When we think of the month of May, our thoughts drift towards planting gardens, watching the flowers bloom, and seeing trees turn a lush green. Considering all the beauty in bloom, it may be difficult to focus on anything else. However, to those in the electrical industry, May is National Electrical Safety Month, an annual campaign sponsored by Electrical Safety Foundation International (ESFi). When the topic of workplace safety is brought up, we normally think of Occupational Safety and Health Administration (OSHA) and the regulations around performing a job safely. And while this makes sense, for our tasks involving possible electrical hazards, we should consider more than just OSHA; we need to also think about (NFPA) 70E®, Standard for Electrical Safety in the Workplace®.

NFPA 70E provides steps that should be taken when tasks involve exposure to electrical hazards so that workers remain safe while doing their job, which leads to the fulfillment of the OSHA requirements. A question I have is, how frequently have inspectors removed panel covers on 120/240-volt residential panels while conducting residential electrical inspections? Only the inspector knows that for sure. Too often, we believe that workplace safety only involves those doing the work, but what about the inspection side of it, particularly electrical inspections? NFPA 70E, Section 90.2(A) explains that inspections are covered under the standard, and therefore steps should be taken to ensure one’s safety. What are those steps, and are inspectors required to wear personal protective equipment (PPE) when conducting inspections where they could be exposed to electrical hazards according to OSHA and 70E?

OSHA Standard 1926, the Standard for Safety and Health Regulations for Construction, Subpart E, 1926.97, explains the types of electrical personal protective equipment (PPE), how to test the equipment, and how to evaluate the equipment, but not when to use the PPE. This is where NFPA 70E comes in. In general, any energized equipment or conductors that are operating at voltages equal to or greater than 50-volts must be placed into an electrically safe work condition (ESWC) or PPE with other protections need to be employed. (See NFPA 70E Article 120 for details on ESWC). An ESWC is not a procedure, it is a state wherein all hazardous electrical conductors or circuit parts that an employee may encounter are maintained in a de-energized state.

Utilizing a lockout, tag out (LOTO) program helps ensure a de-energized state, and therefore, the inspector may also need to have their own LOTO kit to make certain that the installation stays in an ESWC while they conduct the inspection. ESWC applies when any employee is within the limited approach boundary or where the employee interacts with equipment or conductors that are not exposed but may have an increased likelihood of injury from exposure to an arc flash hazard. This would include electrical inspectors conducting electrical inspections, via issued permits, on electrical work completed by electricians and contractors (contract employer) who are working for the general contractor or building owner (host employer) [see NFPA 70E, Section 110.7 for an explanation]. Most importantly, new or existing installations should not be energized until approved by the authority having jurisdiction (AHJ) or electrical inspector. Existing installations, unlike new ones, will require prior planning to establish the ESWC, which may be inconvenient, but rarely infeasible [see 110.4(B)]. With the challenges of establishing an EWSC on existing jobs, some electrical inspectors may have removed panel covers since nothing bad has happened in the past. Removing panel covers has become so routine that some inspectors take it for granted or may not realize the potential hazard that could exist. This can result in them overlooking the possibility of a metal screw hiding on top of the electrical panel that has an open hole in the top of the panel, and when the cover is removed, the jarring could cause the screw to fall into the energized busbar …. BOOM! An arc flash has just occurred, and if you are not protected, severe injury can occur.

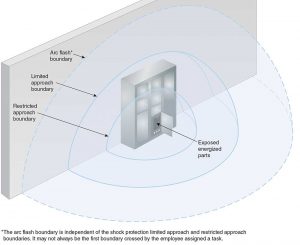

Boundaries are set in NFPA 70E according to the voltages that may be encountered (see Figure 2). They are:

- Arc flash boundary: When an arc flash hazard exists, an approach limit from an arc source at which incident energy equals 1.2 cal/cm2 (5 J/cm2).

- Limited approach boundary: An approach limit at a distance from an exposed energized electrical conductor or circuit part within which a shock hazard exists.

- Restricted boundary: An approach limit at a distance from an exposed energized electrical conductor or circuit part within which there is an increased likelihood of electric shock, due to electrical arc-over combined with inadvertent movement.

According to NFPA 70E, Table 130.5(C), Estimate of the Likelihood of Occurrence of an Arc Flash Incident for ac and dc Systems, the removal of bolted covers that expose bare or energized electrical conductors and circuit parts has a likelihood of an arc flash incident occurring. With that knowledge, we need to determine what boundary is applicable. To do that, we will go to NFPA 70E, Section 130.4, Table 130.4(E)(a), Shock Protection Approach Boundaries to Exposed Energized Electrical Conductors or Circuit Parts for Alternating-Current (AC) Systems, the typical single phase 120/240-volt residential panel has a limited approach boundary of 1.0 m or 3 feet 6 inches and a restricted approach boundary of 0.3 m or 1 foot based on 240-volt phase to phase.

Removal of a 120/240-volt residential panel cover places the electrical inspector within the limited approach boundary. To be in the limited approach boundary where the likelihood of exposure to an electrical hazard is present, an individual must be a qualified person or accompanied by a qualified person. Just because an inspector is registered or even a licensed electrician doesn’t necessarily make them qualified. NFPA 70E, Article 100 defines a qualified person as, “one who has demonstrated skills and knowledge related to the construction and operation of electrical equipment and installations and has received safety training to identify the hazards and reduce the associated risk.” Is the electrical inspector a qualified person? This question would have to be answered by the inspector’s employer and not the electrical contractor. This should make electrical inspectors pause and think about whether he/she is qualified. Even if they think they are, has his/her employer confirmed it with them?

As an electrical inspector, you may find yourself in a situation where an ESWC cannot be established, and the task is within a limited approach boundary where there are energized conductors or circuit parts that could expose you to an arc flash hazard. What precautions should be taken? To determine those protections, an arc flash risk assessment needs to be performed [see NFPA 70E, Section 130.5(A)]. Previously, it was determined that there is an increased likelihood that an arc flash may occur when removing a bolted cover from an energized panel. With this possibility, we need to know the arc flash boundary. Arc flash boundary is where the incident energy calculation equals 1.2 cal/cm2 or use Table 130.7(C)(15)(a), but not both. This table, in addition to the arc flash boundary, also provides the arc flash PPE category. According to the table, our 240-volt residential panel falls under panelboards or other equipment rated 240-volts and below with parameters of a maximum of 25 kA available fault current; maximum of 0.03 sec (2 cycles) fault clearing time; a minimum working distance of 18 inches. This would be a Category 1 PPE and have an arc flash boundary of 19 inches. An electrical inspector may want to consider the following Category 1 options for PPE found in 130.7(C)(15)(c):

- 4 cal/cm2 arc-rated clothing such as a long-sleeved shirt or coverall

- Arc-rated face shield or arc flash suit hood

- Hard hat

- Safety glasses or goggles

- Hearing protection

- Heavy-duty leather gloves, arc-rated gloves, or rubber insulating gloves with leather protectors

- Leather footwear

These should not be considered exhaustive or used as permission to work where there is exposure to energized conductors and circuit parts, but rather, something to consider. Many of the above items could or should be a part of your day, but each situation should be evaluated individually to ensure the proper safety precautions are being taken.

There are no valid reasons that an ESWC cannot be established in most cases. The challenge faced by electrical inspectors is that many building owners or occupants do not want their power interrupted, but that inconvenience is not a justifiable reason to avoid placing equipment in an ESWC. Therefore, prior planning is an essential tool to limit such interruptions and allow the inspection on the electrical installation or equipment to be done safely. As electrical inspectors, you may be exposed to electrical hazards and not be aware of them. It is vital that electrical inspectors take the necessary measures to stay safe on the job. Complacency is not a reason to jeopardize lives or health, so be safe.

NFPA 70E is now available in NFPA LiNK® the association’s information delivery platform with NFPA codes and standards, supplementary content, and visual aids for building, electrical, and life safety professionals and practitioners. Learn more at nfpa.org/LiNK.

Important Notice: Any opinion expressed in this column is the personal opinion of the author and does not necessarily represent the official position of NFPA or its Technical Committees. In addition, this piece is neither intended, nor should it be relied upon, to provide professional consultation or services.

Find Us on Socials