Well, another three years has passed and with it another revision cycle of theNEChas been completed. As so often happens during code cycles, several significant changes occurred during the 2005NECcode cycle. One of the more significant changes is the new requirement for industrial machinery electrical panels, industrial control panels, certain HVAC equipment, meter disconnects, and certain motor controllers to be marked with a short-circuit current rating. This article will discuss these new marking requirements and equipment affected, provide background information on the need for these changes, and discuss the role that the inspector plays in enforcement of these new requirements.

Summary of Change

What Changed?

The 2005NEChas new requirements for the following equipment to be marked with a short-circuit current rating:

- Industrial control panels [409.110]

- Industrial machinery electrical panels [670.3(A)]

- Certain HVAC equipment [440.4(B)]

- Meter disconnect switches [230.82(3)]

- Certain motor controllers [430.8]

Varying, but similar, reasons were provided for these changes; however, they all had one goal, to ensure a safe installation through compliance with 110.10 while simplifying the inspection and approval process.

Significance of this change

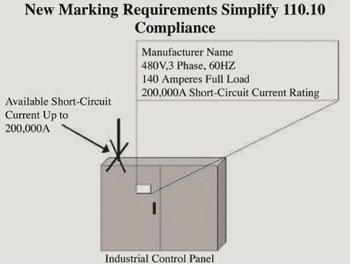

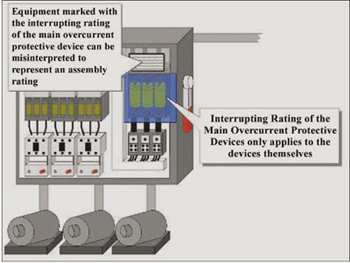

Figure 1. With the new equipment marking requirements, compliance with 110.10 is simplified.

The new 2005 NEC short-circuit current rating marking requirements facilitate the inspection and approval process. The marking of short-circuit current rating ensures a key piece of information needed for a safe installation is required to be provided (see figure 1). The change from marking the interrupting rating of the main overcurrent protective device or no marking at all, to a marking for the component or assembly short-circuit current rating is a much needed revision. This change clarifies the uncertainty associated with past short-circuit markings that users incorrectly assumed were representative of the entire assembly when, in fact, they were only an interrupting rating of the main overcurrent protective device. By providing a short-circuit current rating representative of the assembly, the procedure for ensuring compliance with section 110.10 is simplified. Short-circuit current ratings marked on components and equipment make it easier to verify proper overcurrent protection for components and equipment for specific applications, whether it be the initial installation or relocation of equipment.

Ensuring Compliance

Figure 2. Example of an industrial control panel

For proper protection and compliance with NEC 110.10, the short-circuit current rating for a component or equipment shall be equal to or greater than the available short-circuit current where the equipment is being installed in the system.

For the affected types of equipment, simply require the following:

1. For the plan review process, the engineer supplies the available short-circuit current at each equipment installation point and the specific short-circuit current rating for each piece of equipment or industrial control panel. (The engineer must already be calculating the available short-circuit current to assure compliance with 110.9, so this part of the requirements will not require any new work. Obtaining the short-circuit current ratings for the components or assemblies is new and will require additional work.)

Figure 3. Example of a motor controller

2. Upon site inspection, compare the actual equipment marked short-circuit current rating to the submitted data to ensure the rating is indeed as specified and sufficient for the available short-circuit current available at the point of installation.

New Assembly Marking Requirements

Industrial Control Panels

Article 409 Industrial Control Panels is a new article in the 2005 NEC. This new article provides minimum requirements to facilitate the safe construction, installation, and inspection of industrial control panels. A definition for industrial control panels is provided in 409.2 to aid in determining the types of equipment to which these requirements apply.

One of the more significant parts of new article 409 is the new marking requirement for industrial control panels. Section 409.110 provides a list of information that is required to be marked in a location that is plainly visible after installation. Included in this list of information is a requirement that an industrial control panel be marked with its assembly short-circuit current rating. The short-circuit current rating used for compliance with Section 409.110 must be based on one of the following methods:

a. Short-circuit current rating of a listed and labeled assembly

b. Short-circuit current rating established utilizing an approved method

(Note: UL 508A-2001, Supplement SB, is an example of an approved method.)

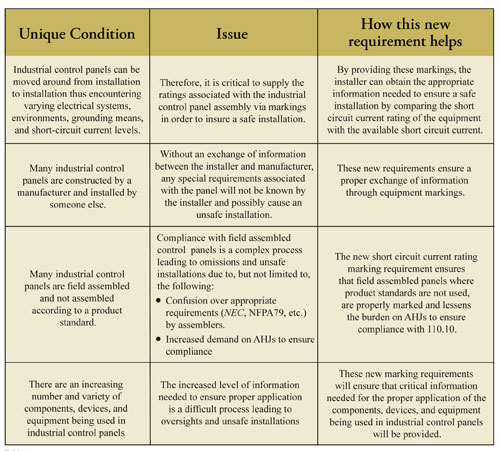

A major part of the substantiation for this new requirement is that control panels are being misapplied in a large number of applications because they have an inadequate short-circuit current rating. These misapplications often result because industrial control panels have unique conditions surrounding them.

Table 1

Air-Conditioning and Refrigeration Equipment with Multimotor and Combination Loads

Section 440.4(B) was revised to require the nameplate of this equipment to be marked with its short-circuit current rating. This new marking requirement includes the following exceptions: one- and two-family dwellings, cord-and-attachment-plug-connected equipment, or equipment on a 60A or less branch circuit. So for most commercial and industrial applications, air conditioning and refrigeration equipment with multimotor and combination loads must have the short-circuit current rating marked on the nameplate.

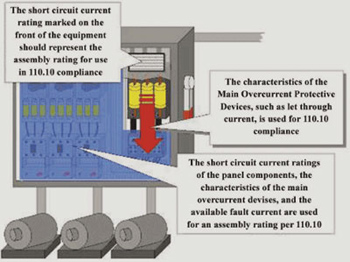

Figure 4. The characteristics of the overcurrent protective device are used along with the component’s short-circuit ratings for 110.10 compliance.

A major part of the substantiation for this change was that there is an increasing number of installations where HVAC equipment installed in commercial, industrial, and multifamily dwellings is subject to high levels of short-circuit current. The majority of HVAC equipment used in these installations was not marked with short-circuit current rating. Without this marking, the installer and AHJ have limited ability to determine if the equipment being supplied is suitable for the application. These new requirements ensure that the equipment is marked with the amount of short-circuit current the assembly can withstand. This information can be used by the installer and AHJ by verifying that the marked short-circuit current rating is less than the available short-circuit current and facilitating a safe installation.

Industrial Machinery Electrical Control Panel

The machine nameplate marking requirements in 670.3(A) were revised. The existing requirements for marking of the machine overcurrent protective device interrupting rating were removed and a new requirement for the industrial control panel nameplate of industrial machinery to include its assembly short-circuit current rating was added. In the past, the NEC required that the machine nameplate include only the interrupting rating of the machine overcurrent protective device, if one was furnished. This marking could be misleading as it did not represent the short-circuit current rating of the entire assembly, but could be

Figure 5. Interrupting ratings pertain only to the overcurrent protective device.

misinterpreted as such. Two options were provided for establishment of this short-circuit current rating:

1. Machine control enclosures that are listed and labeled and provided with a short-circuit current rating established during the listing

2. Machine control enclosures that are not listed are required to provide a short-circuit current rating established using an approved method.

A fine print note was added to provide users an example of a method, UL 508A Supplement SB, that could be used to determine the short-circuit current rating.

New Component Marking Requirements

Motor Controllers

The marking requirements in 430.8 were revised and now require that motor controllers be marked with their short-circuit current rating. Motor controllers cover anything that is used as an on/off device for a motor circuit such as contactors, drives, combination controllers, etc. There are some exceptions to this new requirement which

- Exempt certain controllers for small motors as allowed in Part VII, such as clock motors, attachment plugs and receptacles, and snap switches.

- Permit controller short-circuit current ratings to be marked elsewhere on the assembly.

- Exempt certain controllers used in assemblies which have a short-circuit current rating, as a short-circuit current rating on an assembly covers all of the internal components.

Meter Disconnect Switches (rated up to 600 V)

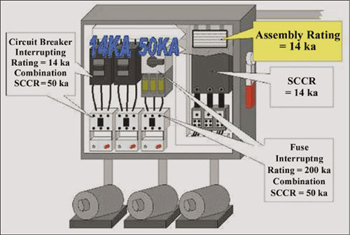

Figure 6. Assembly short-circuit current rating limited to lowest rated device (14 ka)

The list of equipment allowed ahead of the service disconnecting means in 230.82(3) permits a meter disconnect switch, provided the equipment into which it is installed is grounded. This was revised to include a requirement that the meter disconnect switch has a short-circuit current rating adequate for the available short-circuit current.

Frequently Asked Questions

What Is a Short-Circuit Current Rating?

Short-circuit current ratings on components and equipment represent the maximum level of short-circuit current that the component or equipment can withstand and are used for determining compliance with 110.10. This rating can be marked on individual components or assemblies. The new short-circuit current ratings required by 409.110, 440.4(B), and 670.3(A)(4) represent the maximum amount of fault current that the assembly can withstand under fault conditions. Assembly ratings take into account all components contained within the equipment rather than just the main overcurrent protective device.

CAUTION: Short-circuit current ratings are different from interrupting ratings marked on overcurrent protective devices. A common mistake is to assume that the interrupting rating of the overcurrent protective device protecting the circuit represents the short-circuit rating for the entire circuit (see figure 5). Interrupting ratings, used for compliance with 110.9, apply solely to the overcurrent device. The characteristics of the overcurrent device (e.g., opening time, let-through energy, etc.) need to be used in determining compliance with 110.10, not the interrupting rating (see figure 4).

Why is the short-circuit current rating marking needed?

Inspectors and installers need this information in order to ensure compliance with Section 110.10. Equipment installed where fault current levels exceed their short-circuit current limit can be hazardous to persons and property. Short-circuit current ratings marked on components and equipment make it easier to verify proper protection for components and equipment for specific applications, whether it be the initial installation or relocation of equipment.

How is it determined?

For meter disconnect switches and motor controllers, this withstand level or short-circuit current rating is often determined by product testing. For assemblies, the marking can be determined through product listing or by an approved method. With the release of the Industrial Control Panel Standard (UL 508A), an industry method is now available. Any method used, whether UL 508A or another approved method, should be based on the “”weakest link”” approach. In other words, the assembly should be limited to installation where fault levels do not exceed the withstand rating of devices with the lowest short-circuit current rating (see figure 6). The marking determined should represent the limits of the assembly for a safe installation. Current-limiting overcurrent protective devices can be used in the feeder or branch circuits to increase the assembly short-circuit current rating where lower rated components are used. When current-limiting devices that limit fault-current levels to within the lower rated components rating are used, they provide protection for the assembly provided the current-limiting OCPD is used within its ratings.

Helpful Inspection Hints

1. A simpler approach to compliance with 110.10.

The new marking requirements provide important information about equipment that will be used in a particular installation. Compliance is ensured by verifying that the short-circuit current available at each piece of equipment is less than the short-circuit current rating marked on the equipment. This can become cumbersome for installations that use a large quantity of equipment. This task can be simplified for the installer, designer, or AHJ with the use of equipment with high short-circuit current ratings. For installations where all the equipment has high short-circuit current ratings, a simpler method for ensuring compliance with 110.10 is:

a. Verify the maximum, worst case short-circuit current available at the terminals of the supply transformer.

b. If all the equipment in the system has short-circuit current ratings greater than this maximum, worst case available short-circuit current, then the detailed short-circuit current study is not necessary.

2. For unlisted or unevaluated equipment

- Require a field evaluation of the equipment by a certified testing laboratory.

- There is an option for using other methods than listing for determination of short-circuit current rating. The key is that the method used has to be approved. There are many jurisdictions around the country that have alternate methods for approval of equipment that is not listed. The following steps are provided as an example of regulations which could be implemented when an approved method is used rather than listing:

1. Require a bill of material (BOM) with component short-circuit current ratings in the detail and a schematic of the internal circuitry of the equipment. This documentation can be used for pre-authorization similar to plan review.

2. Require documentation from a professional engineer engaged primarily in the design or maintenance of the equipment and licensed or certified in the jurisdiction or state. The method shall be documented and stamped by the professional engineer. This documentation shall be available to those authorized to design, install, inspect, maintain, and operate the system.

3. For final inspections, require documentation for any changes to the BOM or schematics

4. If the short-circuit current rating marked on the equipment matches the interrupting rating of the overcurrent protective device in the supply disconnect, verify that a proper method was used to determine an assembly rating. Make sure that the marked short-circuit current rating is not just based upon the interrupting rating of the main overcurrent protective device. This is particularly common on industrial machinery covered by Article 670, as 670.3 in the previous edition of the Code required this misleading method of marking.

5. If there is a high short-circuit current rating marked on the equipment, check to see if there are current-limiting overcurrent protective devices in the feeders and or branch circuits. High short-circuit current ratings for assemblies can only be achieved by either (1) the use of components and overcurrent protective devices with high short-circuit current and interrupting ratings, or (2) by the use of current-limiting overcurrent protective devices (see figure 7). While components with high short-circuit current ratings exist, it is often very difficult or costly to find or use them. Therefore, it is common to have a device with a high interrupting rating in the supply circuit or main for the panel and components with low short-circuit current ratings downstream. The marking could inappropriately be based on the interrupting rating of the main overcurrent protective device and not represent what the entire assembly can withstand. Current-limiting devices are the only way to increase an assembly short-circuit current rating where devices with low short-circuit current ratings are used.

Summary

The new short-circuit current rating requirements are a major step towards ensuring the safe installation of equipment. There now are mandatory requirements for the marking of short-circuit current ratings of certain components such as motor controllers and meter disconnects and complete assemblies such as industrial machinery [670.3(A)], industrial control panels [409.110], and HVAC equipment [440.4(B)]. These changes simplify the approval process for the AHJ. In order to enforce these new requirements, the AHJ should:

Ensure that the equipment is marked with a short-circuit current rating according to one of the methods listed above.

Ensure that the available short-circuit current at the point of installation does not exceed the assembly short-circuit current rating for compliance with 110.10.

The new short-circuit current rating marking requirements are just one of several significant changes that occurred during the 2005 NEC code cycle. As with any requirement in the NEC, a rule is only a rule if it is used and enforced. Hopefully, we as an electrical industry, from designer to enforcer, can work together to make sure that these changes do what they are intended to do.

Find Us on Socials