Why did the Table 6 change result in fewer conductors in a raceway? The quick answer is that Table 6 in the 2012 CE Code was not accurate for all types of raceways.

This inaccuracy was identified with the introduction of 200 trade size (8 inch) PVC conduit. When adding 200 trade size raceway to Table 9, it was noted that the internal diameter of other sizes of PVC conduit was less than the internal diameter detailed in the existing Table 9. This discovery prompted research to determine why Table 9 was not accurate for all raceway sizes.

Table 9 was originally introduced into the 1930 edition of the CE Code as Table 11.

By 1939, the Table was based on the internal diameter of rigid metal conduit. The internal diameter was taken from the CSA standard for rigid metal conduit C22.2 No 45. Unfortunately, the internal diameter from the standard was in metric, and when Table 8 was created the imperial measurement was rounded slightly, this inaccuracy was compounded in the 1998 edition of the CE Code when the table (now Table 9) was converted to metric and rounded again. This is why the internal diameter in CSA Standard C22.2 No 45 does not match the internal diameter in the 2012 CE Code Table 9.

When Electrical Metallic Tubing (EMT) was added to the CE Code in 1947, the table was not expanded to detail the larger internal diameter of EMT.

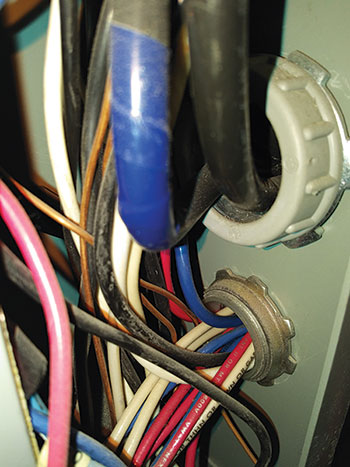

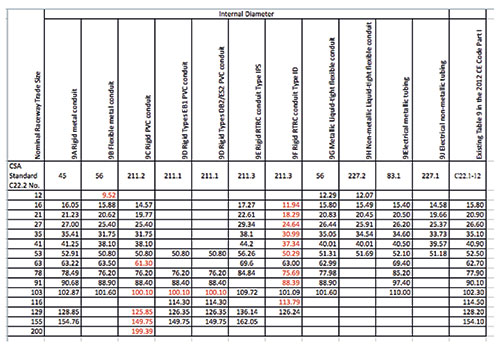

I speculate the table was not expanded as the larger internal diameter would not cause a conflict with the percentage of raceway fill. When rigid polyvinyl chloride conduit (PVC) was added to the 1966 CE Code, the table remained unchanged perhaps as an oversight by the committee to recognize the smaller internal diameter of the PVC conduit. As other raceways were added the table remained unchanged. The research also identified that there are currently ten different internal diameter sizes for any given trade size of circular raceways. As a result of this discovery, Table 9 has been expanded into ten tables.

Tables 9A through 9J cover the cross-sectional areas of the following circular raceways:

- Table 9A – CSA C22.2 No 22.2 No. 45 Rigid metal conduit

- Table 9B – CSA C22.2 No 22.2 No. 56 Flexible metal conduit

- Table 9C – CSA C22.2 No 22.2 No. 211.2 Rigid PVC conduit

- Table 9D – CSA C22.2 No 22.2 No. 211.1 Rigid Types EB1 PVC conduit

- Table 9D – CSA C22.2 No 22.2 211.1 No. Rigid Types DB2/ES2 PVC conduit

- Table 9E – CSA C22.2 No 22.2 No. 211.3 Rigid RTRC conduit Type IPS

- Table 9F – CSA C22.2 No 22.2 No. 211.3 Rigid RTRC conduit Type ID

- Table 9G – CSA C22.2 No 22.2 No. 56 Metallic Liquid-tight flexible conduit

- Table 9H – CSA C22.2 No 22.2 No. 227.2 Non-metallic Liquid-tight flexible conduit

- Table 9I – CSA C22.2 No 22.2 No. 83 and C22.2 No 22.2 No. 83.1 Electrical metallic tubing

- Table 9J – CSA C22.2 No 22.2 No. 227.1Electrical non-metallic tubing

The reason for the additional tables is the internal diameter in the raceway standards listed above is different for individual raceway types.

As a result of the change to Table 9, the existing Table 6 in the 2012 CE Code has become grossly inaccurate and needed to be updated.

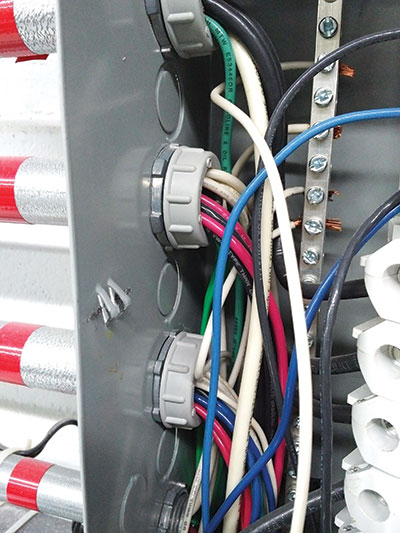

The problem was how to deal with all the different internal diameter sizes available. One option was to delete Table 6; this may not be practical for code users that want to use a table to determine an acceptable raceway size. A second option was to add a new “Table 6” for each of the different internal diameter sizes, as Table 6 consists of eleven actual tables, this would mean adding 100 tables. A third option was to create a new Table 6 based on the smallest internal diameter sizes of conduit and tubing available. Contractors both large and small were surveyed to see how we should proceed. The direction from the electrical contractors was unanimous to develop a new Table 6 for convenience, recognising that code users have the option to calculate the actual raceway fill for the type of raceway being used.

The new Table 6 was created based on the smallest size of conduit and tubing available.

Table A shows the CSA standard number and the smallest conduit or tubing size.

Within the same code proposal, the individual tables now have separate Table numbers from 6A to 6K for easier reference.

The most dramatic change in Table 6 is in the 16 Trade size (1/2″). As an example, if #14 AWG 600V T90 nylon conductors are installed in a raceway, Table 6 from the 2012 CE Code allows 12 conductors in the raceway, while the 2015 CE Code Table 6K will only allow 7 conductors because Table 6K is based on the smallest 16 trade size raceway that is Rigid RTRC ID conduit. As an alternative to using a Table 6, the maximum number of conductors that can be installed in a specific raceway may be calculated using the new appropriate Table 9. Using the same example as above with a rigid metal conduit and the new Table 9A, the maximum number of conductors is 13.

Find Us on Socials