Arc-fault circuit interrupters (AFCIs) have become a familiar technology to electrical contractors during the past decade. The first branch-feeder AFCIs debuted in the late 1990s, and detected exclusively parallel arcs, or current that travels from one circuit conductor to another. They were followed more recently by combination AFCIs, which respond to both parallel and series arcs, the latter of which occurs when a single conductor is severed and electricity travels across the compromised point.

The 2005 National Electrical Code mandated combination AFCIs for all 120-V, 15- and 20-A branch circuits that supply bedroom outlets in new homes starting January 1, 2008, which generally includes receptacle outlets, lighting outlets and smoke alarm outlets. The 2008 NEC expands the requirements for combination AFCIs beyond bedroom circuits to include other areas in a home, such as family rooms, dining rooms, living rooms, closets and hallways.

State and local electrical committees are beginning the process of adopting the 2008 NEC. Electrical contractors and inspectors have played a significant role in the development of the NEC and specifically in supporting the requirements for branch-circuit protection via AFCIs. They will once again play a significant role in supporting adoption of new 2008 NEC requirements, which includes AFCIs, tamper-resistant receptacles and increased conductor and conduit sizes used in direct sunlight on the roof. It is important for those contractors and inspectors playing a role in the adoption process to have a working knowledge about AFCIs in order to ask the right questions and provide informed answers when questions and concerns arise.

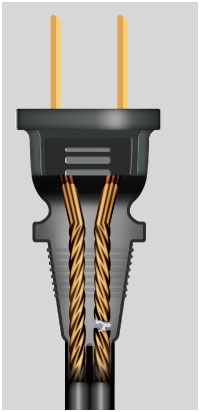

Photo 1. A series arc occurs when a single conductor is severed; for example, if one conductor on an appliance cord is cut or broken completely and current continues to flow in the slight gap between the two compromised points.

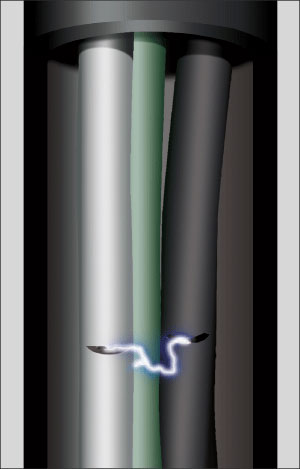

Photo 2. A parallel arc happens when current travels from one circuit conductor to another; for example, if the insulation is pierced by a nail or screw on the two current-carrying conductors at the same point and current travels between the conductors

AFCI basics

An AFCI circuit breaker protects branch-circuit wiring from arcing faults that could start an electrical fire. An arc fault occurs when current flows in an unintended path, and the heat generated at the point of the arc (up to 10,000° F) can set fire to insulation or wood framing. There are several ways an arc fault can occur, and they typically happen due to damage to wires or their insulation. Common arc-fault occurrences include:

- Puncturing a wire with a nail, staple or a tool during installation or maintenance of the electrical system.

- Damaging an electrical wire during tasks like hanging pictures or installing cabinets.

- Damaging extension or appliance cords when furniture or an appliance has been positioned on the cord.

- Advanced age of extension or appliance cords, which can over time experience worn or cracked insulation.

Any of those scenarios can result in a parallel or series arc. A parallel arc can occur if the insulation on an appliance cord is pierced by a nail or screw on the two current-carrying conductors at the same point, allowing current to travel between the conductors that are now slightly gapped. Conversely, a series arc can occur when a single conductor is severed; for example, if one conductor on a cord is cut or broken completely and current continues to flow in the slight gap between the two compromised points.

Unlike standard circuit breakers, all AFCIs use electronic processing technology built into the device itself to detect arcs. Electronics are used in various electronic-trip circuit breakers on the market today to protect circuits in large commercial buildings, so the premise is similar in residential applications. For example, a combination AFCI monitors a circuit for both dangerous and normal arcing conditions—some appliances, like a motor-driven vacuum cleaner, create arcs in order to operate correctly, which the AFCI will simply judge as a safe, operational arcing condition.

When a combination AFCI detects an arc, it employs its signal-processing capabilities to examine the arc’s electrical characteristics. If it deems the signal as a dangerous arc, it will open the circuit, thus removing the arcing condition, and possibly preventing a fire. Operational arcing criteria is based on known behaviors of electrical arcs, meaning the combination AFCI is programmed to detect the signal of a dangerous arc, compared to an operational arc. The device’s electronics will signal the breaker to open when the signature of a dangerous arc is determined to be present.

Branch-feeder vs. combination AFCIs

Proper installation of the branch circuit being protected by the combination AFCI is the most important aspect of ensuring not only an NEC-compliant installation but also a reliable one that does not require a follow-up visit because the AFCI found an issue with the installation. Here are a few items to check:

1. Make sure all connections are tightened properly to avoid creating an arcing condition.

2. Ensure the circuit’s neutral conductor is returned to the combination AFCI and the pigtail is connected to the neutral terminal on the panel. When the circuit neutral is mistakenly returned to the panel and not the AFCI, the AFCI will trip when a load is applied and the current reaches the ground-fault current threshold of the AFCI (typically 30–50 mA, though this value can vary from one manufacturer to the next) since no current is returning through the circuit breaker.

3. Make sure neutral conductors of different circuits are not connected together at any point in the branch circuit. When the neutrals of different branch circuits are connected, an AFCI will trip when a load is applied and the current differential is over the ground-fault current threshold (30–50 mA) of the AFCI. Due to a split in the return current path, the AFCI correctly “sees” this improper connection as a ground-fault.

4. Press the “Test” button on the front of a combination AFCI after the load center has been energized to ensure proper functioning of the AFCI. Many electrical inspectors also utilize a plug-in indicator/tripper in order to ascertain if the circuits required by the NEC are protected by the AFCI, but the AFCI’s “Test” button is the only acceptable method to verify the operation of the AFCI itself.

Photo 4. Combination AFCIs like the Square D (left) and Homeline devices from Schneider Electric use advanced digital signal processing technology to monitor a circuit for both dangerous and normal arcing conditions.

If you find an AFCI is tripping, consider troubleshooting by replacing it with a GFCI to understand if the AFCI is protecting the circuit due to a ground fault or an arcing fault. If the GFCI does not trip, then you may have an arcing condition being detected by the AFCI. The troubleshooting for a combination AFCI differs little from a branch-feeder AFCI. A few common places to look for installation issues before initiating an isolation effort include:

- Switches where the neutrals for different circuits have been connected.

- Receptacle outlets, lighting outlets or switches where the bare grounding conductor has made inadvertent contact with the neutral conductor or terminal.

- Luminaires, including recessed luminaires, where wire insulation may have been compromised during installation.

Also keep in mind that turning off a lighting outlet at a wall switch to make adjustments or installing a ceiling fan without turning off the AFCI may cause the AFCI to trip when the neutral and grounding wire come in contact where the circuit is feeding other loads. The perception is that after the fan is installed and the switch is turned on, the ceiling fan tripped the AFCI, when in fact the AFCI was tripped during installation. It is always best to de-energize the circuit before performing any type work on the circuit.

Eliminating non-compliant NEC installations is important not only to ensure a safe and reliable installation but also to reduce the need for a contractor to make a follow-up visit to a home to rectify the problem. Thus, verifying the installation is correct can help avoid unnecessary cost and labor strains later. That’s particularly important considering a contractor will likely be installing more combination AFCIs in the coming months and years.

It bears mentioning at this juncture that AFCI technology has matured to the point where combination devices are better programmed to discern a dangerous arc from a normal arc or even normal operating conditions, which also reduces the possibility of a nuisance trip occurring even if the installation is sound. Branch-feeder devices have been on the market for about eight years, and though combination AFCIs have been on the market for about the past year, the technology has been extensively field tested by facing day-to-day usage conditions in numerous homes.

In fact, the technology serves as a quality control means for electrical contractors. If a homeowner experiences an AFCI tripping, it could be that a mistake was made during the installation process, but it could also mean an appliance is malfunctioning and causing the breaker to trip. It’s particularly important to note that when an AFCI that trips due to an improper installation or malfunctioning appliance, it should not be considered a nuisance—it is protecting from the hazard it was designed to address.

The question of cost

Expansion of combination AFCI usage to other areas of a home in NEC-2008 is a natural progression from the NEC-2005 mandate for usage in all new bedroom circuits of new homes that become effective on January 1, 2008. However, concerns were voiced by some within the industry about the cost to implement such a requirement, including both the initial payout and the return on investment for the homebuilder and, by extension, the contractor.

National Electrical Manufacturers Association research in August 2007 of hardware stores and home centers found AFCIs priced from roughly $30 to $35, with standard circuit breakers priced between $2 and $4.1 Assuming the high-end price of $35, the cost differential between AFCIs and standard breakers is approximately $31 to $33, which means installing 12 AFCIs in an average home will increase the cost $372 to $396, or .20 percent of the national average home cost.2

That might seem expensive to some, especially considering a combination AFCI device is located behind the door of a load center. But the work of an AFCI as a proactive safety device shouldn’t be minimized—its ability to use advanced signal processing to detect a dangerous arc and open the affected circuit can prevent a fire from igniting in the first place. This differs from smoke alarms or even a sprinkler system, for example, which can be viewed as reactive devices because they detect a fire after it starts. Both smoke alarms and sprinklers are important safety systems and the lives and property they save are significant, but AFCIs could be considered a strong complement by mitigating an arc fault fast enough to result in a fire not starting in the first place.

According to NEMA, residential fires of an electrical origin are a major concern. In 2003, about 67,800 such fires occurred, resulting in $868 million in property losses, quoting data from the United States Fire Administration. What’s more, electrical fires are annually responsible for about 485 deaths and 2,300 injured people, not to mention the loss of a dwelling and sometimes everything in it, including pets and irreplaceable personal items.

Projecting combination AFCIs’ life- and property-saving potential is difficult; after all, very few near-misses are recorded or even known by homeowners. But statistics from the 1980s and early 1990s, following the adoption of the majority of GFCI requirements in the NEC, show that electrocution deaths significantly dropped. Of course, many factors played into that, but the statistics suggest GFCIs played a crucial role. A similar reduction scenario in home fires due to electrical incidents is projected following the combination AFCI expansion post-January 1, 2008.

Extensive support

The support and endorsement for AFCI is extensive. The electrical industry, including the Independent Electrical Contractors (IEC), National Electrical Contractors Association (NECA), International Brotherhood of Electrical Workers (IBEW), Underwriters Laboratories and the electrical inspection community have supported combination AFCI expansion to enhance electrical safety. The National Association of State Fire Marshals (NASFM) endorses installation of combination AFCI protection on all circuits in the home, not just those established by the 2008 NEC. The Consumer Product Safety Commission (CPSC) endorses the installation of combination AFCIs not only in new construction but also during the installation of new services in older homes.

AFCIs have come a long way in a short period of time. The contractor that understands AFCI technology and the implications of code requirements will be better prepared to adjust to the changes it will dictate on the job. Based on the industry embracing the expansion of combination AFCI protection in additional areas of the home as outlined in NEC-2008, electrical contractors, inspectors and homebuilders will be leading the way in not only electrical safety but overall home safety.

1 National Electrical Manufacturers Association whitepaper. “Upgrading the Home: Luxury vs. Safety.”

2 Ibid.

3 2008 NEC210.12(B)

Find Us on Socials