Introduction to Selective Coordination

Selective coordination is often referred to simply as coordination. Coordination is defined in NEC® 240.2 as: “The proper localization of a fault condition to restrict outages to the equipment affected, accomplished by the choice of selective fault-protective devices.”

It is important to note that the type of overcurrent protective device selected often determines if a system is selectively coordinated.

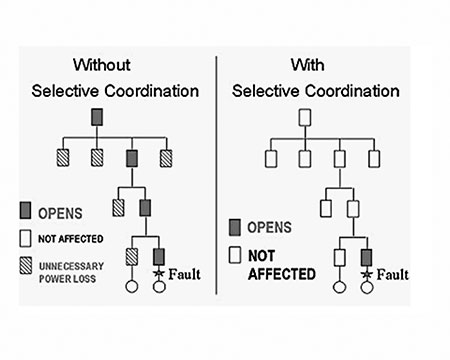

Figure 1 shows the difference between a system without selective coordination and a system with selective coordination. The figure on the left shows a system without selective coordination. In this system, unnecessary power loss to unaffected loads can occur, since the device nearest the fault cannot clear the fault before devices upstream open.

The system on the right shows a selectively coordinated system.

Here, the fault is cleared by the overcurrent device nearest the fault before any other upstream devices open, and unnecessary power loss to unaffected loads is avoided.

Selective Coordination – NEC®

The NEC® discusses selective coordination in 240.12 and states:

“Where an orderly shutdown is required to minimize the hazard(s) to personnel and equipment, a system of coordination based on the following two conditions shall be permitted:

- Coordinated short-circuit protection

- Overload indication based on monitoring system or devices.

The monitoring system may cause the condition to go to alarm, allowing corrective action or an orderly shutdown, thereby minimizing personnel hazards and equipment damage.”

In addition, coordination is specifically required in health care facilities (per NEC® 517.17) and multiple elevator circuits (per NEC® 620.62).

Good design practice considers continuity of service, cost of downtime, lost worker productivity, and safety of building occupants.

Methods of Performing a Coordination Study

Two methods are most often used to perform a coordination study:

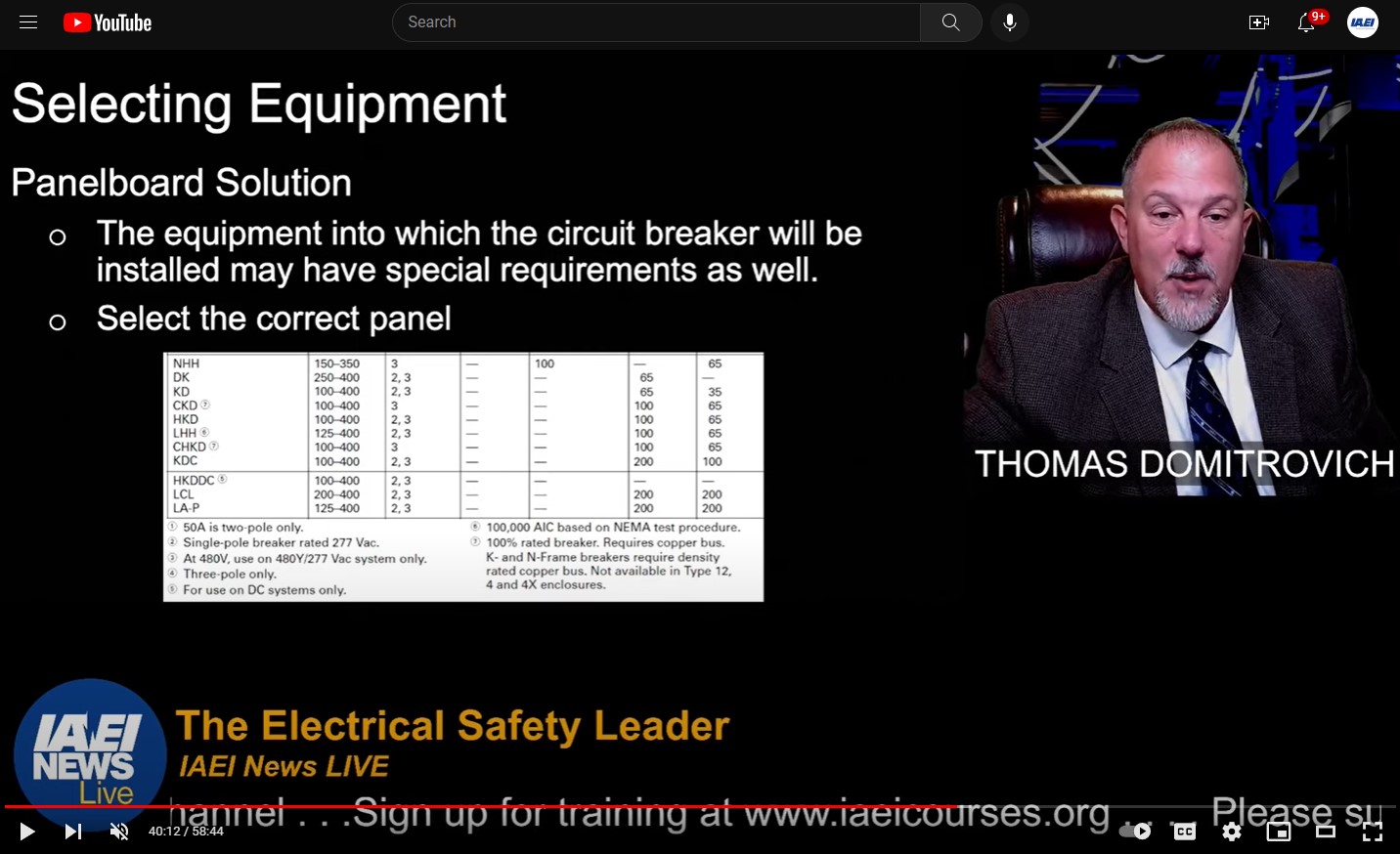

- Overlays of time-current curves, which utilize a light table and the manufacturers’ published data.

- Computer programs that utilize a PC/Laptop and allow the designer to select time-current curves published by manufacturers. (For example, Schneider Electric has an excellent piece of software ‘Direct Curves’ designed to carry out a discrimination study based on protection device tripping curves.)

Regardless of which method is used, a thorough understanding of time-current characteristic curves of overcurrent protective devices is essential to provide a selectively coordinated system.

For fuse systems, verification of selective coordination is quick and easy: merely adhere to fuse ampere rating ratios as indicated by the manufacturer.

It should be noted that the study of time-current curves indicates performance during overload and low-level fault conditions. The performance of overcurrent devices that operate under medium to high-level fault conditions are not reflected on standard time-current curves. Other engineering methods must be utilized.

Selective Coordination–Circuit Breakers

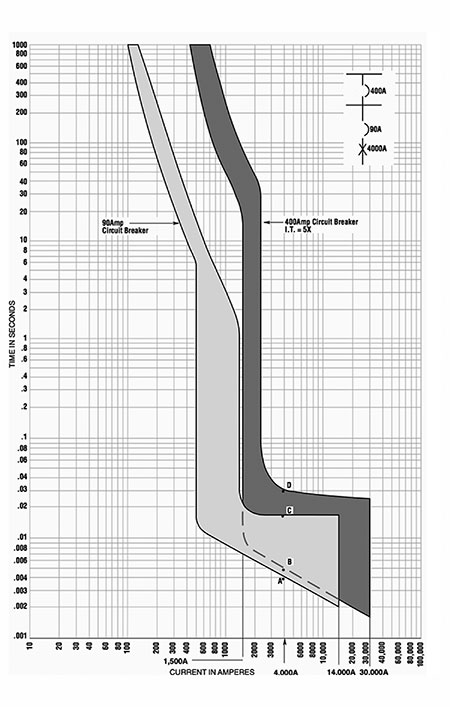

The curve below shows a 90-ampere circuit breaker and an upstream 400-ampere circuit breaker with an instantaneous trip setting of 5 (5 times 400 A = 2000 A).

The minimum instantaneous unlatching current for the 400 A circuit breaker could be as low as 2000 A times .75 = 1500 A (± 25% band). If a fault above 1500 amperes occurs on the load side of the 90-ampere breaker, both breakers could open. The 90-ampere breaker generally unlatches before the 400-ampere breaker.

However, before the 90-ampere breaker can clear the fault current, the 400-ampere breaker could have unlatched and started to open as well.

The example below illustrates this point.

Assume a 4000 ampere short-circuit exists on the load side of the 90 ampere circuit breaker. The sequence of events would be as follows:

- The 90 ampere breaker unlatches (Point A).

- The 400 ampere breaker unlatches (Point B). Once a breaker unlatches, it will open. At the unlatching point, the process is irreversible.

- At Point C, the 90 ampere breaker will have completely interrupted the fault current.

- At Point D, the 400 ampere breaker also will have completely opened.

Consequently, this is a non-selective system, causing a blackout to the other loads protected by the 400 A breaker.

This is typical for molded-case circuit breakers (MCCBs) due to the instantaneous trip and wide band of operation on medium to high fault conditions. In addition, this can affect other upstream molded-case circuit breakers depending upon the size and the instantaneous setting of the circuit breakers upstream and the magnitude of the fault current.

Circuit Breakers with Short-Time-Delay and Instantaneous Override

Some electronic trip molded-case circuit breakers (MCCB) and most insulated-case circuit breakers (ICCB) offer short-time delay (STD). This allows the circuit breaker the ability to delay tripping for a period of time, typically 6 to 30 cycles.

However, with electronic trip molded-case circuit breakers and insulated-case circuit breakers, a built-in instantaneous override mechanism is present.

This is called the instantaneous override function, and will override the STD for medium to high level faults. The instantaneous override setting for these devices is typically 8 to 12 times the rating of the circuit breaker and will “kick in” for faults equal to or greater than the override setting.

Because of this instantaneous override, non-selective tripping can exist, similar to molded-case circuit breakers and insulated-case circuit breakers without short-time delay.

Thus, while short-time delay in molded-case and insulated-case circuit breakers can improve coordination in the overload and low level fault regions, it may not be able to assure coordination for medium and high level fault conditions.

Low Voltage Power Circuit Breakers (LVPCB) with Short-Time Delay

Short-time-delay, with settings from 6 to 30 cycles, is also available on low voltage power circuit breakers. However, with low voltage power circuit breakers an instantaneous override is not required. Thus, low voltage power circuit breakers with short-time delay can hold into faults for up to 30 cycles.

This allows the downstream device to open the fault before the upstream low voltage power circuit breaker opens.

However, if the fault is between the downstream device and the low voltage power circuit breaker, the electrical equipment can be subjected to unnecessarily high mechanical and thermal stress.

Reference

Electrical Plan Review – Overcurrent Protection and Devices, Short-Circuit Calculations, Component Protection, Selective Coordination, and Other Considerations – COOPER Bussmann

Find Us on Socials