A Historic Perspective on Surge Protection

Surge protection was introduced into the first National Electrical Code (NEC) published in 1897. The primary focus at that time was lightning arresters. In 1981, NEC Article 280 was revised and re-titled “Surge Arresters” in order to align with industry terminology. The title change in the NEC also recognized that surge arresters were being installed where the surge source was other than lightning, such as utility switching, or equipment switching within industrial and commercial facilities.

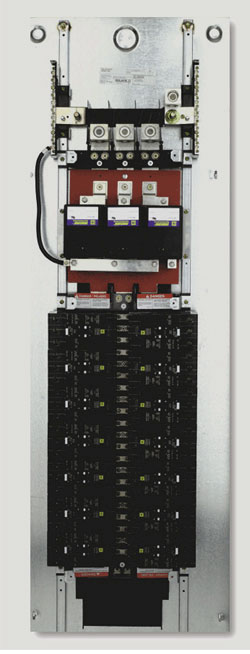

Photo 1. Direct bus connections between the TVSS and panel reduces; the conductor length, unnecessary conductor bends, and impedance with bolted connections.

The vast introduction of electronic equipment such as computers, answering machines, microwaves, HVAC electronic controls, security systems, etc., during the last 20 years has also presented a challenge to the electrical industry to protect this sensitive equipment from less severe surges than lightning. The Transient Voltage Surge Suppressor (TVSS) is the newest product becoming commonplace in residential, commercial, and industrial facilities in order to protect sensitive electronic equipment. In response to the development of TVSS products, Underwriters Laboratories, Inc. (UL) published the first TVSS safety standard, UL 1449, in August 1985. [See photos 1 and 2]

Lightning Arrester, Secondary Surge Arrester, Transient Voltage Surge Suppressor.Where do these fit in the electrical system?

The lightning arrester is generally installed by the utility at the serving transformer and basically acts as a spark plug. When lightning hits the distribution line, the increase in voltage causes an arc to form across the spark gap and the lightning current is diverted to ground, protecting the utility transformer.

Surge arresters and secondary surge arresters are generally installed at the service equipment either on the line or the load side of the service disconnect. They may also be found connected to non-service panelboards where branch circuits extend outside the building. For example, branch circuits feeding parking lot lights are a possible source for a surge to enter the building by backfeeding the electrical system from external sources.

Photo 2. Integral TVSS units within Busway Plug-in Units and MCC buckets reduce the conductor length and enhance performance of the surge protection of the system.

Transient Voltage Surge Suppressors may be installed in any part of the electrical system starting from the load side of the service disconnect in the service equipment to the electronic product being protected. The TVSS may integrate protection of AC, coaxial cable, and telephone to establish a common ground reference for the different services. TVSS products may also be found connected to non-service panelboards where branch circuits extend outside the building.

Installation in Accordance with the NEC

TVSS products may be installed:

1. as an integral part of a listed panelboard.

2. as a field installed product within a panelboard listed and marked for a TVSS kit.

3. external to a panelboard or switch and connected on the load side of a circuit breaker or fuse inside the panel.

4. as an integral component of a Listed wiring device to protect specific electronic equipment connected to that branch circuit.

Article 250 – Grounding and Bonding

Establishing a solid foundation for a safe TVSS installation starts with the grounding and bonding system. Section 250-2(a) clearly states the grounding system be connected to earth in order to limit the voltage levels imposed by surge events.

250-2. General Requirements for Grounding and Bonding

(a) Grounding of Electrical Systems. Electrical systems that are required to be grounded shall be connected to earth in a manner that will limit the voltage imposed by lightning, line surges, or unintentional contact with higher voltage lines and that will stabilize the voltage to earth during normal operation.

The connections of the grounding electrode, grounding electrode conductor, and the bonding jumper are important to facilitate a safe, low resistance path to ground for any surge current being diverted by a TVSS. When adding a TVSS to an existing electrical system, it is important to reinspect the grounding system to ensure a safe and effective path for the surge current.

Article 280 – Surge Arresters

TVSS products are not specifically recognized in the NEC. Since TVSS products are similar in function to a surge arrester, we must turn to Article 280 for installation requirements. The voltage rating of the TVSS must be equal to or greater than the continuous phase-to-ground voltage. Section 280-4 also requires all surge arresters less than 1000V to be listed. UL 1449 only covers products rated 600V and less.

280-4. Surge Arrester Selection

(a) Circuits of Less than 1000 Volts. The rating of the surge arrester shall be equal to or greater than the maximum continuous phase-to-ground power frequency voltage available at the point of application.

Surge arresters installed on circuits of less than 1000 volts shall be listed for the purpose.

The TVSS must be connected on the load side of the service disconnect unlike surge arresters that can be connected to the line or load side of the service disconnect as permitted in Section 230-82. The surge arrester is often evaluated to higher surge current levels than TVSS products. A TVSS evaluated to UL 1449 assumes connection on the load side of the “”main disconnect.”” The listing of a TVSS product may also require connection to the load side of a specified overcurrent device. UL 1449 permits this marking to be placed either on the TVSS or in an instruction bulletin.

A service may contain six disconnects, as permitted in Section 230-71. The main disconnect supplying the TVSS at this service counts as one of the six disconnects. A TVSS is not power monitoring equipment.

230-71. Maximum Number of Disconnects

(a) General. The service disconnecting means for each service permitted by Section 230-2, …, shall consist of not more than six switches or six circuit breakers mounted in a single enclosure, in a group of separate enclosures, or in or on a switchboard. There shall be no more than six disconnects per service grouped in any one location. For the purpose of this section, disconnecting means used solely for power monitoring equipment or the control circuit of the ground-fault protection system, installed as part of the listed equipment, shall not be considered a service disconnecting means.

The routing and length of conductors connecting the TVSS is an important concern, addressed in Section 280-12. The objective of the TVSS is to get any overvoltage conditions to ground as quickly as possible without causing a strikeover or arc-to-ground before the transient is dissipated to earth, ultimately protecting sensitive electronic equipment. Unnecessary bends and conductor length increases impedance in the surge path, driving the surge voltage higher. As the voltage grows, the potential for a strikeover grows since the voltage is not suppressed. The unsuppressed voltage passes on to the electronic equipment that the TVSS was intended to protect. Depending on the size and material (Cu or Al) of the conductor, each foot of wire may add as much as 165V to the suppression rating of the device.

Other Safety Issues

Photo 3. The integral TVSS is becoming common place in panelboards that serve sensitive electronic loads such as school computer facilities, office buildings, and industrial facilities

TVSS products function similar to surge arresters; however, in order to provide protection for electronic equipment, TVSS devices begin to operate (i.e., conduct electricity during a surge), much closer to the system operating voltage than a surge arrester. The NEC does not require all electrical systems to be grounded nor does it prohibit the installation of TVSS products on an ungrounded system; however, there are concerns with ungrounded systems. The voltage in an ungrounded system is not stable and the system voltage-to-ground can rise as high as eight times over the normal operating voltage on the system if a ground fault occurs on the circuit. A voltage rise of this magnitude can be destructive to a TVSS; therefore, a TVSS should not be permitted on ungrounded systems. [See photo 3]

It is important to look for TVSS products that have a short circuit current rating (SCCR), even the more common single-port or parallel devices. TVSS technology commonly uses metal oxide varistors (MOVs) to make direct phase-to-phase and phase-to-ground connections unlike a spark (air) gap used in lightning arresters. When an MOV fails, a short circuit is established. The available fault current will attempt to flow along the shorted path. The circuit breaker or fuse, to which the TVSS is connected, affords short circuit protection for the wire, but the TVSS may or may not be protected unless it has been tested and marked. An example of markings on TVSS products that have been tested for short circuit current ratings would be similar to:

This TVSS is suitable for use on circuits capable of delivering not more than:

25,000A rms, 240V when protected by a 30A max circuit breaker, or

10,000A rms, 240V when protected by a 30A max non-current limiting fuse.

TVSS products can see an extremely high amount of energy before the circuit breaker or fuse limits and disconnects the short circuit current. This energy can be destructive to the TVSS if the internal components are not electrically coordinated with the overcurrent protection. Containment of the TVSS failure within the TVSS enclosure is an important safety concern. The rupture of the TVSS enclosure is a safety concern whether external or internal to other electrical equipment. The short circuit current rating for single-port devices is a safety gap that presently exists within industry standards and can only be evaluated by product testing. UL 1449 currently has a short circuit current test for two-port devices but a similar test is only required at minimal levels for the more common single-port or parallel device. Short circuit current rating markings on products is a good indication that the manufacturer has considered the available fault current to which the TVSS is going to be connected.

Photo 4

The markings on a TVSS mounted externally to a panel should include the SCCR directly on the TVSS. A panel with an integrated TVSS will have SCCR markings on the TVSS, the panel’s wiring diagram, or panel markings that indicate acceptance of a TVSS within the panel. The short circuit current ratings on the panel will apply for an integrally mounted TVSS as part of the panel’s listing. Do not confuse the short circuit current rating with the surge current ratings on the TVSS, they are not the same.

The integration of TVSS products into panelboard enclosures is becoming common. Listed equipment is evaluated to ensure the integrity of the panel with the TVSS installed. The panelboard with an integral TVSS is evaluated in accordance with the UL 67 safety standard for panelboards for heat rise, conductor (bus bar) spacing, wire bending space, wire fill, short-circuit current, etc. A TVSS will reduce the volume of the enclosure, which impacts the heating, wire gutter, and wire bending space. The reduction in volume of the enclosure can also impact the short-circuit performance of the panelboard due to venting characteristics of different circuit breakers. Extending the enclosure using a panelboard extension and adding the TVSS above or below the panelboard will not resolve these safety issues without proper evaluation and testing. Paragraph 30.12 in UL 67 clearly states that components for use in panelboards must be included in the panelboard markings.

30.12 Field-installed equipment

30.12.1 A panelboard to which a unit, such as a circuit breaker, switch, or the like, may be added in the field shall be marked with the name or trademark of the manufacturer and the catalog number or equivalent of those units for which it is intended.

Look for a panel marking that indicates the panel has been listed for use with an integral TVSS. A marking must be provided as part of the panelboard listing that the TVSS has been evaluated for use within the panel.

TVSS Performance Considerations

Photo 4. The “Whole House” surge protection unit integrates surge protection of AC, Telephone/Data, and Coax/cable and Satellite TV by establishing a common reference where the utilities enter the house.

TVSS conductor length is a consideration in product performance. If we consider the conductor lengths by using 165V per foot to calculate new suppression ratings after connection to the electrical system, we start looking for methods to reduce the conductor length in order to increase our protection from surges and transient voltages. Efforts to reduce conductor length to maximize protection from surges prompted the introduction of TVSS products being manufactured integral to panelboards in order to minimize the impact of conductor impedance. [See photo 4]

The entrance of utilities such as electric, cable, and telephone at the same point on the structure is important for effective protection using a TVSS. Electronic equipment (computers, telephones,…) has multiple paths for surges to enter. A surge will destroy electronic equipment due to a voltage differential (between AC, phone, and coax) on the electronic boards within the equipment. These multiple paths can effectively be protected in a residence using a TVSS that integrates protection of AC, coaxial cable, and telephone. By referencing all utilities to a common ground at the service entrance, we have an effective low impedance ground path and establish a common reference for all external surge sources. The utilities will electrically rise and fall together when a surge enters the building, assisting in the removal of any voltage differential between the communication system and electrical system within the computer, phone, or answering machine.

Large residences may have multiple panelboards, such as two 200A panelboards. You enhance your protection of electronic equipment that is connected to multiple utilities, such as telephones and computers, by connecting the TVSS to the panelboard that supplies the branch circuits for those loads. “Point-of-use” protection may also be recommended by an appliance manufacturer or the panelboard TVSS manufacturer to ensure proper protection of sensitive electronic equipment for warranty purposes. Point-of-use TVSS products are also listed to UL 1449 and may be found in the form of a receptacle, direct plug-in connected, or cord-connected devices.

Summary

The NEC does not currently address the unique safety concerns of TVSS installation as compared to surge arresters. However, fundamental elements have been discussed to assist in a safe and NEC compliant installation of transient voltage surge suppressors. Please note those items covered in this article that are safety related but not specifically addressed in the NEC at the present. The following list provides a summary of the items discussed and should be reviewed during the installation of a TVSS:

1. Review the grounding system and connections to ensure an effective ground path for surge current. NEC 250–2(a). The TVSS should not be installed on an ungrounded electrical system.

2. The TVSS must be listed by a recognized certification body. You may find surge arresters installed that may be listed as secondary surge arresters. NEC 280-4(a).

3. The TVSS must be installed on the load side of the service disconnect. UL 1449 (Not in the NEC). Review the TVSS markings for the required overcurrent protection.

4. When the TVSS is installed at the service with six disconnects, it must be connected to one of the six disconnects. Seven is a violation of NEC 230-71.

5. Review the panelboard marking that indicates the panel is listed for use with an internal or integral TVSS. NEC 110-3(b) and UL 67.

6. Look for a short-circuit current rating on permanently connected TVSS products. NEC 110-10.

Find Us on Socials