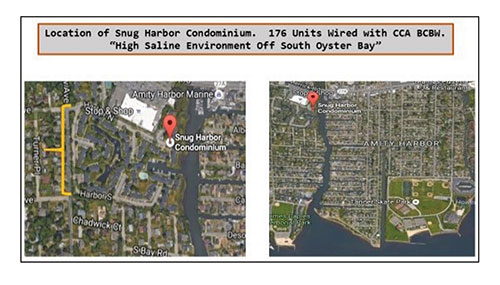

The Case of Snug Harbor Condominium, Amityville, NY.

According to external documentation from April 16, 1976, from the Committee of Aluminum Conductors in Electrical Wiring Systems organized by UL (of which IAEI was one of 11 committee members), Cu-Clad NM-B and THHN is quite safe, and should not be considered in the same breath as solid aluminum BCBW. In a letter addressed to Miss Dorothy Froesse, manager of the Snug Harbor Condominium in 1976 located in Amityville, NY, the secretary of the Ad-Hoc Committee addresses Miss Froesse’s safety concerns about Snug Harbor being wired with Cu-Clad branch circuit building wire (BCBW). The letter reads, “This confirms our telephone discussion of April 8, 1976, and also serves to reply to Mr. William H. Shave’s March 31, 1976, letter concerning the subject of copper-clad and aluminum wiring. You will note in the brochure (supplied by the committee and issued to concerned citizens) that restrictions applying to aluminum are not applicable to copper-clad wiring. On page 6, rules for the use of copper-clad aluminum with receptacles and snap switches are given and are the same as those for the use of copper wire with these devices. Based on all available information, copper-clad aluminum has not been accused of causing any field problems.”

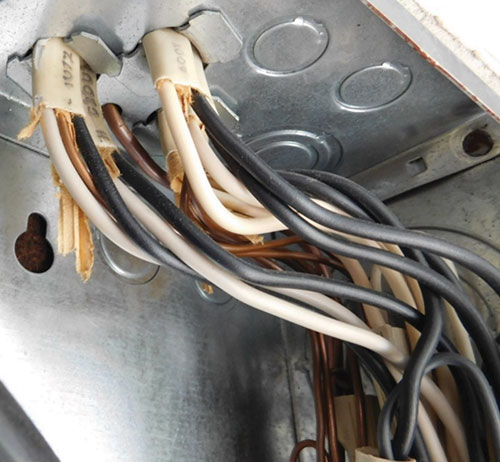

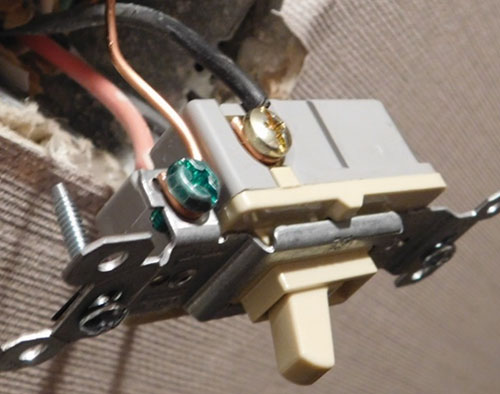

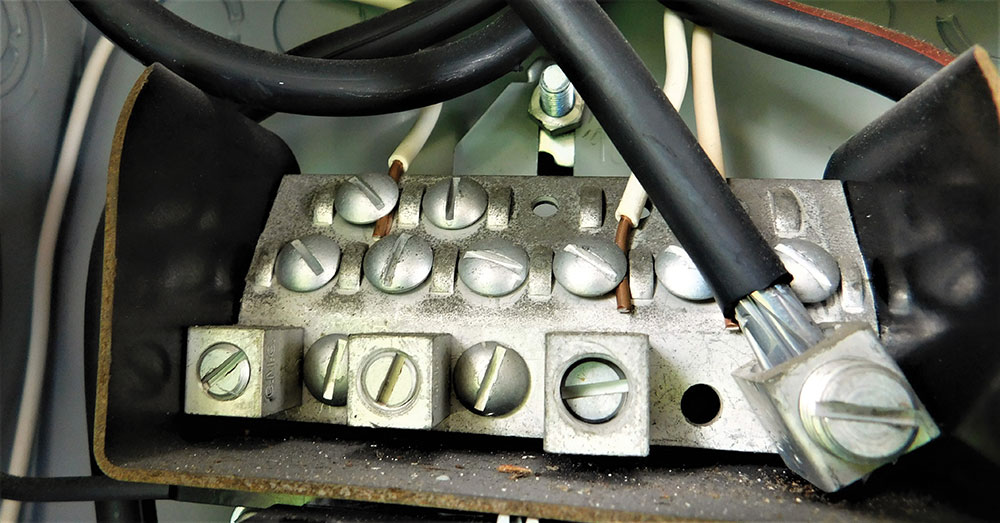

Some forty years after the date of the above official letter from the Secretary of the Ad-Hoc Committee, in July 2016, Mr. Thomas J. D’Agostino, P. E., a Certified ASHI Home Inspector, paid a visit to Snug Harbor to find functional installations. D’Agostino has been a certified home inspector on Long Island for several decades after having spent the majority of his engineering career working with UL in Melville, NY, as an electrical wiring system specialist. He is very familiar with Cu-Clad BCBW, having observed its entire life-cycle from its initial listing at UL to its performance over the last 5 decades within homes of his community. He has inspected hundreds of homes with Cu-Clad wiring. Before the visit to Snug Harbor, D’Agostino requested fire records for the community from the city of Amityville dating back to 1973. He received records starting in 1995. Of the 17 records that he received, none reported receptacle outlet overheating nor faulty electrical wiring. The most common incident in the reports dealt with cooking mishaps. Upon arriving to Snug Harbor, D’Agostino entered one of the oldest units in the development to confirm its use of Cu-Clad BCBW. The back door opened to the community dock. After inspecting the panel, as well as several heavily utilized switches and receptacles in each corner of the dwelling, he was able to confirm that Cu-Clad BCBW was being utilized. D’Agostino was impressed by the stability of the wiring after its four decades of service. The panel looked good. The connections were tight and clean. There were no signs of galvanic corrosion nor wire creep. No sign of Carbonized Path Condition on any of the insulation. The installation was safe and adhered to code.

D’Agostino then moved to a newer unit within the community. The unit opened onto a marsh off the salt-water creek. There he found Cu-Clad BCBW in the branch circuits, too. He repeated the process of checking the panel as well as heavy-use devices and receptacles in each corner of the dwelling. Again, he found the Cu-Clad BCBW to be functioning as intended. He gave the installation a clean bill of health. Moving on, a third unit of the Snug Harbor community was inspected yielding the same results. The branch circuits of all three units were fully functioning, clean and within code.

Other Communities on Long Island Utilizing Cu-Clad BCBW

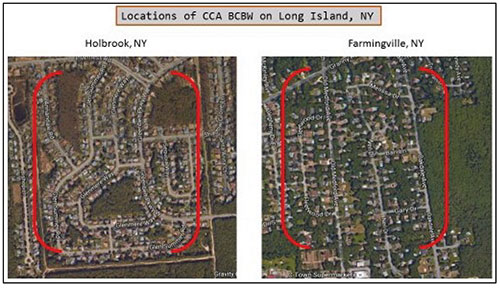

In continuing the task of locating and inspecting homes wired with Cu-Clad BCBW, D’Agostino solicited the assistance of Mr. John Yeamans, a long-time resident of Farmingville, NY, and a local real-estate agent serving all of Long Island. Together, D’Agostino and Yeamans quickly identified neighborhoods in the area where Cu-Clad BCBW is in service.

The homes in the study are located in the towns of Holbrook and Farmingville. Yeamans’ residence, in fact, is wired with Cu-Clad BCBW. The builder of his home, Birchwood Homes, had built a large majority of the homes in his neighborhood, and most with Cu-Clad BCBW. In the four-some-odd decades that Yeamans has lived in his home, he could not recall a house fire in his neighborhood during the time of his living there, nor an electrical problem within his house. Perhaps an insignificant point, but many homes in Yeamans’ neighborhood are being renovated, as well as having solar systems installed to economize energy costs. Electricians are connecting new copper wiring to existing Cu-Clad wiring in the process, an acceptable practice within code.

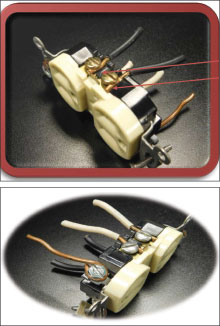

D’Agostino inspected five homes wired with Cu-Clad BCBW in Farmingville and Holbrook. As expected, nothing about the circuits seemed odd. In the opinion of D’Agostino, all circuits were clean, safe and up-to-code. One particular home in Farmingville was undergoing a complete renovation. An offer was made to the homeowner that would allow for the harvesting of the Cu-Clad BCBW and connected devices. These materials should yield a wealth of information regarding the performance and reliability of Cu-Clad BCBW.

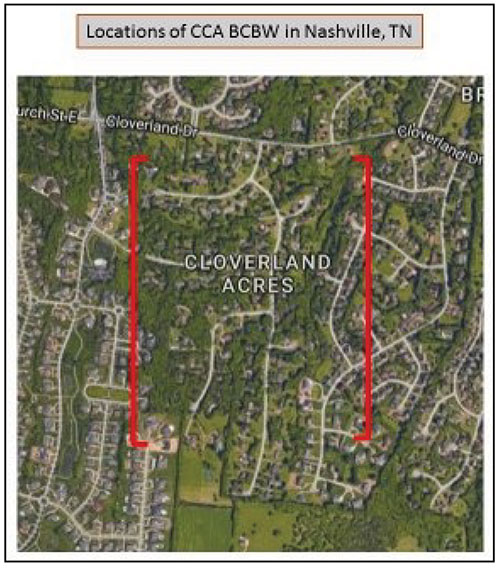

The Case of Cloverland Acres, Nashville, TN.

A leafy seventies-era neighborhood of rambling ranch-style homes on multi-acre lots, Cloverland Acres sits on the southside “Inner-Burbs” of currently booming Nashville, Tennessee. Construction of the neighborhood began in 1972, and it is the kind of neighborhood that was marketed to wealthy city residents wishing to live a suburban lifestyle, as well as to those professional and upper-middle-class transplants from the Midwest and Northeast. By any measure, Cloverland Acres was a very desirable place to live back in the day. To buy a home there required a substantial net worth, especially in lieu of the economic instability of the 1970s. These days, many of the homes have undergone a series of renovations and remodeling projects to keep up with demographic trends. The location within Nashville is ideal. The homes are still very nice. There are an estimated 100 homes in the neighborhood, all of which were originally wired with Cu-Clad BCBW.

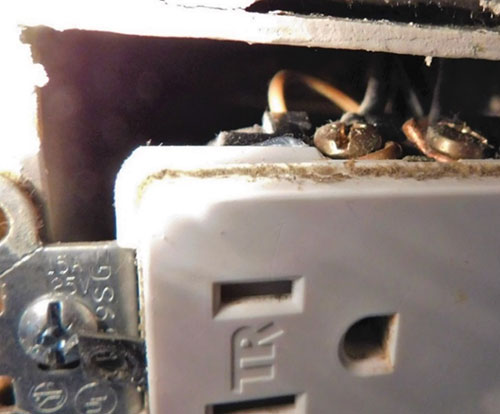

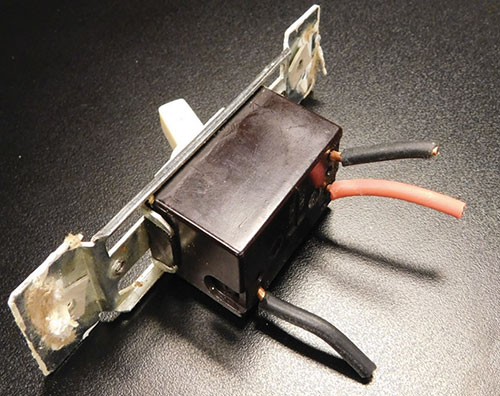

In June 2016, Steve Mallory organized an inspection of a residence in Cloverland Acres. Steve Mallory is a certified electrical inspector for the state of Tennessee, as well as a member of IAEI. The homeowner of the residence built the house, and it is original. Over the last four decades, the home had undergone two significant renovation projects. One was a kitchen remodel where the Cu-Clad BCBW remained in place, and the other was a garage addition where copper NM-B BCBW connects to the existing installation. In exchange for entrance to the home, a free electrical inspection was performed as well as an offer to replace any harvested wiring devices with modern ones. Some of the receptacles were original to the home, as we found several back-stab models from the early 1970s. The home utilizes Cu-Clad NM-B 12/2 and 10/2 from General Cable. Both Cu-Clad NM-B wire and electrical devices (with connections intact) were harvested from the home and replaced with solid copper NM cable and modern wiring devices. The harvested wire and devices will be analyzed for future reporting.

The homeowner, a retired medical professional of sound mind, was asked whether he had ever experienced problems with his electrical service. He replied that he had not. He was then asked if he could remember ever having an electrical fire in his home or any house fire for that matter. The answer was no. He was then asked if he could remember any house fires in the neighborhood in the time that he had lived there, and still his answer was no. He went on to say that a Metro Nashville electrical inspector happened to be a neighbor, and he felt sure that the inspector’s house had the same Cu-Clad wiring, so he felt pretty safe with his own.

Just as with the branch circuits found on Long Island, the home in Nashville was also found to be in good working order. The panels were clean and organized. No wire creep nor galvanic corrosion was observed. The connections to the most heavily used outlets and receptacles were tight and showed no history of overheating. Mallory deemed the installation as being safe and up to Code.

What Does the Fire Data Say About Cloverland Acres?

To document the history of electrical fires within the neighborhood, the Tennessee Department of Commerce and Insurance was contacted to acquire for study the available fire data for the area. Fire Records for zip code 37027 were requested as it includes Cloverland Acres. As fate would have it, the National Fire Incident Reporting System (NFIRS) was only able to provide data starting from 1980, the last year that Cu-clad BCBW was in the market. For this zip code, there were 1,091 residential fire incidents between 1980 and 1999, with 57 being of electrical nature, or 5.2%. Of this number, only 10 were classified where the failure originating with either the wire or wiring devices (the branch circuit system), or in other words, only 17.5% of electrical fires were associated with the branch circuit system, below the national average of 39.1% from 2007–2011 as reported by the NFPA. The NFIRS data from these years did not provide the addresses of these incidents, so it is unknown which of the 10 residences actually contained Cu-Clad BCBW, or if any of these homes were even located in Cloverland Acres. However, it should be noted that a zip code with a known concentration of homes wired with Cu-Clad BCBW for a 19-year period from 1980–1999 (as stated, Cu-Clad BCBW was available only between 1972–1980) had an incident rate of electrical fires originating in the branch circuits of well below the National Average of 2007–2011.

In the years from 1999 through 2016, the NFIRS system was updated to newer statistical standards and computer information systems. The new system can provide addresses for incidents in addition to the zip codes. It is also able to sort by more specific categories for the causes of residential fires. For the zip code of 37027, there were only 293 total incidents of residential fires, with 26 originating from arc-faults, wire or wiring devices, i.e., branch circuits. This is a rate of 11.3%, well below the national average. Of the 26 arc-fault incidents, only 5 of the residences were built between 1972 and 1980, the only period when Cu-Clad BCBW could have been installed in them, or in other words, 1.7% of the total incidents. It should be noted that this report does not confirm Cu-Clad BCBW to be within these 5 residences, only that the possibility that it could be there exists. Thus said, the percentage of incidents for Cu-Clad BCBW could be less than 1.7%. None of these homes were located in Cloverland Acres, a neighborhood where all of the 100 or so residences are known to have Cu-Clad BCBW, and where at least one original homeowner never remembers there being a house fire of any kind in his neighborhood. Notwithstanding, the NFIRS system did report one fire in Cloverland Acres on 7/8/2012 pertaining to the roof exterior at a home on Cloverland Drive. No mention that it was electrical in nature. In short, it is always good to have both statistical data as well as personal testimony to obtain a clear picture of reality.

If any conclusion can be drawn from this analysis, it is that in a zip code where there is a known population of homes wired with Cu-Clad BCBW, the rate of electrical fires due to branch circuit issues is well below the national average. In addition, in one particularly large neighborhood, Cloverland Acres located in Brentwood, Tennessee, where all of the homes have used Cu-Clad BCBW since the early 1970s, the NFIRS does not report one electrical fire incident due to branch circuit failures.

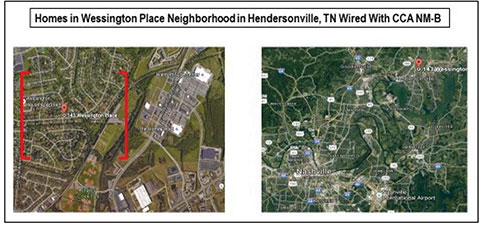

Other Residences in Metro Nashville with Cu-Clad BCBW

With the help of Steve Mallory, the Wessington Place neighborhood in Hendersonville, TN, was identified as being one utilizing Cu-Clad BCBW. These homes differ socioeconomically from those in Cloverland Acres in that they are small working-class bungalows instead of large executive homes.

It is well documented that neighborhoods of lower socioeconomic class experience a higher rate of house fires. The reasons for this do not necessarily point to less adequate electrical installations, but rather to homeowner “user-error” in terms of cooking, general maintenance, overloading circuits, smoking, and a general ignorance of fire hazards. To find evidence of branch circuit system failure in homes of this socioeconomic class was of great interest. However, no evidence turned up within the subject home inspected in Hendersonville. The attic showed signs of a small house fire sometime early in the life of the structure, as the wood in the attic had been sealed with polymer paint to reduce smoke odor, but the Cu-Clad BCBW running throughout the attic space since the early 1970s all looked clean and showed no signs of destruction. All the electrical wiring devices in the home were the originals.

At the completion of the inspection, in the opinion of Steve Mallory, the electrical installation was safe, clean and within code.

Inspections Revealed that Cu-Clad Was Found to Be FORGIVING, Despite Poor Workmanship of Installation or the Use of Questionable Electrical Devices

Poor workmanship and questionable electrical devices have been recognized as being two principal causes of arc-faulting. How does Cu-Clad BCBW compare to traditional products in this respect? Does Cu-Clad BCBW offer an advantage regarding safety in light of the inevitability of questionable decisions by installers within a certain percentage of installations? Perhaps one of the best virtues of any wire product is its ability to be forgiving considering inevitable poor workmanship during installation.

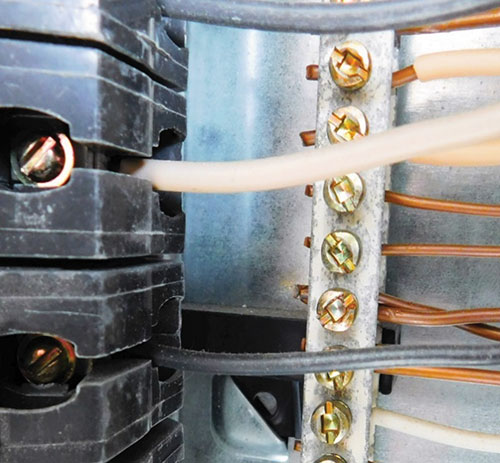

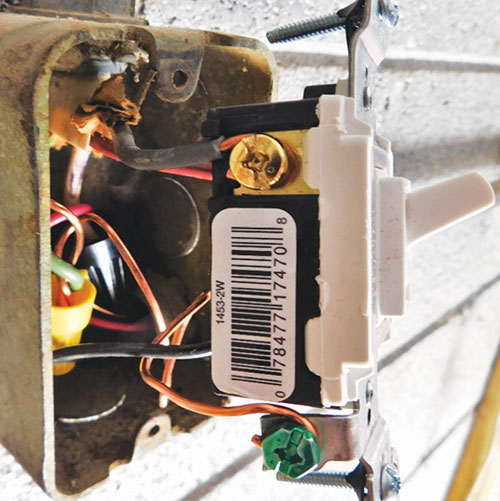

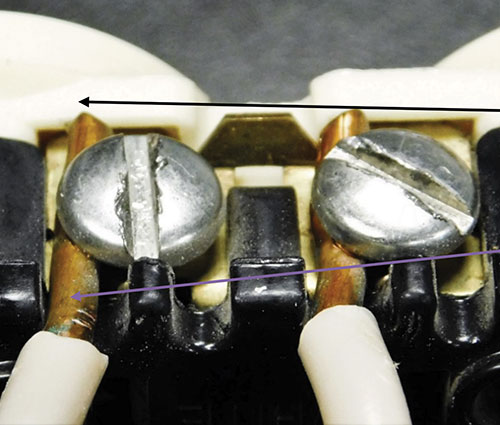

CCA is a thermally stable material, so the chances that it will creep are as low as that of solid copper. If the connection is initially firm, Cu-Clad will not creep over time. Examples of this were found in harvested receptacles in Nashville.

Cu-Clad wire is easier to bend than copper wire even though the Cu-Clad is sized-up within the circuit. This makes the job of installation less fatiguing to the installer, encouraging better workmanship. Conductor wire should always be bent around the screw to maximize the contact to the plate, and to provide tightness and for adequate pressure by the screw. 10 AWG Cu-Clad is much easier to bend than 12 AWG Cu, while the thermal stability factor as measured by UL 486C is equal if not better than solid copper wire.

Cu-Clad BCBW is not fragile, but with any electrical component of a branch circuit, installation should be made with great care. Surface damage to the wire should be avoided regardless of the core conductor metal. According to Tom D’Agostino, “nicks and scratches won’t prevent successful use of the CCA wire as there is plenty of other copper-clad wire surfaces available to be in contact with the wire connector.”

More evidence can be seen as to the reliability of Cu-Clad BCBW by its admirable four-decade performance with “Push-In” wiring devices. Push-In or Back-Stab wiring devices have been criticized for decades as being less reliable than Side-Wiring devices, as their spring components can become brittle due to natural cycle-heat and mechanical wear, compromising the clamping force of the spring, contributing to loose connections. Push-In devices were heavily used in residential construction during the decade of the 1970s when Cu-Clad BCBW was available in the US market. For Cu-Clad BCBW to not have been called into question during this era of questionable devices speaks well of the wire itself. Although more study should be undertaken, it is postulated that the reason for the good performance of Cu-Clad wire with Push-In (back stab) devices rests with the lower heat generated by the CCA wire while in service. The lower heat loss of CCA in relation to solid copper of the equivalent amperage size contributes less to the weakening of the spring steel within the device over time. Excessive heat will anneal (soften) and weaken spring steel over time.

Find Us on Socials