Service-entrance equipment can present unique challenges when it comes to proper application of electrical equipment. The service point is the point of demarcation between utility and premise wiring. Our discussion today will springboard off of a previous article that focused on calculating short-circuit currents. The Safety in Our States article entitled “Calculating Short-Circuit Current” appeared in the May-June 2015 issue of IAEI magazine and is a starting point for the journey to appropriately sized and rated installations.

Today we will focus on the proper application of the equipment at the service entrance location in the power distribution system. We’ll reference the National Electric Code (NEC) but with an understanding that this is also the point of demarcation between the National Electrical Safety Code (NESC) and the NEC. Regardless of the code jurisdiction under which the application falls, when you drop back to the basics, electrical principles, we gain an understanding to help in the proper application of electrical equipment at this and any other location in the power distribution system.

Attention to detail is warranted for safety.

Service Equipment

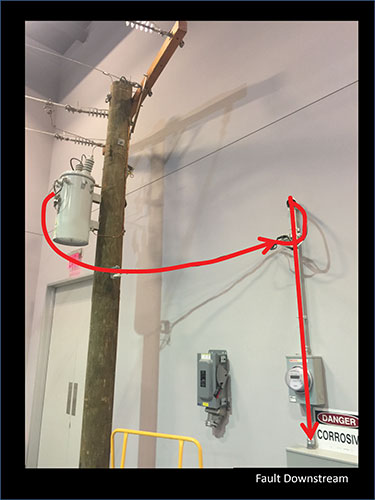

The NEC includes 11 different definitions of terms in Article 100 important for the discussions around services. No need to reiterate them here. A service consists of conductors and other equipment essential for delivering power from the utility to the premise. The NEC provides the requirements for services in Article 230 titled the same. Figure 1 is an example of service-entrance equipment. This image was taken in a demonstration facility and is not energized equipment.

Short-Circuit Current Rating (SCCR)

If you confuse SCCR with Interrupting Rating, you are not alone. I have heard these terms abused. To understand SCCR, consider it the ability of a piece of equipment to hold together while fault current flows through it on its journey to the downstream faulted portion of the circuit. The equipment has to be able to let this fault current pass through without damaging itself. Let’s look at figure 2 to better understand this concept.

The current it delivers is normally a load current that should not exceed its continuous current rating. The current could also be a temporary overload that should not exceed its maximum amp rating. Then again the current could be a very high short-circuit current on the order of many times the magnitude of the normal load current which should not exceed its short-circuit current rating. The meter socket will be equipped with an SCCR which tells us how much current it can let through safely without causing damage to itself. This example shows a single meter with a single service-entrance panel but there are many other types of equipment that may be located at this location including power distribution blocks, busway, conductors, and more. The possible configurations are many but the basic principles remain the same and each component that must deliver current to the load must be appropriately rated. They must have an adequate interrupting rating and short-circuit current rating.

Once we have the basic understanding of what a SCCR label means for electrical equipment and why it is important, it should be evident that all of the equipment that delivers normal load currents may be called upon to deliver high short-circuit currents and will need to have an adequate SCCR rating to do so without creating a hazard. Short-circuit currents place extreme forces on the electrical equipment in the distribution system that it passes through. That includes equipment and conductors. Any equipment that carries current will only do so safely when the magnitude of the current is less than its labeled SCCR. A review of the power distribution system single-line and/or three-line diagrams can help us understand the specific equipment in the system to which an SCCR rating must be applied.

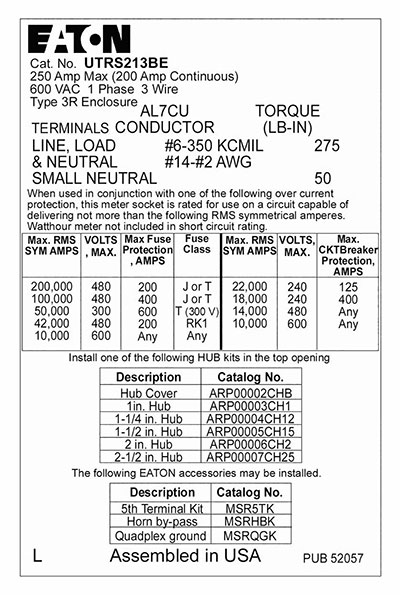

Electrical distribution equipment is equipped with an SCCR label to help ensure proper application of the equipment. Figure 3 is an example of a label for a single meter socket. This is an interesting example as it provides more than one SCCR depending upon the type of OCPD upstream.

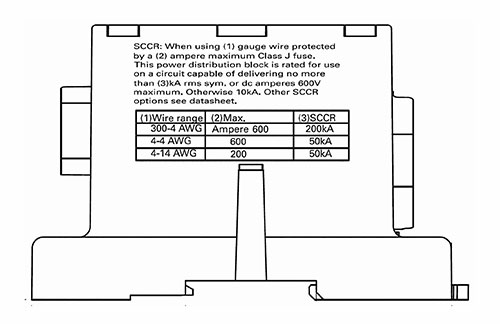

The label in figure 3 tells us that this specific equipment can achieve a SCCR of 100 kA when a class J or class T fuse of any ampacity not exceeding 400 amps is provided upstream. It also tells us that this equipment can only achieve an SCCR of 10 kA without an OCPD upstream. Figure 4 is the label on another item sometimes found on the line side of applications with multiple meters, a power distribution block. The label shown indicates the short-circuit current capabilities of this equipment with and without protection by an overcurrent protective device. As shown on this label, without the help of a device that acts to clear the fault quickly, the maximum SCCR achieved is 10 kA. Figure 5 is an example of an installation that carries an SCCR of 10 kA.

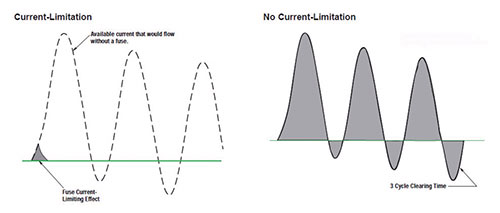

Let’s explore how electrical equipment achieves higher SCCR ratings by exploring the basics of current limitation. The overcurrent protective device upstream ensures that the electrical equipment will not see the stresses and forces that high fault currents cause as the OCPD acts to interrupt the fault current faster than the blink of an eye. When properly protected by an upstream OCPD, the full level of fault current is never seen by the downstream protected equipment. Figure 6 shows the difference between what the equipment sees with and without the OCPD device upstream.

Section 110.10 of NEC 2014 requires that the equipment SCCR “be selected and coordinated to permit the circuit protective devices to clear a fault, and to do so without extensive damage to the electrical equipment of the circuit.” Notice that Section 110.10 indicates that a specific circuit protective device (fuse or circuit breaker) might be required to provide proper protection. Section 110.10 also says that the protective device must protect the equipment from extensive damage implying that damage can occur to equipment after a fault, but it can’t result in a shock or fire hazard outside of the enclosure.

But let’s put the NEC aside for a moment and put on your electrical system basics hat for a moment. Regardless of what the Code requires, we need to design and install a system that is safe and will be safe for years to come through ensuring products are applied within their rating. When we understand the basic principles of how the equipment is designed and expected to be used, the proper application will follow.

We’ll leave this discussion with the definition of SCCR from the NEC. “The prospective symmetrical fault current at a nominal voltage to which an apparatus or system is able to be connected without sustaining damage exceeding defined acceptance criteria.”

Interrupting Rating

The other rating that deserves attention is the interrupting rating of the overcurrent protective device. The difference between a device that has an interrupting rating and one that has a short-circuit current rating is that the former device acts to stop the flow of current and the other does not. Interrupting Rating is defined in NEC 2014 Article 100 as “the highest current at rated voltage that a device is identified to interrupt under standard test conditions.” The interrupting rating of an OCPD is the highest current that an overcurrent protective device is rated to safely clear. According to NEC Section 110.9, the interrupting rating must be greater than the maximum available short-circuit current available at the equipment’s line terminals.

The NEC requires the marking of the interrupting rating of fuses per Section 240.60(C) and circuit breakers per Section 240.83(C). See figures 7 and 8 respectively. The interrupting rating of these devices will depend upon their voltage rating. Figures 7 and 8 illustrate the labels on a fuse and circuit breaker respectively, showing the interrupting rating. A circuit breaker has varying interrupting ratings that are dependent upon the voltage at which it is applied. If a violation of Section 110.9 or Section 110.10 occurs, and the fault current exceeds the IR of the overcurrent protective device or the SCCR of equipment, in this case, a catastrophic and violent failure of the overcurrent protective device or equipment can occur.

Challenges and Risk

The unique challenge presented at the service-entrance equipment is the fact that often there is no overcurrent protective device upstream of the service equipment. The following text is paraphrased from a utility customer guide for electric services.

All metering shall be installed on the line-side of the customer’s main disconnecting means except for a 480Y/277 volt metering installation, where the Company requires a non-fusible meter disconnect ahead of the meter or where the NEC requires a main disconnect ahead of a group of more than six (6) meters.

A non-fused meter disconnect ahead of the meter has a SCCR of 10 kA. This would be adequate only if the available fault current at that location is less than 10 kA. There are some jurisdictions that require the meter disconnect located ahead of the meter to be a fused disconnect. This unfortunately is not the norm.

Equipment with insufficient SCCR subjected to a short-circuit event can expose personnel and equipment to serious danger. Without sufficient SCCR, it is likely that the equipment will sustain and cause damage inside and outside of the equipment.

Insufficient assembly SCCR poses the following hazards:

- Electric shock and burns

- Burns associated with arc flash and contact with heated surfaces

- Injury associated with flying debris

- Damage to equipment or the facility

- Arc blast (shock waves, shrapnel, etc.)

- Vaporized metal

It is very important that all electrical equipment be applied within its rating. SCCR is one such rating that when exceeded can be quite hazardous to those in and around the equipment.

As always, keep safety at the top of your list and ensure you and those around you live to see another day.

Find Us on Socials