As we work our way through the trials and tribulations of COVID 19, there are other ongoing activities that are impacting or will impact the installation of photovoltaic (PV) power systems, both large and small. These and related activities will change the workload of the authority having jurisdiction (AHJ) or the local electrical inspector.

Climate change and global warming are going to have a significant impact on the production and use of electrical energy not only in the United States but globally. We live in a very high-energy society that has been and still is primarily based on electrical energy production using fossil fuels. These fossil fuels contribute to greenhouse gases which are warming the climate. In the not-too-distant future, fossil-fueled power plants will be phased out, and greater reliance will be made on renewable energy sources such as solar- and wind-generated electricity. It is anticipated within the next 20 to 30 years, a large portion of the surface transportation system will be electrified, including automobiles, trucks, ships, and trains. See the lead-in photo showing the new Cadillac Lyriq electric vehicle (EV).

The Basics

Inspection Backlogs. Due to various complications in the workforce associated with COVID 19, many jurisdictions are finding it difficult to keep positions for AHJ/electrical inspectors fully filled. This creates backlogs of numerous PV systems waiting for inspections that are slowing the utility interconnection (photo 1). Budget limitations and an aging workforce are contributors. PV installers are sometimes finding they must wait weeks and even months for an inspection by the local jurisdiction.

IREC (also known as the Interstate Renewable Energy Council, www.irecusa.org) offers several solutions for jurisdictions, including the Solsmart program, which helps communities streamline the permitting and inspection process for photovoltaic power systems. IREC is also a partner in the SolarAPP+, a new automated permitting system to foster rooftop solar adoption by making it easier for local governments to approve installation projects quickly and safely. This program is led by the National Renewable Energy Laboratory (NREL, www.nrel.gov), key code officials, and AHJs at the local level.

Supply Chain Issues. Unfortunately, the PV module production system is undergoing a significant perturbation which may affect the availability and cost of PV modules. Roughly 80% of the PV modules installed in the United States are manufactured in China. Based on a single petition to the U.S. Department of Commerce (DOC) by a PV module manufacturer based in California, an investigation is being started to evaluate the potential for the abuse of anti-dumping and tariff regulations on PV modules from China. Chinese PV modules, and components of modules may be being shipped to Malaysia, Thailand, Cambodia, and Vietnam, assembled there and then shipped to the US. This process may allow the Chinese companies to bypass existing anti-dumping and other import tariffs on Chinese goods, which have been in place for about ten years.

The DOC is considering tariffs on Chinese imports of PV modules of 50% to 250%. Even the threat of tariffs at this magnitude has cast a dark perspective on the near future of PV installations, and forecasts for near-term installations are down as much as 19%. These tariffs, if implemented, will impact tens and hundreds of gigawatts of solar electric projects. An outcome that will severely affect the ability of the country to meet promised greenhouse gas reduction requirements. Members of Congress are becoming involved in this issue, as is the administration.

Interconnection Issues. Large, utility-scale PV systems are facing interconnection issues. Significant numbers of these large systems (tens of gigawatts) are being planned and have been contracted to be installed in locations with high levels of solar energy. These gigawatts of renewable electrical energy are in excess of what can be used in the locations of generation, usually the Southwestern United States. The energy must be transmitted across the country to regions (East and Northeast US) needing that energy as fossil-fueled power plants are phased out. The existing transmission systems in the US are not currently adequate to carry these significantly large amounts of power. New transmission lines must be planned and installed. Unfortunately, the interconnection requirements for large utility-scale PV systems vary from region to region, utility to utility, and jurisdiction to jurisdiction, with significant variations in each area. These varying requirements have put many utility-scale PV projects on hold to the extent that many contracts are being canceled because of the excessive delays (sometimes years) in working out all the varying regional requirements. Module price uncertainty is also a factor.

Residential and Commercial Impacts. As addressing global warming becomes more critical, the electrification of the surface transportation industry will occur at an increasing pace. Some automobile manufacturers report that they may make only electric vehicles (EVs) after 2030 or 2035. Truck manufacturers, including Tesla with its Semi truck (photo 2), are planning on manufacturing over-the-road, long-distance electric vehicle (EV) tractors for semitrailers.

All these current and future EVs will require readily available charging stations. These charging stations will be in residences, apartment complexes, parking garages, big-box stores, offices, and numerous other locations where drivers of these vehicles will need to get their EVs recharged. Service stations currently pumping gas will have to convert to EV charging stations. And all these charging stations will require significantly enhanced and increased utility transmission and distribution systems to provide power at these numerous locations. To deal with the local and long-distance, nationwide trucking system, truck charging stations may have to be installed every 200 to 300 miles on all major US highways. These charging stations will also, of course, provide recharging services for automobiles.

While the transmission and distribution of this significant increase in electrical energy will be generally handled by the various utilities in each region, the actual charging station installations will be accomplished by local electrical contractors, and the inspection of those installations will be accomplished by the local electrical inspector.

Furthermore, to reduce the impact on the utility transmission and distribution system, plans are underway to incorporate photovoltaic power systems and energy storage systems (batteries) at the larger of these charging stations. By design and fact, these integrated charging stations will be considerably more complex than the unmodified charging stations.

LOOKING DEEPER

Qualified Personnel Shortages. Many jurisdictions throughout the country are adopting the simplified and automated permitting, and inspection systems described previously that are becoming available. This is one way of dealing with personnel shortages. Another method is to encourage skilled electricians to make a career move into the AHJ workforce. Community colleges can assist in this effort by offering introductory classes on national, state, and local Code requirements for inspecting electrical systems, including EV and PV systems.

Communities should make additional funding requests to state legislatures where those governing bodies have legislated greenhouse gas emissions reductions, which will require installing and inspecting more renewable energy installations and EV charging stations. Local jurisdictions should also request funding to replace gasoline/diesel-fueled inspection and administration vehicles with EVs in a related area. Funding requests should be made to provide funds to install photovoltaic power systems on their facilities to reduce legislated greenhouse gas emissions and reduce the burden on the utilities in generating electrical energy.

Some jurisdictions are adopting virtual inspections where a well-qualified inspector, after reviewing the plans for an electrical installation, monitors a less qualified inspector or sometimes the installer of the system walking through the system with a video camera showing all the details on an audio/video link back to the office. Questions and answers and close-ups of various details can be used to confirm that the system was installed according to the permitted plans and code requirements. This system will save time because a single inspector in the office does not have to travel between various installations, and several inspectors or installers can be in the field ready for the inspection on short notice. Of course, in some states, such a virtual inspection system must be approved up the chain to the state authority. In some cases, the field inspection personnel must pass a state test on the basic requirements of the various codes.

EV Charging. There are three different levels of EV charging in residential (home) and commercial locations. Level I charging is accomplished with an on-board-the-vehicle charger plugged into the standard 120 V, 15- or 20-amp AC outlet. A dedicated circuit is preferred so that other loads in the facility do not reduce the availability of vehicle charging energy. This level of charging can put about 124 miles into the typical EV battery in about 20 hours.

Level 2 charging is accomplished with a separate charger mounted in a fixed location and connected to a 240 Volt AC circuit at current levels that will vary between 40 and 100 amps or more, depending on the size of the service. The charging system can charge 3 to 7 times faster than a Level 1 charger and the time required depends on the available circuit current, the car and the charger. Level 2 chargers use a SAEJ1772 connector, which must be installed by an electrician and probably inspected depending on jurisdictional requirements. The National Electric Code (NEC) (NFPA 70) Article 625 gives the national requirements.

Additionally, it should be noted that some vehicles like the new Ford F150 Lightning electric truck (photo 3) can provide energy from the vehicle battery to the house through an inverter to provide AC power in the house in an emergency. Other planned technical advances in the world of automotive electric vehicles include bidirectional power flow between the vehicle and the house and between the vehicle and the utility. These bidirectional power flows, where implemented, may be controlled by the house electronics, by electronics in the vehicle or by the utility. The control architecture depends on local jurisdictional, regional, and utility requirements. The NEC in Article 625 is already beginning to address requirements for these types of systems. Where the house or other building has a PV system, energy storage in the building or interactive utility interconnections, other articles (690, 705, 706) in the NEC will apply.

Level 3 charging, also called Direct Current Fast Charging (DCFC), can charge an EV much faster than a Level 1 or Level 2 charger. However, not all EVs can accept charging from a Level 3 charging station which is installed by an electrician in fixed locations. Level 3 fast-charging stations use a CHAdeMO connector or an SAE Combo connector (aka CSS for Combo Charging System). These two connectors are not interchangeable. Tesla EVs use a unique connector for Level 2 and Level 3 charging at the TESLA Supercharging stations located throughout the country. Tesla does provide a connector adapter so that its cars can be charged at non-Tesla charging stations. The DCFC stations will operate at 50kW and up to 350 kW. DC fast charging voltages may be at the 400 volt and now 800-volt levels, with the higher voltage being planned for the freight hauling trucks and other heavy equipment. However, at least two automobiles currently have an internal 800-volt dc power system. The higher voltage systems allow faster charging and reduce the amount, weight, and cost of the copper conductors in the vehicle and the cables between the charging station and the vehicle.

Charging stations located throughout the country will, in most cases, be operated by private businesses, and there are several dozen networks charging businesses in operation at this time. Prices will vary depending on the location, the operator, and any available incentives in the region. While the prices (per kWh or per unit of time) for charging using these commercially operated charging stations will probably be more than the cost of charging at home, they will be necessary to allow for extended range operation of the EVs. Memberships and various discounts are available when using these networks.

Commercial parking structures and on-the-highway charging stations (aka truck stops) will require multiple charging stations. There may eventually be one charging station per parking space in the parking structures as EVs take over from fossil-fueled vehicles. Multiple charging stations per vehicle may be required at truck stops to minimize the wait time. Ideally, the charge time should be no longer than the time required to fill a truck with fossil fuel. Charging systems and vehicle designs are being developed to reduce the charging times.

Adding PV and Energy Storage. The current transmission and distribution system for energy through many parts of the country is inadequate and possibly not appropriately located to handle the substantial increases in electrical demand posed by the conversion of the fossil-fueled surface transportation system to an electric vehicle transportation system. To address these very high electrical loads where automobile charging stations are concentrated (parking garages, malls, etc.) and truck charging stations are concentrated, plans are being made to not only upgrade the current transmission and distribution systems but also to install photovoltaic power systems and energy storage systems at these locations. A combination of on-site energy generation with PV and an energy storage system will help reduce the average and peak loads from that group of charging stations. These actions may reduce the need to substantially enhance the utility transmission and distribution network.

Of course, there must be reasonably close, exposed surfaces such as the tops of buildings or open ground that can be used for the installation of the PV system, which will require sunlight access at the very least from midmorning to mid-afternoon. Additionally, the usual safety precautions associated with energy storage systems (particularly lithium-ion batteries) must be addressed as these systems come into common use. It is well documented that the safety issues associated with the battery systems on electric vehicles have posed some unique problems for firefighters and first responders when these vehicles are involved in an accident. It is apparent that building codes and fire codes throughout the country will have to be updated specifically to address this issue.

Additional Thoughts. In ten to twenty years and beyond, the world we know will look considerably different than it does today. Hopefully, the air will be cleaner, and the noise level will be reduced near highways and railroads. One area that will be apparent is the required proliferation of new transmission lines and distribution systems from the energy sources in one part of the country to parts of the country where that energy is most needed. Because of cost and geological constraints, most of these transmission lines will be above ground.

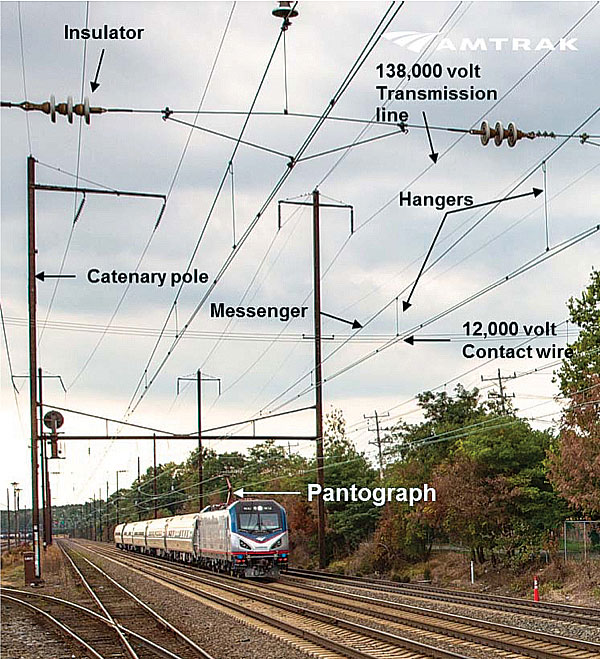

Railroads will be installing poles and catenary power conductors (photo 4) along all their tracks as they electrify their locomotives. These power distribution systems along the tracks will also require a transmission system at higher voltages to supply that power distribution system. The current electric locomotives used in the Northeast corridor by AMTRAK and other agencies are Siemens ACS 64 locomotives rated at 8600 hp while drawing a maximum of 6400 kW (photo 5). Sets of these locomotives coupled in series (2, 4, 6, ?) to pull the long-haul freight trains across the country will draw considerably more power.

Looking at a map of interstate, state, and local highways across the country, it will be noted that these highways cross the country from north to south and east to west and go through all cities and towns. A similar map of the railway systems in the country will show that they too cross the country from north to south and east to west. The rights-of-way for these highways and railroads might be used as transmission line rights-of-way to move the power from renewable energy sources to where that power is needed. Putting the high-voltage transmission lines and the necessary substations along the highways and railroads would facilitate energy distribution to the loads that need that energy.

Summary

As the United States, and indeed the rest of the world, move from an era powered by fossil fuels into an age powered by renewable energy, it is apparent that all people currently involved with electrical power systems will be very involved. That includes, among many others, electricians, PV and energy storage systems designers and installers, and the electrical inspector. Training programs must be rapidly developed to deal with the new technologies that are evolving at the current time. Only by educating our younger workforce in these technologies and encouraging them to enter these fields can we hope to deploy these systems safely and effectively.

Find Us on Socials