Most of my training in college was in electronics. When I graduated in 1971, most of the electronics companies were not hiring so I took a job with the local electric utility until I could find a job in electronics. Thirty-three years later, I’m still with the utility. Over the years working for an electric utility, I have become accustomed to referring to bare wire as wire and insulated wire as cable. In general, most of our aerial or overhead construction involves wire and most of our underground construction involves cable. These are the definitions that are commonly used in many electric utilities around the country. Unfortunately, the published definitions for wire, cable, and conductor vary with the source. The definitions in the 2005National Electrical Code(NEC) are different from those in the 2002 National Electrical Safety Code (NESC), which are also very different from slang some industries use. To reduce confusion, I recommend that if you are dealing with the requirements of the NEC, use the terms as defined in the NEC. Likewise with the NESC or other industry standards. Be aware that there are differences. Since most of the readers of this series are familiar with the NEC, I will try to use the NEC terms and definitions in this segment.

Photo 1. An example of a large conductor: 2505 kcmil Aluminum Alloy Conductor Steel Reinforced AACSR 84/19, 1.972″ in diameter

While working for an electric utility, it didn’t take me long to realize that the main difference between electronics and electric power is a few zeroes. Electronic equipment usually deals with very small currents and voltages, milliamps and millivolts. One milliamp is 0.001amp. Electric power distribution equipment usually deals with high currents and voltages, kilo-amps and kilo-volts. One kilo-volt is 1000 volts. The same is true for conductor sizes relative to electronics and electric power. Since the currents in electronic equipment are small, the conductors are usually small, 14 AWG to 24 AWG. Since the currents in electric power supply facilities are large, the conductors are usually large, from #4/0 AWG to 2000 kcmil.

Conductor area

The current-carrying capacity or ampacity of a conductor is directly proportional to the cross-sectional area of the conducting material. We usually measure area in square inches, or square feet, or square yards, etc. In the late 1800s, the U.S. electric industry standardized on using circular mils for measuring the cross-sectional area of conductors. A circular mil is the area of a circle with a diameter of one mil (0.001 inch). The abbreviation for circular mils is cmil. There are 1,273,200 circular mils in one square inch. For conductors having a cross-sectional area smaller than or equal to 211,600 circular mils, the industry elected to adopt the Brown and Sharpe wire gage designation of 1857, what we now call American Wire Gage (AWG). The area of large conductors is often designated in kcmil (thousand circular mils) rather than cmil. For example, the cross-sectional area of 4/0 AWG is 211,200 cmil or 211.2 kcmil. Prior to 1972, the abbreviation for thousand circular mils was MCM.

Stranding

The conductor most commonly used in houses for receptacle circuit wiring is two conductor 14 AWG copper with ground. The phase and neutral conductors are insulated conductors. The ground conductor is bare. Each conductor is a single solid wire. The cross-sectional area of the 14 AWG solid wire is 4,110 cmil. The 14 AWG power cord on a circular saw is very different. On the circular saw cord, each conductor is made up of numerous small wires or strands all twisted together. This is often referred to as multiple strand conductor. The manufacturer uses multiple strand because multiple strand conductor is flexible and can be flexed hundreds of times before breaking. Single strand conductor is usually used for installation where the conductor is not subject to flexing. If you measure the diameter of each strand of the saw cord, calculate the cross-sectional area of the strand and multiply it times the number of strands, you will find the cross-sectional area is 4,110 cmil. I cut open the power cord of an old electric drill. The cord was not marked as to the wire size. Using a micrometer, I measured the diameter of one of the strands. The diameter was 0.010″ or 10 mils. The area of that strand is the diameter squared times p divided by 4 (p is 3.14159). The area of each strand is 0.000078539 square inches or 100 cmils. To convert square inches to cmil we multiply by 1,273,200. If we then multiply the area by the number of strands (24), we find the total cross-sectional area of the conductor is 2,400 cmil, just short of 16 AWG (2,580 cmil). 17 AWG is 2,050 cmil. It doesn’t matter if the conductor is 17 AWG single strand or 17 AWG 24 strand, the cross-sectional area is the same. With multi-strand conductors, the only way to positively identify the wire size is to use a micrometer to measure the diameter of the strands, count the number of strands, and work through the calculation. I have found that the marking on the jacket isn’t always correct.

Number of strands

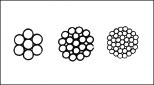

Conductor manufacturers make conductors in a wide variety of stranding. A few examples of stranding are shown in diagram 1.

Diagram 1. A few examples of concentric lay conductors, 7 strand, 19 strand, and 37 strand.

Compressed and compact conductors

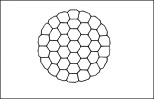

Insulated conductors are often compressed or compacted to reduce the diameter. To create compressed or compact conductors, the manufacturer draws the full strand conductors through a series of funnel shaped dies to reduce the diameter. Full strand conductors have air space between the strands. The compression process squishes the air space out thus reducing the diameter without reducing the cross-sectional area of the conductor. An example of a compact conductor is shown in diagram 2. Note that following compression, the strands are no longer round. The diameter of compressed conductors is reduced by approximately three percent. The diameter of compact conductors is reduced by approximately nine percent. If you elect to purchase compressed or compact conductors, the compression connectors that are designed to fit full strand conductors may not work on compressed or compact conductors. Compact conductors are almost as small as solid conductors. Check with the connector manufacturer before purchasing the connectors (see diagram 2).

Diagram 2. A compact concentric strand conductor.

Alloys and temper

Conductor manufacturers use many different alloys of aluminum to make aluminum conductors. The alloy of a metal defines what elements and what proportions of elements are used to make the metal. The alloy is like a recipe for the metal. Alloys are identified by number. The temper of a wire defines how the wire is thermally treated after it is manufactured. If you have ever seen a blacksmith making something out of iron, you might have noticed the blacksmith putting the item into a bucket of water while the item is still very hot. By cooling the item very quickly, the metal becomes very hard and brittle. Drill bits and other tools are tempered in this manner. Items that are cooled slowly stay soft and easy to bend. The temper of copper wire is identified by three terms, hard drawn, medium hard drawn and soft drawn. Copper wire that is cooled quickly to make it hard is referred to as hard drawn (HD). If copper wire is cooled slowly to make it soft and easy to bend, it is referred to as soft drawn (SD). The temper of aluminum is usually identified by a combination of letters and numbers. For example, 1350-H19, 1350 is the aluminum alloy, H19 is the temper. This is aluminum that is commonly used to make what the industry calls all aluminum conductor (AAC). 6201-T81, 6201 is the aluminum alloy, T81 is the temper. This is a high strength aluminum alloy commonly used to make what the industry calls all aluminum alloy conductor (AAAC). The resistance, strength, and flexibility of the conductor is a function of the alloy, temper and stranding.

Composite conductors

Composite conductors are conductors made up of strands of different alloys or materials. One example is the use of 1350-H19 aluminum and 6201-T81 high strength aluminum alloy. This conductor is called aluminum conductor alloy reinforced (ACAR). Some common stranding for ACAR is four strands of 1350 and three strands of 6201, or 15 strands of 1350 and four strands of 6201. Another example of composite conductors is the use of 1350-H19 aluminum and steel. This conductor is called aluminum conductor steel reinforced (ACSR). Some common stranding of ACSR is six strands of aluminum around one strand of steel or twelve strands of aluminum around seven strands of steel. Note that the cross-sectional area of aluminum in a 4/0 AWG ACSR conductor is the same as the cross-sectional area of the aluminum in a 4/0 AWG AAC conductor. That is why the diameter of an ACSR conductor is much greater than the same wire size AAC conductor. This is particularly important when ordering connectors. Some connectors designed to work on AAC conductors will not fit on the same conductor size ACSR conductors.

Code words

As you can see, if we consider the number of standard conductor sizes, the number of different stranding options, the variations in alloy, temper, insulation and composite conductors, there are hundreds of different conductors available from the manufacturers. Rather than trying to identify each conductor with a lengthy description, the conductor manufacturers decided to assign code words to each conductor. Some of the code words are plant names and animal names. Some are just common words like Razor, Fly, and Vienna. It is so much easier to call up a supplier and ask for 10,000 feet of Celtic, rather than asking for aerial quadruplex consisting of 3-1C, 2/0 AWG, 7 strand, AAC phase with 60 mils of PE Insulation, 1-1C, 123.3 kcmil (1350 equivalent 1/0 AWG), 7 strand, 6201-T81 AAAC, bare neutral. The index for aluminum aerial conductors is published in, Code Words for Overhead Aluminum Electrical Conductors. The index for aluminum underground conductors is published in Code Words for Underground Distribution Cables. Both standards are published by the Aluminum Association.

If you want to learn more about aluminum conductors, I suggest you consult the Aluminum Electrical Conductor Handbook, a publication of the Aluminum Association.

Find Us on Socials