A statement like this would automatically include the ANSI/UL 201 requirements because ANSI/UL 201 is included in the requirements of ANSI/ALI ALCTV.

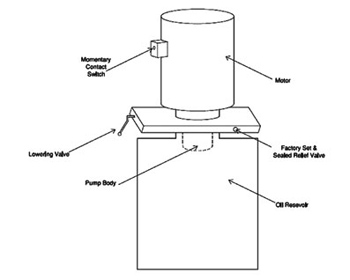

Why is it important that lifts utilizing electrical components have a listing in addition to the ANSI/ALI ALCTV Certification? Simply hooking up a hydraulic power unit to do a lift does not make it electrically suitable. Article 511 of NFPA 70-2005, the National Electrical Code, identifies service garages to be Class I, Division 1 below floor grade level, and to be Class I, Division 2 at all areas from floor grade level to 18 inches above the floor. The location of the power unit in a classified area could cause an explosion under normal operating conditions, and certainly if a fuel leak develops on the vehicle being serviced. An additional aspect of the total listing is that the lift and the power unit must be tested together.

Figure 2. A typical Automotive Lift certification label

A specific lift capacity requires specific hydraulic power. Hydraulic power is a function of motor torque required to power the pump and the time it takes to raise the load. This hydraulic power is a function of pump discharge pressure and oil flow rate. If the lift designers decided to drive a low volume pump at high pressure it may inadvertently overheat the motor by allowing it to run too long. They may have thought that they were making a good decision by reducing the size of the pump required, but they weren’t. All certified automotive lifts have built-in devices that limit the load that the lift can pick up. Motors, pumps and lifts must be matched since there are factors such as internal friction that will affect the hydraulic power required for each different lift model.

All lifts are required to have momentary-contact switches for any motion control. Lifts are not permitted to use multi-position switches with a maintained “on” position for control. Use of a NRTL-listed lift eliminates these concerns from an inspector’s checklist and is the only assurance of compliance with the IBC for new installations and replacement lifts.

Since bid specification writers often consult code officials for technical advice, what should you keep in mind when offering advice on specifying automotive lifts?

1. Is the entire lift certified to both the mechanical and electrical standards? Check the online directory atwww.autolift.orgto be sure.

2. Is the entire lift certified for use with all attachments and options that are necessary for operation?

3. Is the lift being utilized correctly? Does the lift match the application? Some lifts are suitable for use below grade and have components that are either explosionproof or are intrinsically safe.

4. Does the specification call for a general lift style or does it call for a specific manufacturer and model? Not all manufacturers have certified all of their lift models. Make sure that specifications clearly state that a certified lift is required. Do not simply say, “Lift shall meet the specifications found in ANSI/ALI ALCTV.”

Figure 3. Hydraulic power unit

According to the ALI website, purchasers of automotive lifts are often confused by claims made be sellers. False claims are frequently made in good faith by inexperienced sales people. At other times they are made on purpose to confuse the purchaser and obtain an order for equipment that may not actually meet the purchaser’s intended specifications or the national standard.

As an electrical inspector, you are responsible for ensuring public safety relating to electrical installation and practices. With mutually inclusive standards such as ANSI/ALI ALCTV and ANSI/UL 201 that cover different aspects of safety for automotive service technicians, shop owners, and the public in general, safety is assured. Fortunately, authorities having jurisdiction and certain other officials have a tremendous resource in safety materials and publications available through the Automotive Lift Institute at significantly reduced cost. Contact ALI headquarters at (607)-756-7775 for additional information, or visit them online atwww.autolift.org.

1 Recognized means the product is incomplete in some way, shape, or form, and must meet certain conditions prior to being considered suitable for use.

2 A hydraulic power unit is comprised of a motor, hydraulic pump, relief valve, return valve, reservoir and may contain other switches and/or solenoids necessary to operate a lift.

Find Us on Socials