The purpose of the National Electrical Code is stated in Section 90-1 as “…the practical safe guarding of persons and property from hazards arising from the use of electricity.” The term “practical safeguarding” is significant in that it emphasizes that Code rules are designed to provide a level of safety to both people and property that is practical in nature. While the term “practical” is not specifically defined in view of safety rules, input from both the industry and the public through the consensus form of code development helps determine what it means in different situations. Effectiveness of a safety rule in achieving its desired level of protection, the probability that a destructive incident is likely to occur, the cost associated with applying it, and the ability to enforce it are some factors that must be considered when adopting safety rules. Each element must be evaluated when making the decision as to whether or not a safety provision meets the test of “practical safeguarding” as used in 90-1. Electricity is a vital part of our daily lives. It is one of the reasons our quality of life has risen to its present level. We are very dependent upon the use of electricity in our homes and workplaces and need to learn to live and work safely with this very beneficial form of energy. While the ability to use electrical energy has made life much better for us, abuse, misuse, accidents, etc., that result in an uncontrolled release of that energy can be very destructive to people and property. There is a challenge to those in code development to provide reasonably safe living and work locations.

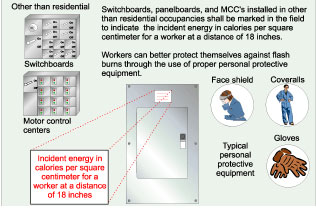

Diagram 1. Flash protection Section 110.16

Three proposals accepted by NEC Code Making Panel No. 1 during the panel meetings held in January 2000 can have, if they are adopted, a significant impact upon those who install and maintain electrical systems. They were influenced by incidents involving electricians being injured or killed while working on energized electrical equipment and the need to add safety provisions in the Code to protect workers. Members of the electrical industry who are involved in the installation and maintenance of electrical systems recognize that hazards exist and that safety procedures should be followed when working with those systems. These three proposals recommend changing provisions in Article 110 in the 2002 NEC to include safety measures that can provide an additional level of safety for workers. All three proposals focus on steps being taken that will allow workers to take action to better protect themselves.

The first proposal involves adding a new 110-16 to cover flash protection. The wording adopted by CMP-1 action on Proposal No. 1-235 during the meeting in January 2000, reads: “110-16. Flash Protection. Switchboards, panelboards, and motor control centers installed in other than residential occupancies shall be marked in the field to indicate the incident energy in calories per square centimeter for a worker at a distance of 457 mm (18 in).

FPN: See NFPA 70E-2000, Electrical Safety Requirements for Employee Workplaces, for calculation methods and charts related to incident energy.” (see diagram 1)

It is probably safe to say that most electricians who work either as construction electricians or in electrical maintenance have either witnessed the occurrence of an electrical fault or know of someone who was involved in one where a tool slipped or something happened to create a line-to-line or a line-to-ground fault. Many incidents occur without damage to property or injury to personnel because factors needed to cause a more severe situation did not occur at the appropriate time or in the necessary order. However, many do cause significant property damage and harm to workers. The proposed new wording will not prevent a fault from occurring, but will require information to be available that can help qualified workers protect themselves where they are required to work electrical equipment while it is energized.

Where people are required to work on switchboards, panelboards, motor control centers, etc., while the equipment is energized, measures should be taken to provide as much protection against injury for workers as practical. Provisions in existing 110-26 require a minimum amount of working space for those workers to safely perform their jobs. This rule provides for a reasonable amount of space for qualified workers to maneuver while at the face of the energized equipment. Requirement in Proposal 1-235 will add an important element. This new provision will require that the amount of incident energy available at a distance of 18 inches be marked on the equipment. Where the amount of energy is known, the qualified worker can use that information to select the proper type of protective clothing and equipment that are designed for that level of energy release. This is an important step in the advancement of safety for personnel.

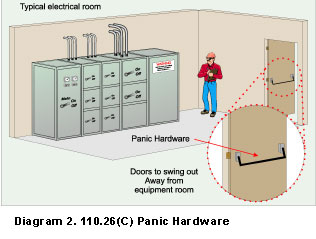

The second set of proposals affects provisions in Article 110 associated with working space around electrical equipment, such as switchboards, panelboards, and motor control centers. These provisions have primarily focused on identifying the location and dimensions of the required space and includes rules on access and entrance to that space. Previous attempts to include specific requirements that provide for workers to exit the designated space have not been successful. While many CMP-1 members agreed with the concept of having a safe and reliable means of exiting electrical equipment rooms, the supporting documentation was not deemed strong enough to justify making such a major change. However, information has been accumulating to support the addition of rules requiring doors leading out of rooms containing certain types of electrical equipment to have simple pressure release mechanisms to permit workers to safely exit the area in an emergency situation. It may be time to give favorable consideration to the addition of this rule to provide additional safety for workers.

Proposal No. 1- 260a includes a recommendation to add new wording to 110-26(C)(2) that provides for workers to be able to readily exit the required working space around equipment rated 0-600 volts, over 1200 amperes, and more than 6 ft wide. The first paragraph in 110-26(C)(2) is proposed to read:

“(2) Large Equipment.For equipment rated 1200 amperes or more and over 1.8 m (6 ft) wide that contains overcurrent devices, switching devices, or control devices, there shall be one entrance to the required working space not less than 610 mm (24 in.) wide and 2.0 m (6 ½ ft ) high at each end of the working space. Where the entrance has a personnel door(s), the door(s) shall open in the direction of egress and be equipped with panic bars, pressure plates, or other devices that are normally latched but open under simple pressure.”

Proposal No. 1-291a is the third proposal and is a companion to Proposal 1-260a. This proposal amends 110-33 to require this same type of equipment for personnel doors used for exiting the area of electrical equipment rated over 600 volts. It will read:

“110-33. Entrance and Access to Work Space

(A) Entrance.At least one entrance not less than 610 mm (24 in.) wide and 2.0 m (6 1/2 ft) high shall be provided to give access to the working space about electric equipment. Where the entrance has a personnel door(s), the door(s) shall open in the direction of egress and be equipped with panic bars, pressure plates, or other devices that are normally latched but open under simple pressure.” (see diagram 2)

If Proposals 1-260 and 1-291a are adopted, they will add another dimension of safety for people who are required to work on energized equipment. Providing a means for workers to readily exit an area where electrical equipment is involved in a destructive release of energy is necessary. Where a worker is injured by occurrence of a fault in electrical equipment, it becomes even more important for the individual to be able to open the door by pressure alone rather than by having to twist the door knob. Panic bars and other types of equipment that provide for a door in an electrical equipment room or area to be opened outward is a positive step in addressing this safety concern.

In conclusion, a fundamental question should be asked regarding these proposals. If they are adopted, will they result in the practical safeguarding of persons? I believe that the answer is Yes.

Find Us on Socials