Introduction

The phrase “Rapid Shutdown” represents a philosophy of workplace safety for firefighters who, in the course of their work, find themselves atop buildings that are on fire. To ventilate an attic, a firefighter will break through a roof, wielding an axe and saw. This activity takes place around the ever-more-common residential, roof-mounted, photovoltaic (PV) arrays. The firefighter’s attention is on firefighting, however, and care cannot always be taken to protect the PV equipment. As a result, PV modules are broken, and electrical conductors are nicked or cut, thereby exposing the firefighter to potentially lethal energies. To address this hazard, the International Fire Code (IFC) requires the electrical portions of rooftop-mounted PV systems to be installed in accordance with the National Electrical Code (NEC). See Section 1205.1 of the 2021 IFC.

Code History

Beginning with the 2014 NEC, the National Fire Protection Association (NFPA) published rapid shutdown requirements for PV systems. Since then, NEC 690.12 has become home to rapid shutdown requirements. Per the 2014 NEC, those portions of direct-current PV conductors that extended more than five feet inside a building and more than ten feet from the array were required to be controlled to not more than 30 volts and 240 volt-amperes within 10 seconds of rapid shutdown initiation. See Section 690.12(1) and (2) of the 2014 NEC. At that time, the NFPA had not yet defined the term array boundary.

In the 2017 NEC, Section 690.12(B) defined the term “array boundary” as one foot from the array in all directions; and a distinction was made between those conductors lying inside the array boundary and those laying outside of it. The focus of this discussion is on those conductors that lay inside the array boundary. When the 2017 NEC went into effect, those direct-current PV conductors that lay outside the array boundary, and those that extend more than three feet inside a building, were required to be controlled to not more than 30 volts within 30 seconds of rapid shutdown initiation; and the 240-volt-ampere requirement, from the 2014 NEC, went away. Except for the 690.7 voltage requirements (600 volts for one- and two-family dwellings; and 1,000 volts for other types of buildings), there was no voltage requirement for those conductors that lay inside the array boundary. Starting January 1, 2019, however, those direct-current PV conductors that lay inside the array boundary, and not more than 3 feet inside a building, were required to be controlled to not more than 80 volts within 30 seconds of rapid shutdown initiation. See Section 690.12(B)(2)(2) of the 2017 NEC. This is when the industry experienced a proliferation of module-level power electronics (MLPEs), such as microinverters, dc-to-dc converters, mid-circuit interrupters, and power optimizers. The function of the MLPEs was to control those direct-current PV conductors that lay within the array boundary, to not more than 80 volts, within 30 seconds of rapid shutdown initiation. Firefighters were, thus, better protected by the MLPEs than they were by the 2014 NEC requirements when they operated in or near the array.

Of particular relevance to this discussion is Section 690.12(B)(2)(1) of the 2017 NEC, which states, “The PV array shall be listed or field labeled as a rapid shutdown PV array. Such a PV array shall be installed and used in accordance with the instructions included with the rapid shutdown PV array listing or field labeling,”

This provided a way for PV contractors and installers to comply with the NEC rapid shutdown requirements without having to install MLPEs. To comply with this new “listed array” requirement, PV equipment manufacturers began to have their products evaluated by nationally recognized testing laboratories (NRTLs) for compatibility with PV equipment from other manufacturers. Not many such arrays have been listed to the standard, mostly because the standard was not published by Underwriter’s Laboratories (UL) until December 2020.

In the 2020 NEC, Section 690.12(B)(2)(1) was changed to include a new phrase, “PV hazard control system.” Section 690.12(B)(2)(1) of the 2020 NEC states,

A PV hazard control system listed for the purpose shall be installed in accordance with the instructions included with the listing or field labeling. Where a hazard control system requires initiation to transition to a controlled state, the rapid shutdown initiation device required in 690.12(C) shall perform this initiation.”

The Exception to 2020 NEC 690.12(B)(2)(1) refers to UL3741, Standard for Photovoltaic Hazard Control.

UL 3741

Underwriter’s Laboratories defines a PV Hazard Control System as,

One or more PV hazard control equipment and other specific or generic specified PV array equipment that have been evaluated to comply with the system requirements of this standard when installed in accordance with the manufacturer’s installation instructions.”

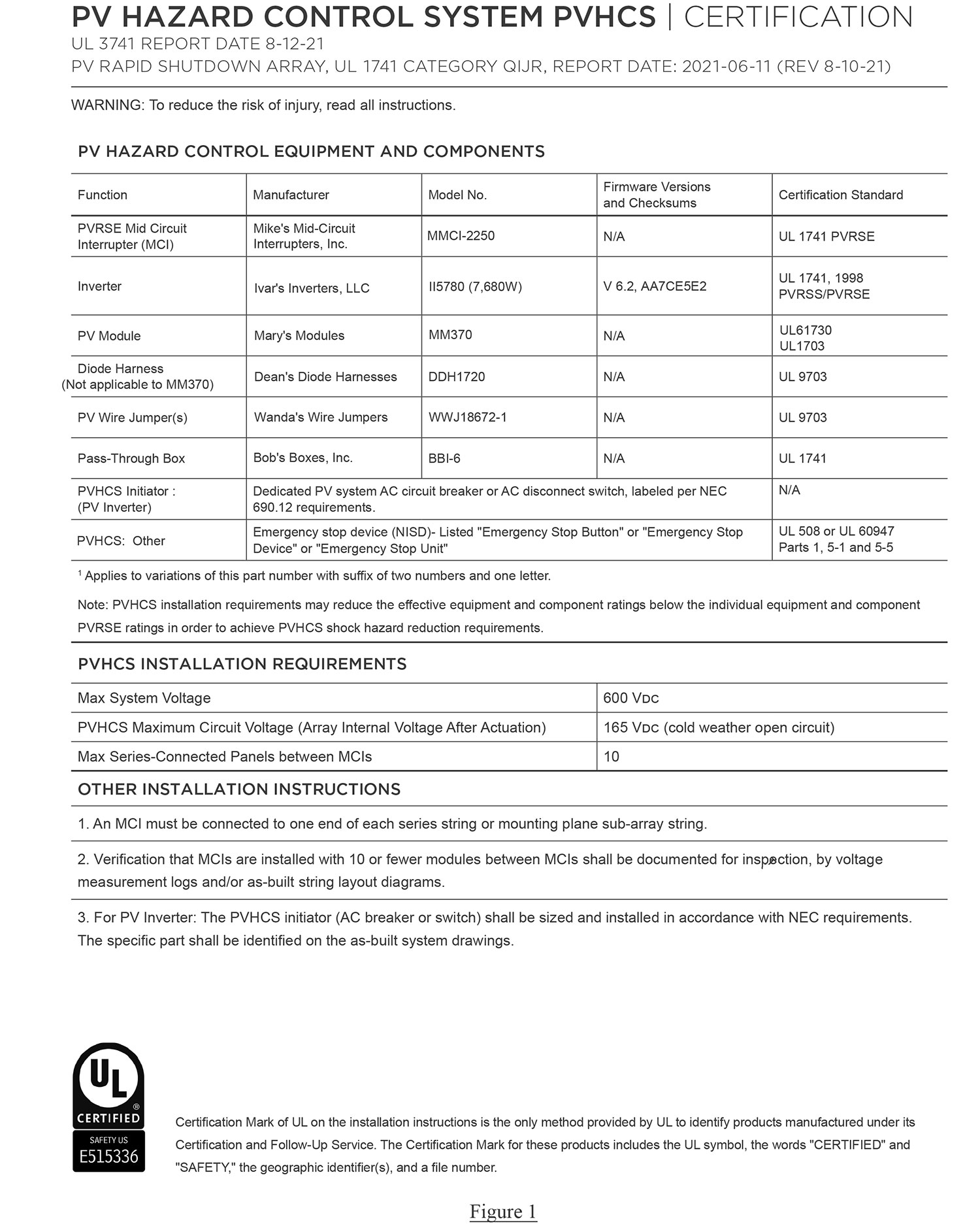

To date, UL has certified (listed) a few such PV arrays under the product category QIJR. See the November/December 2021 issue of IAEI Magazine. To develop the standard, UL conducted extensive analyses of all aspects of firefighter operations, including what types of personal protective equipment (PPE) the firefighters wear, the fire-retardant chemicals that they use, and how they put out fires. Tim Zgonena, a principal engineer at Underwriter’s Laboratories, states that “UL3741 provides an evaluation program that is based upon engineering and science” to “keep firefighters out of hazardous current paths.” To do this, UL evaluates each particular group of products, such as PV modules, wiring harnesses, combiner boxes, inverters, racking systems, etcetera, to determine whether the equipment meets the requirements of the UL3741 standard. When UL has determined that a group of products has met the requirements of the standard, an itemized list of the products is published in a PV HAZARD CONTROL SYSTEM PVHCS Certificate. See Figure 1. When the products in the Certificate are installed by qualified personnel in accordance with the instructions included with the listing, then the products, together, are considered to be a listed PV hazard control array that is NEC rapid shutdown compliant.

2023 NEC

Section 690.12(B)(2)(1) of the 2023 NEC states,

The PV system shall provide shock hazard control for firefighters through the use of a PVHCS installed in accordance with the instructions included with the listing or field labeling. Where a PVHCS requires initiation to transition to a controlled state, the rapid shutdown initiation device required in 690.12(C) shall perform this initiation,”

Informational Note No. 1 to this section refers to UL3741 Standard for Photovoltaic Hazard Control and is substantially the same as in the 2020 NEC, except that a PVHCS will be required to be installed for the purpose of providing electric shock hazard control for firefighters. The standard may allow firefighters to come into contact with as much as 160 Volts or more, but this has already been considered by UL in the development of the standard. Section 690.12(B)(2)(2) of the 2023 NEC, as in the 2020 NEC, will still require those direct-current PV conductors that lay inside the array boundary to be controlled to not more than 80 Volts within 30 seconds of rapid shutdown initiation. In the 2023 NEC, Section 690.12(B)(2)(3) was removed because it was, essentially, absorbed into the UL3741 standard. Also changed is Informational Note No. 2, which states,

Common methods include the use of PV equipment with a limited maximum voltage of 80 Volts as determined by 690.7, PVRSE, PVHCE, or any combination of these.”

The acronym, PVRSE, stands for photovoltaic rapid shutdown equipment; and the acronym PVHCE stands for photovoltaic hazard control equipment. By including PVHCE as a method of complying with the 80V/30 second requirement, the NFPA will provide PV contractors and installers with yet another option by which to comply with the rapid shutdown requirements of 690.12(B)(2)(2) of the 2023 NEC.

Inspecting to the Standards

These standards are only as effective as the effort that the authorities having jurisdiction (AHJs) put into enforcing them. Enforcement is a simple –not necessarily easy– process of 1) Determining which of the two options, in 690.12(B)(2), is being used by the PV contractor or installer; 2) Determining whether the equipment that is itemized in the PVHCS Certificate, comports with approved plans; 3) Determining whether the equipment, that is actually being installed, matches the equipment that is itemized in the PVHCS Certificate; 4) Determining whether the equipment is listed or labeled, and 5) Determining whether the PV equipment is being installed in accordance with the manufacturers’ installation instructions. The responsibility for making these determinations is shared amongst electrical plans examiners, electrical inspectors, third-party evaluators, and PV system commissioning agents.

Electrical plans examiners have the opportunity to examine the electrical plans of PV systems, wherein the electrical engineer or design/build contractor declares which of the two options, in 690.12(B)(2), is to be used. If the option is to install a UL3741 listed PV Hazard Control System, per 690.12(B)(2)(1), then the plans must include a PVHCS certificate that itemizes the specific PV equipment that is to be installed. If the PV equipment that is itemized in the certificate does not match the equipment that is called out on the plans, then a correction notice may have to be written. If, on the other hand, the option is to limit the voltage to 80 Volts within 30 seconds of rapid shutdown initiation, by installing PVRSE or PVHCE or by a 690.7 calculation per 690.12(B)(2)(2), then the specific PVRSE or PVHCE equipment must be called out on the plans, or the 690.7 calculation must be presented to the electrical plans examiner. In either case, the manufacturer’s data sheets for the PV equipment that is to be installed must also be submitted for review.

Electrical inspectors, on the other hand, have the advantage of observing the actual installation of PV systems. At the job site, the inspector can readily compare the approved plans with the manufacturers’ data sheets and with the PVHCS certificate to determine whether the correct equipment is being installed and whether it is being installed in accordance with the manufacturers’ installation instructions. If the inspector finds that the equipment is not being installed to the appropriate standards, then a correction may have to be written into the inspection report. The inspector also has the option of requiring further plan review. When a contractor elects to install an array, in compliance with Sec. 690.12(B)(2)(2), then the inspector should require the contractor to also produce voltage logs as evidence of compliance.

The field evaluating body (FEB) of an NRTL regularly evaluates equipment that is not listed or is installed in such a way as to raise suspicion that the equipment’s listing may be violated. Section 690.4(B) of the 2020 NEC states that,

Inverters, motor generators, PV modules, ac modules, and ac module systems, dc combiners, dc-to-dc converters, rapid shutdown equipment, dc circuit controllers, and charge controllers intended for use in PV systems shall be listed or be evaluated for the application and have a field label applied.”

If a PV contractor or installer installs PV equipment that is not listed, then the inspector has the responsibility of requiring that the equipment be removed and replaced with listed equipment or that the equipment be field evaluated by an NRTL’s FEB.

Commissioning agents are sometimes employed to determine whether PV systems operate within the acceptable limits of applicable codes and standards. Commissioning is based on system performance, however, and not necessarily on code compliance. That is not to say that a commissioning agent must ignore the codes but, rather, incorporate the applicable parts of the codes in the evaluation of a system’s performance. Many jurisdictions require a commissioning agent to file a Commissioner’s Report with the AHJ. If a commissioning agent determines that a PV system is not performing within acceptable limits, then it may be that the system was not installed to the applicable codes or standards. If this is the case, then the report will so indicate which may trigger remedial action by the AHJ, such as scheduling follow-up electrical inspections, issuing a Notice of Violation, or, in extreme cases, issuing a Stop Work Order. A team approach seems to be the best way to ensure that violations of codes and standards do not escape notice.

Conclusion

Firefighter safety is a noble venture that is certainly worthy of the attention of the best minds in our industry. The International Code Council (ICC), NFPA, and UL are constantly developing new safety standards for PV electrical installations, such as the improvement of the NEC 690.12(B)(2)(1) and (2) requirements and the development of UL3741. These and other standards provide firefighters with the protection they deserve. It is, therefore, incumbent upon the Authorities Having Jurisdiction to enforce the rules and standards that our best minds have given us.

Find Us on Socials