Did you realize that in the 1920s (and no, I was not around to submit proposals or public inputs back then), hazardous (classified) locations were referred to in the National Electrical Code (NEC) as Extra Hazardous Locations? Everything else regarding the use of electricity was considered to be a Hazardous Location! All areas were considered hazardous for reasons of shock and fire, not for explosions. NEC rules addressed rooms or compartments in which highly flammable gases, liquids, mixtures or other substances were manufactured, used or stored. At that time, Underwriters Laboratories (UL) had been evaluating and certifying equipment for use in such areas for about two years. One of the first hazardous (classified) location requirements in the NEC was associated with flammable inhalation anesthetic gases for use in health care facilities. This article looks at the hazardous (classified) locations addressed in Chapter 5 of the NEC and gives readers a preview of IAEI’s newly updated textbook, Hazardous Locations, based on the 2014 edition of the NEC.

Classification of Areas and Locations

One of the most important actions associated with safe electrical installations in hazardous (classified) locations is to determine the area classification and the extent of such areas. Before electrical wiring and equipment can be installed in a hazardous location, the hazardous area classification must be known. Some of these classified locations are clearly defined in the NEC, while others require research and reference to other applicable codes and standards. Area classification is often the result of a risk analysis of a particular location or area to determine the likelihood that an explosive hazard exists. Areas are generally hazardous (classified) locations if ignitible concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors, flammable liquids, combustible liquids, or combustible dust, fibers/flyings, either in suspension in the air or in other accumulations that present explosion or fire hazards, exist, or could exist. The degree of the hazard is usually determined by the particular gas, vapor, or other substance and associated process that will produce, or is likely to produce, atmospheres or accumulations of these materials that can be ignited. Electricity presents an ignition source to these areas, and installations of electrical equipment and materials in these locations are much more restrictive and specific. Areas that are not classified as a hazardous (classified) location are defined as unclassified locations as provided in NEC 500.2.

Predetermined Classification Areas

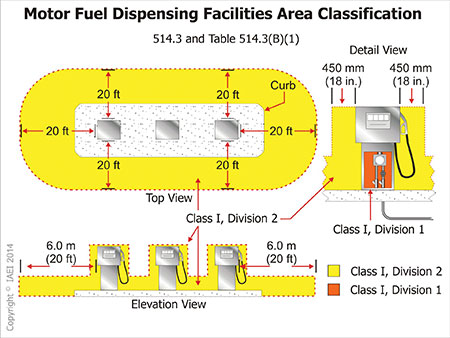

The NEC identifies several predetermined hazardous (classified) locations associated with various special occupancies and conditions. Where the area classification is already predetermined and provided in a Code rule or standard, one can proceed with a design or installation with an understanding of the extent (boundaries) of the hazardous (classified) location. For example, in Article 514, there is a predetermined classified area at a motor fuel dispenser identified in Table 514.3(B)(1). This table indicates that the area extending up to 450 mm (18 in.) above grade level within 6.0 m (20 ft) horizontally of an edge of the dispenser enclosure is a Class I, Division 2 location. With that information, the installer and/or design team can plan an electrical design or installation for the dispensing equipment. Electrical wiring and equipment installed in this classified location must be done with the appropriate and identified wiring methods and equipment. This example is just one of many hazardous (classified) locations predetermined and delineated in NEC rules. Several other special occupancies with hazardous locations have well-defined boundaries identified in the NEC, such as aircraft hangars, commercial repair garages, and spray paint booths.

Documentation of Hazardous (Classified) Locations

The NEC requires proper documentation of areas designated as hazardous (classified) locations [see 500.4(A)]. This documentation can be in several acceptable formats, but it must be acceptable to the approving authority having jurisdiction (see the definition of authority having jurisdiction in Article 100). Typically, it is in the form of written documents, accompanied by blueprints or drawings that graphically show the area classification. This documentation must be available to those authorized to design, install, inspect, maintain, or operate electrical equipment at that location. This requirement and the general information provided in this article should assist and reinforce the understanding to installers, designers, inspectors, and the like that risk analysis and determination of hazardous locations is not a process that should be performed in the field during installation. The AHJ can only apply or enforce the specific rules pertaining to hazardous (classified) locations after the design team, electrical engineers, manufacturers, etc., have determined the extent of the hazardous (classified) locations. The design team involved in the determination of the hazardous (classified) locations will require involvement from one or more of the following engineering or design professionals: chemical, process, mechanical, fire protection, civil, environmental, structural, architectural and electrical.

Contributing Factors for Area Classification

Combustible Dust Explosions

Combustible dust explosions can be violent and destructive. They can cause serious injury or death and result in fires that can destroy property. Once ignition of dust has occurred either in a cloud suspension or a layer, an explosion is likely. Often the initial explosion is followed by another much more violent explosion fueled from dust accumulations on structural beams and equipment surfaces being thrown into suspension by the initial blast. For this reason, good housekeeping in all areas handling dust is vitally important and is assumed throughout recommended practices. Dust control systems help in controlling the amount of dust, but should not be considered a substitute for frequent housekeeping.

Vapor Density

An issue related to the specific gas or vapor involves the behavior of the material when it is released. Some materials are lighter than air, while others are heavier than air. Table 4.4.2 of NFPA 497 Recommended Practice for the Classification of Flammable Liquids, Gases, or Vapors and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Area also identifies the vapor density for many common materials. Lighter-than-air gases (those with a vapor density less than 1.0) tend to dissipate rapidly and rarely accumulate to form an ignitible atmosphere near electrical equipment, unless they are released in an enclosed area and are not permitted to escape. Because of their rate of dissipation, classified areas for these materials tend to be smaller. Often these materials have less effect on the electrical installation because it will be located closer to the ground, and this material, when released naturally, leaves the location of the electrical equipment. It should be recognized that lighter-than-air gas that has been cooled sufficiently might behave as a heavier-than-air gas until it absorbs heat from the surrounding atmosphere.

Heavier-than-air gases (those with a vapor density greater than 1.0, tend to fall to grade level or below when released) may remain for a significant period unless dispersed by natural or forced ventilation. This collection of gas near the ground is more likely to occur in the location of electrical equipment. If heavier-than-air gas has been heated sufficiently to decrease its density, it may behave as a lighter-than-air gas until cooled by the surrounding atmosphere. As gases of all densities diffuse into the surrounding air, the density of the mixture approaches that of air. It is easy to understand how vapor density would affect the likelihood that an ignitible concentration of a material could be formed. Vapor density will have a major influence on the rate of dispersion if the material is released. If the material is heavier-than-air and the location includes areas where the material could collect that are close to the ground, the likelihood that an ignitible concentration can form increases. If the material is lighter-than-air and the location is outdoors without a roof or other place for a release to collect, the likelihood of an ignitible concentration forming decreases.

Flash Point

Another characteristic of materials that affects area classification is a flash point. Flash point is the lowest temperature at which sufficient vapor of a liquid is generated to form an ignitible mixture with air near the surface of the liquid. Table 4.4.2 of NFPA 497 identifies the flash point of many common materials. When flammable liquids [those having a flash point below 37.8˚C (100˚F) and having a vapor pressure not exceeding 40 psia at 37.8˚C (100˚F)] are released in appreciable quantity, they begin to evaporate at a rate that depends on its volatility. More volatile materials evaporate faster and therefore have a lower flash point. Vapors of flammable liquids form ignitible mixtures with air at ambient temperatures more or less freely. Even when evolved rapidly, vapors tend to disperse rapidly, becoming diluted to a concentration below the lower flammable limit. Until this dispersion takes place, however, these vapors will behave like heavier-than-air gases. Flammable liquids normally will produce ignitible mixtures that will travel some finite distance from the point of origin; thus, they will normally require area classification for proper electrical system design.

Combustible Liquids

Combustible liquids [those having a flash point at or above 37.8˚C (100˚F)] will form an ignitible mixture only when heated above their flash point. It is possible that some of these materials under the right set of conditions warrant area classification while others would never require special electrical equipment. Again, it is obvious that one flammable or combustible material released in a specific set of conditions might vaporize and form an ignitible atmosphere while a different material might not vaporize nor form an ignitible atmosphere. Flammable liquids are those liquids designated as Class I having a flash point below 37.8°C (100°F) and a vapor pressure not exceeding 40 psia at 37.8°C (100°F).

Special Occupancies Covered in Chapter 5

Articles 500 through 504 provide the general rules for Class I, II, and III locations. Various Code articles also contain specific requirements for hazardous (classified) locations in special occupancies. Sometimes rules in any of these special occupancy articles modify general provisions in Articles 500 through 504 [See 510.2]. In some cases, they also modify the requirements for Zone classified locations in Articles 505 and 506 as well. These articles provide specific designations of the hazardous (classified) locations and areas that are unclassified. Article 510 provides an overview detailing the arrangement of Articles 511 through 517. Articles 513, 514, 515 and 516 permit application of both the Division and Zone area classification systems.

Article 511 applies to service and repair locations for self-propelled vehicles that use volatile flammable liquids or flammable gases for power. Examples of such fuels are gasoline, hydrogen, natural gas, and liquefied petroleum gases. Some of these materials are lighter-than-air while others are heavier-than-air, and the properties of the particular material need to be considered when determining the extent of the classified areas. Liquid hydrocarbons, such as gasoline, are heavier-than-air, but other fuels, such as natural gas and hydrogen, are lighter-than-air. Service stations and repair shops for automobiles, buses, trucks, and tractors are included in the classified area, but facilities limited to repairing electric vehicles would not be included [See 511.1].

Aircraft Hangars

Article 513 applies to buildings or structures where aircraft might be serviced, repaired or stored. The aircraft must contain or have contained, flammable or combustible liquids at temperatures sufficient to form an ignitible mixture. This article does not cover locations used for unfueled aircraft. NFPA 409, Standard on Aircraft Hangars, defines an unfueled aircraft as one that has had the flammable or combustible liquid removed, so no part of the fuel system contains more than 1/2 percent of its volumetric capacity. The Division and Zone systems are both permitted for classification of aircraft hangars [See 513.3]. For additional information see NFPA 409-2011, Standard on Aircraft Hangars and NFPA 30-2012, Flammable and Combustible Liquids Code.

Motor Fuel Dispensing Facilities

Article 514 applies to facilities where fuel dispensing occurs. Previously, the title of this article was limited to gasoline, but because of the variety of fuels used it was changed to broaden the scope. Gasoline stations, propane dispensing stations, watercraft (marine) fueling stations, and group (fleet) fueling stations are included [See 514.1]. For additional information see NFPA 30A-2012, Code for Motor Fuel Dispensing Facilities and Repair Garages. The definition of a motor fuel dispensing facility includes the concept of fuel storage in conjunction with fuel dispensing. Fixed equipment is used to dispense fuel into the tanks of vehicles or marine craft or approved containers. This definition is extracted from NFPA 30A, which provides consistency between that code and the NEC [See 514.2].

Bulk Storage Facilities

Article 515 applies where flammable liquids are stored or blended in bulk. Flammable liquids have flash points below 100°F. The liquids are received by tank vessels, pipelines, tank cars, or tank vehicles and distributed by tank vessels, pipelines, tank cars, tank vehicles, portable tanks, or containers [See 515.1]. For additional information see NFPA 30, Flammable and Combustible Liquids Code. NEC Table 515.3 is to be used in determining the extent of classifications. Classification typically ends at floors, walls, roofs or other solid partitions that have no communicating openings.

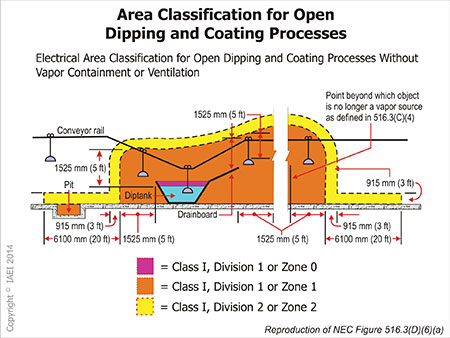

Spray Application, Dipping, Coating and Printing Processes

Article 516 applies where flammable liquids, combustible liquids and combustible powders are regularly or frequently applied. Vapors and dusts in air and residue deposits need to be considered when classifying areas and selecting equipment. Classifications include both the Division system and the Zone system. For additional information see NFPA 33-2011 Standard for Spray Application Using Flammable and Combustible Materials, and NFPA 34-2011 Standard for Dipping and Coating Processes Using Flammable or Combustible Liquids. Ventilation information is available in NFPA 91-2010, Standard for Exhaust Systems for Air Conveying of Vapors, Gases, Mists, and Noncombustible Particulate Solids. Determining the extent of classification is based on the quantity of flammable vapors, combustible mists, residues, dusts, or deposits that are or might be present in quantities sufficient to produce ignitible or explosive mixtures in air. The Division system and the Zone system for classifying hazardous locations are both permitted for locations or operations covered by Article 516.

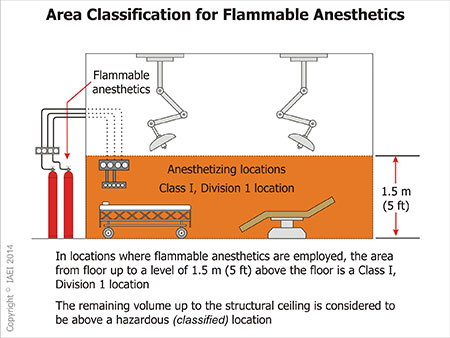

Health Care Facilities

Up until NEC-1968, Article 517 was titled “Flammable Anesthetics.” In NEC-1971, the title changed to “Health Care Facilities” and electrical requirements for circuits systems and equipment in health care facilities were in the scope of the article. Many of the requirements for electrical circuits, systems, and equipment were derived from the information contained in NFPA 99. The electrical requirements in the Code for health care facilities to this day include rules that are also part of NFPA 99 Health Care Facilities Code. Where flammable anesthetics are employed, the area from the floor upward to a height of 1.52 m (5 ft) is a Class I, Division 1 location. The storage room for flammable anesthetics or volatile disinfecting agents is to be considered a Class I, Division 1 location, which includes the whole room. It is interesting that there is no Class I, Division 2 location associated with anesthetizing agents in health care facilities. Any area used for inhalation of nonflammable anesthetizing agents or any room used for storing nonflammable gases is considered an other-than-hazardous (classified) or unclassified location [See 517.60(B)].

Summary

Electrical installations in hazardous (classified) locations if not installed to meet the minimum requirements of the applicable codes and standards can be hazardous to persons and property. Electricity is a source of ignition for atmospheres that can explode. Various hazardous (classified) locations are delineated in the NEC. This article, in conjunction with IAEI’s Hazardous Locations textbook and training material, provided a review of the basics of determining area classification as well as the characteristics of the various classified locations under the Zone system and under the Division system.

Often area classification is not covered by the NEC and requires reference to other applicable standards to determine the classification of a hazardous area and the extent of that area or location. This process should include a team of professionals (experts in their fields) in the risk analysis and assessment. NFPA 497 Recommended Practice for the Classification of Flammable Liquids, Gases, or Vapors and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Area and 499 Recommended Practice for the Classification of Combustible Dusts and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas are among the other standards that have to be used.

Classification of hazardous areas or locations is not the responsibility of the authority having jurisdiction or the installing electrical contractor. There is a process that calls for careful exercises in ingenuity, sound engineering, designs for the best results, and electrical safety. Before electrical equipment and wiring are installed in a hazardous (classified) location, the classification or the area must be known. Various specific methods of protection are required for electrical installations in hazardous (classified) locations.

Excerpts of this article were derived from IAEI’s Hazardous Locations textbook based on the 2014 NEC. You can find greater detail on all the subjects covered in this article and more in the referenced textbook available from IAEI. The author wishes to thank Mr. Ed Briesch (formally of UL) and Joseph Wages (IAEI) for their assistance to the update of the latest edition of the Hazardous Locations textbook and contributing to this article.

Find Us on Socials